Hubs & Spindles

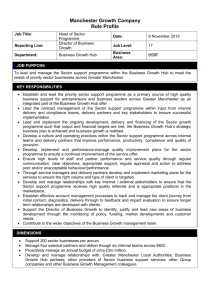

advertisement