Manufacturing Engineering University of Wisconsin-Stout Advisory Board Meeting Fall 2012

advertisement

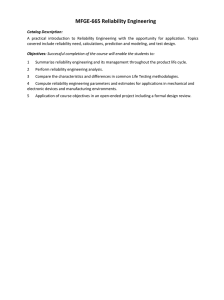

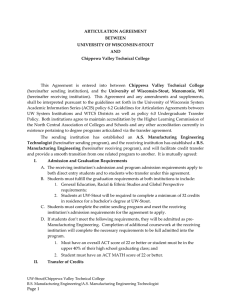

Manufacturing Engineering University of Wisconsin-Stout Advisory Board Meeting Fall 2012 Agenda Welcome – Introductions A Few Words from E & T Department Chair Approval of Spring 2012 Meeting Minutes Program Status Report Review of Student Outcomes L, M, N, O, and P Continuous Improvement of MfgE Program Changes to MfgE Program for 2013 - 2014 Open Discussion Spring Meeting Announcement Adjourn E & T Department Chair A few words from UW-Stout’s Engineering & Technology Department Chair Dr. Jerome Johnson Approval of Spring Meeting Minutes Program Status Report Enrollment Approximately 235 students in program this semester This includes 17 students in Green Bay Thirteen students graduating tomorrow Acceptance History current recruitment year for 2013/2014 100 Manufacturing Engineering Freshmen Applications for 2013/2014 90 80 2003-2004 70 2004-2005 2005-2006 60 2006-2007 2007-2008 50 2008-2009 13/14 2009-2010 2010-2011 40 2011-2012 2012-2013 5 Yr Mean 30 Mean 20 10 0 October November December January February March April May June July August September Student Outcomes Student Outcomes A through K Eleven outcomes defined by ABET In most cases one more student outcome is defined to identify specialty area of program. UW-Stout Outcome L Twelve total student outcomes Assess four student outcomes per year Assess all twelve student outcomes every three year cycle Student Outcome L Student Outcome L Proficiency in materials and manufacturing processes. Supported by MfgE Program Courses: MFGT 251 Polymer & Composites Processes MFGT 252 Material Removal & Forming Processes MFGT 253 Casting & Joining Processes Review of Student Outcome M Student Outcome M Proficiency in process, assembly, and product engineering. Covered under Outcome C An ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, health and safety, manufacturability and sustainability. Review of Student Outcome N Student Outcome N Understanding the creation of competitive advantage through manufacturing planning, strategy, and control. Covered under Outcome H The broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context. Review of Student Outcome O Student Outcome O Proficiency in manufacturing systems design using statistical and calculus based methods, simulation and information technology. Covered under Outcome K An ability to use the techniques, skills and modern engineering tools necessary for engineering practice. Review of Student Outcome P Student Outcome P An ability to measure manufacturing process variables in a manufacturing environment and make technical inferences about the processes. Covered under Outcome B An ability to design and conduct experiments, as well as to analyze and interpret data. Continuous Improvement of MfgE Program Scheduling of Student Outcomes Evaluations Table 2 Planned data collection for 2011-2017 ABET cycle Student Outcome A. An ability to apply knowledge of mathematics, science and engineering. B. An ability to design and conduct experiments, as well as to analyze and interpret data. C. An ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, health and safety, manufacturability and sustainability. 20112012 F. An ability to identify, formulate, and solve engineering problems. An understanding of professional and ethical responsibility. 20132014 20142015 X X X X D. An ability to function on multidisciplinary teams. E. 20122013 20152016 X X X X X 20162017 X X X Continuous Improvement of MfgE Program Scheduling of Student Outcomes Evaluations Table 2 Planned data collection for 2011-2017 ABET cycle (continued) Student Outcome 20112012 G. An ability to communicate effectively. H. The broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context. I. J. K. L. A recognition of the need for, and the ability to engage in life-long learning. A knowledge of contemporary issues. An ability to use the techniques, skills and modern engineering tools necessary for engineering practice. Proficiency in materials and manufacturing processes. 20122013 20132014 20142015 X 20152016 20162017 X X X X X X X X X X X Continuous Improvement of MfgE Program Scheduling of Student Outcomes Evaluations Table 3 Cycle of activity for each student outcome over 6 year period: Activity for each Student Outcome Review of performance indicators that define the outcome Year 1 Year 2 Year 3 X Year 4 Year 5 X Review the map of educational strategies related to performance indicators X X Review mapping and identify where data will be collected X X Develop and/or review assessment methods used to assess performance indicators X X Collect data Evaluate assessment data including processes Report findings Take action where necessary X X X X Year 6 X X X X Continuous Improvement of MfgE Program Scheduling of Student Outcomes Evaluations Table 4 Outcomes Mapping for INMGT, MECH, MFGE, and MFGT Courses: Outcome A B C D E F G H I J K L INMGT 335 422 MECH 293 294 MFGE 325 X MFGT 391 405 410 440 251 252 253 X X X X X X X X X X X X X X X Continuous Improvement of MfgE Program Student Outcome A: Evaluated Fall 2011 Performance Indicators 1. 2. Ability to apply knowledge of mathematics Ability to apply knowledge of engineering science Method(s) of Assessment Where data are collected Final exam question(s) MECH-293 MFGE-391 Average score for PI 1.: 2.5/4.0 Final exam question(s) MECH-293 MFGE-391 Average score for PI 2.: 2.4/4.0 Target Performance ≥ 2.5 Average score for PIs: 2.46/4.0 Continuous Improvement of MfgE Program Student Outcome B: Evaluated Fall 2011 Performance Indicators 1. 2. 3. 4. Demonstrate understanding of the requirements and planning process for experimental design Demonstrate proficiency in conducting experiments Demonstrate proficiency in organization and manipulation of collected data using proper tools (e.g. software) Demonstrate proficiency in interpretation and development of conclusions from data analysis using proper tools (e.g. software) Method(s) of Assessment Where data are collected Term project INMGT-422 Average score for PI 1.: 2.375/4.0 Term project INMGT-422 Average score for PI 2.: 2.0/4.0 Term project INMGT-422 Term Project INMGT-422 Target Performance ≥ 2.5 Average score for PI 3.: 2.0/4.0 Average score for PI 4.: 1.875/4.0 Average score for PIs: 2.06/4.0 Continuous Improvement of MfgE Program Student Outcome E: Evaluated Spring 2012 Method(s) of Assessment Where data are collected Final exam question MECH-294 Average score for PI 1.: 3.0/4.0 Formulate strategies and methods needed to solve engineering problems MECH-294 Average score for PI 2.: 2.52/4.0 Demonstrate the ability to solve engineering problems MECH-294 Average score for PI 3.: 2.52/4.0 Performance Indicators 1. 2. 3. Demonstrate the ability to identify engineering problems Target Performance ≥ 2.5 Average score for PIs: 2.68/4.0 Continuous Improvement of MfgE Program Student Outcome H: Evaluated Spring 2012 Performance Indicators 1. 2. 3. 4. Technical periodicals in manufacturing and plastics engineering Valuation of engineering discipline Impact of manufacturing and plastics engineering activities on the environment and national economy Ability to select an optimal solution based on technology and economic factors Method(s) of Assessment Where data are collected Term project INMGT-335 Average score for PI 1.: 2.77/4.0 Term project INMGT-335 Average score for PI 2.: 2.58/4.0 Term project INMGT-335 Average score for PI 3.: 2.58/4.0 Term project INMGT-335 Average score for PI 4.: 2.77/4.0 Target Performance ≥ 2.5 Average score for PIs: 2.675/4.0 Changes to MfgE Program for 2013 2014 Drop PHYS 281 University Physics I 5 credits Add PHYS 2xx Statics 3 credits Change MECH 293 to MECH 2xx Dynamics Increase MfgE 275 from 2 to 3 credits Increase MfgE 391 from 2 to 3 credits Drop 3 credits due to new GE requirements Decrease MfgE program by 3 credits to 129 Open Discussion Topics for discussion? E & T Department Open House E & T Department Open House in Jarvis Hall Tech Wing hallway until 5:00 pm Capstone I student project oral presentations Student coursework project posters on display Next Advisory Board Meeting Friday, May 10, 2013 Capstone II presentations starting at 10:00 am Advisory Board meeting 12:15 pm Adjourn – thank you for coming!