Design of a Campus Motor Fleet Decision Support System Final Preliminary Report

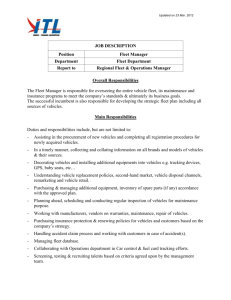

advertisement

GEORGEMASONSENIORDESIGN 2013 Design of a Campus Motor Fleet Decision Support System FinalPreliminaryReport 11/27/2013 ABSTRACT – U.S. energy consumption of fossil fuels has been increasing steadily and is expected to grow by 28% from 2011 to 2040. [1] The United States Federal Government is a large consumer of energy in the United States. As such, the U.S. Government can use its position as a principle energy consumer to stimulate green energy technologies. Executive Order 13514, Federal Leadership in Environmental, Energy and Economic performance, calls for the U.S. Government to increase its sustainability goals. The Federal Aviation Administration (FAA) has over 4300 registered vehicles in its fleet. As per E.O. 13514 and as mandated by the Department of Transportation, the FAA will optimize its ground fleet size and reduce its vehicle fleet greenhouse gas emissions by 12.3% by 2020 compared to a financial year 2008 baseline. To evaluate life cycle costs and potential greenhouse gas reductions, a decision support tool is necessary. The proposed decision support tool will compare different alternative transportation portfolios at the William J. Hughes Technical Center and Mike Monroney Aeronautical Center by evaluating each transportation portfolio’s life cycle costs and greenhouse gas emissions while meeting the demand. This tool will help the FAA meet the requirements set forth by E.O. 13514. 1 Design of a Campus Motor Fleet Decision Support System Shane Armstrong Caleb Benn Alicia Kubokawa Kelly Prim Contents 1. Context .................................................................................................................................................. 6 1.1. Federal Aviation Administration ................................................................................................... 6 1.2. Operational Center Data ............................................................................................................... 7 Both campuses perform a mix of functions unique to the campuses. The type of fleet used to meet the demand of the campus will have different costs and attributes. Initial costs and running costs are incurred during the running of the campus and will be affected by the vehicle make up. The campus’s vehicle fleet will have different attributes such as emissions, and wait time based on the fleet mix. The diagram below shows a black box model of the campus travel system ........................... 8 1.3. E.O. 13514, Federal Leadership in Environmental, Energy, and Economic Performance .......... 10 1.4. Energy Consumption Costs ......................................................................................................... 10 1.5. United States Alternative Fuel Sources ....................................................................................... 12 1.6. Carbon Emissions ........................................................................................................................ 13 2. Scope ................................................................................................................................................... 15 3. Gap Analysis ........................................................................................................................................ 15 4. Stakeholder Analysis ........................................................................................................................... 16 4.1. Federal Aviation Administration (FAA) ....................................................................................... 16 4.2. Council on Environmental Quality Chair and Office of Management and Budget Director ....... 16 4.3. Vehicle Users ............................................................................................................................... 17 4.4. General Services Administration (GSA) ....................................................................................... 17 4.5. FAA Employees ............................................................................................................................ 18 4.6. Taxpayers .................................................................................................................................... 18 4.7. Electricity Company .................................................................................................................... 18 4.8. Department of Energy (DoE) ....................................................................................................... 18 4.9. Department of Transportation (DoT) .......................................................................................... 18 2 4.10. Environmental Protection Agency (EPA) ................................................................................. 18 4.11. Steering Committee on Federal Sustainability ....................................................................... 18 4.12. Federal Energy Management Program (FEMP) ...................................................................... 19 4.13. Agency Senior Sustainability Officers (ASSO) .......................................................................... 19 4.14. Office of the Federal Environmental Executive (OFEE) ........................................................... 19 4.15. Manufacturers ........................................................................................................................ 19 5. Decision Making Factors ..................................................................................................................... 19 5.1. Vehicle acquisition and leasing processes .................................................................................. 20 5.2. Fleet Inventory Selection process ............................................................................................... 20 5.3. Problem statement ..................................................................................................................... 20 5.4. Need statement .......................................................................................................................... 21 5.5. Mission requirements ................................................................................................................. 21 5.6. Derived Requirements ................................................................................................................ 21 6. Design Alternatives ............................................................................................................................. 22 7. Simulation Design ............................................................................................................................... 23 Data Analysis ................................................................................................................................... 24 7.1. 7.1.1. 8. Operational Center Motor Fleet ............................................................................................. 26 Method of Analysis ............................................................................................................................. 30 8.1. Design of Experiment (DOE) ....................................................................................................... 30 8.1.1 Business Rules & Assumptions ................................................................................................... 31 8.2. Phase I ......................................................................................................................................... 33 8.3. Phase II ........................................................................................................................................ 36 8.4. Phase III ....................................................................................................................................... 37 8.5. Value Hierarchy ........................................................................................................................... 38 8.6. Phase II results ............................................................................................................................ 38 8.7. Phase III results ........................................................................................................................... 38 8.8. Ranked Results ............................................................................................................................ 38 8.9. Cost vs. Utility ............................................................................................................................. 38 8.10. 9. Recommendations .................................................................................................................. 39 Acknowledgements ............................................................................................................................. 40 9.1. Electric Vehicle Life Cycle Costs .................................................................................................. 40 9.2. Stochastic Variables .................................................................................................................... 40 10. Project Plan ..................................................................................................................................... 40 3 10.1. Work Breakdown Structure (WBS) ......................................................................................... 40 10.2. Budget ..................................................................................................................................... 41 10.3. Cost Performance Index (CPI) and Schedule Performance Index (SPI) ................................... 41 10.4. Schedule .................................................................................................................................. 43 11. References ...................................................................................................................................... 46 Figure 1: FAA Service Regions ....................................................................................................................... 6 Figure 2: Mon6roney Aeronautical Center ................................................................................................... 7 Figure 3: Hughes Technical Center ............................................................................................................... 8 Figure 4: Campus Demand Black box ............................................................................................................ 9 Figure 5: System Demand Fleet Allocation Model ........................................................................................ 9 Figure 6: Energy Consumption Trends [7] .................................................................................................. 11 Figure 7: Fuel Consumption vs. Time [9] .................................................................................................... 11 Figure 8: Pump price for fuel U.S. & World [12] ......................................................................................... 12 Figure 9: Energy use per capita in Kilograms of oil U.S. & World [12] ........................................................ 12 Figure 10: U.S. Gas Emissions [4] ................................................................................................................ 14 Figure 11: U.S. & World CO2 emissions per capita [12] ............................................................................. 14 Figure 12: FAA Campus Carbon Emissions vs. Time .................................................................................... 16 Figure 13: Primary Stakeholders ................................................................................................................. 18 Figure 14: Stakeholder Flowchart .............................................................................................................. 19 Figure 15: Motor Fleet Purchase Chain ...................................................................................................... 20 Figure 16: Motor Fleet Inventory Vehicle Check Out ................................................................................. 20 Figure 17: Current Vehicle Checkout Process to Meet Demand ................... Error! Bookmark not defined. Figure 18: Feasible Design Alternatives ......................................................... Error! Bookmark not defined. Figure 19: Alternative verse Requirement Matrix ...................................................................................... 23 Figure 20: System Model Flow Diagram ..................................................................................................... 24 Figure 21: Aeronautical Center Building Percentages ................................................................................ 25 Figure 22: Tech Center Building Make up ................................................................................................... 26 Figure 23: Ground Fleet Statistics of FAA Centers ...................................................................................... 26 Figure 24: Fuel Type Portfolio for Aeronautical and Technical Centers Ground Vehicle Fleet .................. 27 Figure 25: Average Demand of Reportable Vehicles ................................................................................. 27 Figure 26: Direct Carbon Dioxide Emissions of the Current Non Low Speed ............................................. 28 Figure 27: Uses of Current Vehicle Purpose ............................................................................................... 28 Figure 28: Operational Centers Vehicle Inventory by Type ........................................................................ 29 Figure 29: Monthly Mileage by Vehicle Type .............................................................................................. 30 Figure 30: Campus Vehicle Statistics .......................................................................................................... 30 Figure 31: Demand Model DOE .................................................................................................................. 31 Figure 32: Life Cycle Costs DOE ................................................................................................................... 31 Figure 33: Demand Analysis Flow Diagram ................................................................................................. 33 Figure 34: Aeronautical Center Simulation Distributions ........................................................................... 34 Figure 35: Technical Center Simulation Distributions ................................................................................. 34 Figure 36: Event Generator ......................................................................................................................... 35 4 Figure 37: Queuing System ......................................................................................................................... 35 Figure 38: Acquisition Costs ........................................................................................................................ 36 Figure 39: Maintenance Costs and Formula ............................................................................................... 37 Figure 40: Energy Costs ............................................................................................................................... 37 Figure 41: Life Cycle Cost Equation ............................................................................................................. 37 Figure 42: Value Hierarchy .......................................................................................................................... 38 Figure 43: Notional Cost vs Utility Graph .................................................................................................... 39 Figure 44: Work Breakdown Structure ....................................................................................................... 40 Figure 45: Project Budget vs. Time ............................................................................................................. 41 Figure 46: CPI vs. SPI ................................................................................................................................... 42 Figure 47: Senior Design Schedule With Critical Path Highlighted in Red .................................................. 43 Figure 48: Task Breakdown of Project Plan Schedule ................................................................................. 44 Figure 49: Risk and Mitigation Table ........................................................................................................... 45 5 1. Context 1.1. FederalAviationAdministration The Federal Aviation Administration (FAA) is a part of the United States Department of Transportation (DOT), with more than 48,000 employees and a 2013 budget of $15.2 billion. The FAA official mission statement is “to provide the safest, most efficient aerospace system in the world” [1], and true to their mission they are directly involved in regulating and monitoring the National Airspace System (NAS). The National Airspace System is one of the most complicated of its kind, and encompasses all aspects of civilian and commercial aviation [2]. The National Airspace System is comprised of not only the people, equipment, facilities but also the procedures necessary for safe and expeditious air travel in the United States of America [2]. While the FAA is heavily focused on the NAS resources, it should also be noted they are responsible for the conduct of studies related to the economic, social and environmental impact of air control monitoring of the U.S. airspace. The FAA is split into 3 service areas: Eastern, Central, and Western. Eastern Service Area: New England, Eastern, and Southern regions. Central Service Area: Great Lakes, Central, and Southwest. Western Service Area: Alaskan, Northwest Mountain, and Western‐Pacific. Figure 1: FAA Service Regions 6 In addition to the headquarters in Washington, D.C., there two Operations Control Centers (OCCs): the Mike Monroney Aeronautical Center (AMC) in Oklahoma City, Oklahoma, and the William J. Hughes Technical Center (ACT) in Atlantic City, New Jersey. The focus of this paper will be on the ground fleets of these two centers. 1.2. OperationalCenterData The Mike Monroney Aeronautical Center (Figure 2) is the centralized service and support facility of the Federal Aviation Administration located in Oklahoma City, Oklahoma. It houses more than six thousand federal employees and contractors, with an operational budget of $1 billion. The AMC campus is over one thousand acres large and houses one hundred twenty eight buildings. The AMC’s services include logistics, training, accounting and financial, information technology, media solutions, acquisition services, and environmental safety and occupational health (ESOH) policy. [1] Figure 2: Mon6roney Aeronautical Center The William J. Hughes Technical Center (ACT) is a five thousand acre aviation research, development, test and evaluation. Its mission is to modernize the United States air transportation system. The ACT located near Atlantic City, New Jersey and is the central facility assisting Next Generation Air Transportation System (NextGen). [2] 7 Figure 3: Hughes Technical Center Bothcampusesperformamixoffunctionsuniquetothecampuses.Thetypeoffleetused tomeetthedemandofthecampuswillhavedifferentcostsandattributes.Initialcostsand runningcostsareincurredduringtherunningofthecampusandwillbeaffectedbythe vehiclemakeup.Thecampus’svehiclefleetwillhavedifferentattributessuchas emissions,andwaittimebasedonthefleetmix.Thediagrambelowshowsablackbox modelofthecampustravelsystem 8 Figure 4: Campus Demand Black box The travel System is affected by campus characteristics and functions that create the type and amount of demand. A fleet is acquired based on expected demand. The type of fleet is used to meet the travel demand. Figure‐5 shows in more detail the black box process of Figure – 4 . Figure 5: System Demand Fleet Allocation Model 9 1.3. E.O.13514,FederalLeadershipinEnvironmental,Energy,andEconomicPerformance The executive order was signed into effect on October 5th, 2009. It was created and signed into action to “increase our prosperity, promote energy security, protect the interests of taxpayers, and safeguard the health of our environment”. [3] To reach these goals the government is leading by example. E.O. 13514 requires federal agencies to take steps towards increased environmental, energy, and economic performance. Federal agencies will measure, report, and reduce greenhouse gas emissions. As part of the initiative, DOT tasked the FAA with optimizing its fleet size. Reducing and replacing campus powered vehicles will take steps towards meeting the requirements of E.O. 13514. The E.O. 13514 mandates targets including: 30% reduction in petroleum vehicle fleet use. 26% improvement in water efficiency by 2020 50% recycling and waste diversion by 2015 95% of all applicable contracts will meet sustainability requirements Implementation of the 2030 net‐zero‐energy building requirement The Aviation Logistics Organization (ALO) is a department of the Federal Aviation Administration (FAA) that is responsible for managing the national fleet of motor vehicles for FAA facilities and other required logistics in support of the Deputy Assistant Administrator for Regions and Center Operations/Chief Logistics Officer (ARC). ALO has been tasked with optimizing the FAA’s campus vehicle fleet while continuing to meet their transportation demand. 1.4. EnergyConsumptionCosts World energy consumption of all power resources has been steadily increasing over time and is projected to continue to increase. 10 Figure 6: Energy Consumption Trends [7] The United States’ dependency on petroleum gas has been increasing and is projected to continue increasing at a dramatic rate. Petroleum is the primary fuel source for transportation. Due to environmental consequences and diminishing fossil fuel resources, alternative fuel sources are necessary to meet and maintain transportation demand. Figure 7: Fuel Consumption vs. Time [9] 11 Figure 8: Pump price for fuel U.S. & World [12] Figure 9: Energy use per capita in Kilograms of oil U.S. & World [12] 1.5. UnitedStatesAlternativeFuelSources 12 The U.S. Energy Information Administration defines the following types of energy as alternative fuel sources for transportation: - Ethanol Ethanol can be used as an additive to gasoline to reduce gasoline consumption. Ethanol emits lower CO2 emissions but is typically less efficient. Ethanol is made from organic materials. - Natural Gas (Compressed & Liquefied) According to the Propane and Education Research Council, there are over 270,000 on road propane vehicles.[10] Propane vehicles come in two main types: dedicated and bi‐fuel. Dedicated propane vehicles run solely on propane, while bi‐fuel have separate fuel systems allowing use of propane and gasoline. - Electric Electric vehicles powered solely on rechargeable batteries. They can be completely electric or hybrid. Completely electric vehicles have zero direct CO2 emissions, and their carbon footprint is directly attributable to the power plant they receive their electricity from. - Low Speed Electric Vehicles (LSEVs) Low Speed Electric Vehicles (LSEVs) are electrically powered vehicles with a maximum speed of 25 mph. They are able to go on publicly maintained roads depending on the state and the speed limit. LSEVs are rechargeable electrically powered vehicles. Because they are only capable of low speeds, they are not required to meet safety standards set forth for passenger vehicles. The total environmental costs associated with using electric vehicles are determined by the source of power from their nearby power plant. Different power plants have different GHG footprints, particle pollution, and financial costs associated with them. - Hydrogen Hydrogen or fuel cell vehicles (FCVs) run on hydrogen gas instead of gasoline with zero tail pipe emissions. The onboard fuel cell stack converts hydrogen gas with oxygen from the air into electricity. There are not many hydrogen charging stations already in existence (they are few and far), and they impose a high infrastructure cost. 1.6. CarbonEmissions Carbon and greenhouse gas emissions are a major factor when it comes to the warming of our atmosphere. According the United State Environmental Protection Agency (EPA), in 2005 carbon dioxide (and carbon dioxide equivalent) emissions numbered close to 40,000 million metric tons showing a 26% increase since 1990. [5] 13 Figure 10: U.S. Gas Emissions [4] Figure 11: U.S. & World CO2 emissions per capita [12] Of those 40,000 million metric tons the United States was accountable for close to 7,000 million metric tons.[4] Emissions reported in 2011 were less, coming in at 6,702 million metric tons, 27% of which 14 created through gas usage, transportation [4]. In 2011 the United States used 3.19 billion barrels of gasoline, which works out to 134 billion gallons with a daily average of 367.08 million gallons [6]. 2. Scope To meet greenhouse gas emission reduction requirements created for the FAA, our design will focus on reducing vehicle emissions of the FAA operational center motor fleets. This project will design a decision support system for campus motor fleets at the William J. Hughes Technical Center and the Mike Monroney Aeronautical Center that will assist FAA fleet managers in reducing CO2 emissions, in accordance with E.O 13514, while maintaining and meeting travel demand and minimizing life cycle costs. 3. GapAnalysis The gap analysis shows the required reduction in greenhouse gases that is mandated by Executive Order 13514. The FAA needs to reduce the petroleum consumption of its ground fleet while meeting transportation demands. The following figure represents the combined emissions and the miles driven to meet the demand of the Mike Monroney Aeronautical Campus and the William J. Hughes Technical Center on the vertical axes, over time. Total carbon dioxide emissions must be reduced while continuing to meet demand, as measured in miles driven by their current fleet per year. There is currently a gap between current carbon dioxide emissions and the mandated 30% reduction in petroleum consumption as per E.O.13514. There is a lack of data available to show the trend of carbon dioxide emissions of previous years. 15 FAA Campus Carbon Emissions vs. Time Figure 12: FAA Campus Carbon Emissions vs. Time 4. StakeholderAnalysis 4.1. FederalAviationAdministration(FAA) The FAA is responsible for implementing the most cost‐effective method to achieve the goals as described in E.O. 13514. Objective – Develop and enforce a sustainment plan and policy to meet the requirements handed down by the DOT. Tension – The requirements are in addition to the FAA’s mission of aviation safety and must be met using existing resources. 4.2. CouncilonEnvironmentalQualityChairandOfficeofManagementandBudget Director The duties of the CEQ Chair and OMB Director are essentially oversight; making sure the proper progress is being made by the FAA and creating scorecards for their progress through goals and metrics. Also, they are responsible for creating the Steering Committee on Federal Sustainability. Objective – To establish targets and track, verify, and grade the progress of federal departments towards the requirements mandated by E.O. 13514. 16 Tension – Targets can be a challenge to meet. 4.3.FleetManagers There are fleet managers at each of the operational centers who oversee the motor fleet inventory. The fleet manager will allocate vehicles to each charge group based on need and handles any issues with the inventory such as not having an available vehicle. Objective – Continue to meet transportation demand while keeping costs low. Tension – Decreased fleet inventory may complicate allocation of vehicles. 4.3. VehicleUsers The staff that will use the replacement vehicles on a day‐to‐day basis will be concerned with the new vehicle’s capabilities and will be directly affected by the replacement vehicles. Whether or not the vehicles emit more or less GHG’s is likely of secondary concern. Objective – Use vehicles to accomplish work responsibilities more efficiently. Tension – Alternative transportation systems may present a change in the way in which job related tasks are completed. 4.4. GeneralServicesAdministration(GSA) The FAA leases traditional fossil fuel reliant vehicles from the GSA. The GSA is concerned with what vehicles the FAA leases and they contract maintenance on those vehicles to a third‐party maintenance contractor. Objective – Provide guidance for Presidential mandate for Federal Fleet Performance. Tension – Additional reporting requirements. 4.5Community The communities surrounding the operational centers live in residential areas and can be impacted by environmental decisions made by the FAA. Objective – Clean local environment. Tension – Additional tax costs. Major Stakeholders Objective Tension FAA Develop a sustainment plan and policy to The requirements given to the FAA are in meet the requirements handed down by addition to FAA’s primary mission, of the DOT. aviation safety, and must be met using existing resources. CEQ Establish targets and track, verify, and Targets can be a challenge to meet. Chair/OMB grade progress of Federal Departments Director towards requirements mandated by E.O. 13514. 17 Fleet Managers Vehicle Users GSA Continue to meet transportation demand Decreased fleet inventory may while keeping costs low. complicate allocation of vehicles. Use vehicles to accomplish work responsibilities more efficiently. Provide guidance for Presidential mandate for Federal Fleet Performance. Community Clean local environment Alternative transportation systems may present a change in the way in which job related tasks are completed. Additional reporting requirements. Additional tax costs Figure 13: Primary Stakeholders 4.5. FAAEmployees The FAA employees mandate good working conditions, which includes the ability to accomplish work tasks in a timely manner; being able to do so will be affected by the replacement of vehicles due to speed and convenience. 4.6. Taxpayers The funds to accomplish E.O. goals come from tax revenue and are therefore funded by the taxpayers who have a concern that their money is well spent. They want a cost effective, reliable, and safe air space to travel as well as clean air. 4.7. ElectricityCompany This company will have to shoulder the increased electrical demand caused by higher electrical vehicle use on each campus. This may lead to higher emissions at the plant itself. 4.8. DepartmentofEnergy(DoE) The DoE’s FEMP is coordinating with the Office of the Federal Environmental Executive (OFEE) to assist and guide the FAA and other government agencies in the reduction of GHG emissions. They also set forth standards in energy that must be observed. 4.9. DepartmentofTransportation(DoT) Similarly to the FAA, the DoT is concerned only with the FAA meeting its individual sustainability goals set forth by the DoT, and to track and report progress to the OMB. 4.10. EnvironmentalProtectionAgency(EPA) The EPA assists in setting the standards for GHG emissions and fossil fuel reductions. 4.11. SteeringCommitteeonFederalSustainability This is an interagency committee comprised of members of the Federal Environmental Executive and Agency Senior Sustainability Officers who will oversee the progress of the FAA/DoT in meeting sustainability targets. 18 4.12. FederalEnergyManagementProgram(FEMP) They will coordinate with the OFEE to assist in the reduction of GHG emissions required by E.O. 13423 at the Department of Energy level. 4.13. AgencySeniorSustainabilityOfficers(ASSO) The Officers appointed to the Committee will assist in oversight and are concerned with the proper implementation of accepted solutions at the Department of Transportation level. 4.14. OfficeoftheFederalEnvironmentalExecutive(OFEE) Their duty involves monitoring and advising the CEQ Chair and OMB Director at the executive level, in their efforts to achieving E.O. 13423’s policies and goals and also assist organizations in the implementation of solutions and reporting progress to the White House. 4.15. Manufacturers Manufacturers will need to fill the orders of the FAA upon the decision of what vehicles to replace current fleet inventory with. Figure 14: Stakeholder Flowchart 5. DecisionMakingFactors 19 5.1. Vehicleacquisitionandleasingprocesses The FAA has the option of leasing or purchasing its motor fleet vehicles from GSA. Currently, most motor vehicles fueled by fossil fuels are leased by the FAA, with the exception of special project vehicles such as fire trucks, heavy duty trucks, security vehicles, etc. In the case of low speed electric vehicles, these are purchased through GSA instead of being leased. Requests for additional vehicles are submitted by the fleet managers of the operational centers, or other FAA locations that maintain a motor vehicle fleet to the ALO for approval. A determination is made by the ALO based on budget and need. If approved, the vehicle is then ordered through GSA and delivered to the fleet manager for dispersal to the charge group in need of the vehicle, who then provides the vehicle to the branch for use and day to day management of the additional vehicle. The process can be seen in the figure below. Motor Fleet Inventory Chain FAA Logistics Division Fleet Manager s Division by Charge Group Branch by Division Figure 15: Motor Fleet Purchase Chain 5.2. FleetInventorySelectionprocess Use of the fleet at the operational centers is decentralized. Branches within a division are delegated vehicles based on the functions of the branch. Vehicle users within the branch are delegated tasks that require the use of different vehicles, depending on the nature of the task. A vehicle user chooses an admin or operational vehicle depending on if the task is administrative or operational. If the required type of vehicle needed is not available, the user must request a vehicle from the motor pool. Once the vehicle user has acquired a vehicle for the task the task is completed and the vehicle is returned it its original location. The diagram below illustrates the process. Figure 16: Motor Fleet Inventory Vehicle Check Out 5.3. Problemstatement The President has issued Executive Order 13514 mandating that government agencies reduce their petroleum fuel consumption, increase alternative fuel consumption, and optimize their vehicle fleet size. The FAA must reduce its vehicle fleet greenhouse gas emissions to meet the executive order. The 20 Aviation Logistics Organization is in charge of meeting this objective. In order to reach this goal, alternative forms of transportation are being considered as replacements/substitutions for current fleet inventory. As is highlighted by the 2013 government shutdown, a consistent budget is necessary. By reducing the impact of highly variable costs of gas prices and making them fixed or lowering the impact of their volatility, the FAA will benefit from stable costs. The focus of this project is the reduction of the carbon dioxide emissions at the Mike Monroney Aeronautical Center and William J. Hughes Technical Center of the FAA, in accordance with E.O. 13514, while meeting and maintaining travel demand and receiving no additional funding. If the current path is maintained, the FAA will not meet the mandates of E.O. 13514. 5.4. Needstatement The ALO needs a process to analyze Life Cycle Costs of current vehicle fleets versus alternative transportation methods applicable to its two main campuses and by extension other secure facilities. The proposed process will be applied to reduce the vehicle fleet petroleum consumption and carbon dioxide emissions. Implementation of these transportation alternatives will assist the FAA in meeting the mandates of Executive Order 13514. 5.5. Missionrequirements The following mission requirements have been derived from our stakeholders. M.R.1 The system shall analyze the life cycle costs of the current inventory versus alternatives. M.R.2 The system shall propose alternatives that lower the level of carbon dioxide emissions by 12.3% at the Mike Monroney Aeronautical Center and the William J. Hughes Technical Center. M.R.3 The system shall propose transportation portfolios that satisfy up to a 2% increase in demand from a 2013. MR.4 The system shall simulate one full year of demand. 5.6. DerivedRequirements Functional - Vehicles shall allow operational and administrative users and equipment to be transported from one location to the next. - Operational vehicles shall have an area specific to operations cargo storage. o Vehicles shall allow the user to transport small parts, mail, and equipment across the campus. Environmental 21 - The system shall estimate the indirect greenhouse gas emissions (CO2) of alternative vehicles. Financial - Alternative portfolios shall be affordable o The system shall only test alternative transportation portfolios that have an acquisition cost of $X or less. o Portfolios to be considered shall have a LCC less than the current inventory Maintainable - Alternatives shall be maintainable Alternatives shall have a mean time between repairs of no more than X hours. Alternatives shall have a mean time between failures of no more than X hours. Infrastructure - Vehicle energy consumption shall be monitored. The system shall include the acquisition cost of the infrastructure in the LCC cost of the alternative portfolio. 6. DesignAlternatives 22 Figure 17: Feasible Design Alternatives Requirements Reduce Meet Maintain Reduce Reduce Meets requirement Reportable Operational or Reduce Feasible Additional research required Inventory Emissions Inventory Demand LCC Status Quo X X X LSEVs ‐ NEVs ‐ ‐ ‐ Shuttle X X Bikes X X Alternatives Natural Gas ‐ ‐ ‐ ‐ ‐ VTC/Telecom X Higher MPG Vehicles X X X H2 Vehicles ‐ ‐ ‐ X LSEVs and Traditional Alternatives ‐ Does not meet requirement Figure 18: Alternative verse Requirement Matrix 7. SimulationDesign The proposed model will take data given regarding the Mike Monroney Aeronautical Center and the William J. Hughes Technical Center to simulate the demand of the two campuses. The demand analysis will be used to calculate the inventory necessary to meet the demand of the campuses. The demand analysis will output the inventory and the energy consumed to meet the demand. The LCC costs of the portfolio will then be calculated through a deterministic and stochastic life cycle cost models. The individual portfolios will then be weighed against each other based upon their cost, CO2 emissions, and inventory size. Figures 19 and 20 show the null and alternate hypotheses for our simulation. The flow diagram for the entire simulation through all phases can be seen in Figure 21. 23 H10:μLCC ≤ X alt cost H11:μLCC > X cost H20: μC02≥ 264t/year H21: μC02 < 264t/year Figure 19: Hypothesis Tests Figure 20: System Model Flow Diagram 7.1.DataAnalysis Data analysis was conducted to accumulate the required information for the inputs of the models based on statistical information of the two campuses. This included building, personnel, and vehicle data. The building and personnel data for the two campuses can be seen in the following figures shows the 24 statistical information related to the vehicles including the number of vehicles, average miles per gallon, CO2 emissions, and average monthly miles driven. The operational campuses have different compositions because of their different functions. The aeronautical center is responsible for administrative functions such as logistics, training, and policy development. The functions of the aeronautical center are similarly reflected by its building composition. The following figure illustrates that the aeronautical center has a large percentage of its buildings are training facilities and offices devoted to administrative functions. The aeronautical center also has a large portion of warehouses because it ships many packages. Figure 21: Aeronautical Center Building Percentages Many operational tasks are performed at the William J. Hughes Technical Center. The tech center is responsible for performing many engineering activities at the campus, such as aviation equipment testing, research, and design. A large proportion of the campus’s buildings are laboratories to perform these functions. 25 Figure 22: Tech Center Building Make up 7.1.1. OperationalCenterMotorFleet The technical and aeronautical centers have different vehicle portfolios. Figure 4 gives general statistics regarding the licensed ground vehicle fleet of the Mike Monroney Aeronautical Center and William J. Hughes Technical Center. Number Number of Operational Inventory Vehicles Technical Center Aeronautical Center 42 47 27 31 Number Total Monthly Average Administrative CO2 Emissions Vehicle MPG Vehicles (Metric Ton) 19 2 18 15 6.4 15.7 Average Monthly Miles Driven Average Monthly Lease Cost 246 550 $ 268 $ 245 Figure 23: Ground Fleet Statistics of FAA Centers 26 The William J. Hughes Technical Center and Mike Monroney Aeronautical Center have varying fuel type portfolios. The Tech Center has a higher proportion of gasoline vehicles. Neither of the centers have access to ethanol fuel though they both have sizable portfolio of ethanol fueled vehicles. The ethanol vehicles are capable of running off gasoline fuel. Tech Center Vehicle Fuel Types 30 25 20 ACT 15 AMC 10 5 0 Ethanol Gasoline Hybrid Diesel Figure 24: Fuel Type Portfolio for Aeronautical and Technical Centers Ground Vehicle Fleet The two centers have different demand. The Mike Monroney Aeronautical Center has more low usage vehicles; vehicles that are used less than 100 miles. Low usage vehicles constitute 40% of the aeronautical center ground fleet portfolio. The William J. Hughes Technical Center has a more even distribution of mileage driven a month per vehicle. Monthly Vehicle Demand Number of Vehicles 30 25 20 Technical Center 15 Aeronautical Center 10 5 0 0 ‐ 100 101‐200 201‐300 301‐400 401‐500 >500 Calculated Average Montly Mileage Figure 25: Average Demand of Reportable Vehicles 27 The two centers have similarly reflected CO2 emissions; the aeronautical center has more pronounced tails. This is to be expected because emissions are a function of miles driven, fuel type, and fuel efficiency. Average Monthly CO2 Emissions 35 30 Frequency 25 20 Tech Center 15 Aero Center 10 5 0 0‐.1 .11‐.2 .21‐.3 >.3 Calculated Average Monthly CO2 emissions per month Figure 26: Direct Carbon Dioxide Emissions of the Current Non Low Speed The inventory was split up into operational and administrative vehicles based on their mpg, weight, miles drive, and engine size. Operational vehicles are vehicles that are used to support the National Airspace System. Administrative vehicles are used to move people and mail. Types of Vehicles 35 Number of Vehicles 30 25 20 Tech Center 15 Aero Center 10 5 0 Operational Vehicles Administrative Vehicles Figure 27: Uses of Current Vehicle Purpose 28 The figure shows the inventory of the Mike Monroney Aeronautical Center and William J Hughes Technical Center split up between vehicle types. The aeronautical center has a large proportion of its vehicle allocated to pickups. The Technical Center has a more diverse portfolio. Vehicle Inventory by Type Technical Center Aeronautical Center Number of Vehicles 25 20 21 15 10 10 5 8 1 6 11 10 7 8 1 2 0 3 1 0 Sedan Minivan Van SUV Pickup Bus Other Vehicle Type Figure 28: Operational Centers Vehicle Inventory by Type The following figure illustrates the amount of monthly mileage by vehicle type of the two campuses. The monthly miles driven by trucks are unexpectedly large. The data outlier might be explained by off campus demand and the distribution of large aviation equipment from its warehouses. 29 Monthly Mileage by Type Total Average Monthly Mileage Technical Center Aeronautical Center 18000 16000 14000 12000 10000 8000 6000 4000 2000 0 Sedan Minivan Van SUV Pickup Bus Other Vehicle Type Figure 29: Monthly Mileage by Vehicle Type Figure 30: Campus Vehicle Statistics 8. MethodofAnalysis 8.1. DesignofExperiment(DOE) In order to determine the best alternative for reducing CO2 emissions by optimizing fleet inventory, we will simulate one year of campus events requiring the use of operational and administrative fleet vehicles. The output will be the number of vehicles needed in fleet inventory to meet demand on the campuses. A buffer will also be added to the demand to ensure vehicles within the alternatives will be able to meet fluctuations. The results of this experiment will be used to determine the best alternative for fleet optimization and reducing CO2 emissions based on requirements. The life cycle cost models will also be used as part of the decision making process by comparing costs against utility. Assumptions will be used as necessary to complete the model. The demand model will use historic campus data and current vehicle inventory as inputs along with the expected value of the yearly demand for the motor fleet of each campus. The demand model will output the required number of vehicles to meet demand for each alternative portfolio as well as the CO2 emissions calculated for each portfolio. The status quo will output the current inventory of vehicles and the yearly CO2 emissions as shown in Figure 22. Figure 23 shows the inputs and outputs of each of the life cycle cost models that will be applied to each portfolio and status quo scenarios. 30 Figure 31: Demand Model DOE Figure 32: Life Cycle Costs DOE 8.1.1 BusinessRules&Assumptions 1.1 Passenger & Distance related rules 31 1.1.1 Any vehicle that is identified as maintenance will have 1‐2 persons (max of 3) 1.1.1.1 Any vehicle that is identified as maintenance in nature will travel xx‐ yy miles 1.1.2 Any vehicle identified as administrative will have 1‐4 persons (max of 5) 1.1.2.1 Any vehicle that is identified as administrative in nature will travel xx‐ yy miles 1.1.2.2 1.1.3 A LSEV will travel no further than its battery will permit without recharging. 1.1.3.1 A LSEV that travels and exhausts its battery but is within x miles of a recharging station will then be able to travel further after (after recharge time is taken into account). 1.2 Vehicle classifications 1.2.1 Any vehicle that is classified as maintenance will be assumed to be used for the following purposes: Transport equipment Transport maintenance personnel 1.2.2 Any vehicle that is classified as administrative will be assumed to be used for the following purposes: Transport staff/students Deliver mail 1.3 Vehicle Maintenance 1.3.1 It will be assumed that all vehicles are well maintained and get the full (average) MPG. 1.3.1.1 It will be assumed since current vehicles are leased major maintenance with costs exceeding $XYZ will not be incorporated into the budget 1.3.2 It will be assumed that vehicle (ethanol and petroleum vehicles) will require an oil change at least once a year (~every 3000 miles) 1.3.3 It will be assumed that LSEV batteries will be replaced every XYZ miles or XY charges 1.3.3.1 It will be assumed that the LSEV battery replacement cost will include disposal and cost YYYY. 1.3.4 It will be assumed that out of the entire fleet no more than x% will be down. 1.3.4.1 It will be assumed that downtime will be no longer than X days per year. 1.3.4.1.1 It will be assumed that the average downtime for LSEVS will cost X per day down 1.3.4.1.2 It will be assumed that the average downtime for Petroleum Vehicles will cost X per day down 1.3.4.1.3 It will be assumed that the average downtime for Ethanol Vehicles will cost X per day down 32 1.3.5 It will be assumed that the petroleum vehicles will cost XX dollars per gallon/mile. 1.3.5.1 It will be assumed the average petroleum vehicle will be able to travel a maximum of YYY miles. 1.3.6 It will be assumed that petroleum & alternative vehicles will produce X (need units) GHG per mile (choose form of distance). 8.2. PhaseI Phase I is the demand model which will generate events for each campus in order to simulate the demand for the vehicle fleet and determine how many vehicles are needed to meet the current demand. These events will be based on the number of trips, passengers, distance, time of use, and load capacity. A comparator will be used to determine if the fleet size and CO2 emissions have been reduced for each alternative. Figure 33: Demand Analysis Flow Diagram The first component of the demand model is an event generator as shown in Figure 36. Historic data determines the likelihood of events based on the type, administrative or operational, and which charge group. An event is created based on these attribute likelihoods and are composed of an origin building, the charge group that owns the vehicle, a destination, number of passengers, and the service time or how long the vehicle will be in use. These events are then passed to the next section of the model. The notional distributions to be used for the event generator can be seen in Figures 34 and 35. 33 AMC Variables Units Distrubtion Min Off Campus Op Arrival events/day Exponential TBD Off Campus Admin Arrival events/day Exponential TBD On Campus Op Arrival events/day Exponential TBD On Campus Admin Arrival events/day Exponential TBD Service Time hours Triangle 0.5 Charge code Charge code weighted discrete People demand operational people discrete People demand Admin people discrete Origin Building building weighted discrete Destination Building building weighted discrete OR Distance Aero miles lognormal Max Mean N/A 1 1 N/A N/A Reasoning Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD .095 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD .088 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 244 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 86 as exponential. It is a well established distrobution. Recently received data to analysize data 6.5 TBD distribution more accurately. Max and min derived from sponsor discussions. N/A dependent Weighted by inventory size of charge code 3 1 A certain range of passegners is more common 4 2 A certain range of passegners is more common N/A dependent Based on the event type. N/A dependent Based on the event type. 0.015 2.1 .07 The Aero Center's buildings are tightly spaced and we expect a small variance Figure 34: Aeronautical Center Simulation Distributions ACT Variables Units Distrubtion Min Off Campus Op Arrival events/day Exponential TBD Off Campus Admin Arrival events/day Exponential TBD On Campus Op Arrival events/day Exponential TBD On Campus Admin Arrival events/day Exponential TBD Service Time hours Triangle 0.5 Charge code Charge code weighted discrete People demand operational people discrete People demand Admin people discrete Origin Building building weighted discrete Destination Building building weighted discrete OR Distance Tech miles triangular Max Mean N/A 1 1 N/A N/A Reasoning Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 0.088 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 0.01 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 145 as exponential. It is a well established distrobution. Lack of data and the actual distribution is unknown. Traditionally arrivals can be modeled TBD 24 as exponential. It is a well established distrobution. Recently received data to analysize data 6.5 TBD distribution more accurately. Max and min derived from sponsor discussions. N/A dependent Weighted by inventory size of charge code 3 1 A certain range of passegners is more common 4 2 A certain range of passegners is more common N/A dependent Weighted by the event type. N/A dependent Weighted by the event type. 0.015 3.3 .44 The Tech Center's buildings are farther spaced and have a large variance in distance Figure 35: Technical Center Simulation Distributions 34 Figure 36: Event Generator Once an event has been created, it is then passed to the queue of the demand model as shown in the figure below. The queuing system assigns a vehicle based on the charge group and type of event. This vehicle will be tracked and considered unavailable until the service time has been completed. Upon completion, the vehicle is then put back in to the inventory and available for another event. The system will keep assigning vehicles as necessary to meet the demand until the expected value of demand has been met. The generated inventory list is the total vehicle inventory needed to meet the campus demand. Additional statistics such as miles driven, number of trips, and down time will also be tracked to analyze availability. This data will then be used to conduct analysis and attempt to determine a more optimal fleet size for each of the operational centers. Figure 37: Queuing System Equations to be used for the calculation and analysis within the demand model can be seen below: 35 8.3. PhaseII The second phase is the deterministic life cycle cost model. Phase II will calculate the life cycle costs for each alternative based on the cost analysis conducted for each component of the system. The life cycle cost equation will be a summation of acquisition cost, maintenance costs, and energy costs. For any alternative that is eligible for incentives, this benefit will be subtracted from the acquisition cost. The equation for the life cycle cost model formula is calculated from the information below. • Lifecycle cost= Acquisition ‐ Incentives + Maintenance & Repair + Energy • L(x)= A(x) – I(x) + M(x)+ E(x) • Where x is in terms of present values by discounting • Present Value= Future Value/(1+i)^n Preliminary data for acquisition, maintenance, and energy costs can be seen in Figures 38 through 40. These numbers will be used to calculate the life cycle costs for the generated motor fleet inventory of each operational center, and then projected out through the year 2020. Figure 38: Acquisition Costs 36 Figure 39: Maintenance Costs and Formula Figure 40: Energy Costs 8.4. PhaseIII Phase III will use a stochastic model to project life cycle costs through 2020. The model will use projections for energy costs, and projected trends for the remaining costs of the life cycle cost equation. The projected costs will be applied to increases or decreases in projected fleet inventory based on demand. The equation for the life cycle cost model equation can be seen in Figure 29. n C acq n n C ma int C ener t t t t 1 (1 d ) t 1 (1 d ) t 1 (1 d ) Figure 41: Life Cycle Cost Equation 37 8.5. ValueHierarchy FAA Campus Transportation Alternatives Efficiency Utility Demand Maximum Weight Maximum Capacity CO2 Emission Reduction Power Consumption Figure 42: Value Hierarchy 8.6. PhaseIIresults 8.7. PhaseIIIresults 8.8. RankedResults 8.9. Costvs.Utility 38 Utility Value 4 3 2 Alternatives 1 0 0 1 2 Total Life Cycle Cost 3 Figure 43: Notional Cost vs Utility Graph 8.10. Recommendations Although we do not have results from our models as of yet, a few preliminary recommendations can be made based on our analysis and research: 1. Utilize Video Teleconference and Teleworking resources when appropriate. 2. Centralize motor pool 3. Keep track of individual usage a. Trip time b. Trip length c. Reason for vehicle 4. Use LSEV’s in place of administrative vehicles with terrain and weather permitting. (tentative) 5. Use LSEV’s in place of operational vehicles carrying loads weighing no more than YY lbs. (tentative) 39 9. Acknowledgements 9.1. ElectricVehicleLifeCycleCosts 9.2. StochasticVariables 10. ProjectPlan 10.1. WorkBreakdownStructure(WBS) Figure 44: Work Breakdown Structure 40 10.2. Budget Budget $80,000.00 $70,000.00 $60,000.00 Dollars $50,000.00 PV $40,000.00 AC $30,000.00 Worst Case $20,000.00 Best Case $10,000.00 $0.00 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 Weeks Figure 45: Project Budget vs. Time 10.3. CostPerformanceIndex(CPI)andSchedulePerformanceIndex(SPI) The Cost Performance Index (CPI) and Schedule Performance Index (SPI) have been calculated weekly over the course of the project. Figure 1 shows the weekly ratio value which provides data as to how far off the team was to staying on budget and schedule; a 1 representing being on cost and schedule. 41 CPI vs SPI 1.40 1.20 1.00 Ratio 0.80 CPI 0.60 SPI 0.40 0.20 0.00 1 2 3 4 5 6 7 8 9 Weeks Figure 46: CPI vs. SPI 42 10.4. Schedule Figure 47: Senior Design Schedule With Critical Path Highlighted in Red Figure 19 represents our schedule with the critical path up until winter break. We created an estimate date for the IEEE paper. The lack of critical path into the bottom two sub calendars can be explained by the lack of predecessor successor relationships as we plan to divide our resources during winter break and at one point be running simulation and analysis simultaneously. 43 Figure 48: Task Breakdown of Project Plan Schedule Figure 20 is our list of tasks, the highlighted tasks representing the tasks along the critical path. 44 10.5. Risk Figure 21 presents identified project risks and their associated mitigations. Initial Risk Level 17 23 7 15 Risk Description Mitigation Mitigated Completion Risk level date Mitigation IF the government shutdown continues, 1. Develop business rules to approximate THEN the collection of data will be slowed missing data IF not enough hours are dedicated to the 1. Start on simulation earlier. simulation, THEN results will not be 2. Schedule more hours for simulation work available for analysis IF alternatives do not meet future demand 1. Add potential projection of future demand to THEN fleet inventory needs will be incorrect simulation based on FAA hiring trends IF assumptions used for simulation are 1. Consult subject matter experts 2. Seek approval from sponsors incorrect THEN results will be misleading 10/25/2013 8 Complete 6 1/1/2014 6 11/1/2013 9 th Risk Management Guide for DOD Acquisition 6 ed. August, 2006 Figure 49: Risk and Mitigation Table 45 11. References [1] http://www.faa.gov/about/office_org/headquarters_offices/arc/key_officials/coppedge/ [2] http://www.faa.gov/about/office_org/headquarters_offices/ang/offices/tc/about/ [3] http://www.gpo.gov/fdsys/pkg/FR‐2009‐10‐08/pdf/E9‐24518.pdf [4] http://www.epa.gov/climatechange/science/indicators/ghg/us‐ghg‐emissions.html [5] http://www.epa.gov/climatechange/science/indicators/ghg/global‐ghg‐emissions.html [6] http://www.eia.gov/tools/faqs/faq.cfm?id=23&t=10 [7] http://www.eia.gov/todayinenergy/detail/2013‐07‐25/eia‐projects‐world‐energy‐consumption‐will‐ increase‐56‐2040 [8] http://www.afdc.energy.gov/vehicles/propane.html [9] http://www.eia.gov/forecasts/aeo/chapter_executive_summary.cfm [10] http://www.afdc.energy.gov/vehicles/propane.html [11] http://www.eia.gov/forecasts/aeo/MT_electric.cfm. [12] http://www.google.com/publicdata/explore?ds=d5bncppjof8f9_&met_y=eg_use_pcap_kg_oe&hl=en&d l=en&idim=country:USA:CHN:CAN#!ctype=l&strail=false&bcs=d&nselm=h&met_y=eg_use_pcap_kg_oe &scale_y=lin&ind_y=false&rdim=region&idim=country:USA&ifdim=region&tdim=true&tstart=90842400 0000&tend=1350273600000&hl=en_US&dl=en&ind=false 46