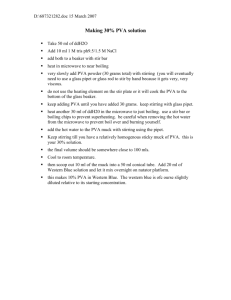

ALCOHOL) USE SYNTHETIC ARTICULAR CARTILAGE DE

advertisement