.. THE MIT JAPAN PROGRAM

advertisement

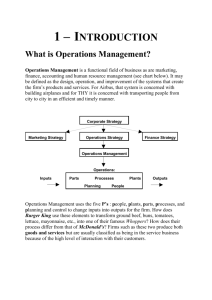

THE MIT JAPAN PROGRAM (a a. '. Science, Technology, Management Is * %%IV~~~B . JAPANESE FOREIGN DIRECT INVESTMENT AND TECHNOLOGY TRANSFER IN ASIA Shujiro Urata MITJP 96-23 Center for International Studies Massachusetts Institute of Technology _ _II Distributed courtesy of the MIT JAPAN PROGRAM Science * Technology * Management E38-754 Centerfor InternationalStudies 77 MassachusettsAvenue, Cambridge, MA 02139 Tel: 617-253-2839 Fax: 617-258-7432 Email: <robartimitedu> OMIT Japan Program JAPANESE FOREIGN DIRECT INVESTMENT AND TECHNOLOGY TRANSFER IN ASIA Shujiro Urata MITJP 96-23 ____ __ I I_ About the MIT Japan Program and its Working Paper Series The MIT Japan Program was founded in 1981 to create a new generation of technologically sophisticated "Japan-aware" scientists, engineers, and managers in the United States. The Program's corporate sponsors, as well as support from the government and from private foundations, have made it the largest, most comprehensive, and most widely emulated center of applied Japanese studies in the world. The intellectual focus of the Program is to integrate the research methodologies of the social sciences, the humanities, and technology to approach issues confronting the United States and Japan in their relations involving science and technology. The Program is uniquely positioned to make use of MIT's extensive network of Japan-related resources, which include faculty, researchers, and library collections, as well as a Tokyobased office. Through its three core activities, namely, education, research, and public awareness, the Program disseminates both to its sponsors and to the interested public its expertise on Japanese science and technology and on how that science and technology is managed. The MIT Japan Program Working Paper Series provides an important means to achieving these ends. II_ P _ _ _ I. Introduction Foreign direct investment (FDI) in the world has increased rapidly in recent years. One of the main interests on the part of the countries hosting FDI is to acquire technologies, which would contribute to their economic growth. Among various means of internationaltechnology transfer (hereafter, technology transfer for short) including international trade in technology in the form of patents and international trade in capital goods embodying technology, the importance of FDI has increased significantly as multinational enterprises (MNEs) have expanded their FDI activities rapidly. Technology transfer is also a main concern for MNEs, as success or failure of technology transfer is a crucial element in determining the outcome of their overseas operation. In light of increasing importance of technology transfer involving FDI in recent years, this paper attempts to examine the following two issues. One is to identify the patterns of technology transfer through FDI and the other is to analyze the determinants of the successful technology transfer. Such analysis will be of interest not only to academics but also to both MNEs undertaking FDI and policy makers formulating FDI policies and technology policies. The analysis will be conducted on Japanese firms in four machinery industries (general machinery, electric machinery including electronics, automobiles, and precision instruments) in East Asia, as a unique set of detailed information on technology transfer by Japanese firms in these industries became available. The choice of Japanese firms as a subject of the analysis is of interest at least for the following two reasons. One is that Japanese firms have undertaken FDI actively in East Asia and as a consequence their impact on economic activities 1 __1__1_____11__1______ _ of the host countries hat grown. The other is that the pattern of technology transfer by Japanese firms has been argued to be different from that by foreign firms of other countries. Despite the interest in making a comparison on the patterns of technology transfer involving Japanese firms on the one hand and those involving non-Japanese foreign firms on the other, this paper undertakes an in-depth analysis of the patterns of technology transfer by Japanese firms only due to data availability, and carries out some comparisons based on casual observations made by local workers with experiences in working for foreign firms. The paper is organized as follows. Section II discusses the recent development of Japanese outward FDI with a focus on East Asia, with a purpose of presenting background information for the analysis in Section III. Section III examines the pattern of technology transfer by Japanese firms in East Asia and identifies the factors that would influence the success or failure of technology transfer. Section IV, the final section, presents some concluding comments. II. Japanese Foreign Direct Investment in Asial Japanese FDI increased on a large scale and underwent major changes in its regional and sectoral composition in the latter half of the 1980s (Figures 1 and 2). The scale of FDI during the four year period of 1986-89 was unprecedented, far exceeding the total FDI from all previous years combined. Equally as dramatic as the size of the boom was the pace at which Japanese FDI declined after reaching a peak in 1989. Several factors may be responsible for such changes in Japanese FDI in the l This section draws on Kawai and Urata (1995). 2 L^.P·il-l-I·X-·-__---1_1_·--__1^.^____.._Xll.i-.ll.I _I__ 1I1-·-1 latter half of the 1980s. First, the recent globalization of business activities, made possible by a general rise in Japanese firms' managerial and technological capabilities, was a natural underlying factor behind the surge of Japanese FDI. Needless to say, the rapid and steep appreciation of the yen exchange rate against the major international currencies was the most important macroeconomic factor leading to the expansion of FDI in the second half of the 1980s and also in the early 1990s. The drastic yen appreciation stimulated Japanese FDI in two ways. One way was the dramatic "relative price" effect. The yen appreciated by 37% between 1985 and 1988 on a real, effective basis. These relative price effects substantially reduced Japan's international price competitiveness. To cope with the new international price structure, a number of Japanese firms moved their production base to foreign countries, especially to East Asia, where production costs were lower. Another way in which yen appreciation had a positive impact on Japanese FDI was the "liquidity" or "wealth" effect. To the extent that yen appreciation made Japanese firms relatively more "wealthy" in the sense of increased collateral and liquidity, it enabled them to finance FDI relatively more cheaply than their foreign competitors. Liquidity was also injected into the economy by the Bank of Japan in the second half of the 1980s, pushing up the prices of shares and stock and land, to result in the "bubble economy." Such an increase in liquidity and the subsequent asset-price inflation also had a positive impact on Japan's FDI. Japanese FDI in the 1980s was directed largely to North America and Europe, mainly in services and manufacturing. These two developed regions together 3 __11_ __· IL__ absorbed two-thirds of Japan's FDI outflows. Although a smaller share of Japan's FDI went to East Asia in the 1980s, investments in manufacturing were relatively active. The 1990s have seen some changes in the patterns of Japan's FDI. First, Japan's FDI to East Asia started to rise, resulting in an increase in its share in Japan's FDI. Major factors behind Japan's FDI in East Asia include the region's robust economic growth, low unit labor costs, liberalization and pro-FDI policies, and yen-rate appreciation. Another noticeable change was that manufacturing firms have been undertaking FDI actively, particularly in East Asia. Since the mid-1980s, geographical distribution of Japan's FDI to Asia has changed significantly, from the Asian NIEs(Newly Industrializing Economies) to ASEAN (Association of South East Asian Nations), and then to China and other Asian countries. 2 The NIEs attracted FDI until the late 1980s through FDI promotion policies. Policy makers in Korea, Taiwan, and Singapore, in particular, promoted inward FDI in their pursuit of high-tech industrialization. These countries enjoyed positive growth brought about by the simultaneous expansion of trade and inward FDI. However, Japanese FDI in the Asian NIEs reached a peak in the late 1980s just as its overall FDI also peaked. The Asian NIEs started to lose some of their cost advantages due to rapid wage increases and currency appreciation. Firms in Japan and other advanced economies therefore started to look at other East Asian countries such as ASEAN as hosts for investment. One important factor in 2 This observation applies to new FDI. A lack of data precludes one from obtaining accurate statistics, but there are signs showing that Japan's FDI undertaken with reinvested earnings has continued to grow in the ASEAN countries. See, for example, Okamoto and Urata (1994) for the case of Malaysia. 4 ------ Y1I~ I___ ___ ___ · _I_ __1_11_ attracting FDI in manufacturing to ASEAN has been the ASEAN countries' shift from inward-oriented towards outward-oriented strategies, which were carried out through their unilateral liberalization of trade and FDI inflows. Such regime changes have been prompted by the earlier success of outward-oriented policies in the NIEs. FDI inflows into China have also grown quickly since 1988-1989 due to China's gradual but persistent economic reforms, open-door liberalization policy, and its political and social stability despite the Tiananmen Square incident in 1989. As of 1994, China was the largest recipient of Japanese FDI in Asia. Attractiveness of China as a host to FDI has increased recently because some ASEAN countries have lost their attractiveness due to the emergence of serious bottlenecks in conducting businesses in these countries such infrastructure and shortage of skilled manpower. as underdevelopment of In recent years, despite at significantly lower scale, Japanese FDI to other Asian countries such as Vietnam and India has begun to increase. Since the 1980s, Japanese FDI in East Asia has primarily been aimed at the manufacturing and services sectors. A distinct characteristic of Japanese FDI in Asia is the relatively large share of manufacturing in comparison to other regions. The magnitude of Japanese manufacturing FDI increased more than seven-fold in eight years from $0.5 billion in 1985 to $3.7 billion in 1993. The rate of increase in Japanese manufacturing FDI in East Asia during the period was greater than the corresponding FDI to the world, and the share of East Asia in Japanese manufacturing FDI rose from 19.6 percent in 1985 to 32.9 percent in 1993. The share of manufacturing in overall Japanese FDI in East Asia also rose from 32 5 __ __ __1__1_1____1_1________I_ percent to 55 percent over the 1985-93 period. The geographical shift in the importance of Japanese manufacturing FDI away from the NIEs to ASEAN and then to China is pronounced. Sectoral composition of Japanese manufacturing FDI in East Asia has changed notably since the latter half of the 1980s. The most remarkable development is that Japanese FDI in the electric machinery (including electronics) has expanded sharply. At the end of 1991 the share of electric machinery in total Japanese FDI in Asia stood at 9.4 percent, the largest share among manufacturing sectors (Table 1) 3. The importance of electric machinery in Asia can be observed by the fact that its share in Japanese FDI in Asia is significantly greater than the corresponding share in Japanese FDI in the world (6.4 percent). Among other manufacturing sectors, chemicals and metals have relatively large shares in Japanese FDI in Asia. The shares for general machinery, transport machinery, and other manufacturing, in which precision instruments are included, are respectively 3.6, 3.5 and 4.7 percent. III. Technology Transfer by Japanese Firms in East Asia This section investigates the pattern of technology transfer from Japanese workers to local workers at Japanese firms in East Asia by using the results of a questionnaire survey conducted by the Nikkei Research Institute of Industry and Market. A main purpose of this exercise is to identify the effective strategies for 3 The discussions here refer to Japanese FDI in 1991, as the subsequent analysis on technology transfer will be conducted by utilizing information in 1991. 6 ____I_____II__IYY___ULiLI ----------·---------------·-__111-·-· ------ ---I·-I-- transferring technologies . In the analysis a brief attempt is made to compare the patterns of technology transfer by Japanese firms and by U.S. firms based on the observations drawn from the interviews with local workers employed by foreign firms in several Asian countries. Ideally an identical questionnaire survey is conducted on Japanese and non-Japanese foreign firms to identify similarities and differences regarding their patterns of technology transfer. III.1 Characteristics of Japanese Firms Surveyed A questionnaire survey was conducted on Japanese firms in October 1991.5 In addition to questions regarding the patterns of technology transfer, a number of questions were asked regarding the characteristics of the firm and the methods used to facilitate technology transfer. Table 2 presents some characteristics of the surveyed firms. Out of 133 firms, electric machinery has the largest representation, followed by general machinery, automobiles and precision machinery. These sectoral shares among the machinery sectors are similar to those reported in the official statistics (Table 1). As for the year of start-up, the sample is almost evenly distributed among the The issue of technology transfer has been extensively analyzed theoretically and empirically. A large part of empirical studies have analyzed technology transfer by Western firms and reviewed by several authors including Caves (1982) and Reddy and Zhao (1990). Empirical studies on Japanese firms published in English are very few, one of which is Yamashita (1991). The survey was carried out by the Nikkei Research Institute of Industry and Market as a part of a research project on technology transfer by Japanese multinationals. The author participated in the project as a member of the project. The results of the survey became available for independent research recently. Questionnaire was sent to 326 firms and 175 firms returned the questionnaire. Out of 175 firms, response from 133 firms were considered reliable. 7 ~~~~~~~~~~~ _____I_· __s~~~~~~~~~~~~l________ _____~---- firms starting operation before 1985 and after 1986. As for the type of ownership, for approximately 70 percent of the firms Japanese hold majority ownership while for the remaining 30 percent of the firms Japanese have minority ownership. The rate of job separation over a one-year period was investigated for each job rank because of the conjecture that technology transfer would be undertaken effectively under the environment where employment is stable. It was found that the average job separation rate for officers of the executive class or higher was a mere 0.6 percent. Evidently, the people who serve in positions where local management is policy determined stay, with the company. Even at the middle-management level of section chief or higher, the separation rate on average was no more than 4.1 percent. This finding counters a popular perception of high job separation rate, characterized as "job-hopping." On the other hand, the job separation rate among personnel who work at production sites was as high as 16.9 percent. This translates into a complete turnover of personnel within about 6 years. Among different industries, the job separation rate is low for automobiles. And among the countries under study, Hong Kong has a particularly high turn-over rate, while the corresponding rate is quite low in China and Indonesia. The job separation rate for engineers, who are generally involved in technology transfer, was found to be 4.7 percent, a level which roughly equals that of middle management. It is often maintained among Japanese corporations that transfer of technology does not add to the benefit of the company because the local personnel who acquire the technology soon quit the company. Yet judging from the results of the survey, it seems that this belief does not hold true, at least not for 8 .__1 ___1111_ 1_··-·--·-_11__.11___1-1·__1^ -.- engineers. Adoption of Japanese style management by the Japanese firms in their overseas operation is an interesting question. It is often argued that the success of Japanese firms in the post-WWII period is due to their practicing of Japanese-style management, which is generally characterized as having such features as life-time employment system, labor-management rotation and multi-task operation . conferences, job Life-time employment system and labor- management conferences lead to an environment, under which both workers and management can have mutually agreeable long-term plans for themselves as well as the firm, which would maximize the firm's profits as well as workers' benefits. Job-rotation and multi-task are operation likely to improve technological capability of the workers, as both of these systems enable the workers to increase their understanding of the technologies perspective. used in the firm from a broader Recognizing the importance of Japanese style management for the success of Japanese firms, one would assume that the success of overseas affiliates of Japanese firms may depend on the extent to which Japanese firms have successfully adopted Japanese style management in their overseas operation. 6 The issue of adoption of Japanese style management is closely related to the issue of "appropriate technology," which has been one of centralissues regarding technology transfer by foreign firms from developed countries to the recipient developing countries. According to the critics of the behavior of foreign firms, foreign firms bring with them technologies suited to developed countries but not suited for developing countries without modifying the technologies, thereby exacerbating the problems such as unemployment that host developing countries face. See, for example, Caves (1982) for more detailed discussion. I See Kawabe and Kimbara (1991) for concise discussions on Japanese style management. 9 __·__I According to the results of the survey, adoption of Japanese style management by Japanese firms in their East Asian operation appears to be limited, as the share of the firms that practice Japanese style management in total number of firms under survey is less than 50 percent. Specifically, the respective shares of firms adopting various components of Japanese style management considered here in total number of firms are as follows: life-time employment system (30.8%), labor-management operation (47.4%). conferences (40.6%), job-rotation Among the industries considered, (35.3%), and multi-task a large proportion of Japanese firms in automobiles have adopted job rotation and multi-task operation systems, as approximately 70 percent of firms have adopted these systems. This may be explained by the fact that the production of automobiles requires a large number of processes and technologies. Accordingly, the need for and the usefulness of job-rotation and multi-task operation is high. As for the geographical destinations of the sales of the firms under survey, on average 46.6 percent of their sales were exported and the remaining 53.4 percent were sold in the local market. There are wide variations in the export ratios (exports/total sales) for the firms in different sectors and for those located in different countries. Among the industries under survey, the export ratio is high for electric machinery and precision machinery. These findings largely reflect the types of policies pursued for different industries by the host country governments. Specifically, protective measures are applied in automobiles and general machinery for their promotion, resulting in a greater emphasis on local sales, while such measures are not applied to electric machinery and precision instruments, leading to greater sales orientation toward export market. 10 _______1m_1*__1______I____ __·I __ _____I As for the firms located in different countries, the export ratio is high for the firms in Hong Kong, Singapore, Malaysia, the Philippines and Thailand, while it is low for the firms in Indonesia, Korea and Taiwan. These observed patterns largely reflect the types of trade policies pursued by these countries and the size of the local market; the export ratio of the firms in the countries, where export promotion policy is applied and/or where the local market is small, tends to be high, while the export ratio of the firms in the countries, where import substitution policy is applied and/or where the local market is large, tends to be low. The differences in the geographical patterns of sales destinations by Japanese firms in different industries and in different countries clearly reflect the motives behind their FDI, export sales or local sales (Table 3). In addition to the consideration for sales, availability of cheap labor was an important motive for the firms in generally machinery, electric machinery and precision machinery. For the firms in the automobile industry, more than 50 percent of them were motivated to undertake FDI by the FDI undertaken by their business partners. This observation reflects the importance of subcontracting production system, or Shitauke, in automobile production, under which parent firms, assembler of final products, and subcontractors, supplier of components, have close business ties. As for the role of FDI promotion policy in attracting FDI, approximately 30 percent of the Japanese firms considered the incentives given by the FDI promotion policies an important factor in making their decision on FDI, indicating some effectiveness of FDI promotion policies. It is interesting to find the variations in the importance of FDI promotion policies as an FDI motive among the host 11 ___II countries. For as many as 50 percent of the Japanese firms in Thailand and in Malaysia, whose governments are active in FDI promotion, the incentives given to FDI played an important role in making their decision on FDI. III.2. Technology Transfer by Japanese Firms To revealthe current status of technology transfer, two indicators are used in the survey. One indicator measures the extent of the targeted level of technology transfer that has been achieved so far by drawing on the response to the following question; to what extent (in percentage terms) the level of technology transfer that was targeted at the time of start has been completed? This is an indicator commonly used by other researchers, but it suffers from its subjectivity 8 . The targeted level of technology transfer is usually not explicitly specified by investing firms, and moreover, the judgement as to the extent of technology transfer being accomplished is often not based on observable indicators but based on an impressionistic evaluation of the person responding to the questionnaire. To remedy the shortfall associated with the indicator just discussed, a more objective indicator is devised. This indicator attempts to find the extent of technology transfer being accomplished responsible for the specific operation. by finding who is If the local staff, not expatriates, are responsible, technology transfer is deemed as completed. In the survey technologies are divided into 10 different types, and the extent of technology transfer achieved for each technology measured by the latter See, for example, Yamashita (1991). 12 -^-·~~~~--- ~ ^I-~~~~~~---~~---~· ~~~~---------- -^--- I.-I·------ indicator is shown in Table 49. According to the results, more than 70 percent of the Asian affiliates of Japanese firms transferred the four types of technologies, operation technology, maintenance and inspection, process control and quality control. These observations indicate that Japanese firms have rigorously transferred the types of technologies that are required for manufacturing or assembling operation. The proportion of the firms that completed technology transfer in total number of firms goes down significantly for the other types of Specifically, less than 50 percent of the firms have transferred the technologies. technology for the development of molds and tools. For technological improvements and development of manufacturing process, approximately one out of three firms has completed technology transfer. The proportion of the firms completed technology transfer in the total number of firms goes down to around 20-30 for design technology, the introduction and development of new products. These observations clearly show that Japanese firms have not successfully transferred more sophisticated technologies such as those require modification or new development. One observes interesting variations in the extent of technology transfer undertaken among the affiliates of Japanese firms in different economies. For most technologies, transfer has advanced further for the affiliates in the NIEs than those in ASEAN countries. The difference is particularly notable for the relatively more sophisticated technologies such as introduction and development 9 In Table 4 technologies are arranged in a descending order in terms of the level of technology transfer achieved. It should be noted that the ordering based on the other indicator is identical except "introduction of new technologies" and "development of new products," whose orderings are reversed in comparison to the ordering shown in the table. 13 ---------- IIIIPC·--- -------L_ of new technologies. These differences reflect the differences in the technological capability of the host countries. Technology transfer may be performed relatively smoothly in the NIEs as their technological capability is higher than that in ASEAN countries. It may be worth commenting at this point on the differences in the patterns of technology transfer undertaken by Japanese firms and by non-Japanese firms. It is often argued that Japanese firms are slow or even hesitant in transferring technologies, compared to firms of other nationals. More explicitly, Western firms are said to be more active in transferring technologies than Japanese firms 0. Although we have to undertake a detailed comparison between Western and Japanese firms to derive a reliable result, it is interesting to note the following observations made by some local workers with the work experiences at both Western and Japanese firms f l . According to their observations, Western firms are active and effective in transferring operating technologies mainly with the help of manuals. To put it differently, at Western firms local workers acquire technologies more or less by themselves with the help of manuals. As such, local workers learn to deal with the problems discussed in the manuals. When a problem which is not discussed in the manuals emerge, local workers call on engineers from the parent office. By contrast to these practices at Western firms, Japanese firms rely more on OJT for transferring technologies. As such, it takes longer for Japanese firms to transfer l0 For example, see Sedgwick (1995). 11These observations are obtained from the author's discussions with local workers of Japanese and Western firms, and with government officials in Malaysia, Thailand and Indonesia. 14 -..- -1_1--_11__-- _._··.· ._.__.--I- technologies. But once technology is transferred, local workers of Japanese firms acquire not only the operational technologies but also the technologies to deal with the problems. As a result, local workers can work more or less independently without an assistance provided by Japanese workers. If these observations are correct, one may argue that for Western firms technology transfer means transferring operational technologies and therefore technology transfer is transferred. By considered completed once operational technology is contrast, for Japanese firms technology transfer means transferring not only operational technologies but also more complicated and sophisticated technologies, and therefore, technology transfer is not completed unless all sorts of technologies are transferred. As stated earlier, this is only a casual observation and therefore it needs to be analyzed more in detail to reveal the differences and/or similarities in technology transfer by the firms with different nationalities. III.3 The Methods Used For Transferring Technologies In order to transfer technologies expeditiously and effectively, a variety of methods, which may also be considered as a means to develop human resources, have been adopted by the Japanese firms (Table 5). On-the-job training (OJT) and training workshops in local areas are two most commonly used activities for transferring manufacturing technologies: i.e. operationaltechnology, maintenance, quality control, and process control. Indeed, approximately 60 percent of the firms use these methods for transferring manufacturing technologies. As the level of technologies involved in transfer goes up, the relative importance of training 15 II_____I_ _il ___1_ II_____ workshops both in local areas and in Japan goes up as a method used for technology transfer in comparison to OJT. The greater weight given to OJT and training workshops as a means of transferring manufacturing technologies observed above indicates that actual practice at the work place is considered to be more beneficial than class room workshop for transferring relatively simple technologies. However, for transferring relatively sophisticated technologies class room workshop is a main method of technology transfer with OJT playing a subordinate role. It is interesting to note that training workshop in Japan is commonly used as a major form of technology transfer in the case of introduction of new technologies and new products, indicating that in-depth and intensive training is provided at parent office in Japan for transferring sophisticated technologies by inviting personnel from overseas offices. The use of small group activities as a means of technology transfer is somewhat limited, compared to OJT or training workshops. In particular, only a small number of Japanese firms use small group activities for transferring sophisticated technologies. Different roles are placed on training manuals written in different Manuals written in local languages are given a major role for languages. transferring manufacturing technologies, while manuals written in English and Japanese are given relatively technologies. greater roles for transferring sophisticated In particular, the use of manuals written in Japanese is high for transferring new technologies and new products. The findings that training workshops in Japan and the manuals written in Japanese are given important roles for transferring sophisticated technologies indicate that the opportunities given 16 ___ 11___ to local personnel for acquiring sophisticated technologies are limited. Although a comparison, it detailed examination is needed to conduct an accurate may be worthwhile to offer some observations regarding the differences in the methods of technology transfer by Japanese firms and by Western firms. Compared to Western firms, Japanese firms rely less on the manuals but more on OJT as a means of technology transfer. Indeed, the manuals prepared and used by Western firms detail the directions for operating the equipments. As a result, local workers can learn how to operate the equipments without much difficulty. By contrast, the manuals prepared by Japanese firms suffer from a lack of detailed information. Japanese firms rely on OJT to overcome the shortcomings resulting from the manuals without detailed explanation. This difference in the importance placed on manuals and OJT between Western and Japanese firms appears to be attributable to the difference in their perception of the meaning or definition of technology transfer. The difference in the meaning of technology transfer perceived by Western and Japanese firms naturally leads to the difference in the extent of technology transfer targeted and the evaluation of technology transfer, which will be discussed in the final section. III.4 The Determinants of Successful Technology Transfer We examined the patterns of technology transfer by the Asian affiliates of Japanese firms and their characteristics such as the motives behind foreign direct investment, length of operation, technology transfer. management practices, and the methods of This section investigates the determinants of technology transfer by conducting a regression analysis. Such an analysis would be useful 17 _I I Ds _I__ not only for academic researchers interested in the behavior of foreign firms and economic development but also for both policy makers and foreign firms involved in formulating effective methods for transferring technologies. The dependent variable is the indicator reflecting the extent of technology transfer carried out, measured by the response to the question inquiring who is in charge of specified technological activities, local workers or Japanese workers. If the answer is local workers, then technology transfer is considered to have been carried out, and the value of 1 is given to the dependent variable. answer to the question is If the Japanese workers, then technology transfer is considered not to have been carried out, and the value of 0 is given to the dependent variable. Independent variables, or explanatory variables, include various firm specific characteristics, FDI motives, management practices, and the methods used for facilitating technology transfer. Below we discuss the expected impact of explanatory variables on the dependent variable and the results of the analysis in turn. The regression analysis is conducted for 10 different kinds of technologies, and their results are shown in Table 6. As the dependent variable takes the value of 1 or 0, the Probit analysis is applied to deal with the statistical problems associated with a truncated dependent variable. The length of operation in the host country is found to have a positive impact on technology transfer, as the coefficient on the variable "year of operation" is positive in most cases. 18 _ ls This finding is consistent with the expectation and the finding from the earlier studiesl 2 . In particular, the positive impact is statistically significant for maintenance/inspection, quality control and process control, indicating that the vintage effect is important for transferring manufacturing technologies. significant impact By contrast, the vintage effect does not have a on transferring more sophisticated technologies. This observation seems to indicate that accumulated experiences on the part of Japanese workers as well as local workers play an effective role in transferring manufacturing technologies, but not in transferring sophisticated technologies. High local participation in equity holdings is shown to promote transferring sophisticated technologies, as the coefficient on local ownership is positive and statistically significant for the transfer of sophisticated technologies. This result is consistent with the expectation, since high local participation may enable local management to put greater pressure on Japanese firms to transfer technologies. Indeed, high correlation between local ownership and use of manuals in the local language may serve as an evidence for this argument. indicate that ownership matters in This finding seems to determining the success or failure of technology transfer; the greater the influence of local management expressed in the share of equity holding, the more advanced in transferring technologies. Along the similar line of reasoning as above, high share of local workers in total workers is expected to contribute to technology transfer. Such expectation is detected with statistical significance only in transferring technologies for 12 In his study of foreign firms in Thailand, Sedgwick (1995) finds that the extent of technology transfer by Japanese firms is limited in comparison with the Western firms, and he attributes the limited extent of technology transfer by Japanese firms to an early stage of development of their operation. 19 I_ _ technological improvement. In many cases it is not the number of local workers but the importance of managerial authority measured by equity holding that influences technology transfer. Related to the issue of workers in the Asian affiliates, high job mobility in Asian countries is often argued to be an obstacle for transferring technology by Japanese firms. The results here do not generally support this argument, as the coefficient on job separation ratio is of expected sign with statistical significance only in one case, transferring technologies for process control..13 Motivation behind FDI is likely to influence the degree of achievement of technology transfer. Firms motivated to set up an export base by FDI may be interested in undertaking technology transfer, as they are under pressure to produce competitive exportable products. This assertion is not supported by our results. Indeed, it appears that technology transfer is not carried out by the firms with a strong export orientation. Firms that have set up operations overseas in order to export their products only have a short time to manufacture competitive products to be sold in the international market. Under these circumstances the firms have little time to transfer technology to local workers. To deal with the situation, they install the most up-to-date technologies but not transfer technologies. The finding that technology transfer is slow for the firms interested in exports is consistent with the result that technology transfer has not been carried out by the firms whose motive behind FDI was to take advantage 13 It may be important to note that "job-hopping" is a problem for a firm, as it cannot recover the cost used for investing in workers, who leave the firm. However, from the point of view of a society as a whole, job-hopping may be beneficial, as technologies get spread by these workers. 20 _______l_l_·__C___I___·I_· 111_._.11111_----0· of low-cost labor. The coefficient on cheap labor is negative in all the equations except one, and moreover, in five cases the coefficient is statistically significant. This observation indicates that Japanese firms invested in Asia to take advantage of low-wage labor in Asia are not interested in technology transfer. Japanese style management is often argued to provide an environment conducive to the assimilation and improvement of technologies. Among the unique features of Japanese-style management, life-time employment system, joint labormanagement conferences, job-rotation and multi-task assignment are taken up here for the analysis 14. Life-time employment system is considered to promote technology transfer. Under the life-time employment system workers do not oppose adoption of new technologies, which tend to be of labor-saving type, because their positions in the firm are secured for life. This expectation is not proven by the regression results. Indeed, technology transfer appears to be deterred under the life-time employment system. One possible explanation may be that workers whose positions are secured under the life-time employment system have not much incentive to work hard or to acquire technology. Joint labor-management conferences facilitate the introduction of new technologies, as acceptable conditions for the introduction of new technologies are sought and agreed by both labor and management through joint labor-management conferences. Indeed, the results weakly confirm this argument, as the coefficient on labor-management conferences is positive in six cases and statistically 14 A large number of works have discussed Japanese style management with significant differences in their views. Kawabe and Kimbara (1991) presents a concise review of these works. Thong (1991) discusses evolutionary changes in Japanese management styles by analyzing Japanese firms in Malaysia. 21 significant in one case: the introduction of new technologies. Job-rotation and multi-task assignment also tend to promote technology transfer. For local workers, the experience at a variety of operations acquired through job-rotation and multi-task assignment not only fosters flexibility but also gives the capacity to grasp the flow of the processes as a whole, and thus facilitates to establish locally the technologies involved. The expected effect is observed with some statistical significance only in a few cases; job rotation leads to technological improvement, while multi-task assignment facilitates transfer of operational technology and design technology. Japanese style management is argued to have contributed to improving technological capability of workers in Japan. However, our results show that the effectiveness of Japanese style management in technology transfer is limited. Japanese firms have adopted various methods for promoting the localization of technology. The effectiveness of four methods have been investigated, namely, manuals, on-the-job training, small group activities and workshops. The results of the statistical analysis show that manuals written in local languages are extremely effective means of transferring technologies. manuals in local languages is particularly The effectiveness of notable for transferring such sophisticated technologies as design technology, development of new products, development of metal molds and machining tools, and development of manufacturing facilities. By contrast, manuals in English and in Japanese turn out to be ineffective for transferring technologies. Indeed, the results show that the use of manuals in either English or Japanese tends to deter technology transfer. This somewhat unexpected result may not be surprising if the use of manuals in 22 ~------~__I--- - -- _ --- foreign languages is interpreted to reflect the backward looking attitude of Japanese firms toward technology transfer. Seminars in local areas are shown to be quite effective in improving technologies, designing technologies and developing new products. Seminars in Japan are effective in transferring process control technologies but not in transferring other types of technologies. Considering the differences in the cost of hosting seminars in Japan and local areas, these observations indicate that the effectiveness of local seminars would be much greater. Contrary to the expectation, on the job training and small group discussion, which are considered to be special features of Japanese practices, are generally not effective for transferring technologies; small group discussion is shown to be effective in transferring technologies for process control. Coupled with the earlier observation that Japanese style management does not promote technology transfer except for few cases, the findings here seem to indicate one of the following two possibilities or both of these possibilities. One is that special Japanese practices per se are not effective for transferring technologies at the Asian affiliates, and the other is that these practices are not adopted in the way that those adopted in Japan. Detailed information on the practices of Asian affiliates is needed to make judgement on this point. 15 IV. Conclusions Japanese firms have actively undertaken foreign direct investment since Sedgwick (1995) gives some examples of the latter case from his study in Thailand. 23 the mid-1980s. The survey conducted by the Nikkei Research Institute of Industry and Markets on technology transfer by Japanese firms in East Asia showed that a large part of manufacturing technologies such as operational technologies, and maintenance and inspection technologies have been transferred to the Asian affiliates of Japanese firms, but sophisticated technologies such as design technology and development of new products have not been transferred in many firms. The analysis of the determinants of successful technology transfer by Japanese firms in East Asia reveals a number of interesting observations. First, the length of operation manufacturing technologies. is technologies an important but not in transfer of factor in facilitating transferring more sophisticated Second, localization of ownership leads to successful transfer of sophisticated technologies, suggesting that ownership matters in transferring sophisticated technologies. Third, transfer of sophisticated technologies is very slow in the Japanese firm, which is set up to take advantage of cheap labor. Fourth, Japanese style management such as life-time employment system and Japanese style technology transfer methods such as on the job training and small group discussion are in technologies. general shown not to be effective in transferring Fifth, among the methods used for technology transfer, manuals written in local language and seminars in local areas are found to be effective in transferring technologies. The importance of technology transfer for the Japanese firms undertaking FDI is going to increase in the future for several reasons. One is increasing competition among the firms not only in the host country but also in the world 24 _____ _11_____1_ ___11_ __11 market. Trade and FDI liberalization, which is under way in a number of countries in Asia, will intensify competition in these markets. Expansion of the activities by multinational enterprises has led to "mega-competition" among them at global scale. Another factor that forces Japanese firms to speed up the process of technology transfer is the emergence of engineer shortage situation. The reduction in the number of engineers in Japan predicted in the near future will put the Japanese firms in a difficult position to run their overseas operation in the same way that they have pursued so far. One way to run overseas operation efficiently is to transfer technologies, so that overseas operation may be run by local workers without much support from Japanese workers. It may not be an overstatement that the success or the failure of overseas operation of Japanese firms depends on technology transfer. Technology transfer is equally important for the host countries to FDI, as successful technology transfer will benefit the recipient countries by improving technological capability, thereby leading to further economic growth. Tofacitate technology transfer, sufficient supply of well educated and well trained personnel has to be provided. Moreover, a well functioning legal framework to protect intellectual property rights has to be maintained, so that foreign firms may engage themselves in active R&D in the host countries. These observations point to the need for further examination of the determinants of successful technology transfer by foreign firms. The important factors that have not been examined in this paper mainly because of a lack of reliable statistics include information on the host countries such as educational level and industrial organization such as the level of competition in the host 25 I__ _ markets. More detailed information on parent offices of Japanese firms such as their R&D activities, overseas operations outside of East Asia, and industrial organization in which these firms operate also have to be considered. Finally, extensions of this type of study on technology transfer by including nonJapanese foreign firms is very important. References Caves, E. Richard (1982) Multinational Enterprise and Economic Analysis, Cambridge University Press, Cambridge. Kawabe, Nobuo and Tatsuo Kimbara (1991) "Review of Studies on Japanese-Style" Management," in S.Yamashita, ed. Transfer of Japanese Technology and Management to the ASEAN Countries, University of Tokyo Press, Tokyo, pp.123133. Kawai, Masahiro and Shujiro Urata (1995) Substitutes or Complements? An Analysis "Are Trade and Direct Investment of the Japanese Manufacturing Industry," presented at "The International Conference on Economic Development and Cooperation in the Pacific Basin," Berkeley, California, June. Okamoto, Yumiko and Shujiro Urata (1994) "Japan's Foreign Direct Investment in Malaysia in the 1990s," presented at the Third Annual Conference on Japan, "Revitalization of Japan's Economy: Implications for Malaysia," Kuala Lumpur, 26 ------~ -1·-1_~_ 1~ I~~~_ _ --~11111 April. Reddy, N.Mohan and Liming Zhao (1990) "International Technology Transfer: A Review," Research Policy, 19, pp. 285-307. Sedgwick, Mitchell W. (1995), "Does Japanese Management Travel in Asia," presented at the conference "Does Ownership Matter? Japanese Multinationals in Asia," September 20-21, MIT. Thong, Gregory T.S. (1991) "Foundations of Human Resources Management Practice in Japanese Companies in Malaysia," in S.Yamashita, ed. Transfer of Japanese Technology and Management to the ASEAN Countries, University of Tokyo Press, Tokyo, pp.135-152. Yamashita, Shoichi (1991), "Economic Development of the ASEAN Countries and the Role of Japanese Direct Investment," in S.Yamashita, ed. Transfer of Japanese Technology and Management to the ASEAN Countries, University of Tokyo Press, Tokyo, pp.3-22. 27 __.___ _1_1____1_*11_______I- ~~ .- cs cls a -O C3 CZ cC-: 0 ~ CDt-r C coC! 09 c4 co c Cs a) O ~ ~ ~ O= (0~ - 0! O: CO: 0 - - U- e - 19 LO o - C, - -O - :rc I O Cd a Ii. 11 a)o o . C- L- 0 0 C' D U) C) C co ( 00 ( 0 a--' cs to Qt- L- C p'- cs o U') Utm ~~~~~~0-0 -- t- t_- ) (0 0 C) 0 OC (0(0 X ') C4to1 0 LC) lb-C C- C_coooa 0( 0)-0 oo C' m L- Ur) 0)0n t I 00 Ln - U 00 cco Co 0 c) 4 -,i a)w cXsu4ve _o C4 a)O C" c-00 m _3o c>-Ose wc co Co --- c') o0 _ -CO c'0 CD~ ( 0 COCOCr a) W a) ale cc -0 CC c,, a) U, . . -c'-_ . . . . -s. C 3 cn o-C')(ocn o~ U) 0oct, C')00 0 0)e x')C')u- 00s C') C') co 2a) . mP. ~ . . . . .cttroco . . . Co cn mr o~-C. oco. cL a w >co C O c CO ( _00 0 C') u' _ C')_') -_ C) o' -0 4 In0i 0 v A 0) CO O0 C') C') U' O _ _- ce no Cd Q, 0 C= b 1; ,* I0 C- c') c') (~~~~~~~0~~~00 -00- ) 00 - C') ..... U 0 0o' CD')o0)0 aavtr -c c') X CO (00 0 O C'O0 cn, CO C-' ' C' - C-4'0) X°CO CO U'cnU' -~ocs ct CC 0(0 -0 s)0)L C) _ cs ur-OU)C C' a) - C' (00CD X sc sC'X)o _a cs 40 C')~ U' O o cu aC) C 0 e P._ b O . C) . C cd) C. . a)0 CC . Q C0 C a O a C--_C. *- . 0 C -=0 0 . v, cm0" ,B= *-4 C aa) C d < r ElC e 1- 0 C > C °0 h. C, 4H . o Cl) 0 C) 0 (L) C') e 0 - C-cU O~ >4 0 Q O O E: C eo Q O Cd :.r D2 _; C- 0 -- "-1"11111~"~~`"1~-"·lls U X C +-cd : .. U C C. -- -I iac *dz Q- 00 0C-) . ~r0~aZ 0. -_ M··CO0·-·c sceFXo CO Q C*:) Oa V - --- CO aQ 4 f3 o0 E3. C. 0) (0; ) C- 0. C. Cd u C a. a) 4 C Q 0L-'Q c, C.., C-S *- c; O C t <O X Q 0 C- C") = Oe rd 0XD l '4-4 0CC (Z O7 - co cc o, U) _ > 0 . td11* "tr C, Coo e cto bP E- OCI mr n .d . go CO ,a:: :; d ) 4 *-I -4- 0 > . . 00 Oo co I oCL = 19 cc C 00 . . . o c o - cc n . nO"O cc . . c . 0 . . c cc C ~ Ism UZ O3 u: 3 cl. tob in 000 -. t-. 0 a)4)- i i0iU .r _ CJC- 0'a'aa)0 a, ;00 a a , C. -EU N ) 4 = C cc 4. a.. a 0 el ' ci" o C4 om _LO 0-~ = cc c - tc';c in iCm cm-C cccc cc cc COi c 00C o . . --- Na . C . . c . = o . O _c CC O c~n a 4. o .4. a, -k s oo aC i- in3 CC o .I 0 c· O wCdls *_* .4.) a _ C 3 to -- : =C co cc 00- - C')cc cc in C00 CO C cn P.. ,cnc .I '40 in C.) -a , .a o C, -a) 3 ar, Os0.4 . d C.) a 0 C') C. in av, C) .4~ 0, 3 c I-t CD O0nn'-. cc _ c -~ cc! - c la cC= on C _ Cccc C') -V c cc -4-4cc0-1-4 UC'Cc C oc c cs0 C' 0cn00c_0 0 000e s C _ _ X _ ~-CC s vo. __c3CCn . . O c;ld;= " CX Sin a a, 0 5: o . N . CO X ' C . jcs O 0d a _ . Ut . -o .40 CO o 'a E- n . . O CO a I" 0 o U 0 c a O- . . . O-O . O . co 0 a, . O O : a, -CoC'Do -4000 a) >4 =1 4) c J C C 0eo cc c: o a -' o C o- - a. c 0 aa -- Z4 a U11 0 M - a)0r C 't M = Y) - 4-4 c -4 a) c cu -Q, 0oL 'a4- CO a) r . 0 ') cn 0 :0*I1 0 ._ in V-c3 _- --a, - ._ 0 a)0 -C C1 in LoC, c- C') Ln t- 00 in 0 o _ - ) cO _ -. = = a, a) ._ C) ~-C· C,,) N c - 00 co C -4C( ) - - 4C1 C c 4. C Cm 0-- a,· o cc C" 0 ; .4. _ __ Q '-._ I_ cu cd >. a, cfi O,0 E ea,&~~~~~ Cd go 2o ad -a *)CJ cm CE Q _:sQ E 0 a) c cc ~· o 0ow O gg C_ ved cnb A =; , 0a,·c._, a) aX a,0)· dL g~~~~a a) .. m·- a C·)Z - bbO bOCM 0 F c X ~a ~~ ),a a 3, C a, - C*_ C.) 4. -Ca - C=-·C- C O Cx IP I_ * 50 0 ccf 02 0 c C co 0 C1 0 a) ax -4- C rc'C- o d4 m 0- _ 13LCUt 1 O s)c i 04 _PCc O cN c 020 C cn 02a~)a) .~ L C~ C! .... Cs Ci ........ ~t Cs L-: C a ' C! C . -t rQQ) 0C 0 a) 2 CD uo0o OCd 00 4C,, 3:a) COcOCOO - a)C Cc t-L -' 4-o a) 4- 2 a) CO= C. - CD CC'2c= C13 CO ' 0 -sr to co cL C2 O v C2 C- U1 C 3 a ~ ~0 --- CO 'cq cO c 0 t-oo O coCQ ' Lo c o O CQ - ov C Co ~ 0 A= bc - c_ C2 1 ~0 0c2 00 a) ,u .E co CO CACC' .4-' P o C c) a . :> "d ;P.. . Cv 0002 02 C Ea0; o S -'a C a) x cd ' so :-o -c a . to P. C13 o CD - co co = CO CO 00 C)o CD 0 .4-' 0 a)..0 -4'&_ 1 Ca) ) -4 0Cd w, c a)- 0 Q C·C 0 :2 Co,1 a) .0 Cd Q'- c·a) c C ._C._ O ,C C - E- >_ O oc o E2).)2. ------------------------·----····----- - C C L Q, MCd L. ._ C a) 0 C V -) Q) Q; C ad a) C, r · C e Cd C' .- Cd,c ._ 0 o C EI d 0) o o 0 C: :,Ec E a)b 5OL~·· C c x S6 's Cd r aa M~ O -C 02aI 0 X a) C._) a) 0Q *- a C *-od - co-c Ea -.- 02 00 C C CE--.*C O0C0 I ---------·1--^11 ------------------- ---- -------------- ·-------------- s 0o Oi C00 c L, C o V, er CQ-CL- CC CO C C' oc C C C - 0· ;N C C . '4C 4. 4_0 4 a) * .;4 4 4) a)O 45Ca ·e 00 o g coeo cc Oz.3 M s2 c'Oc O-c u-,-2 O oo- I o Co Q .. 0- _ t 4)- 4-Ca cdu E3G "C o CC z CD to oo ooN"I co Ct- 00 044C _ CQ C s aC C .cLeC. - o~ - C0002000 0000 4) ~ XcO 4 CO -. CO. _ .c , O csXs UC Co CO :C C-: .-c U. C'= s0>4 ; r- C Ca 4 4-a: . cc C C C' C.9 OOC 00s~d )Cc _ > A C Q C . t. )P ,,P .g a C 0 .ZC) C't C. 44 C. a 4 4 f. :Y -tce-O-X :E 4 _C 'e C] to UID U3cC- O ooC t-t0 00 ce0to dcsd cc '^;' 0u3 co 'C". r Co C,: C C-C dM c e 0co "c - o G:r i g" 5 5. Coax C tSS S o.-. r, 4)-a 'C 4 3) 4 a a C 3t ,e a 44 S.!* :>-24)bo Q 4) Uo C._. O cdab) C C .9 4C > C.))= cii Q 0 O Ut )O 0 4*-0. CD O in 4 -o -t = ca a4 a ) I 0>C 0 t 4 .)5 U - C.C. W 0 04) b3L M oa O4 C. 4. I > 4 0C. , . . 4-. Ca a) c a _= M 0 - a 0) 00 0C C Oc C OS' CA C . 0 .)0 O a~ oc ) > ,, x Q. C . LD 0 E-O 0C 5: aS ae C- C ·- zoQ E: O Oc cJczQ * 04 O4. t b 0t_ 0o 0 0. °d \ wt- . cr CI .(d O 0 Ca ) 4V 4Q 4 co E 5 z C)O I .0o0 C 0 .0O c r, 0 -ciCv 0 ba0 4) 4)C §4 )3 bDCCO C > C ° O _ 0 .0 O 0 03 E3 *-- 4 3 0 .-0 -=0 -b- t1·- GO > 4); z 4) n C ... C ; 0c C -- ze 4 C 0 0 - ff OO~ "! 19 O~' CC 19 1 UcC)cO o C 1CCO er co c\01 C")- C v c CO c· c .2 o .2 r - 01 .E- *- C 9C I - IC C,,)sJ 00 %n s DCDCN-O3 C 0 C! C1C- 01 0 0 Qi M S t3 00 . I aX C1 co c° os * - cn 0C C1C1 = LO =C COt - C " 5, to c t1 CO t - c C C= C,0 -" M C1 CO 0T0 oc 02 02 ._ 0 C0 C- o- x v a c, 5- cO - ' eCC1 ' CO1' C1- C '' c 0)- .o cO;a C- C C 02 .O ¢ c CD 1- CO CD C CO to C 1-41 VI cbr -- 001" M CO - " 01 C 4- co -_ co 0 C: I C 0cc C" Oe o CO v edod~ -OCO C00Co O ,c oCd Co e Ci ._2 o+ ooC- 5 0) bo 02 a) ._ M o E- - a =_ ~ 0dg) El 02 o 02.02 C J >Mo0 O0 O00 * 02 00 b C-0) C4) 0a-X 0 c 9O2 ·C- C .4-C Id 0£U C 00* 0 )C 0 - _ )C C 0)22 O ¢' o C -z O o Cd C)c 0) :Eca 4. 0 o- 0 E M c 0 .0 2 O ,.C . a c 0) 02 C O w c2 E-n C C *~ ._ aD o0 c 0C Q ._ 0) Id O = C Cd w =C v f *.- ) 0J 0)02)QC Q) v CU 02CW C.o o-4 om O *~"M -O . 020.(d02 o 0 tl-O -cO¢ C) = = * - 0) I ; 0 0)C OO 00 C ~ ~ ~ - ---- - ---- I ~ ~ _ 002 coc _ _ C 0 E 0. o C.e I I-qa , I la + I I I I 4 I I I + + + + I + 4-+ I I Cg 4a)C. 0i s ovv C. . 20 -0 ca) J > C a) a, Ca * I I -- I I +- I + + +-- + I* * * * O C l = C -4-4- 00 un t CO Co Ca 4-I b*2 -,~ -I- I -- -- I I I 4- I I4- I+ l OC I l oC 0 0 002 > Q C 0- C 4C _ Rc o Ecr- * * e: - +--+ III + - I 4-4-4 + * * C C C; ++I I4+4+ C. a a) 4.4 0 C)02 * 0 * - , *- 4 -4 +--4 + + 4- Ii a C C. a) * -4+-+ 4. I I - I -+- I I 02 0 0 4C _CC la. C.4-1 1--* Sq S00 -4+ -+4I+ I I I I I I +I I ~-- cw ._ 4 I4- 4 * cn0m CCO q. .0 C4) CCi L -+ I I+-- -+ 4- I- 1 4-1 4- o c- Ci 09 C= -402 eo ** dC O C- o CU 0 O _ E o C:, -+ I a !n -. j C- CO o CC -4+I I e-I 0 0 0 M - 0D C) L +. I U 0+ -+ I I 4- I -+ +- - I I I I I .4 *4 -- - 4- 4- 02 v 'D 020 CD 0o ._. CC C e0 C n O CU ah : C- a)C a)~ ac * +- I 4 I I I o I++ +- +- + + I I I c -+4-++ E-· I _V 02O C00202E. C. 0 >._0 a * * 0.0 4- a)0C 4._ * * I 4- 4- I 4- 4- I I C) oC ._( 0-) I , i 02 Ca ,d 0 c- O O -- :2.0a)0 _ ·9------ oO a) <D CC 0~~a v ci C; -c~ C E a a ct SS ~c.0>.-a o a0 o z C a50 -0200>cz- 1- · - _ cu 0bO I QC- O COar O O PC. Da: C I I I I cd~ C) -e c z- 0 r o) C. . u,c I 02 -·, c Ce C. Q I i 02 od C , <ooa *_ VI c o~~~~a I I cu o C 4.) -- I -o 02 O I _ 02' o c --- .C C) o 0 02 -; Ca) 0 C) =02-.._ '~_*C)C; 0 02 co 0. C 50. 0o 0 ,e 4) a c.. C. a) Q a t U cm i II I l] * U .L*a) C0 . *^ .0 -= * 00 .. -CU D .0 -. 0 02 C, 0 a = 0 0 4.a C" 9= - R C) ._ ~4)I I e C. 0a E ._ 5 C; C~ 0 CDQ)0 S ._ -Q C0 0 0 a) M C. =0202CC 00--0 0 c=0 D .-. CCl C; ·, ; -0 O O _. 0) *- 02C0 2C - _ _ .i _ -,, UC 002.4 ;0C C = C a)~ bO 0 d --a) co 2 M DC <D0 urEI 0 = = = , 0200a.c C, _w ._ ._2 -w tD 8. - 5- M5 5 0 0 c= == ..Cl. c.2 C.2 &)2C-.) oce . _ S .~ U Ud ar d~~~~C .4 L.~~~~~~~~c E Et C](i o z· , C d U ;JJ 4: al L L. C) 0) O O C) 0') c co Ca) a) .I c) .4- C) c) L I CO) I- C D CO L D ._ 3 c E A4 eo 'C) - - cD r C) C\ _ 3C u CL C 4) nc l C , - L. 3 ota~t - L U~c C C 43 L. 4 e3 4 U L c 4-3 ui -c~U C d·i C Q 43O a me C.- rl.-3;=: W CS) CS (S C) (S) S) 8Cs c CZ . I .D O CS U L . 01,1 "7 '- . C (S (S d CD CT) Cr) C) ICM 0) l .0 CD 0)( Ma 03 0) CD ._i a) co , Im -(d E"Sa n == CO 43 0 D ) c 0 co;) a(0 cl- co 1 ) (S ",C CS C) m C cQ c