Attenuation of Disturbances on an Earth Observing Satellite

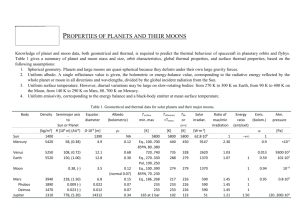

advertisement