Microscale Thermal Engineering of Electronic Systems Thermosciences Division Mechanical Engineering Department

advertisement

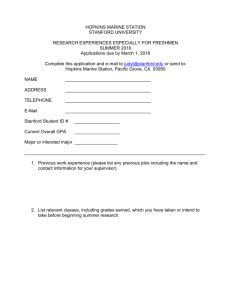

Microscale Thermal Engineering of Electronic Systems Ken Goodson Thermosciences Division Mechanical Engineering Department Stanford University Key Points 1. Self Heating of Transistors and Interconnects IBM 2. Nanothermal Devices for Information Technology silicon 15 µm IBM Zurich / Stanford 3. Microscale Technologies for Heat and Power Management Solidstate EO pump Microprocessor Thermal Challenges ESD Metal Heating Texas Instruments Metal 1 (AlCu) W-plug Silicon Dioxide Thermal damage TiN Siemens Novel Materials 0.2 µm 1 µm n+ Silicon Diffusion Region Novel Geometries IBM Strained Silicon / Si Ge UC Berkeley/AMD Nanotransistors Gate Gate Source Source Drain Strained-Si channel Drain Source Relaxed SiGe SiO2 Si substrate Si substrate Strained-Si FET Thin Body SOI Tbody Gate Source Drain Graded SiGe Lch Classic Bulk FET Tbody Gate Drain Gate Drain Gate Source Double-Gate SOI FinFET (Purdue, IBM) (UC Berkeley, AMD, IBM) Transistor Electrothermal Physics HighImpact Electric of Device Approximate Field Scaling on Peak Phonon Temperatures Hot Electrons (Energy E) lattice wave λ electron field Λ intense electron-phonon scattering phonon E = hω dopant atom E < 50 meV τ ~ 0.5ps E > 50 meV τ ~ 0.1ps Optical OpticalPhonons Phonons τ ~ 10 ps Acoustic AcousticPhonons Phonons d Heat Transfer to Package Channel Length L (nm) phonon Material boundary with roughness η Pop, Banerjee, Dutton, Goodson, Proc. IEDM 2001 Power Q’ (µW/µm) IBM ∆T Increase (K) 225 nm Transistor Simulation Regime Map Atomistic Nanotransistor Regime phonons ~5 nm ~100 nm ~5 nm ~1 nm Research needs for the future ) 83 ) 9 1 i ( 1988 n ( o ob etti c Ja isch F In s es r og pr Electrons , ta t Da 95) 9 (1 m ro t ds n Lu Full Quantum Isothermal electrons Monte Carlo with Quantum Models n to t ra St 2) 6 9 (1 MFP λ Monte Carlo & BTE Diffusion rk wo a h k uc hut m ac W 994) (1 , Ju 00) , 0 p ru n (2 d er so Sv od ar d o G m ju a i, M ) a L 995 ) 90 5) (1 9 (1 199 r ( u Sh vich 0) no 7 a 9 1 ) Ap r ( 985 e ja 1 ek ni ( 6) t oe ara 198 l B cc ( Ba dan Ru BTE Moments BTE or Monte Carlo Drift Diffusion Lattice BTE with Wave models Electron Drift & Phonon Generation at 40kV/cm Thesis work of Eric Pop, 2003 Phonon Emission • • • Monte Carlo, 300 electrons at 300 K Electric Field starts at 0.5 ps Eavg jumps from 39 meV to 290 meV Interconnect Thermal Management d ILD 2 1 .7 ~ j d ρ η N MET MET Peak ∆T k ILD Student: Sungjun Im. Sponsor – MARCO o Temperature [ oC] Temperature Rise ( C) 220 100 50 nm 200 209 °C Global Wires 35 nm 180 50 160 70 nm 100 nm 130 nm 140 180 nm 1200 0 2 4 6 8 10 Distance from Substrate [µm] Temperature Contour Plot (50 nm technology node) The temperature rise in interconnects is small now, but compounding trends in the ITRS roadmap lead to a tremendous increase at the 70 nm node beyond low-k dielectric materials increasing current densities and aspect ratios increasing number of interconnect layers Nanoscale Thermal Data Storage IBM Zurich: Vettiger, Binnig Stanford: King, Kenny, Goodson. See King et al., Applied Physics Letters 78, 1300 (2001) Data Writing Ibias Data Reading Ibias ∆T ~ 300 K “0” ∆T ~ 5 K 100 nm Stanford University Ibias “1” ∆T reduced Cantilever Array Micro- and NanoMechanics Zurich Research Laboratory Microrocessor Thermal Management Heat Sinks, Heat Pipes, Vapor Chambers ~ 102 cm3 ASICs ~1 cm3 RAM ~10-1 cm3 Power Delivery ~1 cm3 ~10 -1 cm 3 Video ~10-1 cm3 HOTSPOTS Microprocessor heat sinks are 3000 times larger and heavier than the chip They crowd away power delivery components, ASICs, RAM, and Video Interdisciplinary Grand Challenge: Integrated Power Delivery & Heat Removal Groups of Goodson, Kenny, Santiago, Saraswat, Stanford Mechanical Engineering Groups of Thompson & Troxel, MIT Materials and Electrical Engineering Thermofluidic Mixed-Signal Power Module (Sponsors: SRC/MARCO & DARPA) Photonic I/O Electrical Connections RF Integrated MEMS Sensing Fluidic I/O Mixed Signal Chip Fluidic Cooling Thermofluidic Module with Solid-State Pump (Sponsors: Intel & DARPA) Free I/O Integrated EO targeted, on-demand Fluid Surface Pump/controller Electrical microchannel cooling Connections Mixed Signal Chip ElectroOsmotic Microchannel Cooler Sponsors: DARPA, Intel, AMD, Apple. Trans CPMT (2002). Best Paper SemiTherm 2001 PIs: Goodson, Santiago, Kenny, Stanford ME 2001: 30 W Demo, 1 cm2 (Intel) 2002: 100 W Demo, 1 cm2 (Intel) 2002: 150 W Demo, 4 cm2 (Intel) 2002: Laptop Demo 2002: Apple Dual Processor Demo 2003: AMD Demo ElectroOsmotic Pump Heat Rejector + Silicon dioxide wall High-Pressure Liquid Pumping ~ 50 nm Charge double-layer + + + + + + Charge Double Layer Microchannel Heat Sink Micro Heat Sink Channels In silicon EO Pump Stanford/Intel 100 W Demo EO Pump Flowrate ~ 20 ml/min Thermal attach Si chip Pyrex seal - ElectroOsmotic Pumps With groups of Santiago and Kenny, Stanford Mechanical Engineering Sponsor: SRC/MARCO, DARPA Idealized pore channel: Glass or fused-silica capillary wall EOF + Charge double-layer Freestanding pump - 1 cm + + + + + ++ + + + ++ + ++ + Deprotonated silanol groups εζE dp (a 2 − r 2 ) u (r ) = − µ dx µ Qmax εζ VA 32εζ = ∆pmax = 2 V µ l d •Very high volume to flowrate ratio •Stanford pump performance (Feb 2002) Pmax ~ 2 atm, Qmax ~ 40 ml/min, Vol. ~ 2 cm3 2370 Charleston Mountain View, CA 94043 www.cooligy.com Cooligy develops thermal management components based on electro-osmotic pumps and novel microscale heat exchangers Heat Rejector • Founded in 2001 by Stanford Profs. Ken Goodson, Tom Kenny, Juan Santiago, Mechanical Engineering • 24 employees (Feb 2003) with engineering expertise including chemical, mechanical, packaging, thermal, & fluidic specialties • Experienced management and directors drawn from Intel, Dell, Corning, Silicon Light Machines. Micro Heat Sink EO Pump • Focussing on reliability demonstration, product implementation, collaboration with computer manufacturers Concluding Remarks • The next decade of IC research & development will bring solutions to “secondary” challenges associated with Moore’s Law, such as power delivery, heat removal, and package integration. • IC thermal management problems will have lengthscales spanning six orders of magnitude, from 10 nm in nanotransistors to more than 10 cm at the package level. • Novel materials and geometries are increasing micro/nanoscale on-chip thermal resistances, leading to hotspots in metallization and interconnects. • Circuit design focuses computation on the chip, yielding mm-scale hotspots that dramatically increase the thermal resistance from the chip to the package. Goodson Microscale Heat Transfer Group Thermosciences Division, Mechanical Engineering Department, Stanford Current Students and Post-Docs (AY 2002/2003) Dachen Chu (Physics) Xuejiao Hu (ME) Sungjun Im (Materials Science) Kevin Ness (ME) Jae-Mo Koo (ME) Yue Liang (ME) Angie McConnell (ME) Eric Pop (Electrical Engineering) Monikka Mann (ME) Sanjiv Sinha (ME) Evelyn Wang (ME) Ankur Jain (ME) Dr. Linan Jiang Dr. Abdullahel Bari Dr. Samuel Graham (Visitor from SNL) Alumni (1999-2002) Prof. Mehdi Asheghi Prof. Dan Fletcher Prof. Bill King Prof. Katsuo Kurabayashi Prof. Sungtaek Ju Prof. Kaustav Banerjee Dr. Uma Srinivasan Dr. Per Sverdrup Dr. Peng Zhou Dr. Maxat Touzelbaev Carnegie Mellon University (ME) UC Berkeley (Bioengineering) Georgia Tech (ME) University of Michigan (ME) UCLA (ME) – with IBM until Fall 2003 UC Santa Barbara (EE) Xerox Intel Cooligy AMD