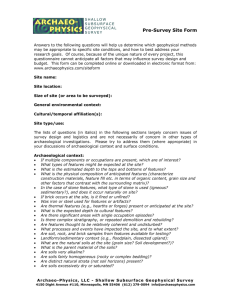

Soils

advertisement