MODELLING OF UNIDIRECTIONAL THERMAL DIFFUSERS IN SHALLOW WATER

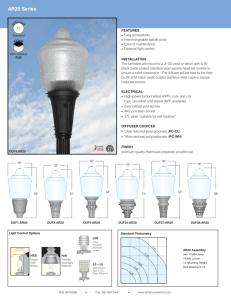

advertisement

MODELLING OF UNIDIRECTIONAL THERMAL

DIFFUSERS IN SHALLOW WATER

Joseph H. Lee

Gerhard H. Jirka

Donald R. F. Harleman

Energy Laboratory

Report No. MIT-EL 77-016

__________

l__--·llll---LIIII

July 1977

I

·IL·"·E)---·s·IT.II*IIIDI-^I.PIII

MODELLING OF UNIDIRECTIONAL THERMAL

DIFFUSERS IN SHALLOW WATER

by

Joseph H. Lee

Gerhard H. Jirka

and

Donald R. F. Harleman

Energy Laboratory

and

Ralph M. Parsons Laboratory

for

Water Resources and Hydrodynamics,

Department of Civil Engineering

Massachusetts Institute of Technology

Cambridge, Massachusetts 02139

sponsored by

New England Electric System

Westboro, Massachusetts

and

Northeast Utilities Service Company

Hartford, Connecticut

under the

MIT Energy Laboratory Electric Power Program

Energy Laboratory Report No. MIT-EL 77-016

July 1977

ABSTRACT

This study is an experimental and theoretical investigation of

the temperature field and velocity field induced by a unidirectional

thermal diffuser in shallow water.

A multiport thermal diffuser is essentially a pipe laid along the

bottom of the water body and discharging heated water in the form of

turbulent jets through a series of ports spaced along the pipe.

A uni-

directional diffuser inputs large momentum in one direction; it can

achieve rapid mixing within relatively small areas, and has the advantage of directing the thermal effluent away from the shoreline.

The theory considers a unidirectional diffuser discharging into

shallow water of constant depth in the presence of a coflowing ambient

current.

diffuser.

A fully mixed condition is hypothesized downstream of the

A two dimensional potential flow model is formulated and solved

in'the near field, where flow is governed by a dominant balance of pressure and inertia.

A control volume analysis gives the total induced flow,

which is used as an integral boundary condition in the potential flow

solution.

The shape of the slip streamline is solved using Kirchoff's

method; the velocity and pressure field are then computed by a finite

difference method.

are deduced.

The correct boundary conditions along the diffuser

Knowledge of the flow field defines the extent of the near

field mixing zone.

The near field solution is coupled into an inter-

mediate field theory.. In this region turbulent lateral entrainment,

inertia and bottom friction are the governing mechanisms of the flow, and

the mixed flow behaves like a two dimensional friction jet.

model is formulated and solved numerically.

An integral

The iiodel predictions of

induced temperature rises, velocities, plume widths enable comparisons of

the overall effectiveness of different heat dissipation schemes.

3

A model for calculating the near field dilution and plume trajectory

of a unidirectional diffuser discharging into a perpendicular crossflow

is formulated and solved.

The phenomenon of heat recirculation from the

far field is ascertained in the laboratory and a semi-empirical theory

is developed to evaluate the potential temperature buildup due to far

field recirculation.

A comprehensive set of laboratory experiments have been carried

out for a wide range of diffuser and ambient design conditions.

The

model is validated against the experimental results of this study as

well as those of hydraulic scale model studies by other investigators.

The analytical and experimental insights gained in this study

will aid future numerical modelling efforts and in better design of

physical scale models.

The principal results are applied to establish

general design guidelines for diffusers operating in coastal regions.

The ecological implications of the model predictions are discussed.

4

ACKNOWLEDGEMENTS

This study is funded by New England Electric System, Westboro

Massachusetts and Northeast Utility Service Company, Hartford,

Connecticut through the Electric Power Program of the M.I.T. Energy

Laboratory.

The co-operation of Dr. William Renfro of Northeast

Utilities and Mr. Bradley Schrader of New England Electric is appreciated.

The material in this study was submitted by Joseph H. Lee,

Research Assistant, to the Department of Civil Engineering in partial

fulfillment of the requirements for the degree of Doctor of Philosophy.

The research work was carried out under the technical supervision of

Professor Donald R.F. Harleman, Professor of Civil Engineering and

Director of the Ralph M. Parsons Laboratory for Water Resources and

Hydrodynamics, M.I.T. and Dr. Gerhard H. Jirka, Research Engineer in the

Energy Laboratory and Lecturer in the Department of Civil Engineering,

M.I.T.

Several discussions with Dr. E. Eric Adams, Research Engineer and

Professors Chiang C. Mei and Keith D. Stolzenbach have been very helpful.

Mr. Roy G. Milley, machinist, and students Richard Trubiano, Jeff Diercks,

Charles Almquist, and David Fry have provided assistance in the experimental program of this study.

Computational work was carried out at the

Civil Engineering-Mechanical Engineering Joint Computer Facility at M.I.T.

This manuscript was capably typed by Ms. Josephine Mettuchio.

5

TABLE OF CONTENTS

Page

TITLE PAGE

1

ABSTRACT

2

ACKNOWLEDGEMENTS

4

TABLE

OF CONTENTS

5

I.

INTRODUCTION

11

II.

1.1

Background

1.2

Multiport

1.3

Objectives

REVIEW

11

20

and Summary of this study

OF PREVIOUS

WORK

2.1

The Free Turbulent

2.2

Turbulent

2.3

14

Diffusers

Buoyant

Interaction

24

Jet

24

Jets

26

27

of Round Jets from the

Multiport Diffuser

2.4

Application

of Buoyant

Jet Models

for

30

Hydrothermal Prediction

III.

2.4.1

Unidirectional Multiport Diffusers

in a Laterally confined Environment

30

2.4.2

Unidriectional Multiport Diffusers

in a Laterally unconfined Shallow

Environment

34

Basis

37

2.5

Criterion for Unstable Near Field:

of a Two Dimensional Approach

2.6

Summary of Previous

Work

A THEORY FOR THE TEMPERATURE FIELD INDUCED BY

A UNIDIRECTIONAL DIFFUSER IN A COFLOWING CURRENT:

THE NEAR FIELD SOLUTION

Statement

of the Problem

3.1

General

3.2

The Complete Three Dimensional Formulation

38

41

41

43

6

Page

3.3

Dimensional Analysis

45

3.4

The Vertically Averaged Equations

47

3.5

A Synopsis

50

3.7

of the Flow Field

3.6.1

Control Volume Analysis

59

3.6.2

Limiting Cases

63

A Potential Flow Model for the Near Field

64

3.7.1

Basic Assumption

66

3.7.2

Derivation of the Boundary Conditions

67

3.7.3

Solution

70

3.7.4

Results

3.7.5

of the Slip Streamline

Sensitivity

75

of Results

to the

81

Polygonal Approximation

3.7.6

3.8

IV.

Solution for the Flow Field

Summary

81

87

THE INTERMEDIATE FIELD SOLUTION

89

4.1

Formulation of the Intermediate Field Theory

89

4.1.1

Model Structure

89

4.1.2

Governing Equations

92

4.1.3

Basic Assumptions

93

4.1.4

System of Integrated Equations

94

Solution of the Intermediate Field Equations

96

4.2.1

Non Dimensionalization

96

4.2.2

Numerical Solution Procedure

98

4.2.3

Initial Conditions

98

4.2.4

Entrainment Coefficients

99

4.2

7

Page

4.3

Solution

4.3.1

100

Analytical Solution in the Absence

of

4.3.2

Physical

Interpretation

Intermediate

4.4

V.

Solution

of the

103

Field Solution

for u

a

0

109

EXPERIMENTAL

INVESTIGATION

5.1

General

Experimental

5.2

Multiport Diffuser Design

118

5.3

Temperature Measurement System

121

5.4

Flow Visualisation and Velocity Measurement

121

5.5

Experimental

124

5.6

VI

Numerical

101

a Current

117

Setup

117

Runs

5.5.1

Series MJ

124

5.5.2

Series FF

125

5.5.3

Series 200

127

Data Reduction

134

COMPARISON OF THEORY WITH EXPERIMENTAL RESULTS

136

6.1

Near Field Mixing

136

6.2

Comparison of Theory and Laboratory

Series MJ and FF

Results:

140

6.3

Comparison of Theory and Laboratory

Series 200

Results:

148

6.4

Detailed Thermal Structure

154

6.5

Comparison of Theory with Perry Model Study

163

6.6

Comparison

173

of Theory

Fitzpatrick Plant

with Field Data:

James A

8

Page

VII.

UNIDIRECTIONAL DIFFUSER DISCHARGING INTO A

PERPENDICULAR CROSSFLOW

179

7.1

179

7.2

7.3

7.4

VIII.

T-Diffuser

in a Crossflow

7.1.1

Near Field Dilution of a

Unidirectional Diffuser in an

inclined Crossflow

181

7.1.2

Calculation of T-Diffuser Plume

Trajectory

184

7.1.3

Theoretical Results

187

Experimental Results

187

7.2.1

Experimental Observation:

This Study

189

7.2.2

Data Analysis of the Perry Tests

192

Comparison of Predicted and Observed

Plume Trajectory

195

7.3.1

Plume Trajectory:

Series FF

196

7.3.2

Plume Trajectory:

Perry Tests

196

7.3.3

Sensitivity of Results to'CD

202

202

Summary

FAR FIELD RECIRCULATION

205

8.1

Conceptual Framework of Heat Recirculation

205

8.1.1

Characteristic Scales of Recirculation

208

8.1.2

A Dimensionless

209

Formulation

of Heat

Recirculation

8.2

Experimental Investigation

210

8.2.1

Experimental Results

211

8.2.2

Empirical Correlation

216

8.2.3

Short vs Long Diffusers

219

9

8.3

IX.

Design Application

8.3.1

Prototype Considerations

220

8.3.2

Design of Models

226

DEISGN

9.1

9.2

220

APPLICATION

228

Diffuser Design in Shallow Water:

Discussion

A General

228

9.1.1

Design Alternatives

229

Design

Interpretation

230

of Theoretical

Predictions

9.3

9.4

9.2.1

Case A: Effect of Diffuser Length

for Fixed Discharge Velocity

232

9.2.2

Case B: Variable Discharge Velocity

and Diffuser Length with Constant

Near Field Dilution

239

Diffuser Performance and Aquatic

Environmental Impact

245

9.3.1

Comparison of Ecological Performance:

Variable Diffuser Length at Fixed

Discharge Velocity

246

9.3.2

Case B: Variable Diffuser Length

and Discharge Velocity at Constant

near Field Dilution

250

9.3.3

Concluding Remarks

252

Prototype Considerations:

Diffusers

Short vs Long

253

10

Page

X.

SUMMARY AND CONCLUSIONS

10.1

257

Objectives

257

10.2

Theory

258

10.3

Experiments

263

10.4

Results and Comparison with Theory

263

10.5

General Conclusions

265

10.6

Recommendations for Future Research

267

LIST OF REFERENCES

269

LIST OF FIGURES AND TABLE S

272

LIST OF SYM4BOLS

278

APPENDICES

A

B

CONTROL VOLUME ANALYSIS VALID FOR ALL DILUTIONS

SCHWARTZ-CHRISTOFFEL TRANSFORMATION FOR AN

ARBITRARY POLYGON WITH SIX VERTICES

285

287

C

COMPUTATION OF ISOTHERM AREAS

294

D

NUMERICAL RESULTS OF SLIP STREAMLINE COMPUTATIONS

297

11

CHAPTER

I

INTRODUCTION

1.1

Background

Technological advances in recent decades have led to man's

increasing consumption of electricity.

A by-product of this

activity is the large quantities of waste heat resulting from

steam-electric power production.

At present the thermal

efficiency

production

of this mode of energy

is about 40% for a

fossil fueled plant, and 33% for a nuclear fueled plant.

Thus

for every kilowatt of electrical energy produced, an equivalent

of 1.5 to 2 kilowatts

as waste heat.

of energy

is rejected

to the environment

The heat rejection rate is about 7x109 BTU/Hr.

for a standard 1000 MWe fossil plant.

As power plants are

usually located far from populated areas, the present state of

technology

has not found

of the low grade waste

it economical

to make beneficial

use

heat.

In many instances a "once through" condenser cooling water

system is employed.

Cooling water is withdrawn from an adjacent

water body, circulated through the plant once, and discharged

back into the water

environment

ambient water temperature.

at 20 to 30 F higher

than the

The increase in water temperature

changes our environment: the chemical composition and physical

properties of the water-dissolved oxygen levels, viscosity,

nutrient concentrations, etc. may be altered; the life processes

of many aquatic organisms may be encouraged or hampered.

The

12

waste heat input affects the ecological system.

knowledge

of interactions

of the essential

Although our

components

of an

eco-system is admittedly meagre, it is important to provide

a sound

basis on which

environment

the impact

can be assessed.

of thermal

discharges

It is of interest

on our

to understand

the various heat mixing mechanisms and induced fluid motion

that govern

the ultimate

distribution

of heat in the water body.

For additional purposes of avoiding heat recirculation through

the plant, it is desirable to predict the various temperature

configurations associated with different thermal outfall

designs.

This is the point of departure

of this study.

Different standards have been set up in the United States

to regulate thermal discharges from power plants.

Prior to the

issuance of a thermal discharge permit the applicant must per-i

form detailed engineering and ecological investigations to

demonstrate that the thermal standards will not be violated.

Depending on the aquatic environmentand a multitude of factors,

the regulatory standards are rather site specific, and vary

from state to state.

A common type of standards dictates that

a certain temperature rise above the natural background water

temperature

mixing

is not to be exceeded

zone; a high rate of mixing

the thermal outfall.

beyond

a relatively

is thus required

small

close to

Other standards may restrict the warm

effluent to an upper layer of the receiving water for protection

of benthic organisms.

Important considerations that are of

interest to biologists include the maximum temperature

13

rise near the discharge,

time to elevated

cooling water

the exposure

temperatues

flow,

of organisms

the location

entrained

in the

and extent of the plume.

In

recent years there has been a tendency to make thermal impact

assessments on a case to case basis, allowing more interdisciplinary interaction involving engineers, biologistsand

ecologists.

This also furthers the need for a more complete

picture of the induced temperature and velocity field.

For once through cooling systems there are basically two

types of waste heat discharge schemes-surface schemes discharge

heated

cooling water

at the free surface

through

number of pipes located near the shoreline.

results

in a relatively

but has the advantage

stratified

a canal or a

This method usually

large surface area of elevated temperatures,

that the heated water

surface layer

forms a stably

and the effect on the bottom

of the

receiving water is reduced.

Submerged discharge schemes consist

of single port or multiports

located near the bottom

water body.

of the

The first type of thermal standards usually precludes

the use of surface discharge or submerged single port discharges.

A submerged multiport diffuser discharging the heated water in

the form of high velocity

turbulent

jets has proved

to be an

efficient device to achieve rapid temperature reduction within

a relatively

small

area.

Condenser cooling water systems require large quantities

of cooling water.

MWe

plant

A typical condenser flow for a standard 1000

is in the order of 1000 cfs.

The projected

daily

14

condenser cooling water requirement for steam-electric power

generation for 1970 and 1980 was 113 and 193 billion gallons,

as compared to the nation's average

runoff of 1200 billion

gallons/day (National Water Commision, 1971).

Thus for once

through systems, there has been a trend to build plants adjacent

to coastal

areas

(great lakes or oceans)

where there is an ample

supply of water, the mixing capacity of thermal discharges in

rivers being limited by the ratio of the river flow to the

condenser flow.

1.2

Multiport Diffusers

A multiport diffuser is essentially a pipe laid along the

bottom of the water body and discharging waste water in the

form of turbulent jets through a series of ports spaced along

the pipe.

performance,

sufficient

The ports

can be oriented

and are usually

interaction

closely

to give optimal mixing

spaced

so that there is

among the jets to approximate

a line

source of pollutant, flow, and momentum.

Historically, submerged multiport diffusers have been used

for sewage disposal in the marine environment.

Recently they

have been used in thermal discharge applications.

There is,

however, a marked difference in the mixing mechanisms of the

two cases:

Submerged

sewage

diffusers

are characterised

by

high buoyancy of the discharge under deep water conditions.

The relative density difference between the discharge and

receiving water is about 0.025, and the typical water depth

15

about

100 ft.

equivalent

two dimensional

as an

can be represented

Thus the discharge

slot jet in an infinite

and

field,

classical theories of buoyant jet analysis are applicable to

Submerged thermal diffusers,

predict diffuser performance.

on the other hand,

by low buoyancy

are characterised

discharge under shallow water conditions.

difference

is about 0.003

of the

The relative density

and the typical water depth 20 ft.

For thermal discharge applications the buoyant jet patterns

predicted by classical theories cannot be maintained and fully

mixed conditions occur downstream of the diffuser (Fig. 1-1).

In almost all practical situations, three dimensional thermal

diffusers produce fully mixed conditions downstream; the nature

of the flow field

is altered

considerably,

and traditional

methods of predicting diffuser performance for sewage

applications cannot be carried over.

fig. 1-2 shows

A

three basic

types of multiport

diffusers.

unidirectional diffuser consists of ports all pointing in

one direction and discharging perpendicular to the diffuser

axis.

A unidirectional diffuser inputs large momentum in one

direction; it can achieve rapid mixing within a relatively

small area, and has the advantage

effluent

away from the shoreline.

of directing

the thermal

The ports in an alternating

diffuser discharge alternately in opposite directions.

net momentum

input is zero; the plume extends

The

in both directions

and flow is driven by buoyancy beyond a near field mixing zone.

16

V

f-,I-

-4

ly

tified

entrainment

X

xXX

Fig. 1-1 a)

II

X

X

x

X

x

xx

Multiport diffuser discharge in deep water:

Stable buoyant jet

V

->

discharge

induced

flow

/

./

X '

Fig.

x

1-1 b)

x

x

x

/

/C

X

x

,q;

/

JX

/

/Full

Vertical

/ixing

MX-X

~1

Multiport diffuser discharge in shallow water:

Unstable flow situation

17

ional

Alternating

Diffuser

;2:lis-~---L

............

-----. .

z-~~~~~~~~~

~

Fig. 1-2

~

Staged

Diffuser

-----

Basic types of multiport diffuser configurations

18

As the induced

diffuser

flow has no preferred

is suitable

direction,

this type of

with

for use in a tidal situation

reversing currents. In a staged diffuser the ports are oriented

in a tandom fashion:

by a narrow

diffuser

plume

axis.

this type of arrangment

and distributed

momentum

For a given heat rejection

is characterised

input along the

rate and under

stagnant conditions, the diffuser length required to achieve

a specified

degree

of initial mixing

is shortest

for the

unidirectional design (Harleman, Jirka, Stolzenbach, 1977).

The impact of a multiport diffuser operating in shallow

water can be illustrated as follows:

plant with

a condenser

Consider a hypothetical

flow of 2000 cfs and having

flow of 20,000

of 10, the total induced

low flow of the Mississippi

a dilution

cfs approaches

River in Illinois!

the

Tor a typical

discharge nozzle velocity of 20 fps, the induced velocity

around

is of the order of 2 fps-larger

the diffuser

current speeds frequently found in coastal regions.

initial mixing

also means

distance offshore

the diffuser

than

The high

has to be placed

some

so as to ensure a sufficient entrainment

flow from behind.

Fig. 1-3

shows

an example

of induced

temperature

rise at

the James A. Fitzpatrick Nuclear Power Plant on Lake Ontario.

The site is characterised

ambient

stratification,

by a relatively

small condenser

and a strong offshore

flow,

slope of 1/50.

19

0O

21

I)

rh

Ca

0

c2

,--I

Cd

14-4

C

.,-

%::O

E

~4

U 0

P-J CF

ci)

CI

" I'D

"

u 3

e

,

f

r

-2E

r

-iU

Crl

--

f_

aCdJ aca)

~·r

Pk

-)

d

P)

t

,

c

r-,

Cl)

a)

Pd

4-4

,

~4

rm c

cXr

o

0l

fW

*;r

-

r

·r

Cd U

w

.H

av C1 V sU

Hci

,,4 t-la) C4 O:

O*- ;cd

P a) N)

o ·- 4 Cd 0

Qc7Z

)

1-'I

s-I

Si

0

0 Co

HuX4

)

X *'da)

r ,

W1

$cSr J5

z

kiG

rW

s z

44 o 4W

ao

r )

C)

u

a-

4-4

U )c4-

..

5U)

20

The isotherms

are inferred

from measurements

of dye concentration

taken in a hydrothermal field survey (Hydrothermal field studies,

Stone and Webster,

1977).

For unidirectional

discharge

dominated

diffusers

flow regimes

the travel time in the

is of the order of an hour;

for such time scales surface heatloss to the atmosphere is

negligible, and the temperature reduction is governed by

turbulent mixing with the ambient water.

1.3

Objectives

and Summary

of this study

This study is an analytical and experimental investigation

of the temperature

field and velocity

by a

field induced

unidirectional thermal diffuser in shallow water.

This type

of design provides an effective source of horizontal momentum

and is capable of meeting stringent thermal standards as

regards allowable mixing zones and temperature rises.

This study considers a unidirectional diffuser discharging

into shallow water

depth in the presence

of constant

ambient unidirectional current.

hypothesized

downstream

of an

A fully mixed condition is

of the diffuser.

The objective

is to

develop a theory that predicts quantities of environmental

interest; velocities, temperature rises, areas of surface

isotherms.

Surface temperature patterns are crucial for a

comparison of the overall effectiveness of different heat

dissipation

schemes.

Based

on an understanding

of the

diffuser induced flow field, the effect of the heat return

21

from the far field on potential

the

temperature

near field can be evaluated.

build up in

The analytical insights

gained in this study will aid future numerical modelling

efforts and in better design of physical scale models.

The

principal results are applied to establish general design

guidelines for diffusers in coastal zones.

In Chapter

II a summary

of previous

work on submerged

multiport diffusers is presented and the conceptual basis

underlying the present analytical and experimental modelling

efforts is discussed.

Chapter III presents a two dimensional potential flow

model

for the near field of a unidirectional

coflowing

current.

In this region

flow is governed

dominant balance of pressure and inertia.

analysis

gives

the total induced

diffuser

in a

by a

A control volume

flow, which is used as an

integral boundary condition in the potential flow solution.

The shape of the slip streamline

is solved using Kirchoff's

method; the velocity and pressure field are then computed by a

finite difference method.

along

the diffuser

defines

the extent

The correct boundary conditions

are deduced.

Knowledge

of the near field mixing

of the flow field

zone.

This is

important in the prediction of surface temperature configuration

and in future numerically

conditions.

modelling

for a variety

of ambient

22

In Chapter

IV the near field solution

intermediate field theory.

is coupled

into an

In this region turbulent lateral

entrainment and bottom friction are the driving mechanisms of

the flow, and the mixed

friction jet.

numerically.

flow behaves

like a two dimensional

An integral model is formulated and solved

Considerable

of no current,

insight

when an analytical

can be gained

solution

for the case

can be obtained.

The model is capable of predicting velocity,plume width,

temperature rises, and area of surface isotherms.

In Chapter V the experimental

employed

design

apparatus

in this study is described.

of each set of experiments

and run procedure

The motivation

is discussed.

for the

The run

parameters are tabulated and the experimental results presented.

In Chapter VI the predictions

of the model are compared

with laboratory experiments conducted in this study as well as

results of hydraulic scale model studies carried out by other

investigators.

In Chapter VII the effect of diffuser orientation with

respect to current is discussed and experimental results are

interpreted

in light

of the theoretical

insights

set forth in

the simpler situations.

In Chapter

the far field

VIII the phenomenon

is ascertained

of heat recirculation

in the laboratory

and a semi-

empirical theory is developed to evaluate the potential

temperature

build

from

up due to far field recirculation.

23

In Chapter IX the theoretical and experimental results

in this study are interpreted

from the view-point

of practical

design of thermal diffusers for once through cooling systems.

An

ecological interpretation of the model predictions is

advanced.

In Chapter

X the findings

in this study are summarised.

General conclusions are drawn and recommendations are made

in areas requiring further research.

24

CHAPTER

II

REVIEW OF PREVIOUS WORK

A multiport

diffuser

can be characterised

by a line of

equally spaced incompressible turbulent jets issuing into a

receiving water body of depth H.

2.1

The free turbulent

The mechanics

free turbulent

jet

of a two dimensional

fluid has been studied

jet in an infinite

extensively (Abramovich, 1963).

jet from a finite source.

or three dimensional

Fig. 2-1 shows a turbulent

Near the source the sharp discont-

inuity in velocity produces a region of high shear.

This

unstable situation gives rise to eddies, resulting in the

less turbulent ambient fluid being entrained into the turbulent fluid. The jet, or the region of high turbulent intensity,

thus grows

in width

as it entrains

more ambient

fluid.

The

mechanism of turbulent entrainment dilutes the concentration

of any tracer material

that may be introduced

at the source.

For this type of free shear flow experiments have shown

that pressure is approximately constant throughout the jet

and that the jet width is small compared with the longitudinal

length scale.

legitimate.

A boundary layer type approximation is then

Based on different hypothesis of relating the

turbulent shear terms -u'v' to the mean flow quantities, exact

similarity solutions have been obtained by Prandtl, Taylor,

25

I

-1-

I

'V

tA IV

Id~

A

.4

sW

r.

Q)

,

.4

I4

0

1T

1

rla)

15

p4

or

fsisq

4..

W

w

I

4%,

-

-

4

I eL*

4.

r1C4d

i ?~

%t~

'r4

26

Reichardt (Abramovich).

pure source

of buoyancy

True similarity also exists for a

or a plume;

this case was treated by

Rouse, Yih and Humphreys (1952), and Morton, Taylor, and

Turner (1956).

The similarity of velocity profiles and concentration (or

buoyancy) profiles has been confirmed experimentally.

The

profiles can also be well approximated by Gaussian functions

(Albertson

where

et al, 1950)

u(x,y)

= u(x,O)

e

b

c(x,y)

= c(x,O)

e(

Xb)2

c : concentration

of tracer

: empirical constant

2.2

Turbulent buoyant jets

establishment

Fig.

2-2

Schematics

of a slot buoyant

s,n: axial co-ordinates

uc : centerline axial

velocity

I: ambient density

jet

u: axial velocity

e,:angle of discharge

B: slot jet width

27

The free jet theories have been extended by

many

investigators to study.t.hebehavior of turbulent buoyant jets

in a variety

of situations

(Abraham,

Stolzenbach and Harleman, 1971).

1963; Fan, 1967;

The turbulent buoyant jet

possesses both initial momentum and buoyancy, and as such it is

neither a pure source of momentum nor a pure

source of buoyancy.

(Fig. 2-2) A review of previous work on turbulent buoyant jets

as related to multiport diffusers has been given by Jirka and

Harleman (1973).

For purposes of predicting gross quantities of interest in

many practical applications it has been found convenient to assume

a priori cross-sectional profiles for the velocity and

concentration (buoyancy).

across

integrated

The equations of motion are then

the jet to yield a set of ordinary

differential

equations for the jet characteristics-plume position, centerline velocity, jet width, centerline concentration.

This so

called 'integral technique' has been successfully extended to

other buoyant jet flows where true similarity does not exist

(Abraham,

2.3

1963; Fan, 1967; Hoult et al, 1969).

Interaction of round jets from the multiport diffuser

The round jets issuing from the diffuser will gradually

merge into one another as they spread by turbulent entrainment

(Fig. 2-3).

turbulent

Knystautas

(1963) studied

the interaction

of

jets from a series of holes in line and discharging

into a still fluid at incompressible speeds.

Longitudinal

28

I'

i g,1

'I

a)

N-4

42

0

4d

0O

4.3

,-4

co

0

4-)

t"

p,

Q)

S

kA

Itl

A

III

4--

I

cY

I

bt

CNJ

FC'4

'a

7

-

It TM

I

.,s

Lll*

.

29

variations

in static

are assumed

pressure

thus the jet momentum

is conserved.

hypothesis

for the turbulent

linearises

the equation

to be negligible

By extending

shear stress

for the square

and

Reichardt's

in a free jet which

of the mean velocity

downstream, the momentum fluxes at each point of the interfering

The theory predicts

jet group may be found by superposition.

that fully merged two-dimensional flow occurs at approximately

12 hole spacings downstream of the source.

Cederwall

(1971) examined

the same problem

diffuser used in sewage and thermal outfalls.

momentum

and volume

slot jet for a seriesof

equivalent

TrrD

to be B =

radius

fluxes per unit width,

.

Defining

at the point where

By conserving

the width

momentum

b as the nominal

for a multiport

of an

jets can be shown

jet half-width,

the local jet velocity

equals

the

l/e of

the centerline velocity, and assuming interaction occurs when

2b=s,

it can be shown

that the jets merge

at x4.4s.

The same

line of reasoning can be worked through for a series of round

plumes, in which case interaction occurs at x5.1s.

the velocity

point of merging,

¥2

-u

M

.e

At the

at the edge of the jet is

uc =0.52 uc (obtained by summing the momentum

contributions from the individual jets); thus flow is far from

fully two dimensional.

Fully two dimensional flow is established

over a transitional region beyond the point of merging.

Cederwall

momentum

compared

jets with

comparison,

E is

the mixing

efficiency

that of an equivalent

defined

as

of a row of round

slot jet.

An index of

30

Dilution for multiple ports

Dilution

for equivalent

slot jet

At the point of merging, using well established relationships

for free jets E was shown

to be

0.95.

For the case of a

row of round plumes E0.78.

2.4

Application of buoyant jet models for hydrothermal

prediction

The considerations in the preceding sections are applicable

to multiport diffusers under deep water conditions, such as

the case for sewage applications, when the static or piezometric

head can be regarded

as constant

flow can then be modelled

in the flow field.

as an equivalent

buoyant

The diffuser

slot jet.

Predictions of dilutions of sewage pollutant or temperature

reduction of thermal discharges can then be estimated using

buoyant jet models based on integral techniques (Brooks, 1972).

Under shallow water conditions, however, the presence

of the free surface

of the flow field

regarded

and the bottom

drastically;

as constant,

boundary

pressure

and the momentum

changes

the nature

can no longer

be

flux is not conserved.

Multiport diffusers designed for use as thermal outfalls

usually fall into this category.

(Jirka, Abraham, Harleman,

1975)

2.4.1

Unidirectional multiport diffusers in a laterally

confined environment

Cederwall (1971) carried out an experimental classification

of the different

of a buoyant

types of flow regimes

slot jet in a confined,

that can occur downstream

uniformly

flowing environment

31

5.00 F

I

~ ~ ~~

~~

!

'

1

I

....

I~~~~~~~~~~~~

I

I

I

I

II

I

I

I 1111

Legend: Critical flow

I

-

I .

.I

·

__ ....

I

sf

I

I I

7

Maintained buoyant o

EI0~

.

-

jet flow pattern

.I

t,I

E

C

u

discharge in river]

1.00

-

a'8~~~~~~~~~~~~~~~~~~~~~~~~

+Zl

O..

,

0

U.

=1

0

S

Subcritical flow

0

Jet or plume-like

patterns .

.-

d--13

o3

-

-1_1%

I-

El

0.10

Occean disposal

nn

of sewvage o

r .I

I

0. .

I

I

I

0.5

I II

_

1.0

I

I

I

I

I

I

llI

5

The momentum flux ratio

I

'10

V

I

I

I

I I

50

uH

UB

-.

Observed flow regimes for a horizontal buoyant slot jet in a co-flowing stream..

Critical flow defined as the situation when the formation of a surface wedge is

incipient at the reference section.

- -

Fig. 2-4

Downstream flow regimes for a horizontal

buoyant slot jet in a coflowing stream

( from Cederwall, 1971)

U4 jet velocity

8 jet width

Uc ambient current velocity

A initial density difference

b' buoyancy flux

100

32

(Fig. 2-4). This simulates a unidirectional thermal diffuser

operating

in a river

situation.

For a horizontal

jet the

downstream flow condition is primarily governed by a source

Froude

number

defined

by F

u

3

APo

/g -

u B, a measure

of the

a

strength

of the current

relative

to the buoyancy

flux at the

source.

When F<l a subcritical flow with a surface wedge

penetrating upstream of the diffuser is observed.

When F>l

a super-critical flow occurs with the jet flow swept downstream when reaching the surface; this represents the situation

when the buoyant jet cannot entrain all the oncoming flow while

maintaining the free buoyant jet flow pattern.

The jet then

breaks up and efficient mixing takes place close to the source.

Hydraulic scale model studies and field tests done for

the thermal outfall into the Mississippi River from the Quad

Cities Nuclear Plant, Illinois, also indicate complete

vertical mixing of condenser water with the river flow downstream

of the diffuser

(Jain, Sayre,

1971; Parr, D., 1975).

Similar conclusions were also reached by Harleman, Hall, Curtis

(1968) in a study

of thermal

diffusion

of condenser-water

in

a river with application to the T.V.A. Browns Ferry Nuclear

Power Plant.

Harleman, Jirka, Stolzenbach (1971) investigated the

mixing downstream of three jets placed in a channel. Temperature measurements demonstrate that full horizontal and vertical

mixing are obtained in the downstream region.

temperature profiles are shown in Fig. 2-5.

Typical

33

12 FT. FROM PORTS

Ho"atvramLSLE

VECIc¢L

-a45'. 3."'

SCILE : -

3F

7.5 FT. FROMPORTS

Horizontal

Temperature

profiles

3' FROM PORTS

PORT

Q~~~BTWPOt

BETWEENPORTS

~~~~~~~~'

_

WATERSURFACE :

i

3 FT. FROMI

12 FT.FROM PORT

-"''..

.

..

-

-

.~~~

..

HORIZONTAL SCA

VERTICAL SCA

Vertic

CHANNEL

.

OTTS..

Temper

._1

Prof i

.CHANNEL BOTTOM

Fig. 2-5

Temperature profiles downstream of heated jets

placed in a channel

F

34

Jirka and Harleman (1973) gave a theoretical treatment

of the stability

stagnant

shallow water.

combination

measure

of a two dimensional

of H/B

It was

(a measure

of the buoyancy

buoyant

found that for a certain

of shallowness)

of the discharge)

flow is possible near the jet.

slot jet in

and FS ( a

no stably stratified

Intense vertical mixing is

created and consequently the temperature profile downstream

is vertically homogenous.

Whereas

the instability

in a confined

ambient

in the case of a buoyant

flowirg environment

current,

the instability

is primarily

induced by the

of a buoyant

slot jet in

stagnant water is dominated by discharge conditions:

momentum

and the shallowness

slot jet

of the receiving

the jet

water.

It should be pointed out that the rate of initial mixing

of a multiport

of the river

with length

diffuser

in a river is determined

flow to the condenser

comparable

to the width

flow.

by the ratio

Also, for diffusers

of the river

(the Quad

Cities Plant or the Browns Ferry Plant, for example), the

mixing downstream is strongly influenced by lateral boundaries.

2.4.2

Unidirectional multiport diffusers in a laterally

unconfined shallow environment

A theory

on the initial

mixing

performance

of a unidirec-

tional multiport diffuser in an unconfined environment was

first proposed by Adams (1971).

Assuming full vertical mixing

a control volume analysis indicates a contraction of the mixed

35

flow downstream.

The theory predicts the total induced flow

downstream from the diffuser in a coflowing current.

However,

the two-dimensional nature of the flow field was not discussed.

The location of the contraction, the boundary conditions along

the diffuser, the extent and nature of the flow field cannot

be obtained from the solution.

discussed

in Chapter

Adams's analysis is further

III.

Boericke (1975) studied the interaction of multiple jets

with an ambient current by solving the vertically averaged

equaions of motion numerically.

Predictions of flow patterns

surrounding the proposed thermal outfall for the D.C. Cook

Nuclear Plant on Lake Michigan were in qualitative agreement

with dye studies reported by the Alden Research Laboratories

(Fig. 2-6).

The numerical solution reveals large scale

recirculation (in which the discharge flow is re-entrained in

a circulatory flow pattern) can occur when the ambient current

is not strong enough to supply the entrainment demand.

This

would impair the dilution cooling near the diffuser as heat

is being recirculated.

Although the numerical modelling

promise

for a more complete

description

approach holds much

of the flow and temp-

erature field, there are several shortcomings;

In Boericke's

work the velocity boundary conditions around the thermal outfall are obtained

by adding

the velocities

due to each

individual slot jet at the outfall vectorially.

However, even

36

___

___

s7wit

Patterns Observed

FIG. 1.-Recirculation

ft = 0.305 m; 1 fps = 0.305 m/s)

4*

.S4

-.

_-.

c,*

e4.-

.7.

,

in Dye Studies of Hydraulic Mldel

t

o

~~

i::~

4,..*- o

e G.-o..e

-

W

-..

-"---- :.::

--

4k

t

e,

Flow Pattern for 0.5-fps Ambient Current (1 fps 0.305 ms;

I ft - 0.305 m)

dl.4h4M!*4' .~0,. r

Flow Pattern for 0.5-fps Ambient Current (1 fps = 0.305 m/s;

0.305 m)

IFIG.

ft =4.--Calculated

FIG. 4.-Calculated

Fig. 2-6

b

Numerical predictions of diffuser75

induced flow patterns ( from Boericke,19 )

37

if the water

momentum

body can be considered

fluxes can be

superposed

infinite,

only the

and not the velocities.

Furthermore, as discussed before, in shallow water pressure

can hardly be considered constant and therefore even superposition of momentum fluxes is not justified.

introduced

in the particular

The error

case cited may not be large as

there are only four slots oriented in different directions

in the thermal outfall.

In the general

case of a unidirec-

tional multiport diffuser with many closely spaced ports, the

interaction of the jets in shallow water have to be accounted

for in order

to arrive

at the correct boundary

be imposed around the diffuser.

conditions

to

In some cases, the near field

mixing of a diffuser may be strongly influenced by the presence

of an ambient

current,

i.e., the boundary

conditions

for the

vertically averaged equations may be coupled with an ambient

condition and cannot be specified independently.

2.5

Criterion

for unstable

near field:

basis of a

two dimensional approach

Fig. 2-7 shows the stability criterion given by Jirka

and Harleman

water.

for a horizontal

On the same diagram

slot buoyant

jet in stagnant

the (F , H/B) values

of

unidirectional diffuser experiments in a laterally unconfined

water body for which direct temperature measurements have

verified the vertical homogeneity of the temperature field

downstream are plotted.

From all the available data, we

38

see that the prediction

of stability

for a two dimensional

slot jet is a good indication of the near field stability

of a three dimensional unidirectional diffuser.

The foregoing

discussion

suggests-it is useful

to look

at the diffuser induced temperature field two dimensionally

and ignore the vertical variations as a valid approximation.

Except for an initial jet mixing region of limited extent,

this approach is valid up to the point where stratification

becomes

important

in determining the flow field.

In practice

the region of validity will cover the surface isotherms of

interest.

Furthermore, under prototype conditions, wind

induced mixing

and turbulence

created by heat flux out of the

water surface will enhance the vertical homogeneity of the

temperature field.

2.6

Summary of previous work

It has been recognised both experimentally and theoretically

that the heat discharged by thermal multiport diffusers in

shallow water will be vertically fully mixed.

plume

like patterns

cannot

be maintained

Buoyant jet or

and the nature of the

flow field is changed considerably.

For unidirectional multiport diffusers in an open water

body, simulating the Great Lakes or ocean coastal regions,

existing theory can only predict the total induced flow near

the diffuser.

To date no comprehensive treatment of the

temperature field induced by a unidirectional diffuser

39

i-

, Us

Fig. 2-7

us equivalent slot jet velocity

initial density difference

p$ ambient density

H water depth

8 equivalent slot jet width

A

Near Field Instability of Unidirectional thermal

diffusers in shallow water

40

Data reported by previous workers are

has been done.

limited to hydraulic scale model studies of specific sites

and as such little general insights can be extracted from

these scatteredexperimental

data.

modelling of thermal discharges in shallow

Numerical

water has been attempted.

However, previous efforts suffer

from the lack of knowledge of the correct boundary conditions

for the flow and temperature

field near the diffuser.

Areas of knowledge requiring further research include:

understanding

1.

A better

2.

A predictive

model

of the diffuser

of the temperature

flow field.

induced

field as a function

of diffuser design parameters.

3.

set of experiments

A comprehensive

that can provide

a

data base for validation of existing or future theoretical

modelling efforts, as well as providing meaningful empirical

guidelines

in situations

that are too difficult

to model

analytically.

4.

An understanding

field;

of the nature

this may be self-induced

the diffuser

situation,

over

of heat return

by the pumping

from the far

action of

prolongedperiods of slack in a tidal

or due to the interaction

of an ambient

with the diffuser flow.

All the above

points

are addressed

in this study.

current

41

CHAPTER III

A THEORY FOR THE TEMPERATURE FIELD INDUCED BY A UNIDIRECTIONAL

DIFFUSER IN A COFLOWING CURRENT: THE NEAR FIELD SOLUTION

The next

two chapters

are devoted

to a theoretical

discussion of the diffuser induced temperature field for the

case when the diffuser momentum is aligned in the same direction

as the ambient current.

in a coastal

This simulates a diffuser operating

zone and in particular,

the limiting

case, when

there

is no current, often reprsents the most severe design condition

for thermal diffusers.

this chapter.

A

near field theory is presented in

The coupling of the near

field solution with an

intermediate field theory is treated in the next chapter.

The

near field theory does not consider the question of heat return

from the far field.

3.1

General

Statement

of the Problem

Consider a unidirectional multiport diffuser consisting of

N identical ports of cross-sectional area a , equal spacing s,

and discharging heated water in the form of turbulent jets at

temperature

T

and velocity

u

in the same direction

into an

infinite receiving water body of depth H and uniform temperature

The ports are located near the bottom.

Ta.

LD

is defined

port.

as the distance

The upstream

schematized

current

between

velocity

The diffuser length,

the first and the last

is ua.

in Fig. 3-1 and the relevant

The problem

parameters

is

are defined.

42

J

-h

T(x,I gc(bs@}>

L-+ ,Ta,

,.

I

L

-- y

J~

-4

Pl

:O

IT

-§--

-40

-4

PLAN VIEW

!

j

4

4 U&

-

H

I

//

J

-

I

///

I6

. ,at///

~~ ~~~__~ ~ ~ ~

-

//

ELEVATION

/

/

//

///

/

ELEVATION

u,

a,

N

s

LD

To

c

discharge velocity

port area

number of ports

port spacing

diffuser length

discharge temperature

port clearance from

bottom

Fig. 3-1

ua

T

Ha

h(x,y)

OT=T-T

Oh=h-Ha

ambient current velocity

ambient temperature

receiving water depth

free surface elevation

temperature excess

free surface deviation

Unidirectional diffuser in a coflowing current:

Problem Definition

z

'7

43

3.2

The Complete Three-dimensional Formulation

Setting up a Cartesian co-ordinate system (x,y,z) with

the origin

at the center of the diffuser

q (x,y,z) = [u,v,w]

velocity:

and defining

(x,y,z)

T (x,y,z)

temperature:

h (x,y)

free surface:

level

A turbulent flow situation is considered and the quantities

over the scale of turbulence.

are time-averaged

Assuming

an

incompressible fluid and neglecting molecular viscosity and

transport terms, the following governing equations are obtained

for steady

flow:

Continuity:

+

+

0

az

ay

ax

(3.1)

Momentum:

au

au

au

vy a+ +w at~Z)=

pax

+ auv

ay

(u av

Bax (+

+

ap

au2

a x

ax

(3.2)

az

v + w a)

av)

ay

az

= pg -

-

ay

ax

+ avw'

+ aw'

ay

az

~

(u

+ v

w +

ay

ax

+

w w)

az

v'w'+

aw

ay

az

(3.3)

g

p

uw

az

ax

(3.4)

44

Heat conservation:

T

IT +

=y

w

v

X

UUT

ax

ay

a

av'T'

ay

u'"T'

x

w'T'

aZ

(3.5)

For small temperature differences the equation of state can be

written

as:

P -Paa =

where

e

(3.6)

(T-T a)

a

e aa

is the coefficient of thermal expansion of water at T .

a

The Boundary conditions are:

z = h (x,y)

On the free surface,

ah

ah

ax

ay

u ax + v

= w

-y

p=o

At large distances from the diffuser,

(x,y) +

(U,V,W) * ua

h(x,y)

At the bottom,

+

H

T(x,y,z)+ Ta

a

z=0

aT c

az

At each discharge port

(u,v,w)

T =

=

(u

T

o

,o o)

(3.7)

45

The system of governing equations (3.1 - 3.6) with the

associated boundary conditions presents a formidable task in

arriving at a complete solution valid for the entire region.

Instead a zone modelling approach is taken.

Physical insight

gained from experimental experience allows the division of the

entire solution domain into several regions, each with distinct

hydrodynamic properties.

In the following sections, the

approximate governing equations for each region are presented;

the solution

is sought

in each region

and the solutions

are

coupled to give a global solution for the entire field.

3.3

Dimensional Analysis

As a prelude

to the ensuing

theoretical

discussion,

a

dimensional analysis is presented in this section to single

out the important

Letting

dimensionless

AT = T - T

a

of the problem.

parameters

excess

be the temperature

above

the

ambient temperature, we can write the functional relationship

, u

f(AT,AT ,x,y,z, a ,N,H,LD,U,V,w,c,u,g,T

Choosing

as the fundamental

AT ,H,u

O

variables,

a)

= 0

(3.8)

the following

o

parameter groupings can be obtained,

AT

(u,vw))

u

F(

c

H

(xy,z)

H

s

H

uO

0-

LDH

D

'Na.

u

u

a

u

_

AT

'N

(3.9)

46

-

-

-

.

l

-

Dimensionless

Parameter

-

Nomenclature

Typical

in this

study

range of

- -

-

|

LDH

Na

50-500

O

or

sH

a

physical interpretation and

comments

values

--

H/B

|--

--

-

--

-

_

ratio of intercepted crosssectional area per

port to port area:

relative submergence

o

of equivalent

jet-B

For

-

=

a

/s

slot

is

the

width of

the slot

jet having the same

discharge flow and

momentum per unit

length

N

large

LD

H

10-50

relative diffuser

length

U

u

a

o

u

< 0.1

strength

current

Fc

50C-500

densimetric Froude

S°

number of the equivalent slot jet:

measure of the buoyancy of the discharge

<

H

of ambient

o

,/gBeAT

S

Y

3.0

relative spacing:

important only in

initial jet mixing

zone where temperature

field is three

dimensional

C

< 0.2

H

relative clearance

of the ports

U

0gH

s/gH

0(1)

O

jet Froude

number based on the

water depth

m

Table 3-1

Summary of Governing Dimensionless Parameters

47

The physical interpretation of each parameter is given in Table 3-1;

typical values are also indicated.

hider vertically fully mixed conditions variations in the

z direction

can be neglected

and the two dimensional

problem

ceases to depend on the details of the diffuser design described

by

c

s

H ' H.

LDH

D

AT v)(u F((xLy)

AT

u

H

o

'Na

o

LD

D

H

u

' u

u

a

u

o

o

Na

/gB AT

3.4

L

o

o

gH

LD

The vertically Averaged Equations

In this section,

integrated

the equations

in the z direction

of motion

and energy are

to yield a set of equations

for the depth averaged quantities.

Assuming u,v>>w, so that pressure is hydrostatic we

integrate

eq. 3.1, 3.2, 3.3, and 3.5 vertically

z = h(x,y).

Invoking

free surface

and the no slip condition

repeated

the kinematic

use of Leibnitz's

boundary

from z = 0 to

condition

at the bottom,

rule, we arrive

at the

and with

at

Continuity

a fh(xy)

u dz +

o

x

y

(xy)

v

dz = 0

(3.10)

48

M omentum

h

P ( (!_

a I

y

d

udz

uvdz)

+

h

x

h

h

(ph) dz

h

2

P

u'

a

dz

1P uTdz

+ ay

J p u'v' dz

2

-

(3.11)

T

vTd =z-

u

3h

T-h

ax

I

p uv'

-ay

uTdz

a

a

ay

0v 2 dz

vTdz

-

(3.12)

T'

a

3'T'dz

aV'T' dz - w'T'

dz

v

(3.13)

-

49

Defining the vertically averaged quantities

h

u

=

u dz

(3.14)

v dz

(3.15)

Jo

h

V=

J

we have

h22dh

o

udz

=

(

)

22

v2dz

2

v dz = (

v

) h -2

(3.17)

hv

o

h

fh

o

(3.16)

hu

hu

uvdz

uvdz (- 5

h- uv

) huv

(3.18)

The following assumptions are made:

i)

The coefficients

resulting

3.18 are close to unity.

from the averaging

in eq. 3.16-

For turbulent open channel flows,

for example, the vertical variation of velocity can be assumed

to obey a 1/7 power

law; the coefficient

computed

for this

profile is 1.015.

ii)

Changes

in free surface

level are small,Ah/H,<<

1.

50

iii)

Density

differences

are small, AP

<<1, and can be

a

neglected except when multiplied by the gravity term in the

equations of motion (The Boussinesq approximation).

iv)

A quadratic friction law is assumed for the bottom shear

Pu2

o

zX = 8°

8

2

vu2+v

XT:

u

(3.19)

f

:

0

T

= -

zy

2

of

U +v

8

2

Friction

Factor

v

transfers

(3.20)

v)

Turbulent

vi)

Surface heat transfers are neglected.

Incorporating

in the x direction

these assumptions

is neglected.

into eq. (3.10 - 3.13) we

obtain the vertically averaged equations. For simplicity the

depth averaged quantities will henceforth appear without bars.

au + av

v = 0

ay

ax

au

ax

au

ay

(3.21)

h

ah _

aAT

eg

ax

dz

ax

u'v'

f

ay

8H

2+v2

(3.22)

av

av

ax

va ay

Uay 5dz

ay-o

9ay

aTdz

ah

f

8H

/u2+v

v

2

2

(3.23)

u

3.5

aT

aT

ax + v ay

-

A synopsis

A brief

_v'T'

(3.24)

ay

(3.24)

of the flow field

description

of a physical

picture

of the diffuser

induced flow field is given in this section.

Turbulent mixing is created by the high velocity shear near

each discharge port.

The jets merge with one another and the

51

spreading reaches the water surface at approximately

a predominantly

A negative

two dimensional

flow field as shown in

pressture zone is created

a fluid particle

at infinity

jets produces

of the multiple

'he interaction

away.

5 to 10

behind

the diffuser,

would tend to converge;

Fig.3-2a.

to which

the flow

pattern behind the diffuser resembles that of a sink flow.

The

momentum input riises the pressure across the diffuser, creating

a positive

behind

pressure

'separates'

diffuser

from theambient

and is confined

Fig. 3.2b illustrates

field

3.5.1

fluid at the ends of the

stream

contracting

in a

flow from

The induced

in front of it.

an instantaneous

snapshot

tube.

:

of the flow

in an experiment.

Scaling

Through a proper choice of characteristic scales for the

physical variables we can estimate the relative importance of

the terms

in eq. (3.21-3.23)

for each region.

Let

(U,V) be characteristic

velocities

(L,6) be characteristic

lengths

in the x,y direction

in the x,y direction

pagAH be characteristic pressure deviation

Ap be a characteristic

density

difference

52

>

-4I

I

Ua,

/ Late alr

Ent

MV0,ctf

inmenK

Ent

It

p<o

-40

2

-

Fig.

3-2 a)

?I

l

--- >svmmetrv

line X

x

z~-

Schem

.Li

1L6

- I

Fig. 3-2 b), An instantaneous snapshot of the diffuser

induced flow field in slack water

( photo by C. Almquist )

53

Thus in eq. 3.22,

inertia

3.23

U2/L

pressure

gAH/L

buoyancy

The magnitude

p gH/L

of the lateral

turbulent

shear stress

terms can

be estimated and related to mean flow quantities by mixing

length concepts commonly used in free shear flows (Abramovich)

-u'v'

where

2 (.u)2

-

: mixing length

The mixing

length

can be assumed

transverse length scale

to be proportional

= c'6

where c' is an empirical constant.

a)

The Near

the following

L

Field:

In a region

scales apply:

LD

UsingV

6

LD

AH

U2/2g

Using typical values of

LD =

1000

ft.

H

=

20

ft.

U

=

2

fps

to the

For free jets

c ' 101

close to the diffuser

L

LD

54

temperature

f

=

o

to an induced

(corresponding

= 0.0004

Ap/p

of 4 0 F)

rise

0.02

The relative importance of each term can be estimated:

H 0(1)

pressure %

U2

inertia

,2U2L2

2

6

shear

inertia

inertia

lateral

U

2

2

X

/L

inertia

bottom shear .

L

-2

3

( 6 )3

0

(10-2)

0 (10-2

g

2

buoyancy

c'

fL

o D

0 (

8H

inertia

We therefore conclude that pressure must balance inertia in

this region.

Lateral shear, buoyancy and bottom friction are

not important

in the near

for the near field

au + av

ay

ax

au

ah

ay

ax

av

ay

g ah

ax

u

aT + v aT.

ax

equations

0

ax

v

The approximate

are then

au

u av

field.

ay

Oy

_ av'T

ay

(3.25a)

55

Field

The Intermediate

b)

the near field,

In a region beyond

takes on a boundary

6

layer character,

10LD, the flow

L

so that

<<L

V <<U

The scale of free surface deviation is then due to turbulent

side entrainment

(U) U

AH

where

2g

a = entrainment

= 0.06

coefficient

Then

pressure

a2

103

inertia

so that the dominant

balance

is among the convective

This region of extent

lateral shear and bottom friction.

103H

is called

field'.

the 'intermediate

terms,

Beyond

a certain

point, when friction has reduced the velocity to a scale

that

Ap

g AP

H

P2 -

0(1), buoyancy effects will have to be accounted.

U

The governing equations for the intermediate field are

then

au

av =O

_

+

ay

ax

au +v

ax

aau+ _

ay

_-

au'v

ay

fo

8Hu

ulul

(3.25b)

56

Cont.

(3.25b)

av

3.6

2

av

av'

aT

aT

av'T'

ax

ay

ax

ay

fo

ay

u

8H

ay

Outline of Near Field Theory

A two dimensional

model

for the flow field downstream

of

the undirectional diffuser is presented in the following sections.

A vertically fully mixed condition is hypothesized, the equations

of motion

are then independent

of the temperature

field.

The

total induced flow near the diffuser is first derived by a

control volume analysis.

This is then used as an integral

boundary condition to obtain a potential flow solution of the

near field.

In Chapter IV the near field solution is coupled

into an intermediate field theory that predicts the global

temperature field.

A definition sketch of the near field problem is illustrated

in Fig. 3-3.

1)

The following

As a first approximation,

neglected

hold.

in this region

assumptions

turbulent

and Laplace's

As far as the depth-averaged

are made:

side entrainment

equation

motion

is

is assumed

is concerned,

to

in the

region beyond the initial jet mixing zone, vorticity can be

generated only by turbulent lateral shear.

that if turbulent

entrainment

It thenfollows

has a negligible

effect

on the

fluid motion in this region (as shown by the scaling arguments),

--

-------

57

f~~~~~I

57Ar

t

I -f

A

\ t2

\:4

X

-P

.\

.e

tL

'.~~~~~~~~

L

()

1D

--)

-?

I\

I,I

,II

of)

1

I

;

21

W

~

4~ 4'1

'~-7

I1----.1

II

6L,

I~~~~~~~~~~~~~~~~~~~~

lI

~I

I

I

41 ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~I

A.

-:>

I

I

.

I

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~1

s1,

I

--30!

I

I I

I

i

I

1'

_~j

p,4

(~3

ELV

Fig. 3-3

nON

Control volume analysis of a unidirectional

diffuser in a coflowing current

58

the two dimensional fluid motion can be considered irrotational.

Furthermore, a solution of Laplace's equation also satifies

eq. (3.25).

2)

The induced flow from behind the diffuser 'separates'

from the ambient

confined

at the ends of the diffuser,

fluid

A A A' A'.

in a streamtube

The slip streamline

as a locus of velocity

can then be regarded

and is

discontinuity

separating the flow within the streamtube from the ambient

Pressure is continuous across the slip streamline.

fluid.

In a real fluid

the discontinuity

in velocity

is of course

unstable and generates eddies that will draw the ambient fluid

into the streamtube.

included

This correction

as a perturbation

is small and can be

in the development

of the inter-

mediate field theory in Chapter IV.

3)

A

high

rate of mixing

is assumed;

i.e. the induced

flow

is large compared with the discharge flow.

The momentum

4)

of the diffuser

input

creates a pressure

discontinuity across the diffuser; but velocities are

continuous across it.

AH/H << 1.

Alternatively, depth changes are small

In principle,

this amounts

to a "rigid lid"

assumption.

Bottom friction is neglected.

5)

_

L_

I_

59

3.6.1

Control Volume Analysis

In this section

an integral

quantity

of interest,

the

total induced flow QN' is derived using a control volume

analysis of the two dimensional flow field.

the same as given

by Adams

(1972).

The approach is

The analysis

is included

here for completeness; unnecessary assumptions are removed and

issues relating

to the formulation

of a complete

two dimentional

problem are discussed in greater detail.

The following quantities are defined:

QN= SQ

S

~qD(y)

total induced flow from behind

near field dilution

velocity distribution along the diffuser

(x=0,-LD/

qD ( Y ) =I

D

(Y )

2

< Y < LD/

2

)

I

As shown in Fig. 3-3, two control volumes are chosen:

Bounded by the free surface

and the bottom

in the vertical

direction, the outer control volume A 1 A 2 A 3 A 4 is chosen such that

A1A4 is sufficiently far upstream from x=O, A2A 3 at a downstream

position where h=H.

The four corners are at y = + a.

The

inner control volume, B1AArB2, is chosen to just enclose the

diffuser.

The

then:

boundary conditions along the control surfaces are

60

Along

A1A 2

q

=

A4 A 3

h'n=

(u a,O)

(3.26)

H

A 1A 4

A2 A

A A'

3

X

Along

A co A' oo

=

(uNO)

h= H

Along

B1B 2

q

AA'

= qD (

)

h = h

(y)

q = qD

(Y )

h

(y)

= h

Applying Bernoulli's theorem along any streamline that

extends from A1A4 to B1B2, we have

Ua2

a

2g

Similarly

U 2

2

2g

_____111_____1_11___.__11.1·1111111

qD 2 (y)

H =(y)

2g

+

for the same streamline

q

(3.27)

leading

from AA' to A A'

2

2(y)

H = +2g

+ h+(y)

_11_1^1_1__

.1^^__

.1_1____.·._._

.·

(3.28)

61

Subtracting eq. 3.27 from eq. 3.28, we have an expression for