Document 10821071

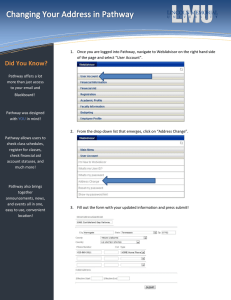

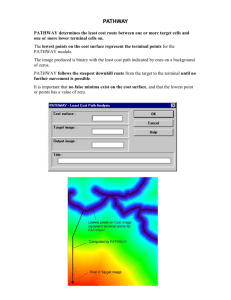

advertisement