High Throughput Optimization Approach for Single Step Polishing

advertisement

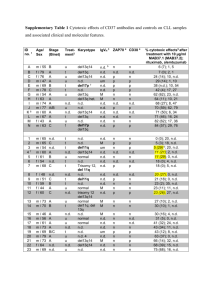

High Throughput Optimization Approach for Single Step Polishing of Monoclonal Antibodies Post Protein A Capture Aleksandar Cvetkovic1, Amitava Kundu2 and René Gantier1 1Pall Life Sciences, Westborough, MA, USA; 2Genmab MN, Inc., Brooklyn Park, MN, USA inTRoduCTion Mixed‐mode chromatography is a flexible and cost‐effective technique applicable to intermediate and polishing steps in monoclonal antibody (MAb) purification. We used various mixed‐mode sorbents to develop a single polishing step of MAbs following Protein A capture. High‐throughput experimentation (HTE) tools were employed to select conditions in both bind/elute and flow through modes to be transferred to column chromatography. Mixed-mode sorbents used in flow‐though (FT) mode (HEA HyperCel™ sorbent, Pall Life Sciences) provided good contaminant (aggregates and HCPs) clearance with MAb loads up to 150 mg/mL of sorbent. This study confirms the applicability of mixed‐mode chromatography for post‐Protein A purification of MAbs. mixEd‐modE ChRomaTogRaphy: mEp, hEa and ppa hypERCEl soRbEnTs sElECTion oF FT modE opERaTion CondiTions using hTE O CH2 CH2 CH2 S CH2 CH2 H+ N CH2 (CH2)4 CH3 (Spacer) HEA HyperCel Sorbent Does not meet requirements MEP HyperCel Sorbent 20 15 PPA HyperCel Sorbent 30 30 25 25 20 15 20 15 10 10 10 5 5 5 3.5 40 4.5 5.0 5.5 6.0 3.0 pH 3.5 40 4.5 5.0 5.5 6.0 3.0 3.5 40 pH 4.5 5.0 5.5 6.0 pH Operation Space Criteria: (red) MAb yield > 80%; (green) FT HCP Content < 25 ppm; (blue) FT Aggregate Content <1% CH2 CH2 hEuRisTiCally dEduCEd mab load impaCT on pERFoRmanCE oF mixEd-modE soRbEnTs Figure 5 Schematic Representation of the Heuristic Approach Implemented on the Experimental HTE Data Collected on HEA Hypercel Sorbent at 5 mg MAb per mL Load and the Results Obtained Using Same Approach for MEP and PPA Hypercel Sorbents Figure 2 Mixed-mode Chromatography Optimization Strategy HEA HyperCel 30 ad pH Lo Buffer Sorbent bed Filter plate 2. Screening on 96-Well Plates • AcroPrep™ Advance Filter Plates • AcroPrep ScreenExpert Plates • Vacuum manifold sorbents: MEP, HEA, PPA HyperCel Table 2 HTE Evaluation Conditions 20 15 5 3.0 3.5 40 4.5 pH 5.0 5.5 6.0 FT yield >60%, HCP <10 ppm, Agg. <0.75% 30 AU 0.004 0.002 20 15 Optimal conditions Wash: pH 4.4, 29.2 mS/cm 10 Min 11 12 13 14 Elution pH 300-350 250-300 7.5 200-250 7.0 6.5 150-200 6.0 5.0 4.0 4.2 4.4 4.6 4.8 5.0 Load pH 5. Transfer to Column MAb FT Yield (%) 30 10 MAb Yield % 80 100 FT HCP, ppm 0 25 Aggregates % 0 1 25 Conductivity Conductivity 15 3.5 40 4.5 pH 5.0 5.5 5.5 6.0 PPA HyperCel 20 15 10 5 3.0 6.0 20 Experimental conditions Pall 1 mL PRC prepacked columns (0.5 cm I.D., 5 cm bed height) 4 minutes residence time Load sample: up to 150 mg MAb per mL of sorbent 3.5 40 4.5 pH 5.0 5.5 6.0 Results HEA HyperCel sorbent - best aggregate removal performance (Figure 6A) HEA HyperCel sorbent – also good HCP clearance and MAb yield even at 150 mg MAb load per mL of sorbent presented (Table 4 and Figure 6B) Figure 6 Transfer of Optimized HTE Conditions on Column A HEA, PPA and B MEP HyperCel Aggregate Content (C/C0), % 9 8 Aggregate Content (C/C0), % 0 5.5 20 5.0 0.001 4. Result Analysis • Design space for optimum performances 25 4.5 pH TRansFER oF opTimizEd FT modE CondiTions To Column ChRomaTogRaphy 0.003 8.0 <1 1 – 10 10 – 20 20 – 30 30 – 40 40 – 50 50 – 60 60 – 70 70 – 80 80 – 90 90 – 99 > 99 40 0.005 HCP (ppm) MAb Yield (%) 30 3.5 0.006 8.5 30 3.0 25 10 3. Analytical Testing • Aggregate quantification (SEC HPLC) • HCP quantification (ELISA) • MAb elution yield (Poros A, OD280nm) Determination conditions for FT steps was based on an axial point response surface DoE (Minitab◆) 15 5 Predicted responses mAb Yield > 90 % HCP < 10 ppm Aggregates < 0.5% 25 3.0 MEP/HEA/PPA HyperCel 5 mg/mL of sorbent Low pH High pH 3 to 6 6 to 9 4 to 30 mS/cm 9 3 17 mS/cm 20 10 5 Conditions Tested 25 100 80 60 40 20 0 0 50 100 150 MAb Load (mg/mL) HEA HyperCel 30 100 25 80 20 60 15 40 10 20 5 0 0 150 0 50 100 HCP Content (ppm) 235 ppm (ng/mg MAb) host cell proteins (HCP) Table 3 Optimal Conditions for FT Processing of MAb Determined by HTE Study Sorbent pH Conductivity, mS/cm MEP HyperCel 4.5 5.1 PPA HyperCel 3.9 4 HEA HyperCel 4.4 29.3 Conductivity 1.9% aggregate Optimal conditions Wash: pH 4.5, 12.4 mS/cm 10 Elution Cond 1. Design of Experiment (DoE) • Critical parameters (loading and elution conditions) • Quality attributes (yield, HCP and aggregates) 30 25 Elution pH MAb concentration: 19.5 mg/mL MEP HyperCel FT yield >80%, HCP <25 ppm, Agg. <1% Conductivity opTimizaTion oF mixEd-modE soRbEnTs FoR posT pRoTEin a sTEp mab puRiFiCaTion Conductivity (Spacer) PPA HyperCel Sorbent Conductivity H+ N CH2 pKa ~ 8 Load Conductivity Elution pH Elution Conductivity HEA HyperCel Sorbent 3.0 pKa ~ 8 Alternative/complement to conventional HIC or hydroxyapatite Sorbent Protein Load Load pH 25 PPA HyperCel sorbent: Alternative to ion exchange when feedstock is directly loaded (no dilution or UF/DF) (pI 7.6) HEA - better flexibility pKa = 4.8 Alternative to traditional methods (ion exchange, HIC, affinity…) load: Post Protein A elute MAb Selectivity for MAb vs. aggregates 30 Conductivity MEP HyperCel Sorbent Broad affinity for HCPs Conductivity Meet operational requirements Figure 1 Ligand Structure of HyperCel Mixed-Mode Sorbents Mixed-mode chromatography exploits multiple, distinct protein-ligand interactions to adsorb target proteins or impurities. Mixed-mode chromatography offers new solutions to separations: Figure 4 Identification of Sweet Spot pH and Conductivity in FT Under Low pH Load Conditions Conductivity MEP and HEA HyperCel sorbents: MAb Load (mg/mL) Table 4 Best Column Performance: HEA HyperCel Sorbent (150 mg/mL MAb Load) 15 5 3.0 3.5 4.0 4.5 pH 5.0 5.5 10 HCP (ppm) 30 FT HCP (ppm) <1 1–5 5 – 10 10 – 15 15 – 20 20 – 25 25 – 50 50 – 100 > 100 25 Conductivity Sweet spot cond. Yield >80% HCP <25 ppm Aggregates <1% 6.0 20 15 5 3.0 3.5 4.0 4.5 pH 5.0 Optimizer Minitab 10 Optimal High D 0.62446 Cur Low 5 3.0 3.5 4.0 4.5 pH 5.0 5.5 6.0 30 < 0.1 0.1 – 0.5 0.5 – 1.0 1.0 – 2.0 2.0 – 4.0 4.0 – 6.0 6.0 – 8.0 8.0 – 10.0 > 10.0 20 15 FT, % Targ: 99.0 y = 90.1255 d = 0.53292 HCP, ppm Targ: 1.0 y = 8.3630 d = 0.69321 10 5 3.0 3.5 4.0 4.5 pH 5.0 5.5 6.0 Aggregate % Targ: 0.10 y = 0.4068 d = 0.65917 Contact: +800.717.7255 (USA) • +41 (0)26 350 53 00 (Europe) • +65 6389 6500 (Asia/Pacific) • E-mail: biopharm@pall.com • Web: www.pall.com/biopharm Aggregate < 0.5% HCP 23 ppm ConClusions Optimal load conditions: Wash pH 4.3 Cond. 12.4 mS/cm Aggregates % 25 Conductivity Cond 30.0 [12.3626] 4.0 MAb Yield 94.9% 6.0 Composite Desirability 0.62446 Aggregates (%) Figure 3 Data Processing Approach Used to Determine Optimal Operation Conditions (MAb Yield of Recovery and Purity) Using HEA Hypercel Sorbent in FT Mode pH 6.0 [4.5057] 3.0 5.5 Conductivity 29.3 mS/cm pH 4.3 Predicted responses: MAb Yield = 91.3 % HCP = 5.5 ppm Aggregates = 0.4% High Throughput Screening on AcroPrep™ 96-well sorbent plates allows fast process optimization Use of Pall mixed-mode sorbents in FT mode after Protein A step provides excellent separation performance – High yield of recovery – Efficient contaminant removal (aggregate, HCP) – High MAb load g reduced sorbent volume – HEA HyperCel sorbent provided best performance with specific MAb • ~ 95% MAb yield at 150 mg/mL MAb load • < 0.5% aggregate and < 25 ppm HCP Mixed-mode sorbents operated in FT mode are a good alternative to high capacity IEX sorbents © 2014, Pall Corporation. Pall, , Acrodisc, AcroPrep, and HyperCel are trademarks of Pall Corporation. ® indicates a trademark registered in the USA. ◆Minitab is a trademark of Minitab, Inc. 7/14, GN14.9444