Functional and Responsive Surfaces via ... Chemical Vapor Deposition (iCVD) JUN 13 ARCHIVES

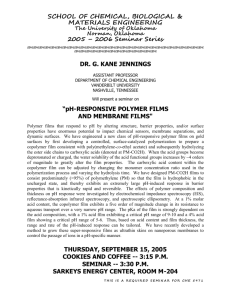

advertisement