Method of Analysis Need Statement & Alternatives Context: Climate Change & Sustainability

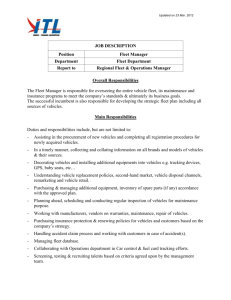

advertisement

Context: Climate Change & Sustainability Complete Demand andand Life Cycle Simulation Simulation Analysis Problem Statement Scope The Federal Aviation Administration (FAA) Method of Analysis Need Statement & Alternatives Vehicle Inventories Based on direction by DOT and E. O. 13514, the FAA must reduce its GHG emissions by 12.3% by 2020 and meet campus demand within existing funding. Presidential Environmental Initiatives Executive Order 13514 October 5, 2009 50 Gasoline Costs Electricity Costs 48 46 6% increase Gasoline Vehicle 42 Technical Center Inventory Composition 40 13% reduction Low-Speed Electric Vehicle Optimize Inventory Emissions Trend 35 36 Carbon Neutral E.O. goal 34 32 30 25 15 2007 2008 2009 2010 2011 2012 2013 2014 2015 Time (years) 2016 2017 2018 2019 2020 0 Gasoline Diesel Hybrids Meet Travel Demand Deterministic LCC LSEV’s NEV’s CNGV’s X Demand Model Alternatives Discrete event queuing model evaluates inventories & estimates average vehicle mileage Historic Data 20% NOT Random Simulation Output Total Cost Underutilization Inventory Size 42 $18,113 41 (5)* $18,822 41 (2) $19,137 41 (1) $19,546 39 (1,3,5) $22,537 Inventory Waiting Time SD Waiting Time Missed Events Avg cost Avg cost Avg cost Avg cost Avg cost 122 $4,807 42 $1,764 170 $6,026 155 $5,489 0.8 $27 120 121 120 114 $4,679 $4,750 $4,898 $4,462 41 41 41 39 $1,681 $1,681 $1,681 $1,521 186 196 197 260 $6,604 $6,947 $6,988 $9,234 164 161 167 205 $5,830 $5,724 $5,945 $7,279 0.8 1 0.9 1.2 $28 $35 $34 $41 The 42 vehicle inventory had the lowest cost. Reducing inventory size lowered underutilization costs but increased waiting time costs $1,400,000.00 $1,200,000.00 $1,000,000.00 TLLC $800,000.00 $600,000.00 $400,000.00 $200,000.00 $0.00 CNG NEV Gasoline LSEV 6-year Fleet Total Life Cycle Cost Breakdown 1.00 CNG NEV Gasoline LSEV 0.90 0.83 Energy $23,900 $12,100 $96,800 0.80 $11,000 0.83 0.70 Corrective Deterministic $135,900 $78,600 $21,100 $52,400 $6,100 $78,600 $21,100 $52,400 0.59 0.60 SQ-Gasoline 0.50 SQ-CNG 0.40 SQ-LSEV 0.34 SQ-NEV 0.30 0.20 Acquisition $1,302,000 $966,000 $671,100 $747,600 TLLC LCC Model Monte Carlo simulation estimates LCC, CO2 emissions, & forecasts energy prices *indicates which charge code was reduced 40 35 13% reduction 30 25 $1,540,400 $1,051,600 $852,600 $832,100 0.10 0.00 $700.00 $900.00 Emissions Trend Carbon Neutral E.O. goal 46% reduction 20 CNG Fleet 15 10 LSEV/NEV Fleet 5 89% reduction Replace Inventory with Electric Vehicles LSEV’s and NEV’s are the recommended alternative for vehicle replacement, as they have the lowest energy, deterministic maintenance costs, and significantly reduce CO2 emissions. Time (years) Utility vs. Cost (42 vehicle fleet) Utility $1,600,000.00 Weighted Alternatives Implement a detailed fleet management system that tracks vehicle use. 45 Utility Analysis $1,800,000.00 Utility Analysis and rankings of different portfolios Recommendations Improve Fleet Management Technical Center Motor Fleet Yearly CO2 Emissions v. Time $1,100.00 $1,300.00 Cost ($ Thousands) $1,500.00 The graph shows the utility score of each alternative versus cost. LSEVs have the highest utility & lowest cost while gasoline vehicles have the lowest utility with nearly the same cost as LSEVs. The only financially feasible alternative over 6 years is LSEV with approximate savings of $1700 per vehicle. Observations ROI: LSEV v. Gasoline 22000 6-year savings of ~ $1,763 per vehicle 21000 20000 Cost ($) Life Cycle Cost Model Output Gasoline fleets are more cost effective because they are leased from the GSA which also pays for their maintenance. The FAA would be responsible for all costs from LSEV fleets. Objective Function The FAA can meet the emissions reduction goal by replacing 7 gasoline vehicles with LSEV’s or NEV’s 0 6 Year Total Life Cycle Cost by Alternative Calculated CO2 Emissions Minimization function to filter out infeasible inventories for use in the LCC model Observations CO2 Emissions (metric tons) 16 14 12 10 8 6 4 2 0 Demand model output matches historical mileage data with except for high mileage vehicles being out of scope; accounted for by more low mileage vehicles Acquisition Costs Calculated Total Life Cycle Costs Conclusions & Future Work Objective Function Output Frequency of Average Miles Driven Per Month Stochastic LCC and emissions claculation Inventory CO2 Emissions Results Demand Model Validation Preventive Maintenance Costs Maintain/Reduce Operational LCC Suitability X 5 30 Reduce Emissions Alternatives 10 Fleet Size Historic Distributions Gasoline 20 Miles Per Gallon Requirements Meets requirement 40 Compressed Natural Gas Vehicle Neighborhood Electric Vehicle Does not meet requirement 45 38 Number of Vehicles Carbon Dioxide Emissions (t) 44 Mileage Inventory Efficiency Technical Center Motor Fleet CO2 Emissions v. Time Objective Function Fleet Composition A system to be used by the ALO/Fleet Managers of FAA campuses to identify feasible modifications to the current motor fleet vehicle inventory to achieve a 12.3% reduction of GHG emissions. • Requires vehicles to be alternatively fueled by 2016 SD Waiting Time Missed Events Building Data CO2 Emissions Acquisition Costs Preventive Maintenance Costs Need Statement Presidential Memorandum – Federal Fleet Performance Demand Model Campus Layout Number of Trips Personnel Corrective Maintenance Costs Compressed Natural Gas Costs • 30% reduction vehicle fleet petroleum usage • Fleet size optimization • Directs agency mandated reduction of GHG emissions Historic Data and Cost Analysis Electricity Distribution Location: 10 miles north of Atlantic City, NJ Size: ~ 5,000 acre or 7.8 square miles (7x GMU campus size) Functions: Engineering research, development, testing Vehicles: 42 GSA leased Transportation Demand Charge Groups Gas Distribution William J. Hughes Technical Center CNG Distribution FAA must comply with Executive Order 13514, to reduce greenhouse gas (GHG) emissions of motor fleet by 2020. Underutilization Inventory Cost Waiting Time 19000 LSEV 18000 Gasoline 17000 * The size of the fleet can be reduced, but utilization and waiting times are not linearly affected. Decentralized fleets are effective at reducing inventory size while minimizing bottlenecks that occur in smaller inventories. 16000 15000 1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61 64 67 70 73 Time (Months) Utilization