Pre–Charge The Troubleshooting Guide System

advertisement

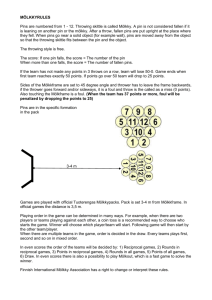

The Pre–Charge System Troubleshooting Guide Joshua Straquadine Table of Contents Glossary of Terms Pin—Name for any conductive metal protrusion designed for 2 Introduction 3 Quick Guide, Warning Printed Circuit Board (PCB)—A flat panel with copper 4 Equipment Needed “wires” etched into its surface. PCBs allow for easy interconnection and sturdy mounting for electrical systems. 5 System Overview Trace—Name for the conductive “wires” which are printed 6 High Voltage Map 7 Isolating the Problem 9 Step 1: General Inspection A three-pin semiconductor device which acts like an electrically controlled switch. Changing the voltage one of the pins can connect or disconnect the other two pins from each other. 11 Step 2: The Relay Relay—Electromagnetic device which acts like an electrically 13 Step 3: The Logic Gate 15 Step 4: The Comparator 17 Still Having Problems? nents. Passing current through any electrical component will cause it to heat up, and the heat sink prevents the heat from damaging it. 18 Glossary of Terms Logic gate—electrical component which performs operations connecting electrical components together. onto a printed circuit board, which create electrical connections between components. MOSFET—Metal-Oxide-Semiconductor Field Effect Transistor. controlled switch. Passing electrical current through the electromagnetic coil creates a magnetic field which closes a switch. Heat Sink—device for dissipating heat from electrical compo- or makes decisions based on its input signals. Comparator—component which takes in two analog signals, and puts out a digital signal depending on which input is at a higher voltage. 1 18 The Pre-Charge System Still having problems? If the problem still exists, consult the detailed design logs which can be found in the Team PrISUm 2011 Electrical Documentation binder. If any questions persist, contact the original designer of the system. He can be reached through email or phone. Joshua Straquadine Email: joshuas@iastate.edu Phone: 952-857-9698 17 Troubleshooting Guide Introduction The topic of solar-powered cars always brings up one nagging question: what happens if it’s cloudy? The answer is that all solar cars carry with them a very large battery pack, which can store the sun’s energy for a cloudy day. Unlike normal automotive batteries, which are commonly charged to 12V, these battery assemblies easily reach above 100 volts when fully charged. While the electronics in the solar car have been designed to work with these high voltages, connecting them directly to the batteries will produce a sudden pulse of dangerously high current before it stabilizes. This current spike can and will damage many of the systems in the solar car. To prevent this event altogether, the electronics must be “precharged,” where the voltage is raised up slowly over a period of time. The pre-charge system makes this possible. 2 Quick Guide Two main problems may be attributed to a malfunctioning pre-charge system: The solar car will not move when the gas pedal is pressed. The solar car’s batteries will not charge from the solar array. Both problems arise from the same root problem, which is that the precharge system cannot or does not close the main battery relay. DANGER! Figure 10: Top view of the pre-charge board, highlighting the location of the comparator. Refer back to Figure 4 on page 8 if you’re unsure about pin numbers. The components on this printed circuit board experience very high voltages (excess of 100 volts DC) when properly wired. EXTREME caution must be exercised when troubleshooting this system. As with all electronics, short-circuiting two exposed pins can and will cause damage to the components. On this high voltage system, however, shortcircuiting two pins can also cause destruction of the probe device, burns, and even electrocution. If the voltage on pin 2 is: Voltage on pin 6 should be: Greater than pin 3 Low Less than pin 3 High Table 1: Table describing the comparator’s function 3 16 Equipment Needed Step 4: The Comparator As mentioned earlier, the pre-charge system slowly increases the voltage for the electronics in the car. In order to decide when to stop the pre-charge process, the system requires some sort of sensor. A comparator module simply compares two analog voltages and outputs a digital signal (high or low) depending on which of those signals is larger. In the context of the precharge system, the comparator makes the decision on whether or not the high-voltage electronics are at a high enough voltage to close the relay. The comparator device on this board is an 8-pin DIP package, as seen in Figure 10. Pins 2 and 3 are the inputs, and pin 6 is the output. Carefully probe the voltages on these three pins. Compare these voltages to the cases in Table 2. If reality doesn’t match one of these cases, replace the chip. One Handheld Voltmeter Two Voltmeter Probes One Soldering Iron One Spool of Solder Tip: Whenever possible, use a testing probe with a spring loaded clip like in Figure 9. They allow you to set it once and then free up your hands, letting you accomplish more. 15 One Malfunctioning Solar Car Figure 9: Spring loaded testing probes can be clipped directly to the pins under test. 4 Overview: What’s what on this board? Figure 1: Elevated view of the board, labeling important components Figure 8: Top view of the pre-charge board, highlighting the location of the logic chip. Refer back to Figure 4 on page 8 if you’re unsure about pin numbers If pin 5 is: And pin 6 is: Then pin 4 should be: Low Low High Low High Low High Low Low High High Low Table 1: Logic function of the chip 5 Figure 2: The connector, shown looking edge-on with the board, labeling the functions of each pin. 14 Step 3: The Logic Gate Digital logic circuits are the basis of any computer system. These circuits are used to perform operations and make decisions. They can require any number of input signals, and generate any number of outputs. Because the system is digital, the inputs and outputs are either “high” (five volts) or “low” (zero volts.) A simple two-input, two-output logic circuit has been implemented in the pre-charge system. It appears in the circuit as a 14-pin Dual Inline Package (DIP) as shown in Figure 8. Pins 1 (top left) and 4 (fourth from top on the left) are the outputs. Pin 1 controls the pre-charge functions of the board, while pin 4 controls the main relay. Carefully probe the voltages on pins 4, 5, and 6. Pins number 5 and 6 are inputs, and pin 4 is an output. This specific chip performs what is known as the NOR function. If neither the voltage on pin 5 NOR the voltage on pin 6 is high, then the output voltage on pin 4 will be high. If the pins do not match one of the cases in Table 1 below, then replace the logic chip. If they do match the table, but still don’t close the relay correctly, proceed to the next section. 13 High Voltage Map The locations marked here in yellow will be at a high voltage when connected, even if the system is off. Top View: The top of the board has been designed to minimize exposure to high voltage Side View: The four exposed pins beneath the black heat sink will always be at a high voltage. Bottom View: Many of the pins on the bottom of this board will be at a high voltage, making the bottom the most dangerous area. 6 Isolating the Problem Before spending much time probing the pre-charge system, test around to make sure that pre-charge is actually the culprit. Note: Never use the continuity setting on a multimeter to check if a relay is closed. Instead, measure the voltage between the terminals. Zero volts means the relay is closed. Check to see if the connector has been plugged into the pre-charge board. The single, eight-wire connector must make good contact to properly transmit signals to and from the board. Using a voltmeter, test the voltage from the power supply (the two light blue pins in Figure 3). These two wires attach directly to the power regulation system, and should be at a voltage at 12 volts (V). If the voltage between these wires is substantially different from 12 V, troubleshoot the Power Regulation System. Check the input “enable” signal from the battery protection system (BPS). This signal will appear on the pin labeled in green in Figure 3. The voltage on this pin should be 5 V when the system is disabled, and 0 V when enabled. If the voltage on this line doesn’t match up to the proper case, then troubleshoot the Battery Protection System. 7 Figure 5: Schematic symbol of a relay. The magnetic field created by the electromagnet pulls the switch closed. Figure 6: Image of the main relay. The two thin protruding wires connect internally to the electromagnet, while the bolts on top connect to the switch. Figure 7: The connector, seen looking edge-on with the board. Marked in yellow are the two pins connected to the main relay’s electromagnet. The voltage between these two pins directly controls when the relay switch should close. 12 Step 2: The Relay A relay is basically a switch controlled by an electromagnet (Figure 5). When the magnet is energized, the switch will close, completing the electrical circuit. A very large, robust relay is used to connect or disconnect the battery pack in the solar car, and it is directly controlled by the pre-charge system. Whenever the relay opens or closes, it is accompanied by a loud click. Tip: Disconnect the pre-charge system entirely for this step. You can insert your voltmeter probes directly into the plug to measure what the other systems are sending to the pre-charge board. In the solar car, this component IS NOT found on the precharge board, simply because of its size. It is located nearby, hooked up to the pre-charge board through the connector. The relay used in the solar car can be seen in Figure 6. Begin by probing the voltage between the C+ and C- pins on the connector (Figure 7). The voltmeter will read 12 volts if pre-charge is trying to close the relay and zero volts if it is not. If the difference between these two pins is 12 V but the relay hasn’t closed, the relay must have failed. Replace the relay with a new one. If the relay responds correctly, then the voltage on the pins must be incorrect. For instance, if the battery protection system is sending the enable signal but the relay pins are at zero volts, some portion of the control system on the board has failed. If this is the case, proceed to the next section. 11 Figure 3: The pre-charge connector, as seen looking edge-on with the board, showing power connections (cyan) and enable signal connection (green) If the problem still exists after checking the above points, the problem must be somewhere within the pre-charge system. 8 Step 1: General Inspection With many electronic systems, problems can be found quickly and easily just by looking at it. Give the board a quick once-over and ask yourself these simple questions: Is the power on? Has the connector been plugged in? Are all of the components installed? Are they all installed correctly? Especially with components in a Dual Inline Package (DIP), it’s easy to install a component backwards. Also, this board contains two 8-pin DIP packages with different part numbers. Refer to Figure 4 to check the orientation of the components. Figure 4: Dual Inline Package (DIP) components and sockets. The sockets make it easy to replace a damaged component, but also make it easy to insert components backwards. If the board still doesn’t work after running though these questions, proceed to the next section. Do any of the components show signs of physical damage? Some devices can burn, melt, smoke, or even explode. Are the solder joints complete? Smooth and shiny joints are best; jagged surfaces indicate weak connections. 9 Tip: If you find yourself repeatedly testing the same hard-to-reach pin, solder an extension wire to it. You can easily remove it when you’re done. 10 Joshua Straquadine English 314 Pre-Charge System Troubleshooting Guide Usability Test Plan The purpose of this troubleshooting guide is to assist a member of the solar car team with finding the problem with, and repairing, a malfunctioning pre-charge system. This document assumes that the reader can read and understand English at an eighth grade level or above, already understands the most basic electrical concepts, and is proficient in the use of a voltmeter. Beyond that, however, nothing else is assumed. The board is presented as if the reader has never seen it before. In order to verify the document’s usability, the following test procedure will be followed: The pre-charge board will be “broken,” simulating a fault which is addressed in the document. For safety, the device will be removed from the high-voltage components of the solar car and instead hooked up to an alternate test rig which can simulate the same conditions, simply at a safer voltage. The reader will be provided all of the necessary equipment: o The “malfunctioning” circuit board and testing rig o Voltmeter and probes o Soldering iron and solder o The troubleshooting guide The reader will be asked to identify and remedy the simulated problem. The entire test will be repeated, this time simulating a different fault. During this procedure, the author will observe the reader’s reactions. Ultimately, the reader’s ability to find and fix the problem will determine the success or failure of the document. Date: To: From: Subject: March 21, 2011 Prof. M. Satterwhite, Engl 314 Joshua Straquadine Results of usability test for Pre-Charge Troubleshooting Guide The usability test outlined in the usability test plan was carried out on Saturday, March 19th. All of the specified conditions were met, with one exception. The reader did not, as specified, have any prior experience with any electrical systems, and did not have a basic understanding of electrical concepts or the use of electrical test equipment. To even the playing field for this test, I instructed her very briefly on a few topics, such as how to use a voltmeter, but nothing specific to the pre-charge system. This test was conducted twice, with two different simulated “fault” conditions. The first was that the logic chip was inserted backwards into the system, and the second was that the comparator chip was replaced with a faulty one. In both cases, the subject was able to find and fix the problems. The reader was able to find all of the necessary information and hints to complete the task, but she did not always have an easy time navigating the text. She frequently had to flip between pages (which were at that time full 8½ by 11 sheets) to reference the different tables and figures. Usually this problem was exacerbated by the fact that she held the voltmeter probes in one hand and flipped the page with the other. Clearly, that format simply wasn’t ideal for the context of use, and has since been reduced to an 8½ by 5½ booklet. I considered rearranging or repeating the important tables and figures, but decided against it. In order to speed along the process of finding the desired graphic or chart, I included a table of contents inside the front cover. Also, the reader had to ask me a few times regarding terminology. All of the concepts were those which I had thought to be very basic, and those which would have been understood by a beginner electrical or computer engineering student. To expand my audience, however, I decided to include a brief glossary of terms inside the back cover of the document. Other than the above points, minimal changes have been made to the document. The test subject did not have any problems reading and understanding the visuals or orienting herself on the circuit board. She was able to follow the logical progression from step to step, and could easily avoid the hazardous “high voltage.” As was specified in the test plan, the high voltage was actually removed from the circuit, but the test subject was able to avoid it anyway. Finally, as an added bonus, she was able to glean an understanding of several basic electrical ideas from it, even though that was not the original goal. Overall, the document was a success, and it has been improved even further since the test.