Steel-Based Infiltration – A Method to Achieve Full Density Higher- ABSTRACT

advertisement

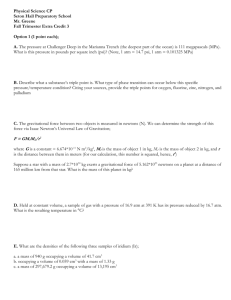

Steel-Based Infiltration – A Method to Achieve Full Density HigherPerformance Powder Metal Parts F. J. Semel and K. S. Narasimhan Hoeganaes Corporation, Cinnaminson, NJ 08077 ABSTRACT This paper presents the current state of the art of the iron base infiltration process. The several papers detailing the efforts made in the last few years to develop the process and assess its mechanical property potential and dimensional change characteristics are reviewed and presented in summary form. INTRODUCTION Recent efforts to develop iron base infiltration, as a viable parts making process were first reported in two papers in 2004 [1, 2]. A survey of the open literature, at the time, indicated that past efforts to develop the process predated the present ones by about twenty years or more. The survey disclosed six articles on the subject [3 - 8]. All were published before 1985 and were apparently the output of independent research in three laboratories. They reported studies on three different alloy systems. However, none of the associated findings were sufficiently compelling to justify continued efforts and subsequent interest in the process waned. A common difficulty at that time, which may have been central to this outcome, was the general inability to prevent the adverse effects of admixed alloy segregation during processing after mixing. Thus, it may well be that the key element underlying the relatively greater success of the present efforts is the intervening development of the binder treatment process [9, 10, 11]. Certainly, there is absolutely no doubt in the case of the present process that it would not have even survived the preliminary assessment stage had it not been for binder treatment. Subsequent to the 2004 papers, which detailed the metallurgical fundamentals of the process, studies were reported in each of the following two years that provided further information as to the properties to be expected of the infiltrated parts. Alloy effects on tensile and transverse rupture properties were reported in 2005, and the effects of thermal processing on dimensional change and infiltrated surface appearance were reported in 2006 [12, 13]. Minus a few results that have patent potential, these four papers represent the present state of the art of the process. However, they still remain to be reviewed and consolidated as such. Thus, the objective of this paper is to indicate the present state of the art of the process by summarizing and, in certain instances, updating earlier findings in the form of a review. Development of the Basic Infiltration Process The focus of the earliest work [1, 2], as presented in 2004, was to establish a basic understanding of the process and to define the conditions needed to implement it as a practical matter. It was shown that infiltration to near theoretical densities was possible in several Fe-C based alloy systems. The necessary processing conditions generally included temperatures below 1200 oC (2190 oF), times of less than ½ hour and the use of standard hydrogen-nitrogen atmospheres with modest methane additions to control the carbon potential (typically less than 0.5 v/o). The required infiltrant composition was at or near the corresponding eutectic liquidus value of the selected alloy system and the required base compact composition was likewise at or near the eutectic solidus value. The possibility to combine an infiltrant composition of one alloy system with a base compact composition of another system was also demonstrated. In addition, it was shown that base compact densities of 6.8 g/cm3 or less were sufficient to obtain a virtually pore free density after infiltration. The optimum base compact density in terms of maximizing the infiltration rate and minimizing the infiltrant weight to full density was determined to be about 6.7 g/cm3. The as-infiltrated carbon contents of the alloy systems that were studied typically ranged from about 2 % to about 2.35 %. In an otherwise un-alloyed Fe-C composition, carbon contents in this range normally result in an as-infiltrated microstructure which consists of pearlite in a network of hyper-eutectoid grain boundary carbides. Such microstructures are inherently brittle and, unless submitted to a so-called ‘malleablizing’ anneal have limited potential for structural applications [14]. Consequently, the possibility to use alloy additions to graphitize the hyper-eutectoid carbon and produce cast-iron like microstructures was investigated. It was found that modest additions of either silicon or nickel were effective in this regard. However, based on what was generally known of their alloying effects as well as the results of a series of trials with pre-alloyed nickel compositions, it was concluded that the silicon was the better choice for future development. Consequently, subsequent work was directed towards obtaining a sufficient understanding of its effects on both the infiltration and graphitization processes to facilitate the design of silicon containing infiltrant and base compact compositions. The ultimate objective was to normalize the development of the technology in terms of one such alloy in each case as standard iron base infiltration compositions. Standard Compositions As it turned out, the defining studies indicated silicon contents that nominally averaged 0.18 % for the infiltrant composition and 0.75 % for the base compact composition. Based on the eutectic equilibrium of the Fe-C-Si system as indicated by the ThermoCalc program [15], the corresponding carbon contents were 4.28 % for the infiltrant and 1.91 % for the base compact. The infiltrant weight to full density in this alloy system is about 15% of the base compact weight. Thus, based on the infiltrant and base compact compositions in each case, its easily shown that the respective carbon and silicon contents to be expected after infiltration are about 2.27 % and 0.66 %. Likewise, assuming that all of the hyper-eutectoid carbon is graphitized during the process and that the balance forms pearlite, it can also be shown that the final density to be expected is about 7.53 g/cm3. The attendant studies of the systems reasonably confirmed each of these expectations. Distortion Effect The distortion effect, which may be unique to iron base infiltration, is a result of density gradations in the infiltrated compact that are manifest as a disparity in the lateral dimensions of the infiltrated and opposing un-infiltrated surfaces. The greatest variations always occur immediately under the infiltrated surface to a depth of a few millimeters but may occur elsewhere as well. As a consequence, the magnitude of the effect is measured simply as the difference in the lengths of the infiltrated and opposing un-infiltrated surfaces. Typically, the effect is large enough that if not otherwise mitigated, the resultant parts will require a machining step before they can be put into service in all but the least demanding applications. Preliminary study of the effect indicated that there were two different causes: a primary one; and an, intermittently occurring, secondary one. The primary cause was determined to be liquid penetration and dissolution during infiltration of the sinter bonds existing in and just below the surface of the base compact followed by lateral expansion of the affected area under the influence of the surface tension forces that act on the as yet un-infiltrated liquid. The secondary cause is incomplete graphitization of the hypereutectoid carbon, which is typically limited to the lower regions of the infiltrated compact. Theoretical considerations suggested several possibilities to mitigate the primary cause of the effect. However, the simplest way found to prevent it is to use an infiltrant compact with a smaller cross section than that of the base compact and to position it on the base compact so that the centerlines of the two roughly coincide with each other. The secondary cause of the effect was determined to be amendable to either or both of the alloy content of the graphitizing element and the cooling rate after infiltration. Given the silicon contents of the standard compositions, the maximum permissible cooling rate needed to prevent distortion due to this cause is about 20 oC/min. (0.6 oF/sec.). Mechanical Property Studies The study reported in 2005 was conducted to survey the transverse rupture and tensile properties of the standard composition as well as to determine the effects on tensile properties of minor alloy modifications of the base compact composition [12]. The latter included one or more of copper, nickel, manganese and molybdenum. In addition to the as-infiltrated properties, the study also surveyed the effects of various heat treatments. These included stress relieving, sub-critical (or so-called light) annealing, and normalizing. The study was conducted in three phases, each with slightly differing objectives in terms of the alloy modifications and the heat treatments that were examined. The sintering and infiltration conditions, however, were the same in all three cases: the infiltrant weight was nominally 13.5% of the base compact weight; thermal processing was in a production belt furnace; the atmosphere was 90 v/o N2 – 10 v/o H2 with 0.25 v/o CH4 added to control the carbon potential; infiltration was at 1185 oC (2165 oF) for ½ hour at temperature; and, cooling subsequent to infiltration averaged about 10 oC/min. (0.3 oF/sec.). Phase I The tensile properties of the standard infiltrant and base compact compositions and the alloy effects of modest additions to the base compact composition of copper, nickel, and manganese were determined in each of the as-infiltrated, stressed relived, and sub-critically annealed conditions. The as-infiltrated results are shown below in Table 1. The final carbon contents of the specimens in this case ranged from ~ 2.0 to 2.1 %. Assuming complete graphitization of the hyper-eutectoid carbon contents involved, the corresponding pore free densities of the specimens would be expected to range from ~ 7.52 to 7.54 g/cm3. Thus, the densities of the five compositions listed in the table were all upwards of 96 % of the pore free value. Table 1 – As-Infiltrated Properties of the Si Base and Cu, Ni and Mn Modified Mixes Yield Strength Ultimate Strength Elongation Hardness Alloy ID 3 MPa (103 psi) % in 2.5 cm HRA MPa (10 psi) 353.7 (51.3) 468.2 (70.0) 1.4 56 Base (0.75%Si) 422.0 (61.2) 597.1 (86.6) 2.2 60 Base + 1 Cu 376.5 (54.6) 504.0 (73.1) 1.7 55 Base + 1 Ni (62.5) 582.6 (84.5) 1.8 60 Base + 1 Cu + 1 Ni 430.9 384.7 (55.8) 515.7 (74.8) 1.5 57 Base + 0.5 Mn Density g/cm3 7.47 7.43 7.46 7.25 7.34 As expected, the tensile and hardness results in the table showed that the Si Base composition had the lowest overall properties. In comparison, each of the alloy compositions exhibited substantially higher strength values and in most cases, modestly higher ductility and hardness values as well. The greatest increases in all four properties were in the specimens of the Base + 1Cu and the Base + 1Cu + 1Ni compositions. In view of the relatively low density of the latter, the general implication of the findings was that copper was the single most effective alloy addition. The stress relief anneal generally led to very modest improvements in the ultimate strength and ductility values but to little or no change in the yield strength, hardness or density values. In contrast, the subcritical anneal led to fairly substantial ductility increases but to equally significant decreases in strength and hardness. The density, in most cases, was unaffected by this treatment. The results of the sub-critical anneal are shown below in Table 2. Table 2 – Sub-Critically Annealed Properties of the Si Base and Cu, Ni and Mn Modified Mixes Yield Strength Ultimate Strength Elongation Hardness Density Alloy ID MPa (103 psi) % in 2.5 cm HRA g/cm3 MPa (103 psi) 315.8 (45.8) 475.8 (69.0) 2.1 55 Si Base 7.47 363.4 (52.7) 561.9 (81.5) 2.7 57 Base + 1 Cu 7.39 326.8 (47.4) 490.2 (71.1) 2.5 55 Base + 1 Ni 7.46 (48.5) 506.8 (73.4) 3.4 53 Base + 1 Cu + 1 Ni 334.4 7.25 324.1 (47.0) 475.8 (69.0) 2.1 54 Base + 0.5 Mn 7.34 The presence of free graphite in these compositions makes them similar in many respects to the cast irons. Apart from alloy content and the microstructure of the iron base matrix, it is the morphology of the graphite precipitates that largely determines the properties of the cast irons. In general, there are four different morphologies that comprise the predominant types in each of the four principal cast iron grades. In order of decreasing symmetry and correspondingly, of decreasing potential in terms of mechanical properties, these include: 1) the nodular or spheroidal type of the Ductile cast irons; 2) the temper carbon type of the Malleable cast irons; 3) the vermicular or compacted type of the Compacted Graphite cast irons; and, 4) the flake type of the Grey cast irons [14]. The predominant graphite morphology of the present compositions including those that have yet to be discussed is the vermicular or compacted type. Thus, it is of interest to compare the properties of the present compositions with those of the Compacted Graphite (or CG) cast irons. These are shown below in Table 3 [16]. A brief review of the data in Table 3 will show that the highest strength and hardness properties are associated with the normalized condition and the highest ductilities are those of the ferritized (full annealed) condition. Predictably, the strength and hardness values of the nickel-containing grade were generally better than those of the un-alloyed grade. Table 3 - Typical Tensile Properties Of Compacted Graphite Cast Irons Yield Tensile Elongation Iron Strength Strength Condition (a) Matrix MPa (ksi) MPa (ksi) % 60% F 263 (38.1) 325 (47.1) 2.8 As-Cast (b) 100% F 231 (33.5) 294 (42.6) 5.5 Ferritized (c) 90% P 307 (44.5) 423 (61.3) 2.5 Normalized 328 (46.7) 427 (61.9) 2.3 As-Cast … (b) 100% F 287 (41.6) 333 (48.3) 6.0 Ferritized (c) 90% P 375 (54.4) 503 (73.0) 2.0 Normalized Hardness HRA 48 47 52 53 49 56 (e) Nickel % 1.5 1.5 1.5 (a) F, ferrite; P, pearlite. (b) Annealed, 2 hr. at 900 oC (1650 oF), furnace cooled to 690 oC (1275 oF), held 12 hr., cooled in air. (c) Austenitized 2 hr. at 900 oC (1650 oF), cooled in air. (e) Converted from Brinell values. Comparison of the data in this table with those in the earlier Table 1 will show that the strength and hardness of all of the infiltrated compositions were significantly better than those of both of the CG irons in the as cast condition and of the plain CG iron in the normalized condition. Otherwise, the strength and hardness of the Si Base composition closely approached those of the nickel-containing grade in the normalized condition while those of the remaining four compositions were either equivalent or substantially better than those of the nickel grade in the normalized condition. The fact that the strengths and hardnesses of the infiltrated compositions were generally better than those of the CG cast irons is thought to be attributable to the inherently lower densities of the cast irons. For example, compared with the present compositions, the cast irons generally have both higher carbon and higher silicon contents and each lead to significantly lower pore free densities. In the case of the CG irons, quantitative estimates indicate that their pore free density ranges from about 7.17 g/cm3 in the ferritized condition to about 7.25 g/cm3 in the normalized condition. It is also of interest to compare the properties of the present compositions with those of the standard P/M grades. Since the microstructures of the infiltrated compositions are predominantly pearlitic, the most realistic comparison is with the predominantly pearlitic P/M grades or, in effect, with the 0.6 to 0.9 % carbon containing grades in the as-sintered condition. MPIF Standard 35 lists three such grades, which are otherwise plausibly comparable in terms of their total ‘second’ alloy contents. These include the following: F-0008, FC-0208 and FN-0208. The highest tensile properties that Standard 35 lists for each are shown below in Table 4. Table 4 – Tensile Properties of Comparable Standard P/M Grades Yield Strength Ultimate Strength Elongation MPIF Grade Designation MPa (103 psi) % in 2.5 cm MPa (103 psi) 275.8 (40.0) 393.0 (57.0) 1.0 F-0008-35 448.2 (65.0) 517.1 (75.0) <1.0 FC-0208-60 379.2 (55.0) 620.6 (90.0) 3.0 FN-0208-50 Hardness HRA * 44 52 54 Density g/cm3 7.0 7.2 7.4 * Converted from HRB values. Limiting the considerations to the Si Base and Base + 1Cu compositions, comparison of the data in this table with those in the earlier Table 1 will show that the properties of the Si Base were far superior to those of the F-0008 grade and otherwise approached those of the FC-0208 grade. Similarly, the properties of the Base + 1Cu composition were generally superior to those of the FC-0208 grade and rivaled those of the FN-0208 grade. Here again, the higher density of the infiltrated compositions is almost certainly the major underlying cause of the indicated differences. Phase II The second phase of the study had the objective to determine the effects on tensile properties of modest additions of molybdenum and molybdenum plus copper. The additions were made to the standard Si Base composition and the properties were again determined in the as-infiltrated, stress relieved, and subcritically annealed conditions. As in Phase I, the properties in the stress-relieved condition were in most cases very similar to those of the as-infiltrated condition. However, in the case of the Base + 0.5 Mo + 2 Cu composition, the stress relief effected significant increases in both the yield and ultimate strength values of the order of 70 Mpa (10,000 psi) each. Thus, in this instance, it is appropriate to present and discuss the stress relieved properties rather than the as-infiltrated ones. These are shown overleaf in Table 5. Table 5 -Tensile Properties of the Molybdenum Containing Alloys in the Stress Relieved Condition Elastic Yield Ultimate Elongation Hard. Den. Modulus Strength Strength Alloy ID GPa (106 psi) MPa (103 psi) MPa (103 psi) % in 2.5 cm RHA g/cm3 162.0 (23.5) 450.2 (65.3) 648.1 (94.0) 2.0 56 Base + 0.3 Mo 7.49 162.7 (23.6) 570.2 (82.7) 685.4 (99.4) 1.3 58 Base + 0.5 Mo 7.53 1.7 61 Base + 0.3 Mo + 1 Cu 171.0 (24.8) 588.1 (85.3) 748.1 (108.5) 7.50 1.3 69 Base + 0.5 Mo + 2 Cu 160.7 (23.3) 557.8 (80.9) 753.6 (109.3) 7.53 In addition to the strength and elongation values, the table also lists the elastic modulus values that were observed in the tests. These data were included because this property is chiefly affected by density and the high densities of the present compositions were expected to manifest as increased modulus values. In fact, the values shown in the table are generally higher than those quoted in MPIF Standard 35 for the majority of P/M grades which, of course, typically involve lower densities. Compared with the properties of the Si Base and Base + 1Cu compositions, as listed in the earlier Table 1, the balance of the data in this table show very substantial strength and hardness improvements but modest decreases in ductility. The best overall properties in the table are those of the Base + 0.3 Mo + 1 Cu composition. The fact that these somewhat exceeded those of the higher alloyed Base + 0.5 Mo + 2 Cu composition suggested that the leaner of the two may actually be closer to the optimum in terms of alloy content. However, as will be seen, the properties in the sub-critically annealed condition did not support this idea. Nevertheless, they did show an unusually high ductility value in the case of the leaner alloy. These findings are shown below in Table 6. Table 6 - Sub-Critically Annealed Properties of the Molybdenum Containing Compositions Elastic Yield Ultimate Elong. Hard. Den. Modulus Strength Strength Alloy ID 3 3 MPa (10 MPa (10 % in 2.5 cm RHA g/cm3 GPa (106 psi) psi) psi) 172.4 (25.0) 344.1 (49.9) 568.1 (82.4) 3.3 51 Base + 0.3 Mo 7.49 171.0 (24.8) 383.4 (55.6) 588.8 (85.4) 3.7 55 Base + 0.5 Mo 7.53 5.1 52 Base + 0.3 Mo + 1 Cu 186.2 (27.0) 373.0 (54.1) 588.1 (85.3) 7.50 2.1 60 Base + 0.5 Mo + 2 Cu 162.7 (23.6) 490.9 (71.2) 608.8 (88.3) 7.53 Copper and molybdenum are commonly added to the Compacted Graphite cast irons and here again, where reasonably direct comparisons were possible, the indications were that the properties of the present iron base infiltrated compositions were generally superior in strengths and hardness and reasonably comparable in ductility [17, 18]. More interesting, perhaps, is a comparison of the properties of the present compositions with those of the well-known P/M grades that contain molybdenum. The properties of three such grades as selected from the Low Alloy Steel and Diffusion Alloyed Steel categories of MPIF Standard 35 are shown overleaf in Table 7. In each case, the data correspond to steels in the as-sintered condition with carbon contents in the eutectoid range from 0.4 to 0.9 %. Significantly, the strength, hardness and modulus values that are shown in the table are essentially the highest values listed in the Standard for steels in the as-sintered condition. As those familiar with the MPIF system of grade designation will appreciate, the alloy contents of the indicated grades are generally both different and, in particular, higher than those of the present infiltrated compositions. All three of the P/M grades contain at least 0.5 % molybdenum and either 1.75 or 4.0 % Table 7 – Properties of Selected Molybdenum Containing P/M Steels Elastic Yield Ultimate MPIF Elong. Modulus Strength Strength Grade Designation GPa (106 psi) MPa (103 psi) MPa (103 psi) % in 2.5 cm 162.0 (23.5) 482.7 (70.0) 689.5 (100.0) 2.0 FLN2-4405-60 158.6 (23.0) 503.3 (73.0) 710.2 (103.0) 1.0 FD-0208-65 168.9 (24.5) 489.5 (71.0) 861.9 (125.0) 2.0 FD-0408-65 Hard. Den. RHA 56 56 58 g/cm3 7.30 7.25 7.40 nickel. In addition, each of the diffusion alloyed (FD pre-fixed) grades nominally contain 1.5 % copper. However, despite these differences, comparison of the data in this table with those in the earlier Table 6 will show that the strength, hardness and modulus values of each of the two copper containing variants of the infiltrated compositions were superior to those of the FLN2-4405 and FD-0208 grades and were either superior to or closely approached those of the FD-0408 grade. Otherwise, the ductility values of the two data sets were reasonably comparable. Phase III The objective of the third and last of the three smaller studies mentioned was to examine the effects on properties of copper modifications of up to 2 % of the Si Base composition in four conditions as follows: as-infiltrated, stress relieved, sub-critically annealed, and normalized. The study also included determinations of the TRS properties in the as-infiltrated condition. These results are shown below in Table 8. Table 8 - TRS Properties of the Si Base and Copper Modified Base in the As-infiltrated Condition Transverse Dimensional Hardness Density Rupture Strength Change Alloy ID 3 % RHA g/cm3 MPa (10 psi) 1051.5 (152.5) 0.59 58 Si Base 7.44 1100.4 (159.6) 0.77 60 Base + 1 Cu 7.40 1148.7 (166.6) 0.63 62 Base + 2 Cu 7.43 The TRS properties were chiefly of interest because target applications include Grey cast iron components and rupture strength is a commonly cited property of the Grey irons. However, the latter is typically quoted in terms of the breaking load of a standard test specimen and is not directly comparable with the usual P/M values. For comparison, standard P/M specimens were prepared from a Grey iron component of interest. They exhibited an average TRS value of 465 MPa (67,500 psi), a hardness of 53 RHA, and a density of 7.23 g/cm3. The tensile properties of the subject compositions in each of the four process conditions mentioned are shown overleaf in Table 9. A review of these data will show that the densities of the Si Base and Base + 1 Cu compositions were a little lower than earlier (Tables 1 & 2) and that the density of the Base + 2 Cu composition was essentially intermediate of these two. All of the values were upwards of 98 % of the pore free value (~7.53 g/cm3). Comparison of the tensile properties of the Si Base and Base + 1 Cu compositions with those of the earlier study will show that the two data sets were generally similar. In the case of the Base + 2 Cu composition, the major effects of the additional copper appeared to be to increase the yield strength and hardness and decrease the elongation values relative to both the Si Base and Base + 1Cu compositions. The indicated increases in the yield strength were in all cases fairly substantial (≥ 70 MPa ≅ 10,000 psi) whereas the hardness increases were generally marginal. Table 9 - Tensile Properties of the Si Base Composition and Two Copper Containing Varian in the As-Infiltrated and various conditions of Heat treatment Yield Strength Ultimate Strength Elongation Hardness Density Alloy ID MPa (103 psi) % in 2.5 cm HRA g/cm3 MPa (103 psi) As-Infiltrated 366.7 (53.1) 502.6 (72.9) 1.9 59 Si Base 7.46 410.3 (59.5) 613.7 (89.0) 2.4 60 Base + 1 Cu 7.39 481.3 (69.8) 604.7 (87.7) 1.5 60 Base + 2 Cu 7.44 Stress Relieved 354.4 (51.4) 528.8 (76.7) 2.3 59 Si Base 7.46 413.0 (59.5) 606.1 (87.9) 2.2 59 Base + 1 Cu 7.39 484.0 (70.2) 580.6 (84.2) 1.1 61 Base + 2 Cu 7.42 Sub-critically Annealed 298.6 (43.3) 524.7 (76.1) 3.4 56 Si Base 7.46 322.0 (46.7) 535.1 (77.6) 4.0 54 Base + 1 Cu 7.42 382.0 (55.4) 535.7 (77.7) 3.1 56 Base + 2 Cu 7.43 Normalized 584.0 (84.7) 781.2 (113.3) 2.2 65 Si Base 7.44 638.5 (92.6) 832.9 (120.8) 2.1 65 Base + 1 Cu 7.40 732.9 (106.3) 835.7 (121.2) 1.1 67 Base + 2 Cu 7.41 A review of the properties in the normalized condition will show that this heat treatment had virtually no effect on density or elongation but very substantial effects on strength and hardness. For example, a general comparison of these properties with those in the balance of the paper will show that in most cases they surpassed the best of the latter including those of the molybdenum modified compositions (Table 5). Finally, its interesting to make a general comparison of the properties in Table 9 with the those of the Ductile irons in the plain or essentially un-alloyed condition (i.e. containing from 3 to 4 % C, 0.1 to 1.0 % Mn, and 1.8 to 2.8 % Si) [19]. Remarkably, in fact, although marginal in ductility, the strength and hardness values indicated by the present findings significantly exceed those of the latter in most instances. For example, the minimum requirements of the three highest strength grades of plain Ductile iron in accordance with ASTM A 536 are shown below in Table 10. Table 10 – Minimum Tensile Property Requirements of Ductile Iron According to ASTM A 536 Yield Ultimate ASTM Elongation Typically Recommended Strength Strength Grade Process Condition 3 3 Designation MPa (10 psi) % in 2.5 cm MPa (10 psi) 413.7 (60.0) 551.6 (80.0) 3.0 As Cast 80-60-03 482.7 (70.0) 689.5 (100.0) 3.0 Normalized 100-70-03 620.6 (90.0) 827.4 (120.0) 2.0 Oil Quenched & Tempered 120-90-02 A cursory comparison of the present findings with these data will show the following: 1) the requirements of the 80-60-03 grade were closely approached by the properties of the Base + 1 Cu composition in the as-infiltrated and stress relieved conditions; 2) the strength and hardness requirements of the 100-70-03 grade were significantly exceeded by the properties of the Si Base composition in the normalized condition; and, 3) the requirements of the oil quenched and tempered 120-90-02 grade were met by the properties of the Base + 1 Cu composition in the normalized condition. To be fair, what is being called normalizing here may be more akin to sinter hardening. As is generally well known, the normalizing heat treatment derives its name from the fact that it consists of austenitizing, usually at a low temperature above the upper critical, followed by normal cooling in still air. As applied to cast irons, the general aims are to eliminate hyper-eutectoid carbides if they exist, refine the grain size and produce an iron base matrix that has a predominantly pearlitic microstructure. The cooling rate of the process naturally depends on the mass of the casting and may be less than ~10 oC/min (0.3 oF/sec). In comparison, the findings in the present case derive from specimens that were ‘normally’ cooled in the cooling zone of a P/M furnace. The average cooling rate was estimated to be ~100 oC/min (3 oF/sec) in the temperature range from 845 to 315 oC (1550 to 600 oF). This, of course, is essentially an intermediate cooling rate in the sinter hardening range and, at the very least, would be expected to produce a finer grain size and a smaller interlamillar spacing than would be typical of a normally cooled large casting. Dimensional Change and Surface Appearance The study reported in 2006 examined the factors effecting the dimensional change characteristics and surface quality of the resulting parts. The dimensional change characteristics included part uniformity as well as part-to-part consistency. The surface quality related to the disposition and effects of infiltrant residues on the structural integrity and appearance of the infiltrated surfaces. The objective was essentially to define the conditions needed to implement the process as a practical matter. Dimensional Change Results It was explained in the introductory remarks of the paper that the infiltrated compositions according to the present technology offer a wide choice of dimensional change possibilities ranging from a high of upwards of 1 % to a low of 0 % or less. However, it was uncertain what effects the processing required to produce a particular value in this range would have on the dimensional consistency of the resulting parts. Thus, the primary objective of this phase of the study was to determine which of the extremes of the indicated range was associated with the best overall dimensional control in terms of part-to-part variability and within part uniformity. Two trials were conducted to evaluate the indicated dimensional change effects. The trials were designed to indicate statistically significant standard deviation differences at the 80% confidence level. The total number of specimens in each case was 48. The base compact geometry in the trials was a cylindrical disc measuring about 4.5 cm (1.75 ins.) in diameter and 1.4 cm (0.55 ins.) in height. In addition to the infiltrated density and dimensional change properties, diametric parameters that indicated the concentricity and the top to bottom uniformity of the specimens were also evaluated. The values of selected statistics of four subsets of the specimens that reflected the order of processing in the trial were compared to assess the operational stability of the processing. In Trial 1 of the study, the specimens were processed at a low temperature (1165 oC ≈ 2125 oF) and using a high infiltrant weight (i.e. 16.5% of the base compact weight). The resulting infiltrated density averaged 7.40 g/cm3 versus an expected value of ~ 7.47 g/cm3 and a pore free value of 7.54 g/cm3.The shortfall in density was traced to relatively high infiltrant residue weights. The standard deviation of the density was 0.018 g/cm3 and the corresponding range of variation in the data was about 1% of the average. The average diametric dimensional change was 1.29 % from green and 1.37 % from die. The standard deviation, in this case, was 0.051 % and the corresponding 4σ value of 0.204% indicated a maximum diametric variation about the average of ± 0.0046cm (0.0018 ins.). The diameter data of the trial confirmed this value. The concentricity parameter indicated that the specimens were out of round by an average of 0.0043 cm (0.0017 ins.). The top to bottom uniformity parameter indicated that the bottom diameters were larger than the top ones in 90% of the cases. The average difference was 0.0031 cm (0.0012 ins). The general indications of the data of the four subsets of the specimens was that the process was stable during the course of the trial. In Trial 2, the specimens were initially processed at the same low temperature as in Trial 1 but using a relatively lower infiltrant weight ( i.e. 12.5 % of the base compact weight) and then submitted to a high temperature liquid phase sintering step at 1190 oC (2180 oF). The infiltrated density averaged 7.47 g/cm3 versus an expected value of 7.54 g/cm3 (i.e. the pore free value). Here again, the shortfall was traced to relatively high infiltrant residue weights. The standard deviation of the density was 0.022 g/cm3 and the corresponding range of variation in the data was about 1.5 % of the average, 50% greater than in Trial 1. The average diametric dimensional change in this case was -0.01 % from green and 0.07 % from die. The standard deviation was 0.060 %, about 20 % greater than in the first trial. The corresponding 4σ value of 0.24% indicated a maximum diametric variation about the average of ± 0.0053cm (0.0021 ins.). The actual diameter data of the trial indicated a slightly lower variation of ± 0.0048cm (0.0019 ins.). Here again, the concentricity parameter indicated that the specimens were out of round. The average was 0.0057 cm (0.0022 ins.), about 30 % greater than in the first trial. The top to bottom uniformity parameter indicated an average difference of 0.0131 cm (0.0051 ins.), a little over 4 times the value of the first trial. In this case, the bottom diameters of the specimens were uniformly larger than the top ones. Frictional effects between the specimens and the sintering trays were apparently responsible for these differences. As earlier, the general indications of the data of the four subsets of the specimens was that the process was stable during the course of the trial. In view of these findings, it was concluded that at least in the near term, there is essentially nothing to be gained in terms of dimensional consistency from using the sinterability inherent in the compositions of the technology to produce a low average dimensional change value. The potential advantage that a near zero dimensional change offers to use the compaction die to size the parts would almost certainly be negated in this case by the very large top to bottom differences that were observed. In addition, the results of earlier studies suggested that the slightly higher infiltrated densities that the associated processing is likely to effect will generally not lead to significantly higher tensile properties. In part, this is because the pores that remain after infiltration are both closed and generally well rounded and in part, because at contents of 1 or 2 %, they are not the dominant stress raising feature of the microstructure. Surface Appearance Results The infiltrated surface appearances of the specimens of both trials were problematic. As expected, the infiltrant slugs had left thin, centrally located residues which were roughly circular in shape and ~ 2 cm (0.75 ins) in diameter. Unexpectedly, however, the residues were somewhat adherent to the underlying surfaces and had to be mechanically removed. This was done manually using a knife-edge as a pry. In the case of the specimens of the first trial , the residues normally came off the surfaces intact and without too much difficulty. In the case of the specimens of the second trial, there was a greater tendency for the residues to breakup during the process and they were generally more difficult to remove. These changes evidently reflected the effects of the generally higher process temperature in the second trial. The general condition of the un-infiltrated surfaces of the specimens as well as of the infiltrated surfaces to within a few millimeters of the residues was excellent. In comparison, the condition of the surfaces under and just adjacent to the residues was poor. In the general case, these areas were either flawed with erosion pits or covered with residual particles including partially melted and/or un-melted iron and residual oxides, sulfides and possibly, un-reacted graphite. In some places, the pitting and particles occurred together. In the case of the specimens of the first trial, low power microscopic examinations suggested that both defects were more cosmetic than structural. However, this was not true of the specimens of the second trial. The erosion pits in particular, in this case, appeared to be deep enough in many places to threaten the structural integrity of the surfaces. Neither these findings nor the aforementioned high residue weights were expected. Earlier, albeit more limited, studies which were also based on a slightly different infiltrant composition, had generally produced very different results. The observed infiltrant residue weights (as a percentage of the starting weights) normally varied somewhat but were never seen to be as high as the present ones. Similarly, although the resultant infiltrated surfaces were seldom flawless, they were generally better than the present ones. These indications led to the third and final trial of the study. The results of this trial largely confirmed the importance of the infiltrant composition and, more generally, showed that material selection in the design of the infiltrant was far more important than hitherto suspected. DISCUSSION AND CONCLUSIONS Experience to date with iron base infiltration suggests that thermal processing will be the difficult step for parts makers. Compared with traditional P/M processing, the required temperatures are of the order of 70 to 85 oC (125 to 150 oF) higher and it’s likely that the process will prove to be more troublesome in terms of establishing and managing the thermal conditions that are needed to produce dimensionally stable parts. Much will also depend on the ability to supply quality mixes to implement the process. In fact, it is precisely the difficulty which the infiltrant mix represents in this respect that has so far been the main sticking point in commercializing the process. Five different approaches to overcoming the associated problems have been identified, so it’s reasonable to expect that a solution exists. However, it still remains to develop and evaluate these approaches in order to decide how best to proceed. Otherwise, the process appears to offer considerable potential versus both regular and high density P/M processing. Its three most obvious advantages in comparison with traditional processing include the following: 1) Base compact densities of 6.8 g/cm3 or less are sufficient to obtain a virtually pore free density after infiltration. Thus, a particular advantage of the technology as compared with the traditional high pressure / high density processes [20, 21] is that the low starting densities essentially provide the potential to press larger parts that can later be infiltrated to the same or even higher final densities. 2) Infiltrated densities within 98% of the pore free value were demonstrated to be routinely possible. In contrast with traditional high density processing as exemplified by the double press and sinter and warm compaction technologies, the pores remaining after infiltration are completely isolated. Hence, infiltrated parts are likely to exhibit better dynamic properties (e.g. fatigue and impact properties) along with better machining and plating properties as well as greater applicability to the manufacture of hydraulic parts. 3) And, finally, the generally higher densities obtainable by iron base infiltration hold out the promise of higher or equivalent properties at significantly lower total alloy contents and thus, the likelihood of greater overall economy in parts production, especially, in view of present alloy costs. ACKNOWLEDGMENTS Special thanks are due to the Ben Franklin Technology Partners of Pennsylvania for funding a part of this research, and (in memoriam) to Mister W. B. Bentcliff of the Hoeganaes Laboratory for his help in obtaining the data used in preparing the manuscript. REFERENCES 1. F. J. Semel, “Iron Base Infiltration For High Density”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, NJ, 2004, 10-1. 2. F. J. Semel, “A New Process For Making High Density Parts”, Euro PM2004 Conf. Proc., European Powder Metallurgy Association, Vol. 5, pp 167-176. 3. A. K. Mashkov, V. V. Chernienko, and Z. P. Gutkovskaya, “Development of a Process for the Production of Dense Sintered Materials by the Method of Infiltration of Porous Blanks with LowMelting Point Iron-Boride Alloys”, Soviet Powder Metallurgy and Metal Ceramics, Vol. 12, No 1, 1973, pp 32-36. 4. A. K. Mashkov, V. V. Chernienko, and G. P. Negoda, “An Experimental Investigation of the Infiltration and Subsequent Heat Treatment of Infiltrated Iron-Base Materials”, Soviet Powder Metallurgy and Metal Ceramics, Vol. 14, No 12, 1975, pp 993-999. 5. A. K. Mashkov, V. I. Gurdin, and E. P. Polyakov, “A Boron Containing Material for the Infiltration of Iron Compacts”, Soviet Powder Metallurgy and Metal Ceramics, Vol. 18, No 5, 1979, pp 344-346. 6. K. A. Thorsen, S. Hansen, and O. Kjaergaard, “Infiltration of Sintered Steel with a Near Eutectic Fe-C-P Alloy”, Powder Metallurgy International, Vol. 15, No. 2, 1983, pp 94-97. 7. S. Banergee, R. Oberacker, and C. G. Goetzel, ”Experimental Study of Capillary-Force Induced Infiltration of Compacted Iron Powders With Cast Iron”, Modern Developments In Powder Metallurgy, Vol 16, 1984, pp 209-244. 8. S. Banergee, R. Oberacker, and C. G. Goetzel, “Mechanism of Capillary-Force Induced Infiltration of Iron Skeletons with Cast Iron” International Journal of Powder Metallurgy and Powder Technology, Vol 20, No 4 1984, pp 325-341. 9. F. J. Semel, “Iron-Based Powder Mixtures”, U. S. Patent 4,834,800. 10. F. J. Semel and S. H. Luk, “Method for Preparing Binder-Treated Metallurgical Powders Containing an Organic Lubricant”, U. S. Patent 5,256,185. 11. F. J. Semel and S. H. Luk, “Iron-Based Powder Mixtures Containing Binder-Lubricant”, U. S. Patent 5,298,055. 12. F. J. Semel, “Mechanical Property Potential of Iron Base Infiltrated Parts”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, NJ, 2005, pp 10-247. 13. F. J. Semel, “Dimensional Change Characteristics and Surface Quality of Fully Dense Iron Base Infiltrated Parts”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, NJ, 2006, pp 5-25 14. J. R. Davis, Ed. “Cast Irons”, ASM International, Materials Park, Ohio, 1996, pp 3-15. 15. “Thermo-Calc” Graphical User Interface Version: 2.1.2.0, Foundation for Computational Thermodynamics, Stockholm, Sweden, 1995. 16. J. R. Davis, Ed. “Cast Irons”, ASM International, Materials Park, Ohio, 1996, pp 85. 17. J. Fowler, D. M. Stefanescu and T. Prucha, “Production of Ferritic and Pearlitic Grades of Compacted Graphite by the In-Mold Process “, Trans. AFS, Vol 92, 1984, pp 361-367. 18. K. R. Ziegler and J. F. Wallace, “The Effect of Matrix Structure and Alloying on the Properties of Compacted Graphite Iron”, Trans. AFS, Vol 92, 1984, pp 735-744. 19. J. R. Davis, Ed. “Cast Irons”, ASM International, Materials Park, Ohio, 1996, pp 9. 20. H. G. Rutz and F. G. Hanejko, “High Density Processing of High Performance Ferrous Materials”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, NJ, 2004, Vol 5, pp 117-133. 21. I. Donaldson, S. Luk, G. Poszmik, and K. S. Narasimhan, “Processing of Hybrid Alloys to High Densities”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, NJ, 2002, pp 8-170.