Vibrations Their effect on electro

advertisement

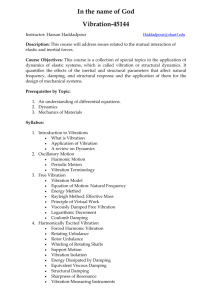

Vibrations And their effect on electro-optical imaging spacecraft Steve Hearon Applied Math Seminar December 14, 2009 (to fullfill requirements of an optomechanics course) Outline • • • • • • Material Properties, Stress/Strain and Bending Vibration Transfer Basics (from J. Burge, Univeristy of Arizona) Electro-optical Spacecraft Examples Types of Disturbances that cause vibration in optical path FEA Models Effects of Vibration on Imaging – Boresight – Primary Mirror Distortion • Conclusions Material Properties • Materials will deform when subjected to a load • Stress-strain relationship is E – where ε is strain (normalized change in length); σ is stress (force/area); and E is Young’s modulus – E = 70 x 10^9 N/m^2 for Aluminum • For an aluminum bar, 1cm x 1cm x 10 cm, 1 Newton force, change of length is : L (1N 0.1m) /( 70e9 Pa 104 m2 ) 14nm – Stiffness k = F/ΔL = 70,000 N/mm Bending example: Bar with force applied at end F Max deflection occurs at end. Max deflection for the Aluminum bar As before 1N force, 1cm x 1 cm x 10 cm: 3FL3 3(1N )(0.1m)3 2.1m 4 4 2 EW 2(70e9 Pa)(0.01m) Stiffness 2 EW 4 k 467 N / mm 3 3L Natural Frequency of Vibration • Natural Frequency of Vibration of a mode is fN 1 2 k m – where k is stiffness and m is mass of the moving structure • For previous examples, assuming a 1-pound mass at the end of the aluminum bar: f AXIAL 1 2 7 e7 N / m 1880 Hz 0.5kg f BENDING 1 2 4.7e5 N / m 154 Hz 0.5kg • Bending direction is much more compliant than axial tension Analysis of Vibrations (J. Burge, University of Arizona) • Each degree of freedom can be represented as a simple mode that has mass, stiffness, and damping • This can be modeled using a simple 2nd-order differential equation • (Charts from J. Burge, University of Arizona) Disturbance Natural Frequency of Vibration Analysis of Vibrations (J. Burge, University of Arizona) • Critical Damping Ratio is Critical Damping Ratio: CR C /( 2mN ) (From J. Burge, University of Arizona) (From J. Burge, University of Arizona) Electro-optical Spacecraft Example Hubble •2.4m Primary Mirror •Richey-Chretien (2-mirror) •SA and Coma corrected •Staring Arrays •24 arcminutes Full FOV for widest sensor •Reaction Wheels for attitude control •Gyroscopes for stabilization Electro-optical Spacecraft Example -IKONOS •0.7m primary mirror •10m focal length •Three-Mirror Anastigmat (TMA) •Controls SA, Coma, Astig, FC •Attitude controlled by Reaction Wheels •Pushbroom detector technology •6500 lines/sec, 12 um pixels PAN •48 um pixels MSI •Fully steerable, swath 12 km •Resolution 0.8m PAN Types of Disturbances That Can Affect Optical Path (1) • Reaction Wheel – – – – Electric motor attached to a flywheel Upon spinup, causes spacecraft to turn other way Work around a nominal zero rotation rate IKONOS and Hubble • Control Moment Gyroscope (CMG) – – – – – Gyroscope that is always spinning during operation ~ 6000 rpm Spacecraft attitude controlled by turning axes of CMG’s S/C rotates in reaction to CMG rotation (ang. mom. conserved) More energy efficient than Reaction Wheels Used in WorldView Satellite, International Space Station • Thrusters – Used for orbit adjusts Types of Disturbances That Can Affect Optical Path (2) • Slewing to acquire a target – s/c decelerates after slewing to begin imaging – Vibration damps out before imaging can begin • Motors – Solar array – Communications antenna – Cryocoolers • Sudden temperature change; thermal snap – Spacecraft enters or exits umbra Finite Element Analysis •Describes material in terms of small elements connected by nodes • Each element models the compliance of the material (J. Burge, University of Arizona) Using FEA Tools in Vibration Analysis (1) • FEA Tools allow the natural frequencies of a complex structure to be obtained • Additionally, the shape of the natural mode is obtained, • For a complete dynamical description, the damping ratio is also needed – – – – Damping ratio is difficult to model for space structures Often a low value is assumed e.g. 0.005 It is possible to perform a factory test (“modal test”) to obtain this However, difficult to transform measurements at std pressure and 1 g to vacuum and no gravity Using FEA Tools in Vibration Analysis (2) • With natural frequencies, mode shapes, damping, and the input disturbance, the time-varying motion of the structure can be obtained • Effect on imaging obtained by importing structure into ASAP or another optical modeling tool • Optionally, can perform an analysis based on analytical calculations FEA Results from a Study for an 8-Meter space telescope • Shown on next slide is a table of natural modes from following report: – “HST Optics Enhancement, preliminary feasibility study summary report”, 2000 • Note that mode shapes and frequencies have been calculated, and damping ratios have all been set to 0.005 FEA Results from a Study for an 8-Meter space telescope Trussed Mirror Concept • Following two slides show NASTRAN results for first natural frequency for a trussed-mirror concept Strutted Mirror - 1st Natural Mode at 73.7 Hz Lockheed Martin Baseline Petal - 1st Natural Mode at 63.2 Hz Lockheed Martin Effects of Vibration on Optical Path – Boresight Variation -- Jitter • • Vibrational Modes that affect telescope as a whole cause jitter Jitter is often spec’d as a PSD in units of microrad^2/Hz – • • On a per-axis basis Frequencies greater than line rate cause image blur Frequencies less than line rate cause frame-to-frame jitter (Line-to-line jitter) PSD (urad^2/Hz) Frequency (Hz) Lockheed Martin Jitter realization With programmed Motion added (pushbroom) Effects of Vibration on Optical Path – Primary Mirror distortions • Distortions of the Mirrors (e.g. primary or secondary mirror) cause spreading of point-spread-function – Results in a decrease of Strehl Ratio • Movie showing time-dependent PM distortions, and resulting variation in Point-Spread Function: – X:\7\7CNO\Hearon\PSFvsTime_2kHz_04.avi Lockheed Martin Conclusions • Vibrations are an important consideration for EO spacecraft, across their entire lifecycle – Development, build, operation • Vibration analysis tools help designers to understand and mitigate potential vibration issues early in the design process Lockheed Martin