Application Note Simple, Efficient 96-Well Plate High Throughput

advertisement

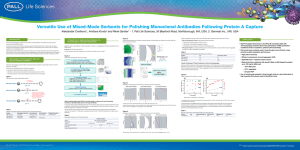

Application Note USTR 2795 Simple, Efficient 96-Well Plate High Throughput Screening Lab Method to Optimize the Use of Mixed-Mode Chromatography Sorbents for the Purification of a Monoclonal Antibody Summary Introduction The benefits of the unique selectivity and chemical stability offered by mixed-mode chromatography for the purification of monoclonal antibodies (MAbs) are well established. Rapid determination of optimum operating conditions earlier in process development maximizes the value of these industrial adsorbents. Current platforms for MAb purification, mostly relying on Protein A as a first capture step, consist of two to three chromatography steps. These platforms are robust and efficient but significantly increase downstream purification costs. To decrease manufacturing costs, industry is increasingly considering the use of alternative purification schemes that could avoid the use of affinity on Protein A sorbents, in addition to reducing the number of steps. This study describes the use of low cost, easy-to-use bench technology to perform high throughput screening (HTS) to optimize separation conditions for the purification of monoclonal antibody using Pall mixedmode chromatography sorbents. Screening conditions and analytical results were completed in three days. Subsequent transfer of conditions to a dynamic column system (1 mL column) were completed in two days. The complete optimization process can therefore take place in a single week. The study shows that the optimized use of HEA HyperCel™ mixed-mode sorbent after a first capture on Protein A could lead to a robust two-step MAb purification process. Mixed-mode chromatography sorbents could fix these issues. Pall MEP, HEA, and PPA HyperCel mixed-mode sorbents carry mixed-mode synthetic ligands immobilized on a robust and scalable matrix (HyperCel) that confers high porosity, chemical stability and excellent stability to harsh cleaning-inplace conditions (1 M NaOH). The ligands include aliphatic (HEA – hexylamine) and aromatic (MEP – mercaptoethylpyridine, PPA – phenylpropylamine) groups (Figure 1). Figure 1 Ligand structures and schematic representation of the adsorption (mostly relying on hydrophobic interactions) and desorption (mainly driven by electrostatic repulsion) mechanism of HyperCel mixed-mode sorbents. These mixed-mode ligands contain hydrophobic (aliphatic chain or aromatic ring) and electrostatic (amine group, hydroxyl hydrogen bonding groups) components. For HEA and PPA HyperCel ligands, electrostatic interactions play a role in protein adsorption at low to moderate conductivity, whereas protein capture by hydrophobic interaction is favored by adding salt to the sample. Protein elution is also controlled by both types of interaction. This unique mechanism of separation on mixed-mode chromatography sorbents offers new selectivities that can reduce the number of purification steps for MAb purification processes. However, to achieve the best separation results, this type of separation requires a good optimization of pH and conductivity conditions. In order to provide a simple tool to optimize the use of mixed-mode sorbents in a MAb purification process, a high throughput screening method based on DoE combined with 96-well plate experiments was developed (Figure 2). A mixed-mode sorbent, HEA HyperCel, was used as a second step of a MAb purification after capture on Protein A. Optimum pH and conductivity were screened to obtain the best performances (yield of recovery and HCPs removal). 2 Figure 2 Optimization of chromatographic run conditions using the combination of DoE and experiments on microplates. Materials and Methods Analytical Methods Quantification of HCP Host Cell Proteins (HCPs) Quantification of HCPs was done by ELISA using a kit from Cygnus Technologies (HCP Host Cell Proteins, #F015). Samples were diluted in a range of 1/1 to 1/10000 depending on the step analyzed. Protein Quantification Antibodies were quantified throughout the purification steps either by evaluation of the peak area obtained during SEC-HPLC analysis or by A280nm measurement using a Nanodrop* 1000 (Thermo Scientific). Protein concentrations were calculated using a mass extinction coefficient of 13.7 at 280 nm for a 1% (10 mg/mL) IgG solution. Preparation of a Post-Protein A Pool As HEA HyperCel sorbent was used as a second purification step, a post-Protein A pool was prepared using a Protein A agarose sorbent. 120 mL of HCP clarified cell culture supernatant containing 1.7 g/L MAb (210 mg total MAb) were loaded onto the Protein A column at 28 mg/mL of sorbent and the MAb was eluted using 10 mM glycine-HCl, pH 3.5. A total of 180 mg post-Protein A MAb pool was recovered (85% yield) and used to screen the best conditions to use on HEA HyperCel sorbent. The HCP content was 400 ppm, whereas the HCP concentration in the initial MAb feedstock was 60,000 ppm. Design of Experiments (DoE) for Screening Conditions on HEA HyperCel Sorbent in 96-well Plates Using statistical models, DoE allows the determination of the effects of different factors on the analyzed responses, and the best run conditions. The factors studied were pH and conductivity for load, wash and elution. The responses analyzed were MAb yield of recovery and CHOPs removal. Considering the total number of factors to be studied, we performed a first screening by varying the load and wash conditions. We used a 4 factors D-Optimal response surface design generated using the Modde◆ software to establish the list of experiments to be performed. The design chosen generated a series of 27 experiments, including one experimental condition performed in triplicate to assess the experimental reproducibility. The experimental points with a wash pH higher than the load pH were removed from the list, as raising the pH would result in increasing interactions to the mixed-mode resin, which is not wished during a washing step. As several points were excluded, the design was slightly modified in order to fully explore the design region contained within the factor testing ranges. The final list of experimental points is shown in Table 1a. A second set of experiments, listed in Table 1b, was then defined to optimize elution pH conditions. Three different elution pH were used. The responses were subsequently processed using the DoE software to generate a valid statistical model, and optimum conditions to be used on mixed-mode sorbents were identified. Table 1a DoE optimization of conditions of use of HEA HyperCel sorbent as second step post-protein A. Results of 96-well Plate Screening Conditions Experiments Elution Load Wash yield Run cond Load cond Wash (% of HCP Exp # order (mS/cm) pH (mS/cm) pH bound) (ppm) HEA1 8 8 6.5 15.0 6.5 75.8 2.3 HEA2 14 15 6.5 2.5 6.5 18.2 ND HEA3 20 15 6.5 15.0 6.5 74.4 4.1 HEA4 19 15 7.0 2.5 7.0 65.5 ND HEA5 21 15 7.0 15.0 6.5 76.4 3.1 HEA6* 25 15 7.0 15.0 7.0 80.5 2.5 HEA7* 26 15 7.0 15.0 7.0 76.4 2.5 HEA8* 27 15 7.0 15.0 7.0 80.2 2.9 HEA9 2 8 7.5 2.5 6.5 31.8 ND HEA10 4 8 7.5 15.0 7.0 66.4 ND HEA11 5 8 7.5 2.5 7.5 78.8 2.6 HEA12 6 8 7.5 2.5 7.0 66.2 ND HEA13 9 8 7.5 15.0 6.5 70.7 2.0 HEA14 11 8 7.5 15.0 7.5 96.9 2.0 HEA15 15 15 7.5 2.5 6.5 40.8 ND HEA16 17 15 7.5 2.5 7.5 69.8 ND HEA17 23 15 7.5 15.0 7.5 53.2 ND Table 1b Conditions Exp # HEA18 HEA19 HEA20 Elution pH 5.0 5.5 6.0 Results of 96-Well Plate Experiments Elution yield (% of bound) HCP (ppm) 81.9 11.9 68.2 11.5 30.1 30.1 a. Optimization of pH and conductivity conditions of load and wash steps. Results obtained regarding elution yield and HCP content are presented in the right part of the table. The HCP content was determined only for the experiments showing an elution yield > 75%. Elution conditions used for all experiments were 50 mM sodium acetate pH 5.0 b. Optimization of elution conditions. The indicated elution pHs were tested for the elution of HEA HyperCel sorbent while applying the optimal conditions previously determined for the load and wash steps. *Triplicate point to assess experimental reproductibility ND = Not Determined www.pall.com/biopharm 3 High Throughput Screening on 96-Well Plate Screening of multiple conditions for the optimization of purification step on mixed-mode sorbents was performed using an AcroPrep™ 96-well filter plate. The selected sorbent was equilibrated and re-suspended as a 50% slurry in the equilibration buffer and the desired amount of slurry was dispensed into the wells to a final volume of 50 µL per well. The liquid was then aspirated using a multi-well plate vacuum manifold. A sequence mimicking a chromatographic run was then performed on the plates following the steps indicated in Table 2. For each step of the sequence, the corresponding solution was pipetted into the wells. The microplate was then covered and incubated under shaking for the indicated time. After incubation, the liquid was drained from the wells using the vacuum manifold and collected in a 96-well plate; then fractions were analyzed. Table 2 General sequence used for microplate experiments. For each step the buffer is determined according to the experimental design specific to the sorbent and conditions tested. Equilibration Load Volume (µL) 200 200 According to experiment design Incubation 5 5 60 time (min) Wash Elution 200 200 200 200 5 5 10 10 Evaluation of Statistical Model Validity The data gathered from the analysis of 96-well plate collected fractions was used to generate a statistical model using the DoE software. The model validity was checked by analyzing the R2 and adjusted R2 values which represent the proportion of variation in the response that is explained by the model. A model was considered as good if both R2 and adjusted R2 were >85%. Transfer to Column of Optimized Conditions The optimal conditions predicted from the statistical model analysis were transferred to 1 mL PRC prepacked column (Pall Life Sciences). The column was equilibrated in 10 mM Na Phosphate, pH 7.0 adjusted to a conductivity of 8 mS/cm by addition of NaCl. 8 mg of the post-Protein A pool equilibrated to pH 7.0 and to a conductivity of 8 mS/cm were loaded onto the column. After a washing step using the same buffer as the equilibration step, the bound proteins were eluted in 50 mM Na Acetate, pH 5.0. 4 Results and Discussion Optimization of Conditions to be Applied to HEA HyperCel Sorbent Generation of Statistical Model and Evaluation of its Validity The results generated during the screening of load and wash conditions for HEA HyperCel sorbent on 96-well plates are shown in Table1a. These results were analyzed using response surface modelling to generate models representing the variations of elution yield and HCP content as a function of load and wash pH and conductivity. Satisfying models, fulfilling the validity requirements, were obtained from the software for both elution yield and HCP content. No non-significant points were identified in the set of obtained data. Models meeting the requirements (R2 and adjusted R2 >85%) were used to generate the contour plots (Figures 3 and 4) illustrating the effects of the load and wash conditions on the elution yield and HCP amount. Optimization of Conditions to be Applied to HEA HyperCel Sorbent Screening for optimal conditions for HEA HyperCel sorbent following a capture step on Protein A was performed in varying pH and conductivity for the load, wash and elution. In order to simplify the DoE, the optimization was split in two parts. In a first part, four variables (load pH, load conductivity, wash pH, wash, and conductivity) were screened to optimize load and wash conditions only. In a second part, the elution conditions were tested using three different elution pH. Optimization of Load and Wash Conditions Using DoE The optimization of load and wash conditions were explored using 96-well plate and the collected fractions were analyzed for MAb yield of recovery and HCP content (Table 1a). For all the conditions tested, no significant amount of antibody was detected in the flowthrough, showing that all conditions tested were favorable to the binding of the MAb to the sorbent. The effects of the load and wash conditions on the elution yield and the HCP content were analyzed. It appeared that either both parameters could dramatically change depending on the conditions used (Figures 3 and 4). Analysis showed that the elution yield was better with lower load conductivities and with an intermediate load pH of 7.0. For wash conditions, a combination of high wash pH and high wash conductivity allows the best recovery of MAb in the elution. Regarding the HCP content, the loading pH shows a bell shape influence, with the most favorable conditions at pH of 7.0. In addition, increasing the load conductivity leads to a higher HCP content in the elution fraction (high salt content apparently favors the binding of HCP on the sorbent). The wash conductivity has been explored in a broader range than the load conductivity, and the highest wash conductivity values lead to the lowest HCP content. The wash pH has a similar bell shape influence as the load pH on the HCP content, with the most favorable condition at pH 7.0. Figure 3 Contour plots showing the effect of load and wash conditions on MAb elution yield obtained using HEA HyperCel sorbent as second step post-Protein A. After having optimized the model to fit with the data measured, the optimum conditions were determined so that we could have a yield of recovery over 80% and an HCP content below 10 ppm. The contour plots presented in Figure 5 show the design space available for the load and wash conditions where both criteria are met (area in white). Based on the model used, the optimal conditions determined for the use of HEA HyperCel sorbent postProtein A were pH 7.0, conductivity 8 mS/cm for the load and pH 7.0, conductivity 15 mS/cm for the wash. This model also predicted a yield of 82% and a HCP content below 10 ppm using these conditions for load and wash. Figure 5 Overlapping contour plots for elution yield and HCP content. The white area shows the design space available to combine acceptable values for the two factors. For this analysis, the acceptable values were set as follows : HCP < 10 ppm and elution yield > 80%. The graph on the left shows the feasible region for load pH and conductivity with defined wash conditions (pH 7.0, conductivity 15 mS/cm) and the graph on the right shows the feasible region for wash pH and conductivity with defined load conditions (pH 7.0, conductivity 8 mS/cm). Figure 4 Contour plots showing the effect of load and wash conditions on HCP content in elution obtained using HEA HyperCel sorbent as second step post-Protein A. Optimization of Elution Conditions After determination of the optimal load and wash conditions, the optimal elution pH for HEA HyperCel sorbent A was determined. Several elution pHs were tested using 96-well plate (Figure 6), and the optimal elution pH was found to be pH 5.0. At this pH, HCP content was close to 10 ppm and yield was 82%, confirming the model predictions. Increasing the elution pH led to increased HCP content and decreased elution yield. The use of DoE in combination with experiments performed in 96-well allowed the determination, in two steps, of optimal operating conditions to be used on HEA HyperCel sorbent as a post-Protein A step. These conditions could next be confirmed by using them on columns. www.pall.com/biopharm 5 Figure 6 Test of elution pH for HEA HyperCel sorbent used as second step post-protein A. Figure 7 Chromatogram of the HEA HyperCel sorbent run on column applying the optimal conditions determined by DoE after capture on Protein A affinity sorbent (1 mL PRC prepacked column with HEA HyperCel sorbent.) The elutions were carried out using 50 mM Na acetate for pH 5.0 and 5.5, and 50 mM Na Phosphate for pH 6.0. The blue line represents the elution yield as percentage of MAb bound on the sorbent and the green bars represent the HCP content in ppm. Load : 8 mg/mL of sorbent Transfer of Optimized Conditions on 1 mL Prepacked Column The optimal conditions determined above were applied to a 1 mL PRC prepacked column with HEA HyperCel sorbent; the chromatogram is shown in Figure 7. Analysis of the elution fractions showed a yield of 83% and a HCP content below 10 ppm. Results indicate a very good correlation between the prediction from the DoE/96-well plate experiments and the data obtained on column. This clearly shows that high throughput screening (HTS) can simplify and accelerate the optimization of pH and conductivity conditions to apply on mixed-mode sorbents. This work could lead to the development of an efficient two-step purification process for the MAb tested. Conclusions Mixed-mode chromatography relies on multiple types of protein-ligand interactions and requires optimization. We used DoE in combination with 96-well plates to simplify and significantly accelerate this optimization as the complete work was performed in a single week. This approach demonstrates the benefits of using mixedmode chromatography in a MAb purification process. A two-step purification process, based on a first capture using an affinity Protein A step followed by a second step on HEA HyperCel sorbent could successfully be used to purify the MAb used in this study. No additional polishing step was required as the contaminants content was already very low after these two steps. This approach could be used as a general tool at early development stage to optimize the conditions to be used on mixed-mode sorbents in any protein purification process. Visit us on the Web at www.pall.com/biopharm E-mail us at biopharm@pall.com United States 1.800.717.7255 toll free (USA) 1.516.484.5400 phone 1.516.801.9548 fax biopharm@pall.com E-mail Europe +41 (0)26 350 53 00 phone +41 (0)26 350 53 53 fax LifeSciences.EU@pall.com E-mail International Offices Pall Corporation has offices and plants throughout the world in locations such as: Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand, Norway, Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland, Taiwan, Thailand, the United Kingdom, the United States, and Venezuela. Distributors in all major industrial areas of the world. The information provided in this literature was reviewed for accuracy at the time of publication. Product data may be subject to change without notice. For current information consult your local Pall distributor or contact Pall directly. © 2011, Pall Corporation. Pall, , HyperCel, and AcroPrep are trademarks of Pall Corporation. ® indicates a trademark registered in the USA and TM indicates a common law trademark. Filtration.Separation.Solution.SM is a service mark of Pall Corporation. ◆Nanodrop is a trademark of Thermo Fisher Scientific, Inc. Modde is a trademark of Umetrics AB. 3/11, PDF, GN10.4619 USTR 2795