Commercial Production of Vegetable Transplants 1

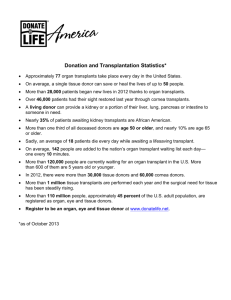

advertisement