ARCGNVE

MASSACHUSE TTS NSTITUTE

OF TECHNOLOLGY

JUN 2 4 2015

LIBRARIES

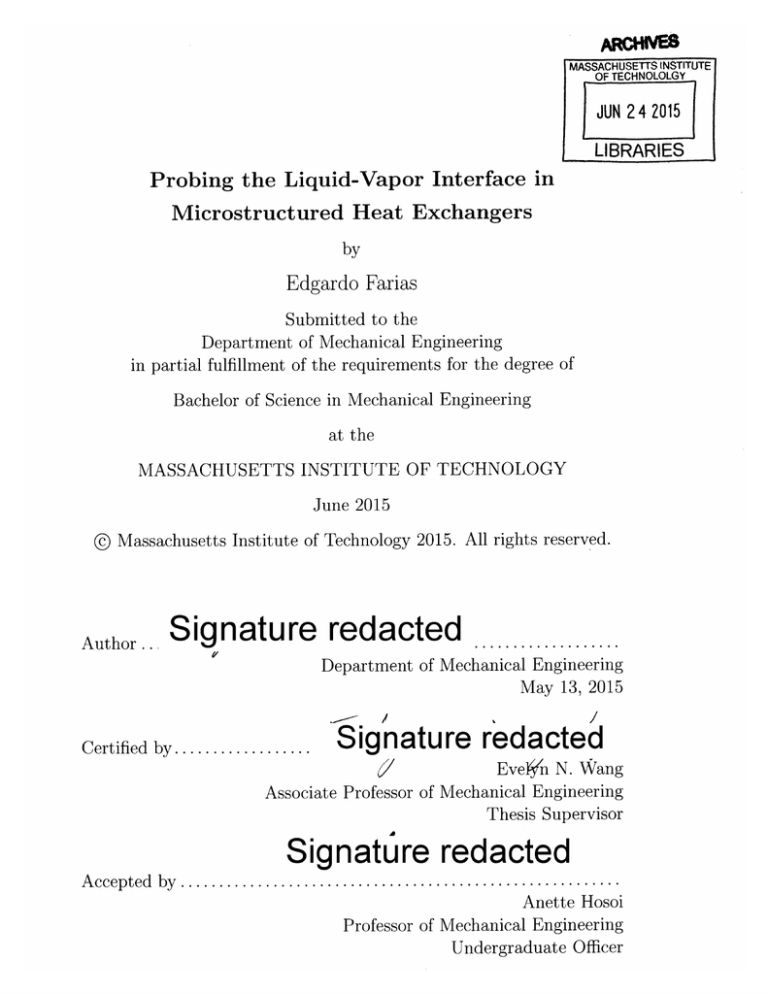

Probing the Liquid-Vapor Interface in

Microstructured Heat Exchangers

by

Edgardo Farias

Submitted to the

Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

Bachelor of Science in Mechanical Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

Massachusetts Institute of Technology 2015. All rights reserved.

Author..

signature redacted ...................

Department of Mechanical Engineering

May 13, 2015

Certified by..................

Signature redacted

EvelVn N. Wang

Associate Professor of Mechanical Engineering

Thesis Supervisor

Signature redacted

A ccep ted by .........................................................

Anette Hosoi

Professor of Mechanical Engineering

Undergraduate Officer

Probing the Liquid-Vapor Interface in Microstructured Heat

Exchangers

by

Edgardo Farias

Submitted to the Department of Mechanical Engineering

on May 13, 2015, in partial fulfillment of the

requirements for the degree of

Bachelor of Science in Mechanical Engineering

Abstract

This thesis describes two aspects of a project designed to understand the liquid-vapor

interface in microstructured heat exchangers. The two aspects include: design and

fabrication of a custom vacuum chamber faceplate and the investigation of the liquid

meniscus shape on microstructured devices. The faceplate for the vacuum chamber

consisted of two metal components that serve to house and seal a viewport. Addition

of the viewport to the chamber was of interest so that experimentation within a pure

environment could be conducted.The second component of this project was to map the

meniscus profile of water on three different device geometries under various conditions

by laser interferometry. The first experiment was a transient study where a droplet of

water fully evaporated from the surface. The purpose was to determine how the profile

changes as evaporation progresses. As evaporation occurs a more curved meniscus is

established within the liquid which causes a greater capillary pressure. The second

experiment was a steady state study with the samples partially submerged in water.

This aimed to determine the profile that arises when evaporation is balanced by

fluid replenishment. The profile that arises after the first several microstructure unit

cells remains constant for the remainder of the microstructured region of the sample

and the meniscus has the highest curvature near the fluid front, indicating a higher

capillary pressure. The final experiment was varying heat applied to the surface. The

aim was to determine how the applied heat flux changes the steady state profile. With

higher temperature more fluid evaporates from the surface, resulting in an increase

of meniscus curvature with increased temperature.

Thesis Supervisor: Evelyn N. Wang

Title: Associate Professor of Mechanical Engineering

4

Contents

Contents

5

1

7

. . . . . . . . . . . . . . . . . . .

7

1.2

Project Overview . . . . . . . .

. . . . . . . . . . . . . . . . . . .

9

1.2.1

Vacuum Chamber Design

. . . . . . . . . . . . . . . . . . .

9

1.2.2

Meniscus Imaging.....

. . . . . . . . . . . . . . . . . . .

9

.

.

.

.

.

.

M otivation . . . . . . . . . . . .

11

2.1

Faceplate Design

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

2.2

Faceplate Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . .

13

2.3

Sealing Existing Chamber . . . . . . . . . . . . . . . . . . . . . . .

13

.

.

.

Vacuum Chamber Design

15

Meniscus Mapping

Device Preparation .

...

. . . . . . . . . . . . . . . . .

15

3.1.1

Device Fabrication

. . . . . . . . . . . . . . . . .

15

3.1.2

Cleaning . . ....

. . . . . . . . . . . . . . . . .

16

. . . . . . .

. . . . . . . . . . . . . . . . .

17

.

3.1

Calibration

3.3

Laser Interferometry

. .

. . . . . . . . . . . . . . . . .

19

3.4

Experimental Set Up . .

. . . . . . . . . . . . . . . . .

19

3.5

Transient Response . . .

. . . . . . . . . . . . . . . . .

21

3.6

Steady State Profile . . .

. . . . . . . . . . . . . . . . .

21

.

.

.

3.2

.

3

1.1

.

2

Introduction

5

3.7

Heating Response

22

4 Conclusions

27

5

Appendix A: Faceplate Designs

29

6

Appendix B: Fabrication G-Code

35

7

Appendix C: Dryout Profiles

37

8

Appendix D: Steady Profiles

41

9

Appendix E: Heating Profiles

45

Bibliography

51

6

Chapter 1

Introduction

1.1

Motivation

Two-phase heat transfer has gained importance in electronics thermal management

due to the bottleneck of high heat flux dissipation [1].

Various methods exist to

dissipate heat from electronic components, but do not meet the growing demand for

high heat flux dissipation. Methods of removing heat include natural convection,

forced flow, and phase change.

Devices that incorporate forced flow include air-

circulating fans and pump driven fluid loops. However, such systems are limited to

a heat flux dissipation of 100 W/cm 2 [2]. Higher dissipation can be obtained under

phase change heat transfer. Phase change, in particular the change from liquid to

vapor, takes advantage of the high latent heat of vaporization, resulting in dissipation

heat flux values as high as 1000 W/cm 2 [3].

In his thesis, Xiao summarizes the

various methods of employing phase change cooling: pool boiling, flow boiling, jet

impingement and spray cooling [4]. Pool boiling, although a passive process, is limited

by the critical heat flux of the working fluid above which a high operating temperature

is required

[5].

Flow boiling also suffers limitations due to high pressure drops that

occur as vapor bubbles expand [6]. Both jet impingement and spray cooling supply

fluid to a surface, which then removes heat by evaporation.

7

These two methods

have the disadvantages of being difficult to implement and requiring high operating

pressures, respectively [4].

An alternative method to cooling is the use of capillary assisted-pumping in microstructured devices [1]. These devices allow for high heat flux dissipation while

removing the need for an active circulation system. Instead, fluid capillary forces

drive fluid flow across the surface as evaporation continuously occurs on the surface.

These microstructured devices allow for thin film evaporation at low operating temperatures. This method of using evaporation is advantageous over methods like jet

impingement and spray cooling as it occurs passively yet still allows for high heat flux

dissipation. This project aims to study fluid behavior as evaporation occurs from microstructured devices. The devices are fabricated with controlled surface geometry,

integrated heaters, and integrated temperature sensors. Varying device geometries

and varying heating conditions were used to study how the fluid's meniscus shape

changes under the various testing conditions. This area of study is of interest because the meniscus shape and its curvature drives fluid flow through the device as

evaporation occurs.

Previous work using similar microstructured devices has resulted in models for

liquid propagation across the surface of the device [7]. These models predict the

propagation rate as a function of device geometry: pillar height, diameter, and pitch.

Additionally, the models take into consideration the capillary pressure and viscous

losses. The models that were developed agree well with experimental results and

allow for design guidelines in selecting device geometry. Although there have been

studies on liquid propagation [8], it is important to study the effect of evaporative heat

transfer on the liquid-vapor interface and the liquid propagation in a heat transfer

system.

8

1.2

Project Overview

This project consisted of two main components: the fabrication of parts for a desktop

vacuum chamber and the characterization of microstructured devices.

1.2.1

Vacuum Chamber Design

Experiments conducted in a pure environment allow for more accurate results of the

fluid meniscus shape. In order for the ambient evaporating environment to be pure the

experiments need to be conducted in a vacuum. A small desktop vacuum chamber was

previously designed and fabricated to achieve this purpose. The chamber, however,

lacked a viewport. Without a viewport experiments within the chamber do not allow

for optical access to the meniscus.

For this portion of the project a replaceable

chamber faceplate that incorporates a 1-inch viewport was fabricated. Additional

modifications were made to the chamber to seal pre-existing leaks.

1.2.2

Meniscus Imaging

The second portion of the project was to use laser interference microscopy to study

the meniscus of a fluid as it evaporates from the surface of the devices. Three main

experiments were conducted to achieve this: a transient study in which a droplet

of fluid fully evaporated from the surface, a steady state study with the samples

partially submerged in water, and a steady state study with varying heat fluxes

induced on the surface. These experiments utilized water as the working fluid. Laser

interference microscopy enabled measurements of the meniscus profile along three

different directions of interest along the samples. Additionally, three different device

geometries were used throughout the study. Comparison of meniscus profiles from

the experiments provided quantitative insight into how device geometries and applied

heat fluxes affect the fluid's meniscus shape and curvature.

9

10

Chapter 2

Vacuum Chamber Design

The purpose of performing experiments in a vacuum chamber is so that a pure environment can be established.

Removing the air from the chamber allows for the

removal of all non-condensable gases that would otherwise interfere with the evaporation process. In a pure environment, evaporation will then only be a result of

temperature differences and not buoyancy differences. With experiments run in the

chamber the evaporating environment will be the the same as the working fluid, resulting in a better analysis of the meniscus profile. Adding a viewport in the existing

chamber then enables the use of laser interference microscopy to study experiments

performed within the chamber. Although the experiments conducted for this project

did not take place in this chamber, this chamber will be used for future experiments.

This portion of the project consisted of two components: fabricating a new faceplate

that contains a glass viewport and sealing all leaks so that the chamber holds vacuum.

2.1

Faceplate Design

Several constraints needed to be taken into consideration when designing the faceplate. The microscope objective lens to be used for interference microscopy imaging

has a working distance of approximately 5mm. Therefore, there could be a maximum

11

Figure 2-1: Section view of the faceplate design. Features for the indium wire o-ring

and bolted joints can be seen.

distance of 5mm from the device surface to the objective lens. Several materials need

to fit within this 5mm distance so that the viewport can be properly constrained.

These materials are: the glass viewport, the metal holding the viewport on either

side, and the acrylic plate which holds the device.

The design of the faceplate consists of two metal pieces which serve to sandwich

the glass viewport in place. Additionally, indium wire is placed between the glass and

metal so that the faceplate can be sealed in order to hold vacuum in the chamber.

Indium wire is very ductile and forms a seal when compressed between two materials.

Detailed drawings of the design are provided in Appendix A. The baseplate is bolted

to the existing chamber and has a center slot for the glass viewport. A secondary

metal piece is bolted onto the baseplate in order to seal the viewport in place. The

fabricated faceplate design houses a 1-inch diameter viewport. A center section view

of the design is shown in Figure 2-1. A secondary faceplate design was prepared

that incorporates a 2-inch viewport. This design, however, was not fabricated. The

increased viewport size in the second design allows for both a wider variety of lenses to

be used and for a larger viewing area of the sample during experimentation. Detailed

drawings of the second design are also provided in Appendix A.

12

Figure 2-2: Assembled and tested chamber with the fabricated faceplate attached to

the chamber.

2.2

Faceplate Fabrication

The faceplate was designed for fabrication via CNC milling. All the toolpaths used

for cutting were generated by writing custom G-Code; this portion of the project

required learning how to write and interpret G-Code. A sample piece of commented

code is available in Appendix B. Custom programs were written for each feature in

the two faceplate pieces. Two additional steps were taken after CNC machining: deburring all edges and tapping holes. The final assembled chamber is shown in Figure

2-2.

2.3

Sealing Existing Chamber

The existing chamber had leaks that needed to be sealed in order for vacuum to be

held adequately. If leaks were present ambient air will seep into the chamber, resulting

in a non-pure environment with non-condensable gasses, deviating the evaporation

process from ideal conditions. Two methods were used to determine leaks and their

locations. The first was to use a Pirani guage and a LabVIEW program to view, in

13

,Arvin

-

25001

2000CL

15001000-

500-

0)

5

1L

15

25

20

3

35

4

445

Time (Hours)

Figure 2-3: Increase in the chamber pressure after bring brought to vacuum and left

to sit for two days.

realtime, the pressure in the chamber. This was useful to determine if a leak existed

or not. A precise method of finding the location of the leak was accomplished with

an Adixen ASM 142 helium detector. All outlets of the chamber were first covered

by Apiezon wax, a sealant. Segment by segment the sealant was removed. Helium

was then sprayed onto the exposed outlets. If helium entered the chamber from these

outlets then the detector would sound an alarm signaling that a leak was found.

Leaks were found at the top of the chamber at the bolted joints. The top surface

of the chamber was flattened and smoothed using the CNC mill to remove these leaks.

Secondly, polytetrafluoroethylene (PTFE) tape was wrapped around the threads of

the feedthrough fittings and then indium wire was applied under the bolt head in

order to seal the top of the joint. The helium detector was used again to verify

adequate sealing.

After the faceplate was fabricated the Pirani gauge was used to see if any leaks

were present. The chamber was brought to vacuum and left to sit for two days. Over

a 42.7 hour time period the pressure in the chamber increased from 7.24x10 0 Pa to

2.51x10 3 Pa, shown in Figure 2-3. This averages to a pressure increase of 58.6 Pa/hr,

an acceptable rate for the proposed experiments.

14

Chapter 3

Meniscus Mapping

3.1

3.1.1

Device Preparation

Device Fabrication

The devices used for these experiments were fabricated at MIT. The fabrication process involves two sets of various fabrication techniques to make features on either

side of a silicon wafer

[9].

The first sequence uses photolithography and reactive ion

etching to create pillars of equal height and spacing. A Scanning Electron Microscopy

image in Figure 3-1 shows these pillar features. After the pillars are made the wafer is

flipped upside down in order to deposit platinum and gold layers using photolithography and ebeam evaporation. This creates an integrated heater and 4 resistance

temperature detectors (RTDs). The integrated heater is used to heat the sample by

supplying power to the device via an external power supply. The RTDs have a resistance based on the temperature of the device and are used to determine temperature

during experimentation. These devices are characterized by 3 dimensions: pillar diameter, distance between adjacent pillars (pitch), and pillar height. Geometries for

samples used in these experiments are given in Table 3.1.

15

2,00'.8

TO mAo.- 10.0' SiuW A- I.L-

Figure 3-1: Scanning Electron Microscopy image of a device with similar features to

those used in this study [9].

Table 3.1: Device Geometries

Diameter (Am)

Pitch (pm)

Height (mm)

3.1.2

Sample 1

3

40

8

Sample 2

5

40

8

Sample 3

7

40

8

Cleaning

Before samples can be used they must be cleaned to remove any impurities or contaminations present on the surface. This was accomplished by both chemical and

plasma cleaning. The samples were first bathed in acetone for 10 minutes. They were

then sequentially cleaned with methanol, isopropyl alcohol, and deionized water. The

samples were dried using compressed air before being placed in a plasma cleaner (supplied with oxygen gas) for 15 minutes. The sample can be used for experimentation

after removal from the plasma cleaner. The sample retains wetting properties for 30

minutes to two hours post cleaning. After wetting characteristics have diminished,

the samples must be re-cleaned before further experimentation.

16

U

3

2

I

Figure 3-2: Circuit diagram for calibrating each device RTD [9].

3.2

Calibration

The devices are fabricated with an integrated heater and four RTDs. When electric

current is passed through the heater the temperature of the device increases via Joule

heating. This heat generation then spreads throughout the device. Use of the RTDs

allow for determining the temperature of the device as they exhibit temperature

dependent resistance. The resistances of the 4 RTDs must be correlated to the device

temperature so that temperature can be determined during experimentation. This is

done by placing the device in an oven where it is allowed to reach thermal equilibrium

at a known temperature. Typically this process takes about two hours for equilibrium

to be reached. A simple circuit is made using a known reference resistor such that

the resistance of the device can be measured, Figure 3-2.

The current passing through the circuit segment with the two resistors in series is

I=

U

Rref + R

(3.1)

The current passing through the smaller loop is equivalent to the current in the

larger loop so that

V = IR

V=( R

U

+)R

Rre + R

17

(3.2)

(3.3)

.

........

......

1480

-+-RTD1

RD

-- RTD4

1460

1420

-

~1380

~1360 ---

'

0-1400--

13401320

13%30

40

50

70

80

Temperature (C)

Figure 3-3: Calibration of sample 3 at four known temperatures to determine RTD

resistance as a function of temperature. A linear behavior is observed.

Resulting in a device resistance of

(3.4)

R = Rref

This is process is repeated several times at various temperatures so that a calibration curve can be made. An example calibration curve is shown in Figure 3-3. The

device resistance scales linearly with temperature resulting in an equation of the form

R(T) = Ro + OT

(3.5)

During experiments the temperature can then be determined by

R(T) - Ro(

T

=

(3.6)

A LabVIEW program and two power supplies were used during the calibration

process to supply U and V. The LabVIEW programs calculates R of each RTD for

use in determining the linear equation above. Matlab's Curve Fitting Tool was used

to determine the linear fits.

18

..

14-Reflected

waves 80'

Out of phase

Reflected

waves

in phase

Path length

difference =

Path length

difference=

of V2

of2

.............

Figure 3-4: Formation of interference fringe patterns in a fluid layer [10].

3.3

Laser Interferometry

The height of the fluid layer is determined using Laser Interference Microscopy. This

technique utilizes a monochromatic laser light that shines through the layer of liquid.

When the light hits the liquid surface, some of the light is reflected and some is

transmitted through the liquid. Because the height of the liquid varies, the distance

traveled by the light also varies.

Constructive and destructive interference occurs

with the transmitted and reflected light, resulting in alternating bright and dark

fringe patterns, as shown in Figure 3-4. The relative thickness of the fluid can then

be determined by counting the number of fringes. The height between consecutive

dark-dark or light-light fringes is

h=

(3.7)

2n

where n is the refractive index of the fluid (1.33 for water).

3.4

Experimental Set Up

The same general set up was used for all the experiments.

holder constrains the device in place.

A custom-built device

The device holder includes pogo pins that

interface with the heater and RTD pads. A VisiTech Hawk laser source and a Nikon

19

. ...............

Figure 3-5: Representative image of fringe patterns that result due to varying fluid

thickness. Marked are the three measurement profiles directions: diagonal (AD),

horizontal (AB), and vertical (BC).

Eclipse LV 100 microscope project a 405nm laser onto the sample. A Prior Optiscan

II moving stage controls the position of the sample. Finally, a Hamamatsu EM CCD

digital camera records the images of the liquid layer on sample surface.

For the transient experiment a MicroSyringe Pump Controller applied a 20nL

droplet of water onto the surface of the sample. For the steady state experiments the

bottom 5mm of the sample was submerged into a pool of water so that continuous

wicking was established.

The heating experiments were also performed with the

bottom of the sample submerged, and electrical power was supplied to the integrated

heater via external power supplies.

Videos were recorded for each experiment at a frame rate of 10 frames per second.

The videos show the liquid meniscus shape in the form of fringe patterns. Individual frames of the video were analyzed to give meniscus profiles in three directions:

diagonal (AD), horizontal (AB), and vertical (BC), shown in Figure 3-5. All image

processing was done using ImageJ, wherein distances between fringes were made using

the measurement tools within the program.

20

3.5

Transient Response

For this set of experiments a droplet of water was placed at the bottom of the sample

surface. The fluid wicked up the microstructured surface and was then allowed to

evaporate to the ambient environment. Videos were taken from the time that the

droplet was applied to the time of full evaporation. The purpose of this set of experiments was to determine how the meniscus shape changes over time as evaporation

progresses until the sample dries out. The analysis shown in Figures 3-6 used a reference time of t=O that corresponds to a steady fluid profile (capillary recovery of

fluid balances lost due to evaporation). These plots are representative of the behavior

that was seen across the three samples; a full set of plots is available in Appendix C.

As time progresses there is greater loss of fluid due to evaporation and thus greater

capillary pressure is established by the higher meniscus curvature seen in Figures 3-6.

The higher meniscus curvature results in a higher capillary pressure. This behavior is

observed until the sample commences drying out and non-uniform evaporation occurs

(typically seen by a receding fluid front or by evaporation from individual pillars).

3.6

Steady State Profile

The steady state experiments aimed to determine the meniscus profile change that occurs when continual wicking balances evaporation. For these experiments the bottom

5mm of the samples was submerged in water. This allowed for continual replenishment of liquid in the device as evaporation removed fluid from the surface. Figure

3-7 shows representative steady profiles in the first five cells following the fluid front.

The first cell is labeled as distance of Opm. A full set of plots is available in Appendix D. A steady meniscus profile is reached within several cells from the liquid

front. The meniscus has the highest curvature near the liquid front, indicating that a

higher capillary pressure is needed to balance evaporation. The meniscus profile that

is established after the initial cells remains constant for the remaining sample cells.

21

.

..

..

.......

1.2

s

tt = 4.9

4

.

S

- -l -11.6

0.6

20.7s

-t

~0.4

s

23.3

9

*~0.2

0

0

2

23.3

018

-0t-0SW

--

t:

1.5

W

5

4.9s 2'11

8

6

10

12

14

16

Is

20

Length along AD (pin)

5

8

07

0.6

4

2

s

-

10s

4.9 s

'

t

20 PMs

t- 116s

tt-20.7s

0.5

0.3.

4

0

0

0

2

4

6

8

10

12

14

16

18

0

20

Length along AB (pm)

1

2

3

4

5

6

7

8

9

Length along BC (sm)

Figure 3-6: Representative interference microscopy images and meniscus profiles from

the dryout study where a droplet of fluid was allowed to evaporate from the surface of

the sample. The images shown are from sample 3 at two different times. The profiles

are in the diagonal, horizontal, and vertical directions.

3.7

Heating Response

The heating experiments had a similar goal as the steady state experiments, but with

the addition of heating of the surface to determine how the applied heat flux changes

the steady state meniscus profile and to investigate the effects of temperature driven

evaporation.

The set up is the same as the previous set of experiments with the

bottom 5mm of the samples submerged in water. Additionally, electrical power was

supplied to the integrated heater via a power supply to promote temperature driven

evaporation. Figures 3-8 and 3-9 show the steady profiles that occur after thermal

equilibrium is established in the device. Only the profiles that occur in the first cell

and fifth cell are shown; a full set of plots is available in Appendix E. The meniscus

profiles in the first cell are highly curved, whereas the profile in the fifth cell is more

stable and remains constant. Unlike the other sets of experiments, only sample 3 was

used in this study. Temperatures of the device were determined via the RTDs using

22

.

.....

.

...

. ......

. ..

..............

Ei 1.4

-WU0 pill

-40 pin

1.2

-

80 pml

11-01

pml

p20m

AA

160pm

S0.6

S0.4

0.2

o1

0

10

5

15

20

25

Length along AD (jim)

0.9

0.8

00 pm

1.6

0.7

-40 pin

1.4

0(.6

-80

0.5

0.4

-120

1.2

pml

pil

* 40 pm

80 pin

120 pm

160 pm

'U>

jr

S0.0

160 gm

= 0.6

*

0.3

.50.2

0I

0

2

4

6

8

10

12

14

16

18

20

6

8

10

12

14

16

Length along BC (Am)

Length along AB (pm)

Figure 3-7: Representative interference microscopy images and meniscus profiles from

the steady state study where the bottom 5mm of the sample was submerged in water

to allow for continual liquid replenishment as evaporation occurred. The images are

from sample 3 at two different locations. The profiles are in the diagonal, horizontal,

and vertical directions. Measurements were taken in successive microstructure cells

(center-center distance of 40pm) from the liquid front. The first cell following the

liquid front is labeled as distance of Optm.

23

.....

..........

..

.......

E 1.4

1.2

-OW

-- 0.43W

-043

E

W

0.96 W

0.8

0.6

--

l.66 W

04

S0

10

5

0

20

15

25

Length along AD (pm)

318

0,9

0.8

%J

1.6

-O W

0

4

W

0

0

-0

W

-0.

11 W

.9

1.-4

y

0A~

0.6

0.3.

0.4

0.20.2

0

0

0

2

4

6

8

10

[2

14

16

18

20

0

2

4

6

8

10

12

14

16

Length along BC (sm)

Length along AB (pm)

Figure 3-8: Interference microscopy image of sample 3 with an applied power of

1.66W. Meniscus profiles are shown in the three directions for sample 3 under varying

input power. These measurements were made in the first cell after the heating front,

L =Opm.

a LabVIEW program. The temperatures determined by each RTD for all heating

conditions are provided in Figure 3-10. The RTDs are located on the back of the wafer

along the center at vertical distances from the bottom of the microstructured area:

7.7mm, 10.9mm, 14.1mm, and 17.3mm. The temperature is approximately uniform

across the sample due to uniform heating, uniform evaporation on the wetted surface,

and high thermal conductivity of silicon. Increasing the power supplied to the device

results in a steadily increasing meniscus curvature. With a higher temperature more

liquid is able to evaporate from the surface and is balanced by the capillary pressure

generated as the meniscus curvature increases. An interesting observation was noted

in that the position of the fluid front remained constant for the supplied electrical

power reported in these experiments. We do not expect this for higher heat fluxes:

the increased evaporation rate caused by a larger temperature rise will overtake fluid

uptake by capillary action, lowering the position of the fluid front.

24

. ....

........

1.4

2W

1.2

1

V

-011

W

-0.43 W

20.

0,96 W

~06

~0.4

1,66W7

;0.2

5

(

10

15

20

25

Length along AD (sr)

0.9

L8

0.8

0.7

0.6

-0

"-OW

-0.11 W

-- 0.43 W

0.96 W

1.66 W

1.6

W

1.4

--. 43 W

(1.96 W

1.66 W

1.2

0.6

03

*

0

0.1

0.2

0

2

4

6

8

10

12

14

16

18

20

0

2

6

8

10

12

14

16

Length along BC (pm)

Length along AB (sim)

Figure 3-9: Interference microscopy image of sample 3 with an applied power of

1.66W. The steady state meniscus profile in the three directions for sample 3 is shown

under varying input power. The meniscus profiles shown remain constant for the

remainder of the the microstructure cells following this location. These measurements

were taken in the fifth cell after the heating front, L = 120pm.

45

RTD I

-*-RTD 2

4-RTD 3

RTD4

40

35

C. 30

25

20

0

0.25

0.5

0.75

1

1.25

1.5

1.75

Electrical Power (W)

Figure 3-10: Measured temperature of each RTD for the supplied electrical powers

on the sample 3 integrated heater.

25

26

Chapter 4

Conclusions

This projected consisted of two components: design and fabrication of a custom

vacuum chamber faceplate and the investigation of the liquid meniscus shape on

a microstructured device. The faceplate for the vacuum chamber consisted of two

metal components that serve to house and seal a glass viewport. The addition of the

viewport into the chamber allows for use of imaging tools to record experiments that

are conducted within the chamber. The components of the faceplate were machined

using a CNC mill, and the final assembly was checked for leaks to verify vacuum was

being maintained. The second component of this project was to map the meniscus of

water on three different device geometries under various conditions. The three sets

of experiments were a transient study in which a droplet of water fully evaporated

from the surface, a steady state study with the samples partially submerged in water,

and a steady state study with varying heat flux applied to the surface. The liquid

meniscus shape was monitored using laser interferometry where fringe patterns arise

due to different liquid layer heights. The videos taken during the experiments were

analyzed using ImageJ to provide meniscus profiles in three directions of interest.

The purpose of the transient study was to determine how the meniscus shape

changes over time: from the development of a steady profile until dryout occurs. As

time progresses there is greater loss of fluid due to evaporation and a diminished liquid

27

source. As a result a greater capillary pressure is established within the fluid which

causes a higher curvature meniscus profile. The steady state experiments aimed to

determine the meniscus profile that arises when evaporation is balanced by continual

fluid replenishment. It was observed that the profile that arises after the first several

cells remains constant for the remainder of the cells on the sample. Additionally,

the meniscus has the highest curvature near the liquid front, indicating that a higher

capillary pressure exists to balance evaporation.

The heating experiments had a

similar goal as the steady state experiments but with the addition of heating of the

surface. The aim of this was to determine how the applied heat flux changes the

steady state meniscus profile and to investigate the effects of temperature driven

evaporation.

With a higher temperature more fluid is able to evaporate from the

surface and the viscous loss of flow through the structures is balanced by the capillary

pressure. This resulted in a gradual increase of meniscus curvature as temperature

increased. Further work needs to be done in this project for analytical models to be

developed. Future work for this project are to expand the device geometries used in

order to quantify the effects of varying pillar height, pitch length, and pillar diameter.

Additionally, replication of the experiments with more fluids would give insight into

how the fluid properties affect the meniscus shape.

28

Chapter 5

Appendix A: Faceplate Designs

Two designs for the chamber faceplate were made. A faceplate with a 1-inch viewport

was fabricated. In addition, a 2-inch design was prepared. The second design design

allows for a 2-inch viewport. The only modifications that occurred in this design

are the dimensions; the same features are used. Detailed drawings of the designs are

shown in Figures 5-1, 5-2, 5-3, and 5-4.

29

5.50

2.20

A

0.50

1.20

CN

0.25

0.40

0

Cf)

0

00.)251

y

0

(N

0

D7

\C'48

cli

0.025

00

0

A

SECTION A-A

#8 Tap Holes ;Equal spacing of 45 degrees

#8 Clearance holes

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONALt

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

<INSERT COMPANY NAME HERE>. ANY

REPRODUCTION IN PART DE AD A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

<INSERT COMPANY NAME HERE> U

PROHIBITED.

NAME

DATE

DRAWN

ANGULAR: MACNV BENDt

TWO PLACE DECIMAL i

THREEPLACE DECIMAL t

CHCE

ENG APPR.

MATER tAL

Q-A-

MFG APPR.

COMMAENTS:

NEXT ASSY

USED ON

APPLICATION

FINISH

SIZE

, G. NO.

iA! acelateOnejnch

DO NOT SCALE DRAWING

WBGI - SHED

- -FI

REV.

RE

Figure 5-1: Dimensioned drawing of the 1-inch faceplate base. This component is

bolted onto the existing chamber.

30

A

0.75

4.00

__

0.348 7

01.00

0.402

00.80

o

0.691

A

SECTION A-A

8 Clearance Holes; equal spacing of 45 degrees

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

<INSERT CMANY NAME HERE>. ANY

REPRODUCTION N PART OR AS A WHOLE

ITHOUT THE WRITTEN PERMISSION OF

<INSERT COMPANY NAME HERE> IS

PROHIBTED

MTERLAL

FINISH

--

-

APPLICATION

HCE

ERG APPR.

MFG APPR.

G.A

COMTENTS

S

USED ON

NEXTASSY

DATE

NAME

DRAWN

-

DIMENS IONS ARE IN INCHES

TOLERANCES:

FRACTIONAL!

ANGULAR: MACH t

BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

I:A

DO NOT SCALE DRAWING

D

kkPae lat Onench

eIc

REV.

---

Figure 5-2: Dimensioned drawing of the 1-inch faceplate cover. The component is

bolted onto the faceplate base.

31

5.50

4.298

3.298

A

2.20

1.20

177-7

V/

0.50

0.25

LO)

0.025

0

0.40157

0.03937

I0

- LO

0.025

0

U-O

SECTION A-A

SCALE 1: 1

#8 Tap Holes; equal spacing of 45 degrees

8 Clearance Holes

DIMENSIONS ARE IN INCHES

TOLERANCES:

- P

ERACTEONALC

ANGULAR: MACE

BEND

TWO PLACE DECIMAL

PROPRIETARY AND CONFIDENIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OP

<INSERT COMPANY NAME HERE>. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THEW

WRITTEN PERMISSION OF

<INSERT COMPANY NAME HERE> IS

PROHIBITED.

NAM

DAT

DRAWN

CHECKED

ENG APPR.

-fDAPPI.

Q.A.

MATERIAL

NEXT ASSY

USED ON

APPUCATION

FINISH

DO NOT

SIZE

SCALE DRAWING

A

Wa

O

CeP

WEIGT:

wSCALTIT

lteIwoInch

E

)w7ETOFI

Figure 5-3: Dimensioned drawing of the 2-inch faceplate base. This component is

bolted onto the existing chamber.

32

4.00

02.00

0.75

01.80 1

A

Q.1 77

D.401 57

-

1

---1Z>

0.69095

L

0

0

I

A

SECTION A-A

SCALE 1: 1

8 Clearance Holes; equal spacing of 45 degrees

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR:MACHt

TWOPLACEDECIMAL t

THREE PLACE DECIMAL :t

BEND+

PROPMETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

<INSERT COMPANY NAME HERE>. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

HINSERT

COMPANY NAME HERE> IS

PROIRTED.

USED ON

APPLICATION

DATE

CHECKED

ENG APPR.

MFG APPR.

O.A

MATERIAL

NEXT ASSY

NAME

DRAWN

AD

kD

SCALE 1:1

;WEIGHT.

s

DO NOT SCALE DRAWING

A BaEEPTateFwonch

REV.

SHEDT I OF I

Figure 5-4: Dimensioned drawing of the 2-inch faceplate cover. The component is

bolted onto the faceplate base.

33

34

Chapter 6

Appendix B: Fabrication G-Code

Custom G-Code was written for each step of the manufacturing process. The code

was used to fabricate each component on a CNC mill. The sample code provided here

was used to mill the central hole for one of the components.

G90 ;

absolute position control

G94 ;

units per minute mode

G57;

set coordinate axis

spindle speed

M03 S3000 ;

coolant on

M08 ;

#1

=

0.2 ;

z-height variable

x-distance variable

0.1875;

#2

"while" loop to position z-distance

WH[#1 LE .4] DO 1

G90 G01 XO YO F1 ;

postion at center

G90 GOl Z-#1 F0.1 ;

cut into material in z-direction

= #1 + 0.2 ;

increase z-distance for next loop

#1

"while" loop to cut circles

WH[#3 LT 0.75] DO 2;

position to cut in circle

G90 GOl X#2 F0.1 ;

cut semicircle

G02 X-#2 YO R#2 F1;

cut semicircle in the opposite direction

G02 X#2 Y0 R#2 F1 ;

35

increase radius for next cut

#2 = #2 + 0.1875

DO 2;

end of inner loop

;

end of outer loop

DO

end program

M02

36

Chapter 7

Appendix C: Dryout Profiles

Below are meniscus profiles in the diagonal, horizontal, and vertical directions for the

three samples. These profiles are from the dryout study wherein a droplet of fluid was

allowed to evaporate from the surface of the sample. A baseline of t=O was chosen

where a steady profile was observed prior to meniscus change due to evaporation.

37

---------------

Figure 7-1: Raw images of sample 1 during various times (t = Os, 9.9s, 21.5s, 23.9s)

in the evaporation process. These images were analyzed in ImageJ in order to plot

meniscus profiles.

20 pim

t=0 s0p

20 pm

t=13.5s

t=

2

5.9 s

pm=1.s

Figure 7-2: Raw images of sample 2 during various times (t = Os, 5.9s, 13.5s, 16.8s)

in the evaporation process. These images were analyzed in ImageJ in order to plot

meniscus profiles.

38

Figure 7-3: Raw images of sample 3 during various times (t = Os, 4.9s, 11.6s, 20. 7s)

in the evaporation process. These images were analyzed in ImageJ in order to plot

meniscus profiles.

1.2

1.2

-M-I-OS

t

.

2.9

9. S

t

=51.9

s

0.4

0.4

0.2

I; 0

0.2

0

2

4

6

8

10

18

16

14

12

4

2

0

20

6

8

10

12

14

16

18

20

Length along AD (pm)

Length along AD (stm)

.

1.2

a.8

4.9

11.6

0.6

S

20.7s

23.3 s

0.4

0.2

0

2

4

6

10

9

12

14

16

18

20

Length along AD (pm)

Figure 7-4: Temporal liquid profile in the diagonal direction for the three samples.

39

. ..............

S0.8

30.7

+r =Os

E 0.

1.6

E

Wt = 0 S

S0.6

0.5

+t

0.4

0.3

*-t

21.5 s

0

-t

23.9 s

03

=099 s

-t

=

16.8s

-

'.2

.1

0

0

4

2

6

11)

8

12

16

14

0

20

18

2

4

6

Length along AB (pm)

-

10

8

12

14

16

18

20

Length along AB (sim)

08

S07

-t= 4.9s

t

0.5

*t 11.6 s

--

t = 20.7 s

t= 23.3 s

02

2

I

4

6

6

12

t0

14

16

Is

20

Length along AB (pm)

Figure 7-5: Temporal liquid profile in the horizontal direction for the three samples.

1.5

1.5

-5.9s

9.9

E

0.9

-

21.5s

309

1

l3.s

-t=23.9 S

0.6

M 03

x

S0

(o

0

2

4

6

8

10

12

3

2

14

4

5

6

7

8

Length along BC (im)

Length along BC (pm)

1.5

E

+Wt=0s

t=4.9s

1 II,

t 11.6 s

1.2

-t

09

207 s

23.3s

t

06

0.3

0

0

1

2

3

4

5

6

0

9

Length along BC (jIm)

Figure 7-6: Temporal liquid profile in the vertical direction for the three samples.

40

9

Chapter 8

Appendix D: Steady Profiles

Below are meniscus profiles in the diagonal, horizontal, and vertical directions. These

profiles are from the steady state study wherein the bottom 5mm of the sample

was submerged in water to allow for continual liquid replenishment as evaporation

occurred.

Measurements were taken in successive cells (center-center distance of

40Am) from the liquid front. The first cell following the liquid front is labeled as

distance of Opm. The cell that contains the fluid front is only partially filled with

liquid, so was neglected in this analysis.

41

Figure 8-1: Raw images of successive cells in sample 1. These images were analyzed

in ImageJ in order to plot meniscus profiles.

20 pm

2L=0

L=0 pm

pm L=20

20 pm

pm

L

40 pm

L=120 PM

Figure 8-2: Raw images of successive cells in sample 2. These images were analyzed

in ImageJ in order to plot meniscus profiles.

42

.....

...

.............

..............

..

...

I

Figure 8-3: Raw images of successive cells in sample 3. These images were analyzed

in ImageJ in order to plot meniscus profiles.

i

1.4

.0

mil

[4

0 pm

40 pm

1.2

-40 ptm

l80

-- Jim

I

-120

pm

-AA

*

0.6

2 4

A

0,4

0.4

0.2

,Air

0.2

0 W-

.

0

20 pm

60 pm

0.8

160 pin

0 .6

5

10

20

15

10

0

25

15

20

25

Length along AD (pm)

Length along AD (pm)

1.4

.2

(Pill

40 pn

-80 pil

W

o

-

120 pm

160

mtn

0.6

0.4

-A-ni

0.2

0O

0

5

10

15

20

25

Length along AD (pm)

Figure 8-4: Steady state liquid profile in the diagonal direction for the three samples.

43

....

....

. ......

M

0.9

0.9

0.9

Ar-

pin

pm

-40

M

pm

+

0.4

-.

-. 8

Om

+40

E 0.6

- 0.5

A pm

211 pm

0.5

-

08

0.7

A

-80

pm

pm

120 pm

04

'

E

160

pm

03

~0

0

2

4

6

8

10

14

12

18

16

--

0

20

'

0

S01

2

4

8

6

10

12

14

18

16

20

Length along AB (pm)

Length along AB (pm)

'.0.9

0.$

E

M

+9

C 0.7

40pm

0.6

pm

-80

-0.5

-120

AV

pm

10pm

0.4

01.3

S0.2

S0

0

2

4

6

8

10

12

14

16

18

20

Length along AB (pm)

Figure 8-5: Steady State liquid profile in the horizontal direction for the three samples.

2

2

2

1.4

-0 pm

-40 pm

0 pm

1.2

-120

U40pm

1.6

E1.2

160 pm

1.6

3

-

1.4

80 pm

120 pm

E

pin

0.8

0.6

0.8

O.6

0.4

0.4

-

160 pm

0

0

0

2

4

6

8

10

12

16

14

0

2

6

4

0

10

12

14

16

Length along BC (pm)

Length along BC (pm)

2

pml

pin

40 pm

-WO

-40

S1.4

E

1.2I4

A

-120

pm

160 pm

0.6

0.2

o1

0

2

4

8

6

Length along

10

12

14

16

BC (pm)

Figure 8-6: Steady State liquid profile in the vertical direction for the three samples.

44

Chapter 9

Appendix E: Heating Profiles

Fluid profiles are provided for sample 3. The device was heated via joule heating at

varying wattage supplied by an external power supply. For each supplied power the

fluid profile in three directions was measured. These measurements were taken at the

first five cells following the fluid front.

45

Figure 9-1: Raw images of successive cells for no applied power. These images were

analyzed in ImageJ in order to plot meniscus profiles.

i 0.9I

E1.4

:L

1.2

4(1AM

I

40pm

j

20 pm

pin

0.8

160

0.8

-a(0 m

0.7

-40

0.6

-80

0.5

pm

-a

120 pm

160 pm

0.4

0.6

f0.4

pm I

0.3

S0.2

.! 0

0

5

10

20

I5

0

25

4

2

6

8

10

12

Length along AB (pm)

Length along AD (psm)

2

A-0 pm

-40 pm

-80 pm

-120 pm

160 pm

6

4

E

.2

10.2

0

0

2

4

6

8

10

12

14

16

Length along BC (pm)

Figure 9-2: Steady state liquid profile for no applied power.

46

14

16

18

20

17!1,

Figure 9-3: Raw images of successive cells for 0.11W power input. These images were

analyzed in ImageJ in order to plot meniscus profiles.

'i 0.9

i 1.4

=L

1.2

-

1

0 Pin

+40 pin

0.0,

0-7

80 AI

0.

-20

0 .6

40

--

0.5

ymi,

120

0.4

--M

41-

In

.

0.4

ipm

40 pm

0.2

0.2

S0.

1

S0

0

5

10

15

0

25

20

6

4

2

8

10

12

Length along AB (pm)

Length along AD (pm)

2

0

1.6

1.4

-40 pm

1.2

-8

pm

120 pm

f0 o

i0.6

0

2

4

6

1

N

Length along

BC

12

14

16

(pm)

Figure 9-4: Steady state liquid profile for 0.11W power input.

47

14

16

18

20

Figure 9-5: Raw images of successive cells for 0.43W power input. These images were

analyzed in ImageJ in order to plot meniscus profiles.

1.4

Jim

0.9

40 pm

0.8

W0

80

0-7

-40

0.6

-80pm

0-5

04t

-120

+00

1.2

-

-120

m

E

pm

60 pm

0.6

pm

pm

_41

pm

160 pm

0.3

0.4

0.21

5

10

15

0

25

20

2

4

6

8

10

12

Length along AB (sm)

Length along AD (sim)

2

5.8

16

1.

-8040 pm

pm

1.2

I

AM

-

120pm

160 pm

-

0

.3-

0.6

S0.4

.20.2

0

2

4

8

6

10

12

14

16

Length along BC (sim)

Figure 9-6: Steady state liquid profile for 0.43W power input.

48

14

16

19

20

L

.I

.L .I

....

.....

.11 ....

.... -..

I

Figure 9-7: Raw images of successive cells for 0.96W power input. These images were

analyzed in ImageJ in order to plot meniscus profiles.

I

-i

=. 0.9

S1.4

S1.2

*-0

pm

in

-

0.8

~*40 pm

Z

80 Pml

.3<

60

0.6

0.6

40 pil

pil

pi

-120

04

-A

pm

-0

0.5

-

120pm

0.0i

U-0 pm

0.

160

pm

0.3

S0.4

0.2

<Air

1.2

~0

0

5

10

15

20

2

0

25

6

8

10

12

Length along AB (pm)

Length along AD (pm)

2

6

1.6

L4

r

- -it

pin

-40

pin

80 pill

.2

120 p

m

160

m

p

-a-

-A

0.8

0.6 *'

0.4

0.2

0

2

4

8

6

10

12

14

l(

Length along BC (pm)

Figure 9-8: Steady state liquid profile for 0.96W power input.

49

14

16

18

20

.......

.....

Figure 9-9: Raw images of successive cells for 1.66W power input. These images were

analyzed in ImageJ in order to plot meniscus profiles.

1.4

E,0.9

W0

1.2

I

0(.6

pm

140 Pin

160 pm

7

0.8

+0

0.7

--

0.6

-4 p42

o-5

0.4

-n

PI

4) pm

B (ps

160 p~m

(0.3

0.(4

0O.2

;0.2

o(.1

0

10

15

20

0

25

4

2

6

8

10

12

14

Length along AB (pm)

Length along AD (pm)

-2

10 pm

1.8

1.6

-40

1.4

jim

__80 PM

2

120

pmn

160

-m

S0.8

6

0O.

0.4

0.2

0

0

2

4

8

6

10

12

14

16

Length along BC (pm)

Figure 9-10: Steady state liquid profile for 1.66W power input.

50

16

18

20

Bibliography

[1] Chu, Kuang-Han, Micro and NanostructuredSurfaces for Enhanced Phase Change

Heat Transfer. MIT Ph.D. Thesis. January 2013.

[2] Mudawar, I., Assessment of High-Heat-Flux Thermal Management Schemes,

IEEE Transactions on Components and Packaging Technologies, Vol. 24, No. 2,

pp.122-141, Jun. 2001.

[3] Pautsch, G., Thermal Challenges in the Next Generationof Supercomputers. Proc.

CoolCon MEECC Conference, 2005: p. 1-83.

[4] Xiao, Rong, Nanoengineered Surfaces for Advanced Thermal Management. MIT

Masters Thesis. May 2008.

[5] N.Zuber, Hydrodynamic Aspects of Boiling Heat Transfer, AEC Report AECU4439, Jun.1959

[6] S.G.Kandlikar and A.V.Bapat, Evaluation of Jet Impingement, Spray and Microchannel Chip Cooling Options for High heat Flux Removal, Heat Transfer Engineering, Vol. 28, No. 11, pp. 911-923, Nov. 2007

[7] Xiao, Rong; Enright, Ryan; Wang, Evelyn N. Prediction and Optimization of

Liquid Propagationin MicropillarArrays, Langmuir Letter. September 2010.

[8] Xiao, Rong; Wang, Evelyn N. Microscale Liquid Dynamics and the Effect on

Macroscale Propagationin PillarArrays, Langmuir Letter. July 2011.

51

[9] Adera, Solomon, Personal communications. April 2015.

[10] wikipedia.org/wiki/Interference-(wave-propagation)

52