Manufacturing Engineering University of Wisconsin-Stout Advisory Board Meeting Fall 2013

advertisement

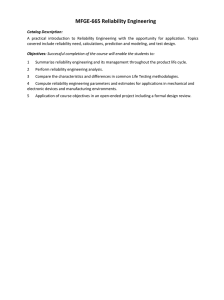

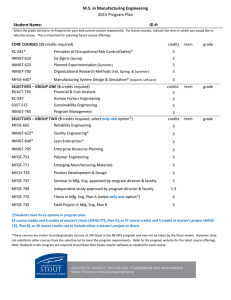

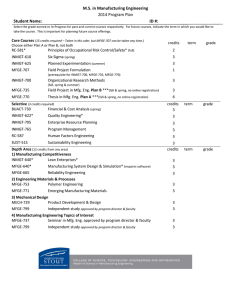

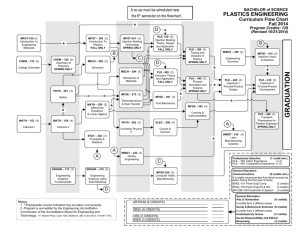

Manufacturing Engineering University of Wisconsin-Stout Advisory Board Meeting Fall 2013 Agenda Welcome – Introductions Approval of Spring 2013 Meeting Minutes Program Status Report Student Outcomes Rubric Review Open Discussion Engineering & Technology Dept. Open House Spring Meeting Announcement Adjourn Approval of Spring Meeting Minutes Program Status Report Enrollment Approximately 256 students in program this semester Nineteen students graduating tomorrow Acceptance History current recruitment year for 2014/2015 110 Manufacturing Engineering Freshmen Applications for 2014/2015 100 90 2004-2005 80 2005-2006 2006-2007 70 2007-2008 2008-2009 60 50 2009-2010 2010-2011 2011-2012 14/15 2012-2013 40 2013-2014 2014-2015 30 5 Yr Mean Mean 20 10 0 October November December January February March April May June July August September Program Status Report Recruiting Efforts: STEPS FIRST LEGO League Science, Technology, Engineering and Mathematics Career Day SkillsUSA Science Olympiad (Stout to host 2016 national contest) Visiting and hosting middle and high school groups Visiting and hosting community colleges Minnesota National College Fair MfgE Program 2013/2014 A co-op can most easily be scheduled after the 6th semester on the flowchart. MFGT – 251 (3) MFGT – 252 (3) Fundamentals of Plastics Materials and Processing Material Removal & Forming Processes C CHEM – 341 (4) Chemistry of Materials FALL ONLY CHEM – 135 (5) College Chemistry Curriculum Flow Chart Fall 2013 C MFGT – 253 (3) INMGT – 300 (2) Joining & Casting Processes Engineering Economy MFGE – 351 (3) Manufacturing Process Engineering 1 MECH – 294 (3) PHYS – 291 (3) Calculus I Statics MECH - 292 (3) Dynamics * MFGE – 275 (3) Thermodynamics & Heat Transfer PHYS – XXX (5) Fluid Mechanics ENGL – 101 (3) ENGL – 102 (3) Composition 1 Composition 2 SPCOM-100 (3) ENGGR – 210 (3) Engineering Graphics Fundamentals Engineering Graphics Using Solid Modeling Fundamentals of Speech MFGE – 441 (3) Design of Jigs, Fixtures & Tooling * MFGE – 405 (3) Capstone I: Concurrent Design * MFGE – 352 (3) Manufacturing Process Engineering II INMGT - 335 (4) Lean Manufacturing Systems C MFGE – 363 (4) * Controls & Instrumentation B A INMGT – 422 (3) Quality Engineering Curriculum Critical Path ARHU (6 CREDITS) Notes: 1. * Prerequisite course indicated may be taken concurrently. 2. Program is accredited by the Engineering Accreditation Commission of the Accreditation Board for Engineering and Technology, 111 Market Place, Suite 1050, Baltimore, MD 21202-4012, 410/347-7700. MFGE – 415 (2) Machine Vision & Robotics * * Circuits & Devices STAT – 330 (3) Probability & Statistics for Engineering & the Sciences ENGGR – 112 (3) MFGE – 440 (3) Manufacturing Systems Design & Simulation MFGE – 410 (3) Capstone II: Manufacturing Systems Design ELEC – 290 (4) * MATH – 250 (3) Differential Equations & Linear Algebra Calculus II * MFGE – 391 (3) Engineering Physics MATH – 154 (4) B MFGE -325 (3) Computer Aided Manufacturing Mechanics of Materials A MATH – 153 (4) Program Credits: 129 (Revised 25 Nov 2013) A SBSC (6 CREDITS) CISS (3 CREDITS) SRER (3 CREDITS) GE Elective (3) ARHU * GE Elective (3) SBSC GE Elective (3) GE Elective (3) SBSC CISS GRADUATION MFGT-150 (3) Intro. to Engineering Materials BACHELOR of SCIENCE MANUFACTURING ENGINEERING GE Elective (3) SRER GE Elective (3) ARHU Professional Selective: (1 credit min.) MFGE - 349 Intern Experience (1-2) MFGE - 449 Cooperative Experience (1-2) General Education: Arts & Humanities (6 credits) 6 credits from 2 different areas Social & Behavioral Sciences (6 credits) 6 credits from 2 different areas Contemporary Issues (3 credits) Social Responsibility and Ethical Reasoning (3 credits) Student Outcomes Rubric Review Outcomes to be assessed Spring 2014: Outcome F An understanding of professional and ethical responsibility Course used for assessment: MFGE 405 Capstone I: Concurrent Design Outcome L Proficiency in materials and manufacturing processes Courses used for assessment: MFGT 251 Fundamentals of Plastics Materials and Processing MFGT 252 Material Removal & Forming Processes MFGT 253 Joining & Casting Processes Outcome F Rubric Outcome L Rubric Student Outcomes Rubric Review Outcomes to be assessed Fall 2014: Outcome A An ability to apply knowledge of mathematics, science and engineering Course used for assessment: MECH 292 Dynamics Outcome B An ability to design and conduct experiments, as well as to analyze and interpret data Course used for assessment: INMGT 422 Quality Engineering Outcome A Rubric Outcome B Rubric Open Discussion Topics for discussion? E & T Department Open House E & T Department Open House in Fryklund Hall first floor hallway until 4:00 pm Capstone student project posters on display E & T Department student coursework project posters on display Next Advisory Board Meeting Friday, May 9, 2014 Capstone II presentations starting at 10:00 am Advisory Board meeting 12:20 pm Adjourn – thank you for coming!