Energy Conservation and Alternative Energy Option Awareness

advertisement

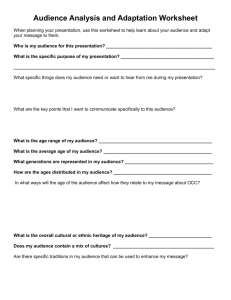

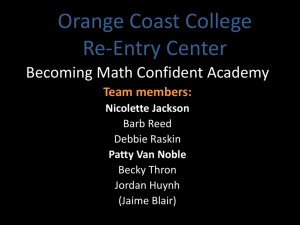

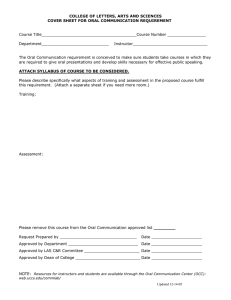

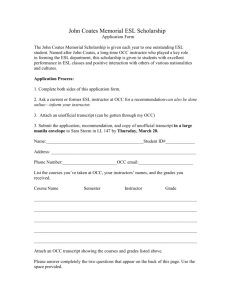

Energy Conservation and Alternative Energy Option Awareness By: Joel McVenes Brock Miller Youzhu Wang TABLE OF CONTENTS Table of Contents .........................................................................1 Topic Selection ............................................................................2 Current Situation ..........................................................................2 Scope ............................................................................................5 Other Universities are doing ........................................................5 Renewable Energy Options..........................................................9 Conservation of Energy .............................................................13 Applied Arts Air Handler Units Maps .......................................19 Case Study .................................................................................22 Occupancy Sensors Cost/Life Expectancy ................................28 Triple Bottom Line ....................................................................30 Conclusion .................................................................................32 Contacts......................................................................................34 Timeline .....................................................................................34 Email Correspondence ...............................................................39 Room Pictures ............................................................................54 Works Cited ..............................................................................57 Thank You ................................................................................59 1 Topic Selection Our original project topic was Renewable Energy on campus, based off our interest in the feasibility of implementing renewable energy on campus as well as curiosity as to why there wasn’t any renewable energy use currently on campus. The other underlying motive was to have a positive impact on the environment through using renewable energy or through the reduction in energy use and thus conventional fossil fuels. Our topic evolved from renewable energy to energy conservation after research into renewable energy proved that implementing a renewable energy project on campus would be difficult and not economical. Some of the issues that we faced were high initial cost associated with renewable energy. Even on small scale projects there is thousands of dollars in cost upfront and very little payback. That coupled with meeting with John Paulus the Assistant Building & Grounds Superintendent, who introduced us to some energy conservation project ideas that would have more of an impact in the short term and were more feasible to accomplish. Current Situation All energy used on campus for heating, cooling and electricity currently comes from conventional sources rather than renewable energy sources such as wind or solar energy. No major campus wide renewable energy projects are in progress or being pursued at this time. The main issues that have hindered the use of renewable energy on campus have been funding and feasibility. As not only are funds not being allocated to renewable energy projects, but also these projects tend to have a large initial cost. Feasibility was also a main issue with the location of 2 Menomonie (We will go into more depth on this later). The university currently sources its electrical energy needs from Xcel Energy. Figure 1 below shows Xcel Energy’s power generation mix for our region. As you can see, Xcel’s energy profile in the Upper Midwest (which includes Wisconsin and Michigan) is quite diverse and offers some renewable energy options. However, a majority of their energy still comes from fossil fuels and Nuclear, which are less than desirable sources from a sustainability standpoint. Figure 1 3 Figure 2 2011-2012 Campus Energy Use Energy Type Electricity Natural Gas Fuel Oil Amount Consumed 22,395,078 169,933 1,115 Units kWh MCF gallons Total Cost $ 1,658,822 $ 405,178 $ 2,064,000 Coal was not used in the 2011-2012 school year as natural gas was cheaper. As shown above in Figure 2, overall Stout currently spends $0.86 per square foot on energy and a total of $2,064,000. This makes Stout the most energy efficient four-year campus in the UW System for all but one year in the past decade including this past year. Currently there are a few energy conservation projects ongoing at Stout. A recent project conducted by a sustainability student Paul Duerst in conjunction with John Paulus, reduced lighting usage costs for the stairwells by 30% simply by installing motion detectors in Fryklund Hall’s stairwells. This was achieved by placing a 9 watt LED in between the current two 60 watt bulbs currently in place. Instead of running the two large lights all the time they installed motion detectors so that the 60 watt bulbs only run when people are present. That being said, there are many opportunities for improvement in energy conservation. 4 Scope The scope of our project is to spread awareness of the economics and feasibility of using renewable energy on Stout Campus and to discover the most efficient ways to conserve energy by reducing energy use on campus through exploring occupancy sensors that will more efficiently utilize the lighting and air filtration systems. Other Universities To better understand some of the potential options for our project, we researched what some of the other area universities were doing for renewable energy. Some of the universities we looked at included: UM-Morris, UW-Whitewater, UW-Platteville, UW-Oshkosh, and UW-Eau Claire. Shown below in Figure 3 is a quick look at some of the basic information about these universities renewable energy initiatives in a table format. More depth on these initiatives will be covered in the following sections. University of Minnesota-Morris University of Minnesota-Morris is the leader in renewable energy production on a university campus and is the gold standard other universities strive toward. They are the first public university to generate on-site energy from a commercial scale wind turbine. They also have other sources of renewable energy from a biomass plant and a solar thermal array. Near campus Morris has two 1.65 megawatt wind turbines that average 70% of all campus electrical needs. These wind turbines are run by Morris and in conjunction with the University of Minnesota West Central Research and Outreach Center (WCROC). These wind turbines are 5 230 foot tall towers with three 135 foot blades and can produce energy at wind speeds as low as 7.8 mph and has high as 50 mph before they are turned off to avoid damage. Their max electricity output is reached at 29 mph and totals 5.6 million kWh of electricity per year. These wind turbines cost approximately $4 million total and eliminates roughly 6,000 tons of CO2 per year from being emitted. UM-Morris’s other big renewable energy project is from their $6 million Biomass Gasification Plant on campus. This plant uses biomass instead of traditional fossil fuels for energy; this biomass is produced within a 20 mile radius of campus and is primarily wood, prairie grasses, and crop residue. Most of this biomass is produced from local farmers and provides $500,000 per year back to the local economy through purchasing of crop residue. By using biomass 80% of campus heating and cooling is provided for without using natural gas or other fossil fuels. By reducing the use of natural gas the university figures to have reduced their CO2 emissions by 8,000 tons per year. On a smaller scale Morris also employs the use of solar thermal panels that collect the suns energy and use it to heat their recreational swimming pool in their fitness center. This solar array is made up of 32 flat solar thermal panels and eliminates 30,000 lbs. of CO2 emissions a year. So as one can see UM-Morris campus’s comprehensive sustainability strategy is widespread and is quite effective. The Morris campus is a nationally recognized sustainability leader and serves as a model community for the country and other universities to aspire too. 6 Figure 3 Other Universities Renewable Energy Projects University Renewable Energy Source Notes UM-Morris Wind Turbine, Solar Thermal panels, and Biomass Gasification plant 70% of campus electricity needs are supplied by the wind turbines and 80% of heating and cooling is provided by the Biomass Gasification plant. UWWhitewater Photovoltaic Solar panels Generates about 40,000 kWh per year, enough to power several high energy rooms in their business building. UW-Platteville Sustainable and Renewable Energy Systems major. Program looks in depth at renewable energy such as wind, solar, geo-thermal, wave, hydrogen, and bio-energy. UW-Oshkosh Purchase renewable energy, Biomass plant, and Thermal Solar panels 23% of campus electricity is purchased from renewable sources. An additional 8% of campus electricity comes from biomass produced on campus. Thermal panels heat water in 4 campus buildings. UW-Eau Claire Stationary bikes used to generate electricity, Solar Thermal Panels, and purchase wind energy through Xcel Energy's Windsource program. Roughly 10% of campus energy is wind energy purchased through Xcel Energy's Windsource program. Small amount energy generated by stationary bikes and solar thermal panel’s heat water in a campus building. University of Wisconsin-Whitewater UW-Whitewater’s renewable energy is based of Photovoltaic Solar panels they have on one of their academic buildings. It is a 32.4 kilowatt, double stacked solar array and cost the university $167,000 on solar energy that produces an estimated 39,755 kilowatt hours per year. This cost was reduced for the university through grants from We Energies and Focus on Energy. By employing the use of this solar array the university will not have any significant cost savings but will provide clean renewable energy and reduce the carbon footprint of campus. 7 University of Wisconsin-Platteville While UW-Platteville does not have any renewable energy initiatives that we could find, we thought they were worth mentioning since they do offer a degree in Sustainable and Renewable Energy Systems. The program strives to help students develop an in-depth understanding of issues related to energy and renewable energy, including bio-fuels and renewable products. The program takes an in depth look into renewable energy such as wind, solar, hydro, geo-thermal, wave, hydrogen, and bio-energy. University of Wisconsin-Oshkosh Wind power on campus is the largest source of renewable energy at UW-Oshkosh. The wind energy is supplied through Wisconsin Public Service Nature Wise program and from the state purchase of wind power for a total of 23% of electricity on campus is generated from wind power. Another renewable energy project was having solar thermal panels installed on 4 different buildings for 4 different purposes. Albee Hall: Heat indoor swimming pool Blackhawk Commons: For dishwashing Taylor Residence Hall: Hot water for showering Heating Plant: Pre-heat water for steam production Oshkosh also boasts the first commercial-scale, dry anaerobic bio-digester in the Americas. Owned by the UW Oshkosh Foundation, the plant uses organic waste from campus dining halls and local yards, supermarkets and farms to produce methane gas that is burned to power turbines 8 that generate electricity. The energy produces approximately 8% of the electricity used on campus. UW Eau-Claire UW-Eau Claire employs the use of multiple renewable energy sources. One of which is solar thermal panels. These panels are used in provide hot water in their Davies Center building without the use of fossil fuels. Another source of renewable energy is through Xcel Energy’s Windsource program, in which they buy energy sourced from wind farms at an additional price. They purchase enough of this to power roughly 10% of their campus through wind energy. Lastly, another program Eau Claire has is using special stationary bikes that student’s bike on to generate electricity. Although the yields are low, the energy is renewable and shows that even small changes can make an impact. These bikes cost roughly $30,000 and produce 2.5-3 kWh per spin class, which will be what the bikes will be allocated for. While this doesn’t provide a lot of bang for your buck, it is used for educational purposes and shows a commitment to sustainability. Renewable Energy Options Initially we wanted to look into all options for renewable energy that was feasible, realistic, and affordable. As mentioned above, Xcel energy is the company that provides Stout with energy and is the only option Stout has for an electrical provider due to state legislation and location. The first renewable energy option that we eliminated was geothermal. This was due to the fact that geothermal in our location could only be used for heating and it would be difficult to incorporate with the way the current district heating works, which is already quite efficient. 9 Another option that we looked into was solar panels to produce energy for campus buildings. After talking to Sara Rykal we found out that solar energy on campus had been considered previously by Stout Sustainability personnel and in fact there was a solar assessment conducted in 2010 by Future Energy Consulting. The solar assessment was conducted for the Sports and Fitness Center because it was determined to be the most efficient option for placing solar panels based on the solar rays pathfinder device results and having a large roof top area to work with. A solar ray’s pathfinder is a device that tracks the movement of the sun and figures out how much sunlight that area would be exposed to. Figure 4 Photo- Solar pathfinder device used in solar assessment on campus 10 Solar Assessment Summary Breakdown (Figure 5) Production Solar electric array rated capacity (KW DC) Estimated output year one (KWh/yr.) 42 49,020 Cost Estimated installed cost Focus Incentive (net after tax) Other first cost incentives System cost after first cost incentives Value of year 1 to year 10 power production $378,000 $73,540 $0 $304,460 $44,125 Economics 10 year discounted NPV 25 year discounted NPV 30 year IRR Years to cost recovery -$272,499 -$199,093 -1% 30+ Environment CO2 emission reduction per year (tons/year) 54 Key Assumptions **Cost of System Per kW (dc) Electricity rate year one ($/kWh) Estimated electricity price inflation rate (%/yr.) Expected output degradation (%/year) Discount rate (used only in NPV) These numbers are all in 2010 dollars. $9,000 $0.07 6.00% 0.50% 3.0% The solar assessment consisted of an analysis of a 42 KW DC system that is estimated to produce 49,020KWh/year which accounts for about 10% of the total Sports and Fitness Center electrical energy needs per year. The payback on the 42KW solar electric array option is an estimated 77 years. With an optimistic estimate solar panel lifetime of 20 years, the payback on this is almost 4 times the lifetime of the solar panels. While the cost of solar panels has reduced in the last 3 years, they haven’t to the point of making this remotely financially feasible. Also the numbers above in the study was also depending on a $73,540 grant from Focus on Energy 11 that wouldn’t be a guarantee to receive anymore. However the proposed 42KW solar panel system will save an estimated 50 tons of CO2 annually and will also have a positive influence on the environment through the reduced amount of fossil fuels used. That being said we eliminated solar panels mostly due to the economic feasibility of the project not being there. The next option to be considered when we look into feasible renewable energy options was wind energy. The first thing we looked at was putting up a wind turbine but came to find that the geographical location of the area is not ideal conditions for wind turbines. That coupled with the significant upfront cost being detrimental to the concept, we eliminated putting up wind turbines from our potential projects. Another look at wind energy we were introduced to was through Xcel Energy and was the Windsource renewable energy program. This program offered to provide 100% wind energy to Xcel customers from their wind farms. The only thing was there is a premium of $1.37 per 100 kWh of electricity. The Windsource program wind energy comes from wind farms in Minnesota that supply energy to the grid that serves Wisconsin. For perspective it is roughly $8 per 100 KWh normally and with the premium of $1.37 per 100 kWh energy totals at $9.37 per 100 kWh. This is an increase of about 19% to the current energy prices that the customer receives. But by participating in the Windsource program, the $1.37 premium is put towards creating more wind farms in your region (in this case Minnesota) which helps provide the funding to increase the amount of wind energy produced. The Windsource program has been a very large success for Xcel. In fact, Xcel is the largest wind source supplier in the United States and they currently source 15% of their energy profile through renewable sources. Some advantages for Stout to become a part of the Windsource program includes not only to reduce our environmental impact, 12 but to obtain LEED certification points, and to encourage Xcel to continue to expand their Windsource program and ultimately investing in more wind farms. While this was a viable option this year with the surplus of energy funding, it would be an annual cost that would occur every year. This was concerning for us since we couldn’t guarantee these funds would be available year after year. That and we wouldn’t be creating any cost savings or producing any energy as a campus but just paying a company to give us renewable energy when they already provide us with 15% renewable energy. So while not a bad option we decided to try to find a different option. These were the main options we looked into there were a few other options that we dismissed immediately. One of these was hydro power, which wasn’t really an option for us since almost all of Wisconsin’s hydro potential has been already tapped and especially since there is a damn right here in Menomonie already. But overall we mainly focused on solar and wind energy. Conservation of Energy UW-Stout Utilities Overview As mentioned earlier UW- Stout is the most efficient campus of the 13 four year colleges in the UW system. Stout currently spends only $.86 per square foot annually on energy, but there is always room for improvement. Most of this improvement could be made by more efficiently controlling the heating, ventilation, and air conditioning system (HVAC) on campus, as 75% of energy is used for HVAC leaving the other 25% for lighting and appliance usage. At Stout, from 2011-2012 there has been 22,395,078 kilowatt hours of electricity used on campus which amounts to $1,658,822. We have also burned 169,933 MCF of natural gas and 13 1,115 gallons of fuel oil. There was no coal being used for the 2011-2012 heating season because its cost was more than natural gas. The below physical annual report table breaks down the amount of electricity used since 2006. Physical Plant Annual Report 2011-2012 Figure 6 HVAC Overview Heating, Ventilation, and Air Conditioning accounts for a majority of the energy expended from a building. The basics to understanding how HVAC systems work is to understand that there is constantly air being cycled through buildings from outside to inside back to outside. This air is cycled using supply fans and return fans. There is one supply fan and one return fan per air handling unit most often. The supply and return fans both have dampers that open to speed up the air flow or close to slow down the air flow. The dampers are being controlled by Variable Frequency Drives. These VFD’s are programmed to maintain a certain amount of air flow that is needed based on flow set points set by HVAC specialists. 14 Once the air is being pulled into the building by the supply fan, it is then being heated by the heating coil or cooled by the cooling coil (depending on the season and temperature of the air). The air is cycled to the appropriate rooms at the appropriate flow based off of Variable Air Volume (VAV) control units which are electronically control the air handling unit speed. When the VAV control units run the air handler on occupied mode, it cycles the air at a much faster rate to account for the people that are in the room and to make sure that a sufficient amount of oxygen is in the room. The use of occupancy sensors let the VAV control units know when there is no one in the room so that the air handlers run on unoccupied mode during that time. The below section goes into detail on running an air handler on occupied mode versus unoccupied mode. Figure 7 - Jarvis air handling unit one 15 HVAC Occupied Mode vs. Unoccupied Mode An individual room within an air handler runs on occupied or unoccupied mode. Unoccupied mode is similar to a default standstill mode where the air handling unit generator is still heating or cooling air and cycling air through the room, but using around half the energy as the occupied mode. The use of occupancy sensors allows rooms to run on unoccupied mode during times where no one is using the room. Without these occupancy sensors, the room is only run on unoccupied mode when the building is closed. There are no variable levels of occupied mode that the air handlers supply to each individual room. The air handler is either heating or cooling an individual room on occupied mode or unoccupied mode; therefore, as long as there is someone in the room it is irrelevant as to how many others are occupying the room as well. On the same note without the occupancy sensors, the air handler will run on occupied mode the entire day that the building is open because there is a chance that someone will be occupying the room. The air handling units in the Applied Arts run at around 60 Hertz when all rooms that the air handler controls are run on occupied mode. When all the rooms are run on unoccupied mode the air handler will run at 30-35 Hertz. Now a single air handling unit generator may be heating certain rooms on occupied mode yet only heating other rooms at unoccupied mode simultaneously; therefore, at this time the air handling unit generator will be running between 30-60 Hertz at that particular moment and it is dependent on the area of the rooms that are run occupied versus unoccupied as to whether the air handler generator is running closer to 30 Hertz or 60 Hertz. This is why it is more important to place occupancy sensors in larger rooms because you are saving more energy per hour that they run on unoccupied mode. 16 HVAC on Campus The heating, ventilation, and air conditioning of the buildings built in the last 5 years have efficient HVAC systems already because they are all run on electronic control systems with occupancy sensors that allow the system to monitor and control the amount of air that is heated or cooled then cycled through the room based on the occupancy of the room. Due to technological advancements and more efficient generators, the newer HVAC systems are more energy efficient. All the HVAC systems on campus can be controlled electronically, but the buildings built in the last 5 years are run through updated electronic control systems instead of pneumatic systems like the applied arts where they can control themselves and the Stout HVAC workers can more easily make changes to the system from their computers through input changes in the variable frequency drives and variable air volume control units which control the air handling units that heat or cool the air that is being pushed through a room at a given time. Applied Arts Air Handling Units The Applied Arts building includes a total of 10 air handlers and each of them controls different areas of the building. Some air handlers in Applied Arts handle much larger areas than others. Below Figure 8 breaks down each air handling unit and the amount of area it covers. An occupancy sensor will need to be placed in each individual room in order to control it. Due to instillation costs, it is common for multiple sensors to be installed at once in rooms that run off the same air handling unit. This is because it more price efficient to install multiple versus just one. 17 Figure 8 TABLE 1 Applied Arts- Air Handling Units Air Handler # Surface area (ft2) Volume (ft3) Estimated Annual HVAC Cost ($) 1 25,836 310,032 $16,664.22 Estimated Annual HVAC Energy use (KWh) 208,303 2 875 10,500 $564.38 7,055 3 600 7,200 $387.00 4,838 4 9,000 108,000 $5,805.00 72,563 5 15,124 253,488 $13,624.98 170,312 6 23,840 295,920 $15,376.80 192,210 7 150 + (back up 1,500 $96.75 1,209 supply) 8 (back up supply) 9 16,400 302,750 $10,578.00 132,225 10 6,000 72,000 $3,870.00 48,375 $66,967.13 837,089 Annual Applied Arts Energy Costs & Usage 0 Cost estimates based on 2011-2012 energy costs of $0.86 per square foot on campus (info. provided by Sarah Rykal’s, UW-Stout Environmental Sustainability Coordinator) and an estimated 75% of Stout’s energy comes from HVAC (info. provided by Dennis Luedtke, HVAC specialist). Estimates adjusted for 1.5-2 story rooms. Energy costs based off current (3/2013) Xcel pricing for UW-Stout provided by Robert Schultz of Xcel energy. 18 Maps of Applied Arts Air Handling Units Figure 9 19 Figure 10 20 Figure 11 21 Case Study The larger the room, the more energy required for heating and cooling, therefore there is more energy savings potential from the occupancy sensors. The sizes of the rooms in the Applied Arts are broken down in the following table along with which air handling units they belong to. The percent occupancy is provided for the rooms that we conducted our case study on as well as the amount of energy savings potential from the sensors. (Details below) Figure 12 Table 2 Applied Arts Case Study-Largest Rooms Estimated annual Surface Room # Volume (ft3) Air H. # % occupancy area (ft2) 132 210 112 216 302 321 5 9 6 6 1 9 Averages 5,760 4,104 4,200 2,400 2,100 1,386 3,325 Energy (cost in $) Est. annual Energy Use (KWh) Energy savings with Occ. Sensor (cost in $) Energy savings with Occ. Sensor (KWh) Energy savings with occ. Sensor (%) 97,920 82,080 71,400 28,880 33,600 20,790 44% 69% 46% 76% 34% $5,572.80 $5,294.16 $4,063.50 $1,548.00 $2,401.98 $1,117.46 69,660 66,177 50,794 19,350 30,024 13,968 $1,365 $718 $960 $252 $323 17,063 8,975 12,000 3,152 4,033 24% 14% 24% 55,778 54% $3,333 41,662 $724 9,045 20% 10% 29% * Energy use cost estimates based on 2011-2012 energy costs of $0.86 per square foot on campus (info. provided by Sarah Rykal’s, UW-Stout Environmental Sustainability Coordinator) and an estimated 75% of Stout’s energy comes from HVAC (info. provided by Dennis Luedtke, HVAC specialist). Energy savings cost estimate based on air handlers running on a 18 hour day occupied mode running and 50% energy savings during the time when the air handler could have run on unoccupied due to running at a reduced rate. 22 Key: Occ= occupied, but not routinely scheduled Occ‐ class= routinely scheduled class X= lights off and unoccupied Occ‐ lab= routinely scheduled lab hours L= lights on and no occupancy ?= unknown occupancy and lights Figure 13 Applied Arts‐Room 112 Occupancy Study Time of day Monday Tuesday Wednesday Thursday Friday Saturday Sunday (4/15) (4/16) (4/17) (4/18) (4/19) (4/20) (4/21) 0:00 1:00 2:00 3:00 Unoccupied mode 4:00 5:00 6:00 7:00 ? ? X X X 8:00 Occ‐class Occ‐class X Occ‐class X X X 9:00 Occ‐class Occ‐class L Occ‐class X 10:00 X Occ‐class Occ Occ‐class Occ‐lab 11:00 X Occ‐class Occ Occ‐class Occ‐lab X X 12:00 Occ‐lab Occ‐lab Occ Occ‐lab Occ‐lab 13:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐lab 14:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐lab X X 15:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐lab 16:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐class 17:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐class X X 18:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab X 19:00 Occ‐lab Occ‐lab Occ‐lab Occ‐lab X 20:00 X Occ‐class Occ‐lab Occ‐class X X X 21:00 X X X L X 22:00 X X X X X 23:00 ? X X X X X X 23:59:00 ? X X X X Height Length Width Volume 17' 70' 60' 71400'(^3) (military time) Room dimensions 23 Key: Occ= occupied, but not routinely scheduled Occ‐ class= routinely scheduled class X= lights off and unoccupied Occ‐ lab= routinely scheduled lab hours L= lights on and no occupancy ?= unknown occupancy and lights Figure 14 Applied Arts Room 210 Occupancy Study Time of day (military time) 0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 22:00 23:00 23:59:00 Room dimensions Monday (4/15) ? ? X Occ X X Occ ? ? ? X X X X X X ? ? Tuesday (4/16) Wednesday Thursday (4/17) (4/18) unoccupied X X X Occ X X X X X X X ? L X ? Occ‐ Class Occ Occ‐ Class Occ‐ Class ? Occ‐ Class Occ‐ Class ? Occ‐ Class X ? X OCC X X Occ Occ Occ X Occ Occ X X Occ X X Occ X X Occ X X ? X X ? Friday (4/19) ? ? X X X ? Occ Occ Occ X ? ? Occ Occ Occ ? ? X Height X Length ? Width ? Volume 25' 76' 54' 82080'(^3) 24 Saturday (4/20) Sunday (4/21) ? X X Occ Occ X X X X X X X Key: Occ= occupied, but not routinely scheduled Occ‐ class= routinely scheduled class X= lights off and unoccupied Occ‐ lab= routinely scheduled lab hours L= lights on and no occupancy ?= unknown occupancy and lights Figure 15 Applied Arts Room 132 Occupancy Study Time of day Monday (military time) 0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 22:00 23:00 23:59:00 Tuesday (4/15) ? ? X X Occ‐class Occ‐class Occ Occ‐class Occ‐class Occ‐class Occ‐class Occ‐class Occ X X X ? ? Room dimensions (4/16) Wednesday Thursday (4/18) unoccupied X X L X Occ Occ Occ ? Occ Occ‐Class Occ Occ‐Class Occ Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ‐lab Occ‐Class Occ‐lab Occ‐Class Occ‐lab Occ‐Class Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ‐lab Occ Occ X ? X ? X ? Length Width (4/17) X X X L Occ‐Class Occ‐Class Occ‐Class Occ‐Class X ? ? X X X X X X X Height 17' Friday 96' 25 60' Saturday (4/19) ? ? Occ L X ? Occ Occ L ? ? ? Occ Occ X ? ? ? Volume 97920’(^3) Sunday (4/20) (4/21) ? X Occ X X X X X X X X X Key: Occ= occupied, but not routinely scheduled Occ‐ class= routinely scheduled class X= lights off and unoccupied Occ‐ lab= routinely scheduled lab hours L= lights on and no occupancy ?= unknown occupancy and lights Figure 16 Applied Arts Room 321 Occupancy Study Time of day (military time) 0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 22:00 23:00 23:59:00 Monday (4/15) ? ? Occ‐Class X X Occ‐Class Occ Occ‐Class Occ‐Class ? X X X X X X ? Tuesday (4/16) Wednesday Thursday (4/17) (4/18) unoccupied X X X X L X X Occ‐Class Occ Occ‐Class L Occ‐Class Occ‐Class Occ Occ‐Class ? Occ‐Class ? X Occ‐Class ? Occ‐ Class Occ‐Class Occ‐ Class Occ‐ Class Occ‐Class Occ‐ Class Occ L ? Occ Occ ? X Occ Occ L Occ Occ Occ L X L X X X X ? X X ? ? Room dimensions Friday (4/19) ? ? Occ‐Class Occ Occ Occ‐Class Occ X X X ? ? X X X ? ? X Height X Length ? Width ? Volume 15' 42' 33' 20790'(^3) 26 Saturday (4/20) Sunday (4/21) ? X Occ Occ Occ X X X X X ? ? Figure 17 Key: Occ= occupied, but not routinely scheduled Occ‐ class= routinely scheduled class X= lights off and unoccupied Occ‐ lab= routinely scheduled lab hours L= lights on and no occupancy ?= unknown occupancy and lights Applied Arts Room 302 Occupancy Study Time of day military time 0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 22:00 23:00 23:59:00 Room dimensions Monday Tuesday (4/15) (4/16) (4/17) (4/18) ? ? Occ Occ‐Class Occ‐Class Occ Occ Occ‐Class Occ‐Class Occ‐Class Occ‐Class ? Occ Occ X X ? ? Wednesday Thursday Occ Occ Occ Occ Occ ? X Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ Occ L Occ X X X Height 16' unoccupied X X X Occ Occ Occ Occ‐Class ? Occ‐Class ? L ? Occ ? Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ‐Class Occ Occ Occ Occ Occ Occ Occ Occ Occ ? X ? X ? Length Width 70' 27 30' Friday Saturday Sunday (4/19) (4/20) (4/21) ? ? Occ Occ‐Class Occ‐Class ? Occ Occ Occ Occ ? ? Occ Occ Occ ? ? ? Volume 25200'(^3 ) ? X Occ Occ Occ Occ Occ Occ Occ X X X Occupancy Sensors Cost Breakdown and Life Expectancy According to our case study and calculations, we have concluded that occupancy sensors can save an average of 20% of the annual Heating and Ventilation and Air Conditioning costs for the room that they are installed in (refer to details of Figure 12). If occupancy sensors were installed in all rooms in the Applied Arts, although unlikely to be feasible due to the labor and time involved in instillation initially, the energy consumption in Applied Arts would decrease by 167,417 KWh annually saving a total of $13,393 of energy per year. The cost of the occupancy sensors themselves is only $150 each whether it is a motion occupancy sensor or light occupancy sensor. Both occupancy sensor types are expected to last 15 years before replacement is needed. The sensor types operate similarly and the obvious difference being the motion sensor type triggers when it senses motion and the light sensor triggers when someone physically turns the lights on. The light occupancy sensor involves getting an occupancy light switch which costs an additional $100. Our group, along with UWStout HVAC specialist Dennis Luedtke believes that light occupancy sensors are the best route for this application because they only trigger the HVAC system to run onto occupied mode from unoccupied mode if someone turns the lights on in the room instead of just walking by and triggering the motion sensor type of occupancy sensor. It takes a lot of energy for the air handling unit to switch from unoccupied mode to occupied mode and if a custodian or student is just walking by the room, they will run the system unintentionally and waste energy. The costs to install an occupancy sensor in a pneumatic air operated system such as applied arts can be broken down into two parts: the variable air volume (VAV) control unit instillation and the labor. The VAV control units are $500 a piece and two are needed per air handler to switch 28 over to the electronic system needed, regardless of the number of occupancy sensors installed. Next the labor ranges from $500-$1500 on a pneumatic air operated system instillation such as Applied Arts per occupancy sensor. The total cost per occupancy sensor instillation will drop if the occupancy sensors are installed at the same time on the same air handling unit. The table below shows a breakdown of the estimated payback on the rooms that we conducted our case study on in the applied arts. Again the life expectancy for the occupancy sensors is 15 years. Figure 18 Table 3 Occupancy Sensor ROI Room # Air H. # Light occ. Sensor cost VAV control unit cost Labor costs (assuming 2 occ. Sensors installed per AH) (avg.) Energy savings with Occ. Sensor (cost in $) Energy savings with Occ. Sensor (KWh) Return on Investment (years) 132 5 $250 $500 $1,000 $1,365 17,063 1.3 210 9 $250 $500 $1,000 $718 8,975 2.4 112 6 $250 $500 $1,000 $960 12,000 1.8 216 6 $250 $500 $1,000 - - 302 1 $250 $500 $1,000 $252 3,152 6.9 321 9 $250 $500 $1,000 $323 4,033 5.4 $724 9,045 3.6 Averages * Instillation cost estimates based on the assumption that two sensors in two different rooms are being installed at the same time on the same air handler. (Refer to Figure 12 for Energy savings details) Note, the energy savings calculations only include HVAC and do not show the additional 29 cost and energy savings that the occupancy sensors provide from keeping the lights off when the room is unoccupied. Triple Bottom Line People- The effect of this project will affect different groups of people in different ways. The HVAC workers at Stout will have more work from the instillation of the occupancy sensors and the continuation of our project to ensure the best rooms to put the sensors in. The extra work may result in the addition of a part time worker and if not it will help to prevent the campus from cutting back on the HVAC workers. The conservation of energy involved in the project will help to ensure that Stout stays the most energy efficient campus for energy of the 13 four year colleges. The fact that we are the most energy efficient campus in Wisconsin makes Stout more desirable and remains a sense of pride for students and faculty. Profit- There is an obvious profit advantage to the occupancy sensors because the sensors last around 15 years and have a return on investment is an average of 3.6 years according to our case study. On average, the energy savings per room is $724 per year. The expected increase in energy costs will cause these energy savings to increase annually. In addition to the $724 per year per room, there is more profit that may result from occupancy sensors which involves government tax incentives from increased energy efficiency. Also from 30 saving more money now, that money can be used to conduct more energy savings projects in the future that may lead to even more profits. There are also profit opportunities from being a more energy efficient campus which will be more desirable for students that care about the environment which may raise enrollment. Planet- Reducing the carbon footprint was the main focus of our project while be financially feasible. According to our research, the energy savings we calculated includes 9,045 KWh saved annually per Applied Arts room in our case study that an occupancy sensor is added to. Since the University of Wisconsin - Stout does not use any renewable energy, the energy savings will reduce amount of fossil fuels burnt. 31 Conclusion In conclusion we found that implementing a renewable energy project would not be an easy task. We found that economically implementing a renewable energy project would not be fiscally smart decision to make since the options we looked at were not even close to recouping money invested through energy savings. We wanted to make a direct and a lasting impact on campus that would be economically smart decision as well as reducing the carbon footprint of our campus. We then looked to conservation of energy and were directed to occupancy sensors by John Paulus. We found through our case study that occupancy sensors would be a valuable asset to the Applied Arts building. Through our research as shown in our Case Study, we found that the air handlers in Applied Arts would all benefit from the installation of occupancy sensors. The air handlers that would achieve the greatest savings according to our case study were air handlers six and nine. The rooms on these air handlers that would experience the greatest savings would rooms: 112, 210, and 321. We found that by using occupancy sensors the energy and carbon footprint of that room can be reduced by 20%, which in our case study proved to be an average reduction of 9,045 kWh a year. The occupancy sensors have a life expectancy of 15 years, and according to our case study the average return on investment which included one-time VAV control unit installation cost, was 3.6 years. Proving that this is a financially feasible project as well as an appropriate option in reducing the carbon footprint of this campus. Overall occupancy sensors in Applied Arts will reduce the carbon footprint at UW-Stout and will help to reach the goals described in the climate action plan initially reported in September of 2009. After seeing the positive impact of just applying occupancy sensors in Applied Arts, we can only imagine the opportunities in the other 32 campus buildings through occupancy sensors. The reduction of energy and our carbon footprint would be outstanding and truly make a large impact. Especially since Applied Arts is one of the most used campus buildings, so return on investment would be even faster potentially in other buildings. With all the monetary savings achieved through energy savings through occupancy sensors realized, there could be other energy savings projects and even renewable energy projects. 33 Contacts Sarah Rykal, Environmental Sustainability Coordinator at UW-Stout John Paulus, Assistant Building & Grounds Superintendent at UW-Stout Dennis Luedtke, HVAC Specialist at UW-Stout Robert Schutz, Community Service Manager: Xcel Energy Ricky Kaiser, Account Manager for Xcel Energy Scott Correll, Registration and Records at UW-Stout Martha Daines, Capstone Class Project Facilitator Project Timeline 2/7/13 Assigned groups and introduced to team members Created and signed team contract and expectations Exchanged contact information and determined member availability Initiate research and begin to plan out project Emailed Sarah Rykal to set up a meeting to discuss renewable energy on campus 2/8/13 Response received and date set for meeting with Sarah Rykal 2/12/13 Presented an overview of initial plan to Martha Daines 34 Researched what other universities are doing for Sustainable energy initiatives 2/14/13 Meeting with Sarah Rykal discussion included o Current Renewable energy options on campus o Funding for projects o Xcel energy contact information o Facilities and Maintenance Contact information o Solar panel study in 2010 o Focus on Energy Program 2/20/13 Emailed Rob Schultz of Xcel to set up a meeting and talk about renewable energy options 2/21/13 Researched what different Universities are doing for renewable energy and renewable energy options 2/26/13 Researched renewable energy options and looked through the information provided to us by Sarah Rykal Emailed John Paulus to set a meeting to discuss project ideas 3/1/13 Meeting with Rob Schultz and Rick Kaiser of Xcel Energy, who provide service for UWStout, discussion included: o Their Wind-Source program o Solar panel study done for campus 35 o Focus on Energy o Geothermal Options o Xcel Energy background information o Xcel’s energy profile and sources 3/4/13 Prepared Progress Report #1 paper and presentation Looked into information provided by Xcel Energy 3/6/13 Meeting with John Paulus, discussion included: o Insight on renewable energy on campus o Energy conservation project ideas as well as past examples o Energy dashboard project o Occupancy sensors benefits o How the energy is used in campus buildings o Air circulation systems in buildings 3/7/13 Presented Progress Report #1 PowerPoint to class and fielded questions pertaining our project. Listened to presentation from other groups in class. Handed in Progress Report #1 paper to Martha Daines. 3/12/13 Went over information that had been attained and organized what we were focusing on. Emailed John Paulus and requested more information on occupancy sensors as well as information on a previous case study he helped with. 3/14/13 36 Met with Martha Daines to discuss project scope and direction. Answered questions and concerns that were brought up. Decided on title for project: Energy Conservations and Alternative Energy Option Awareness. 3/26/13 Emailed Registration and Records to request information on class schedules in Applied Arts. Worked on narrowing down case study ideas. 3/28/13 Received class schedules for Applied Arts from Registration and Records 4/4/13 Briefly discussed project direction with Martha Daines and options for case study. Begin working on compiling information for final report. 4/12/13 Meeting with John Paulus and Dennis Luedtke discussing case study and learning more about air filtration systems. Received direction on case study and ideas of implementation Talked about variable volume control of air into buildings and different types on occupancy sensors. Switching from pneumatic to electronic based systems 4/15/13 Worked on final report rough draft Complied information that applies to project 37 Worked on Case Study of Applied Arts Worked on Progress Report #2 presentation 4/16/13 Worked on final report rough draft Complied information that applies to project Worked on Case Study of Applied Arts Worked on Progress Report #2 presentation Talked to Martha about project guidelines and requirements 4/17/13 Worked on final report rough draft Worked on Case Study of Applied Arts Worked on Progress Report #2 presentation 4/18/13 Gave Progress Report #2 presentation to class Worked on final report rough draft Handed in rough draft of final report 4/23/13 Met with Martha Daines and discussed project direction Went over comments on rough draft of the report Started work on STEM poster 4/29/2013 Worked on STEM poster Revised final report and added more information 38 4/30/2013 Finished and submitted STEM poster Worked on revisions for final report Compiled more information for report Worked on final presentation 5/1/2013 Started finishing touches of report Worked on final presentation 5/2/2012 Finished final draft of report Email Correspondence ______________________________________________________________________________ From: McVenes, Joel Sent: Thursday, February 07, 2013 4:51 PM To: Miller, Brock Cc: Wang, Youzhu Next steps for Tuesday 2/12. Research what other colleges have in place for renewable energy. -------everyone Research renewable energy options and details (ignore implementation costs for now) -------everyone Find a contact for university of Minnesota- Morris. Windmill -----------Joel Joel C. McVenes B.S. Packaging 39 University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ From: <McVenes>, Joel <mcvenesj@my.uwstout.edu> Date: Thursday, February 7, 2013 4:43 PM To: Sarah Rykal <rykals@uwstout.edu> Cc: "Miller, Brock" <millerbroc@my.uwstout.edu>, "Wang, Youzhu" <wangy8068@my.uwstout.edu> Subject: meeting for Sustainability project Sarah, Brock, Youzhu and I would like to set up a short meeting with you (under 30 min.) to talk about our group project for sustainability 425. The topic we selected is renewable energy and we would like to discuss the scope for our project and need your help in pointing us in the correct direction to keep moving on the project. Our hours of availability for next week are: Monday (2/11) before 10am. Tuesday between 2:30- 6:00pm, Wednesday 12:15-3:00pm, Thursday 2:30-6:00 and Friday before 10am. Please let us know what half hour time slot will work for you. Thanks Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ From: <Rykal>, Sarah Rykal <rykals@uwstout.edu> Date: Friday, February 8, 2013 1:44 PM To: "McVenes, Joel" <mcvenesj@my.uwstout.edu> Cc: "Miller, Brock" <millerbroc@my.uwstout.edu>, "Wang, Youzhu" <wangy8068@my.uwstout.edu> Subject: Re: meeting for Sustainability project Hi Joel, This sounds great! How about 2:30-3:30 next Thursday? We can meet in my office — 225 Administration Building. Thanks, Sarah -Sarah Rykal Environmental Sustainability Coordinator 40 University of Wisconsin-Stout 715.232.5254 ______________________________________________________________________________ From: Rykal, Sarah <rykals@uwstout.edu> Sent: Thursday, February 14, 2013 5:07 PM To: McVenes, Joel Cc: Miller, Brock; Wang, Youzhu Subject: Re: meeting for Sustainability project Attachments: UWStout_Sports-Fitness_Solar_Electric_Assessment Appendix.pdf; DSF Grant Proposal - Revised.docx Hi everyone, Thanks for meeting with me today! I'm excited about your project! I'm attaching the solar assessment we discussed today. I'm also attaching the grant that Alan and I worked on, to request funding for solar panels. I was informed today that the university has about $116,000 set aside for various energy projects, so if we can get Xcel Energy or other contributors, we would be able to match the funds to start a renewable energy project. So keep that in mind as you move forward. Thanks, Sarah -Sarah Rykal Environmental Sustainability Coordinator University of Wisconsin-Stout 715.232.5254 www.uwstout.edu/sustainability www.facebook.com/sustainablestout ______________________________________________________________________________ From: Rykal, Sarah Sent: Thursday, February 14, 2013 5:10 PM To: Paulus, John Cc: McVenes, Joel; Miller, Brock; Wang, Youzhu Subject: Renewable Energy Project Hi John, I met with some students in the Sustainability capstone course today. They're interested in assessing renewable energy options for the campus and I think they'll be contacting you very soon. They're copied here. If you have any questions, please let me know. Thanks a bunch! Sarah -Sarah Rykal 41 Environmental Sustainability Coordinator University of Wisconsin-Stout 715.232.5254 ______________________________________________________________________________ From: <Paulus>, John <paulusj@uwstout.edu> Date: Friday, February 15, 2013 6:59 AM To: Sarah Rykal <rykals@uwstout.edu> Subject: RE: Renewable Energy Project Thanks, I am always interested in meeting with students. I look forward to talking to them. You are Welcome. John ______________________________________________________________________________ From: Sent: To: Cc: Subject: Rykal, Sarah <rykals@uwstout.edu> Friday, February 15, 2013 2:40 PM Paulus, John McVenes, Joel; Miller, Brock; Wang, Youzhu Re: Renewable Energy Project Thanks John! -Sarah Rykal Environmental Sustainability Coordinator University of Wisconsin-Stout 715.232.5254 www.uwstout.edu/sustainability _____________________________________________________________________________ From: McVenes, Joel [mailto:mcvenesj@my.uwstout.edu] Sent: Tuesday, February 26, 2013 4:22 PM To: Schultz, Robert C Cc: Wang, Youzhu; Miller, Brock Subject: UW-stout renewable energy project Bob, Brock, Youzu and I are conducting a renewable energy project for UW-stout's campus. We are looking to add renewable energy to Stout in whichever way feasible yet favorable to the campus. Attached is a copy of the assessment for solar energy on campus conducted in 2010. We would like to meet with you to discuss the solar power option as well as possible leasing situations for wind energy. The hours we are available to meet this week (week of 2/25) are as follows: Tuesday 3-6, wed. 1:30- 3:30, Thurs 3:30-6:00 and Friday 8-10. For the next week (week of 2-4) 42 is availability is as follows: Monday- 1:30-3:30, Tuesday 3-6, wed. 1:30- 3:30, Thurs 3:00-6:00 and Friday 8-10. If these times do not work; please let us know and we will accommodate to meet your schedule with whoever can make it. Please let us know what works for you and we look forward to meeting you. We are willing to meet at your office if you would please provide us with the address. Thanks Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu 608-963-6886 From: Schultz, Robert C Sent: Wednesday, February 27, 2013 8:49 AM To: 'McVenes, Joel'; Kaiser, Ricky S Cc: Wang, Youzhu; Miller, Brock Subject: RE: UW-stout renewable energy project Hi Joel, thanks for the follow-up note. Yes Rick Kaiser & I would be available to meet with you at our office in Menomonie this Friday at 9:00 AM. Rick is the Account Manager for this area and UW Stout is one of his assigned accounts so I have invited him to our meeting. Rick’s office is in Menomonie as well and he can be reached at 715-232-7474 for your future reference. We are looking forward to meeting with you to discuss the universities interest in renewable energy projects. Please reply to this e-mail confirming you are able to meet this Friday at 9:00 AM. Best Regards! Bob Robert C. Schultz Xcel Energy | Responsible By Nature Community Service Manager, CEM 320 Heller Road, Menomonie, WI 54751 P: 715.232.7401 C: 715.577.4927 E: robert.c.schultz@xcelenergy.com ______________________________________________________________________________ From: McVenes, Joel Sent: Thursday, February 28, 2013 2:21 PM To: Miller, Brock; Wang, Youzhu Subject: not making it to class today 43 Brock and Youzhu, I am not going to be able to make it to class today, but we are meeting with Rob Schultz from excel energy in his office at 9:00 tomorrow at 320 Heller Road, Menomonie, WI 54751. If you need a ride please let me know 608-963-6886. I will prepare questions for him and I ask that you both do the same (at least have a couple questions ready). We want to discuss the solar power option as well as leasing wind power options. I will print out the solar power assessment and bring it to the meeting. Any questions please ask me. Please respond to this email to confirm that you can make the meeting. See you tomorrow. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ Feb 28, 2013,2:29 PM, "Miller, Brock" <millerbroc@my.uwstout.edu>: Joel, I can make the meeting tomorrow, I will drive myself to the meeting as well. Youzhu, do you want to meet for class today? Since this is a small group and we are meeting tomorrow I think we should just skip today and plan on meeting tomorrow. Brock ______________________________________________________________________________ From: Wang, Youzhu Sent: Thursday, February 28, 2013 3:36 PM To: Miller, Brock Cc: McVenes, Joel Subject: Re: not making it to class today Do we have class today? I can go tomorrow, but I must come back before10:10. Additional, I need a ride, if one of you pick me at North Hall? My phone is 7155014525 Youzhu 发自我的 ______________________________________________________________________________ From: Schultz, Robert C <robert.c.schultz@xcelenergy.com> Sent: Friday, March 01, 2013 1:15 PM 44 To: McVenes, Joel; Kaiser, Ricky S Cc: Wang, Youzhu; Miller, Brock Subject: RE: UW-stout renewable energy project Joel, Youzhu & Brock; Thanks for meeting today with us at Xcel Energy. Rick & I both enjoyed your visit and hope you found it well worth your time. The following contact at Focus On Energy could assist you with who from their organization would be your Representative. Amy Wanek 608-277-8040 Take care and let us know if you would like to meet again or if you have follow-up questions. Thanks! Bob Robert C. Schultz Xcel Energy | Responsible By Nature Community Service Manager, CEM 320 Heller Road, Menomonie, WI 54751 P: 715.232.7401 C: 715.577.4927 E: robert.c.schultz@xcelenergy.com From: Wang, Youzhu Sent: Monday, March 11, 2013 11:59 PM To: McVenes, Joel; Miller, Brock Subject: CLASS Hi guys, I cannot go class tomorrow. Do you want to change to go class on Thursday or you want to go tomorrow? Youzhu From: Miller, Brock Sent: Tuesday, March 12, 2013 12:18 AM To: McVenes, Joel Subject: RE: CLASS You cool with just meeting with Martha on Thursday? I am fine with it, but doesn’t really matter to me. Also if we do not meet with Martha tomorrow, do you want to meet quick to go over some things? Brock ______________________________________________________________________________ 45 From: McVenes, Joel Sent: Tuesday, March 12, 2013 11:41 AM To: Miller, Brock Subject: RE: CLASS Brock, I am fine with just meeting with Martha on Thursday. If you want to meet beforehand to go over some things, it works for me. I'm just going to be working on the CPIT test all day at my house. Swing by if you want to meet with me. 408 18th ave e. right by the tennis courts. I will be working on it from now til 6. Then I’m going to eau claire. If you want to meet tomorrow to go over stuff, that works too but I might be going to Stevens Point for a 4 o clock meeting which would mean I would have to meet between 11:15 and 2. Ill email youhzu and tell her that we will meet Thursday with Martha. ps. do we have to email Martha and tell her when we want to meet? Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu From: Miller, Brock Sent: Tuesday, March 12, 2013 12:20 PM To: McVenes, Joel Subject: RE: CLASS Joel, I don’t think we need to email Martha but I could be wrong. I am not sure how my afternoon is shaping up right now but if I am going to stop over I will shoot you a text in advance. Brock PS Good luck on your CPIT test. ______________________________________________________________________________ From: Paulus, John [mailto:paulusj@uwstout.edu] Sent: Thursday, March 14, 2013 10:07 AM To: Miller, Brock Subject: FW: Final Draft of the BIL Stairwell Analysis Here you are have fun. 46 John __________________ Subject: FW: Final Draft of the BIL Stairwell Analysis John: Someone else proof read my paper and said that had a couple of words misspelled. My spell checker missed them. There were a couple of other modifications to the report. Please use this copy if you need to submit it for purchasing the BIL fixtures. Thanks again and speak with you later this week. Paul __________________ John: Thank you for your time on Friday. I am wondering what day this week would work the best for you to go over this final report. It should only take 5 – 10 minutes. The sound quality on my last interview was not the good, and I was not as prepared as I should have been and need a better recording. Please let me know what day the alligators are least likely be at your feet, and I will schedule my time around yours. I thank you for your time and patience on completing me course requirements. Best regards, Paul Duerst ______________________________________________________________________________ From: McVenes, Joel Sent: Thursday, March 14, 2013 11:54 AM To: Miller, Brock Subject: RE: Final Draft of the BIL Stairwell Analysis nice. Thanks brock. do you want to meet before class today to discuss what we need to go over with Martha? should we just meet at 3:00 at the table on 3rd floor Fryklund overlooking the campus??? Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ 47 From: dainesm@uwstout.edu [dainesm@uwstout.edu] Sent: Thursday, March 14, 2013 5:13 PM To: McVenes, Joel; Miller, Brock; Wang, Youzhu Subject: Website link PLUS need your STEM expo title by tomorrow I meant to ask you for a title for your STEM expo poster. Could you send me one by tomorrow noon? Thanks! Here's the link to the energy use in state buildings document: http://www.doa.state.wi.us/docview.asp?docid=7596&locid=4 Martha J. Daines Instructor Engineering and Technology Department University of Wisconsin-Stout ______________________________________________________________________________ From: McVenes, Joel Sent: Thursday, March 14, 2013 11:15 PM To: dainesm@uwstout.edu; Miller, Brock; Wang, Youzhu Subject: RE: Website link PLUS need your STEM expo title by tomorrow Title for STEM expo poster: Energy Conservation and Alternative Energy Option Awareness Any objections Martha or group? I am fine with the title above, and also "energy conservation and renewable energy" would work too. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ From: Miller, Brock Sent: Thursday, March 14, 2013 11:17 PM To: McVenes, Joel; dainesm@uwstout.edu; Wang, Youzhu Subject: RE: Website link PLUS need your STEM expo title by tomorrow I am good with that. Brock ______________________________________________________________________________ From: McVenes, Joel [mailto:mcvenesj@my.uwstout.edu] Sent: Tuesday, March 26, 2013 4:18 PM To: Registrar's Office Cc: Miller, Brock; Wang, Youzhu Subject: FW: class occupancy times in applied arts 48 Greetings registration and records personnel, Brock, Youzhu and I are currently working on an energy conservation project for Martha Daines Sustainability Design and Development Capstone 425. We are looking at the benefits of putting occupancy sensors in the applied arts building that will control not only the lights but also the air filtration systems. What we would like to get from you guys at registration is a list of times that classes are in each particular room in applied arts. The number of people who attend each of these classes is not vital, but it would help if it is easy to obtain. Please email me back if you have any questions or give me a call (cell listed below). Thanks for your help. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu 608-963-6886 ______________________________________________________________________________ From: Correll, Scott <corrells@uwstout.edu> Sent: Thursday, March 28, 2013 2:06 PM To: McVenes, Joel; Miller, Brock; Wang, Youzhu Cc: Sveum, Kathryn Subject: FW: class occupancy times in applied arts Attachments: McVenes 03282013 Room Request.xls Hi Joel, Here is the information that you requested. Please let Kathy or I know if you have additional questions. Thanks. //Scott Scott Correll Registration and Records UW-Stout Wisconsin’s Polytechnic University 715/232-1233 corrells@uwstout.edu ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Monday, April 15, 2013 8:51 AM To: McVenes, Joel 49 Cc: Paulus, John Subject: Occupancy Sensors,etc. Joel The Occ. Sensors are about $150,the VAV control units $500,Occ lite switches $100. Labor on an existing DDC [ Direct Digital Control] would about $ 500, on an older pneumatic [air] operated system the labor would be about $1000-1500, depending on situation. If you need help calculations on annual cost/savings/ payback, etc. feel free to contact me. Dennis From: McVenes, Joel Sent: Monday, April 15, 2013 8:18 PM To: Wang, Youzhu Cc: Miller, Brock Subject: case study format Attachments: applied arts-occupancy study.xlsx Youhzu, Here is the case study template. I filled in when class is and labs are, but we will trade off doing walk throughs to see if people are in the rooms and/or if the lights are on. Read the key at the top of the page to see what you need to fill in. Call me if you have questions. See you in class tomorrow. Print this off for your reference if ya could. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu From: McVenes, Joel [mailto:mcvenesj@my.uwstout.edu] Sent: Tuesday, April 16, 2013 4:54 PM To: Luedtke, Dennis Cc: Miller, Brock Subject: RE: Occupancy Sensors,etc. Dennis, 50 We would like to meet with you briefly to discuss a couple things later this week about our project. Our hours of availability are: Wednesday after 12, Thursday between 2:30 and 3:30, and Friday before 10 am. Should only need a half hour of your time. The main things we want to discuss/ accomplish from this meeting are: - get a copy of the AutoCAD drawings of applied arts layout - discuss the rooms we picked for our case study that we recently revised and began this Monday (attached) - Discuss annual savings from the occupancy sensors Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ From: McVenes, Joel Sent: Thursday, April 18, 2013 5:04 PM To: Luedtke, Dennis Cc: Miller, Brock Subject: RE: Occupancy Sensors,etc. We plan on stopping in tomorrow (Fri) at 8:30. hopefully you are not busy otherwise we will try and reschedule for early next week. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 7:46 AM To: McVenes, Joel Subject: RE: Occupancy Sensors,etc. Thursday at 2:30 works for me, Dennis ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 8:03 AM To: McVenes, Joel 51 Subject: Emailing: DSF-11B3V.JCI UWSTOUT APPLIED ARTS LAB EXHAUST HVAC CONTROLS ASBUILDS.pdf Your message is ready to be sent with the following file or link attachments: DSF-11B3V.JCI UWSTOUT APPLIED ARTS LAB EXHAUST HVAC CONTROLS ASBUILDS.pdf Note: To protect against computer viruses, e-mail programs may prevent sending or receiving certain types of file attachments. Check your e-mail security settings to determine how attachments are handled. ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 7:56 AM To: McVenes, Joel Subject: Emailing: EQUIP-HVAC_AA-1.pdf, EQUIP-HVAC_AA-3.pdf, EQUIP-HVAC_AAb.pdf, EQUIP-HVAC_AA-p.pdf, EQUIP-HVAC_AA-R.pdf, Exh.Fans A.A..xls, HVAC Equip A.A..xls, Map of Card Access-1.pdf, Map of Critical Equip-1.pdf, Map of Critical Equip-b.pdf, Map of Selective Your message is ready to be sent with the following file or link attachments: EQUIP-HVAC_AA-1.pdf EQUIP-HVAC_AA-3.pdf EQUIP-HVAC_AA-b.pdf EQUIP-HVAC_AA-p.pdf EQUIP-HVAC_AA-R.pdf Exh.Fans A.A..xls HVAC Equip A.A..xls Map of Card Access-1.pdf Map of Critical Equip-1.pdf Map of Critical Equip-b.pdf Map of Selective Equip-1.pdf Map of Selective Equip-2.pdf Map of Selective Equip-3.pdf Map of Selective Equip-b.pdf Map of Selective Equip-p.pdf ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 7:54 AM To: McVenes, Joel Subject: Emailing: AHU-1.pdf, AHU-2.pdf, AHU-3.pdf, AHU-4.pdf, AHU-b.pdf 52 Your message is ready to be sent with the following file or link attachments: AHU-1.pdf AHU-2.pdf AHU-3.pdf AHU-4.pdf AHU-b.pdf ______________________________________________________________________________ From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 7:53 AM To: McVenes, Joel Subject: Emailing: APPA-1.pdf, APPA-2.pdf, APPA-3.pdf, APPA-b.pdf, APPA-p.pdf, APPARoof Info 0019.pdf, Room Report_Applied Arts.pdf Your message is ready to be sent with the following file or link attachments: APPA-1.pdf APPA-2.pdf APPA-3.pdf APPA-b.pdf APPA-p.pdf APPA-Roof Info 0019.pdf Room Report_Applied Arts.pdf ______________________________________________________________________________ From: Wang, Youzhu Sent: Thursday, April 18, 2013 12:42 AM To: Miller, Brock; McVenes, Joel Subject: draft Attachments: Social impact.docx This is "social and environmental impact". And I will do other universities' in the morning. You can see this first. Because the time is so limited, there must be lots of bugs. If there is anything else need help, just let me know. Good Night!:) Youzhu From: McVenes, Joel [mailto:mcvenesj@my.uwstout.edu] Sent: Thursday, April 18, 2013 12:48 PM To: Luedtke, Dennis Subject: RE: Occupancy Sensors,etc. 53 Dennis, Please disregard my last email. We do not have time to meet today due to our other class conflicts that came up. Could you meet with us tomorrow (fri 4/19) before 10 am, or Monday any time after 12:00, or Tuesday between 2:30-5:00?? Sorry for the reschedule. Joel C. McVenes B.S. Packaging University of Wisconsin - Stout mcvenesj@my.uwstout.edu From: Luedtke, Dennis [luedtked@uwstout.edu] Sent: Thursday, April 18, 2013 3:25 PM To: McVenes, Joel Subject: RE: Occupancy Sensors,etc. Try Fri. ______________________________________________________________________________ The Rooms Room 112 54 Room 132 Room 210 55 Room 321 56 Works Cited University of Minnesota, M. (2010, August 23).Discovering Renewable Energy Solutions. Retrieved from http://www.morris.umn.edu/sustainability/research/ University of Wisconsin, E. C. (2013, April 22). Renewable Energy . Retrieved from http://www.uwec.edu/centers/sustainability/daviesCenter/renewable.htm University of Wisconsin, P. (2013, April 09). SRES at UW-Platteville. Retrieved from http://www.uwplatt.edu/ee/renewableenergy/ University of Wisconsin, O. (2012, November 09). Renewable Energy. Retrieved from http://www.uwosh.edu/sustainability/what-were-doing/energy University of Wisconsin, W. (2010, December 22). Solar Panels Generating Electricity Atop Hyland Hall at UW-Whitewater. Retrieved from http://www.uww.edu/news/archive/2010-12-solar-electricity-hyland-hall Rykal, S. (2013, February 19). Interview by J McVenes []. Sustainability at University of Wisconsin-Stout. Paulus, J. (2013, March 06). Interview by B Miller []. Conservation of Energy on Campus. Schultz, R. (2013, March 01). Interview by B Miller []. Xcel Energy and Renewable Energy Options. Luedtke, D. (2013, April 12). Interview by J McVenes []. HVAC Systems and Occupancy Sensors. Rundus, Richard. E. User Guide for Occupancy Sensor Lighting Controls in Army Administrative Facilities. Retrieved from http://www.dtic.mil/dtic/tr/fulltext/u2/a283888.pdf.Champain,IL.61826 57 Xcel Energy, C. (2013, May 01). Upper Midwest Wind Power. Retrieved from http://www.xcelenergy.com/Environment/Renewable_Energy/Wind/Upper_Midwest_Wind_Po wer 58 Thank You We would like to extend a big thank you to everyone who has helped us along the way with this project. This project would not have been a possibility without you! Martha Daines Ricky Kaiser Dennis Luedtke John Paulus Sarah Rykal Robert Schutz 59