HIGH PERFORMANCE MATERIALS – ANCORLOY MD SERIES Suresh O. Shah,

advertisement

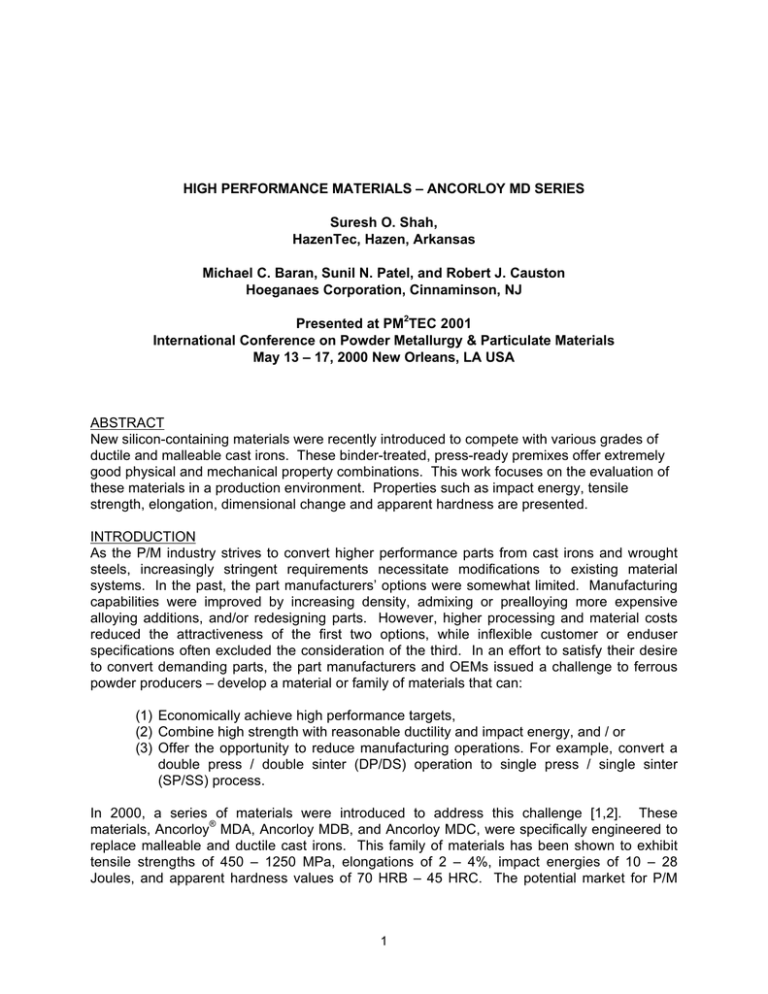

HIGH PERFORMANCE MATERIALS – ANCORLOY MD SERIES Suresh O. Shah, HazenTec, Hazen, Arkansas Michael C. Baran, Sunil N. Patel, and Robert J. Causton Hoeganaes Corporation, Cinnaminson, NJ Presented at PM2TEC 2001 International Conference on Powder Metallurgy & Particulate Materials May 13 – 17, 2000 New Orleans, LA USA ABSTRACT New silicon-containing materials were recently introduced to compete with various grades of ductile and malleable cast irons. These binder-treated, press-ready premixes offer extremely good physical and mechanical property combinations. This work focuses on the evaluation of these materials in a production environment. Properties such as impact energy, tensile strength, elongation, dimensional change and apparent hardness are presented. INTRODUCTION As the P/M industry strives to convert higher performance parts from cast irons and wrought steels, increasingly stringent requirements necessitate modifications to existing material systems. In the past, the part manufacturers’ options were somewhat limited. Manufacturing capabilities were improved by increasing density, admixing or prealloying more expensive alloying additions, and/or redesigning parts. However, higher processing and material costs reduced the attractiveness of the first two options, while inflexible customer or enduser specifications often excluded the consideration of the third. In an effort to satisfy their desire to convert demanding parts, the part manufacturers and OEMs issued a challenge to ferrous powder producers – develop a material or family of materials that can: (1) Economically achieve high performance targets, (2) Combine high strength with reasonable ductility and impact energy, and / or (3) Offer the opportunity to reduce manufacturing operations. For example, convert a double press / double sinter (DP/DS) operation to single press / single sinter (SP/SS) process. In 2000, a series of materials were introduced to address this challenge [1,2]. These ® materials, Ancorloy MDA, Ancorloy MDB, and Ancorloy MDC, were specifically engineered to replace malleable and ductile cast irons. This family of materials has been shown to exhibit tensile strengths of 450 – 1250 MPa, elongations of 2 – 4%, impact energies of 10 – 28 Joules, and apparent hardness values of 70 HRB – 45 HRC. The potential market for P/M 1 parts with cast iron properties is vast and could offer lucrative high volume opportunities to the P/M industry. Ductile iron is used in applications such as crankshafts because of its (a) good machinability, (b) fatigue strength, and (c) high modulus of elasticity; in heavy-duty gears because of its (a) high yield strength and (b) wear resistance; and in automobile door hinges because of its ductility [3]. Since it contains magnesium as an alloying element, ductile iron is stronger and more shock resistant than gray iron. The three basic types of malleable iron are ferritic, pearlitic, and martensitic. Ferritic grades are more machinable and ductile, whereas the pearlitic grades are stronger and harder. The martensitic grades are thought of as higher strength extensions of pearlitic malleable iron. Malleable iron castings are often used for heavy-duty bearing surfaces in automobiles, trucks, railroad rolling stock, and farm and construction machinery. Pearlitic grades are highly wear resistant, with hardness values ranging from 80 HRB to over 32 HRC. Applications are limited, however, to relatively thin-sectioned castings because of the high shrinkage rate and the need for rapid cooling to produce white iron. BACKGROUND The use of silicon in P/M materials can be highly beneficial. In addition to its relatively low cost and tendency to increase hardenability, it can accelerate sintering in hybrid alloys and substantially impact mechanical properties [4]. However, despite the inherent metallurgical advantages of silicon, its use in P/M has been largely unsuccessful in the past. The difficulties associated with conventional methods of silicon addition are numerous. For example, the addition of ferrosilicon almost invariably leads to a high degree of shrinkage and distortion in a P/M compact. Oxidation of silicon during sintering frequently results in an undesirable decline in mechanical properties. Similar problems are experienced in prealloyed powders. Silicon oxide pickup during atomization and/or annealing can lead to lower compressibility and diminished mechanical performance. Through advancements in atomizing, annealing, and binder-treatment technology, new siliconbearing materials have been developed to provide exceptional property combinations without large quantities of expensive admixed additions such as nickel, copper, etc. Additionally, production experience has indicated that these materials exhibit higher mechanical properties than diffusion-alloyed materials without the production costs associated with diffusion alloying. In practice, the use of higher performance materials in part production can reduce the processing steps required for that part. This reduction can minimize variation (especially when heat treatment can be avoided), curtail costs, and offer a more robust part/process to the customer. Although HazenTec’s manufacturing capabilities have allowed it to secure a very demanding automotive part for the P/M industry, the company was extremely interested in reducing costs and offering added value to their customer. The part is fairly complex with an overall height exceeding 38 mm. Both the current and proposed production processes are illustrated in Figure 1. EXPERIMENTAL PROCEDURE Two press ready, binder-treated materials, Ancorloy MDB and Ancorloy MDC, were tested in a production environment in order to evaluate mechanical properties achieved through a SP/SS process. 2 Current Process Proposed Process Compact Compact Presinter High Temperature Sinter Repress Temper High Temperature Sinter Heat Treat Temper Figure 1: A Comparison of the Current Production Process and Proposed Process for the Demanding Automotive Application Considered in this Study A third material, denoted as “standard”, was utilized in order to determine the effect of silicon in a FLNx-4405 type composition, where x is equal to 2 or 4. The “standard” material is the current composition utilized for this demanding automotive application. Chemical compositions for all tested materials are listed in Table I. Test and production specimens were produced at HazenTec from production lots of 4,550 kg (10,000 lb). Although the ideal objective of this work would be to replace a DP/DS process with a SP/SS one, all testing enumerated in this work was performed on SP/SS specimens and parts. Tensile tests were conducted on standard dog-bone tensile specimens. Whenever possible, compaction pressure was adjusted to maintain consistent green densities. All test pieces were sintered at HazenTec in a production loaded, high temperature, pusher furnace. The sintering / tempering cycle used for specimens was as follows: Sintering Temperature: Atmosphere: Time in Hot Zone: Cooling: Tempering: Various (from 1230 – 1315 °C) 80 v/o N2 , 20 v/o H2 45 minutes Standard Water-Jacketed Section 205 °C for 1 hour in Air Apparent hardness measurements were performed on the surface of the specimens using a Rockwell hardness tester. All measurements were conducted on the Rockwell B or C scale (HRB or HRC). Transverse rupture strength was measured according to ASTM B 528. Impact 3 energies were determined according to ASTM E 23. Tensile testing was performed on a 267 kN Tinius Olsen universal testing machine at a crosshead speed of 0.635 millimeters/minute. Elongation values were determined by utilizing an extensometer with a range of 0 to 20%. The extensometer was left on until failure. All specimens were tested in the as-tempered condition. Dimensional change was determined per ASTM B 610 by measuring the major outer diameter of the production part. RESULTS AND DISCUSSIONS Powder Properties and Chemistries The powder properties of interest were apparent density, flow, and chemical composition. These properties are presented in Table I. In the scope of this investigation, “standard” refers to the premix composition used in the current application. As can be seen, the flows and apparent densities of MDB and MDC do not represent a significant departure from similar “high performance” materials. Table I: Chemical Compositions, Apparent Density, and Hall Flow for Material Grades Tested Grade “Standard” FLN4-4405 MDB MDC AD (g/cm3) Flow (s/50g) Fe (w/o) Si (w/o) Cr (w/o) Mn (w/o) Ni (w/o) Mo (w/o) Gr (w/o) 3.30 28 Bal. -- 0.03 0.13 4.0 0.85 0.6 3.19 3.25 28 28 Bal. Bal. 0.7 0.7 0.03 0.03 0.13 0.13 2.0 4.0 0.85 0.85 0.6 0.6 Mechanical Properties A great deal of data was collected during the course of several production trials. In the interest of brevity, only key data was organized and presented in this paper. Mechanical properties are listed in Tables II-IV. It was immediately evident that the tempered densities of both MDB and MDC were lower than the standard material used in the study. Nonetheless, these materials were found to be competitive with or vastly superior to the FLN4-4405 composition that was traditionally used for this application. Despite its lower nickel content (2 w/o vs. 4 w/o), MDB may offer a more economical alternative to the standard material. MDC, on the other hand, was capable of easily outperforming the “standard” in almost every respect – apparent hardness, TRS, impact energy, ultimate tensile strength, and yield strength. Furthermore, no decrease in ductility was observed with this exceptional increase in properties. Dimensional Change From a production standpoint, it was felt that mechanical properties without dimensional control were of little use to the industry. Hence, the effort to determine dimensional change and its variation was undertaken. The tempered dimensional change values for the materials studied can be found in Figure 2 and Table V. The data illustrate that MDB and MDC exhibited a lower degree of shrinkage than the “standard” material at every sintering temperature considered. More importantly, the dimensional change ranges were much tighter in the Ancorloy materials. As evidenced in Table V, the total dimensional change range for MDC 4 represented a 75% reduction from the range exhibited by the FLN4-4405 composition (0.07% vs. 0.28%). This tighter dimensional control became increasingly significant when the size and complexity of the part were considered. In all cases, dimensional change, as determined by the measuring the major outer diameter of the part, was in the range of –0.0015 to –0.0080 mm/mm. Table II: As-Tempered TRS Properties of All Materials Utilizing Various Sintering Temperatures Grade “Standard” FLN4-4405 MDB MDC Sintering Temperature (°C / °F) Density (g/cm3) TRS (MPa / 103 psi) Apparent Hardness (HRB / C) 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 7.13 7.12 7.13 7.16 6.96 7.04 7.03 7.05 7.03 7.07 7.08 7.09 1675 / 245 1675 / 245 1730 / 250 1835 / 265 1540 / 225 1580 / 230 1675 / 245 1730 / 250 2060 / 300 2165 / 315 2340 / 340 2370 / 345 95 HRB 94 HRB 95 HRB 95 HRB 91 HRB 93 HRB 94 HRB 94 HRB 28 HRC 32 HRC 32 HRC 34 HRC Table III: As-Tempered Impact Properties of All Materials Utilizing Various Sintering Temperatures Grade “Standard” FLN4-4405 MDB MDC Sintering Temperature (°C / °F) Density (g/cm3) Impact Energy (J / ft.lbf) Apparent Hardness (HRB / C) 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 1230 / 2250 1260 / 2300 1285 / 2350 1315 / 2400 7.14 7.09 7.13 7.14 6.97 7.01 7.03 7.00 7.01 7.05 7.04 7.06 22 / 16 19 / 14 20 / 15 20 / 15 20 / 15 23 / 17 27 / 20 30 / 22 24 / 18 30 / 22 33 / 24 34 / 25 94 HRB 94 HRB 96 HRB 98 HRB 89 HRB 93 HRB 93 HRB 94 HRB 32 HRC 32 HRC 32 HRC 38 HRC 5 Table IV: As-Tempered Tensile* Properties of All Materials Utilizing Various Sintering Temperatures Grade Sintering Temperature (°C / °F) Density (g/cm3) Ultimate Strength (MPa / 103 psi) Yield Strength (MPa / 103 psi) “Standard” FLN4-4405 1230 / 2250 7.20 770 / 110 565 / 80 1260 / 2300 7.21 855 / 125 625 / 90 1285 / 2350 7.24 825 / 120 625 / 90 1315 / 2400 7.26 875 / 125 625 / 90 MDB 1230 / 2250 7.02 725 / 105 510 / 75 1260 / 2300 7.07 745 / 110 550 / 80 1285 / 2350 7.09 745 / 110 515 / 75 1315 / 2400 7.10 765 / 110 545 / 80 MDC 1230 / 2250 7.13 1015 / 150 745 / 110 1260 / 2300 7.14 1075 / 155 780 / 115 1285 / 2350 7.16 1125 / 165 840 / 120 1315 / 2400 7.14 1180 / 170 860 / 125 *All tensile properties were collected using dogbone type specimens Elong. (%) Apparent Hardness (HRB / C) 1.6 1.9 1.9 1.9 1.8 1.7 2.1 2.2 1.7 1.8 1.8 2.0 97 HRB 97 HRB 97 HRB 97 HRB 94 HRB 93 HRB 93 HRB 94 HRB 34 HRC 34 HRC 34 HRC 36 HRC 0.00 -0.10 -0.20 Dimensional Change (%) Ancorloy MDB -0.30 -0.40 Ancorloy MDC -0.50 -0.60 -0.70 FLN4-4405 -0.80 -0.90 -1.00 1200 1220 1240 1260 1280 1300 1320 1340 Sintering Temperature (°C) Figure 2: Dimensional Change Variations for All Materials Over a Wide Range of Sintering Temperatures 6 Table V: Tempered Dimensional Change from Die Size of the Actual Production Part Collected Over a Wide Range of Sintering Temperatures (1230 – 1315 °C) Grade 1230 °C / 2250 °F D.C. (%) 1260 °C / 2300 °F D.C. (%) 1285 °C / 2350 °F D.C. (%) 1315 °C / 2400 °F D.C. (%) Total D.C. Range* (%) “Standard” FLN4-4405 -0.52 -0.61 -0.70 -0.80 0.28 MDB -0.15 -0.19 -0.22 -0.28 0.13 MDC -0.38 -0.37 -0.39 -0.43 0.06 *Data represent dimensional change over a range of sintering temperatures CONCLUSIONS When two new materials, Ancorloy MDB and Ancorloy MDC, were compared to a standard FLN4-4405 material in the single press / single sinter production of a demanding automotive part, the following items were noted: • MDB was competitive with the FLN4-4405 material, despite a lower nickel content and a lower sintered density, • MDC exceeded the standard’s tensile strength and impact energy by over 30% and 50%, respectively, • Significant dimensional control benefits were realized when the Ancorloy materials were substituted for the FLN4-4405 standard, and • A potent sinter-hardening response was noted in MDC under standard cooling conditions. FUTURE WORK The next stage of this work, which has already begun, will compare the DP/DS properties of each material. Additional data collection on fatigue performance, machining performance, and reliability of MDB and MDC continue to be pursued in separate studies as well. As previously stated, the underlying objective of these investigations will be to replace a fairly laborious production process with a simpler three step process. ACKNOWLEDGEMENTS The authors wish to acknowledgment the support of HazenTec and Hoeganaes Corporation. They would like to thank the staff of HazenTec and, in particular, Karen Hasley and Enola Altis for their assistance in producing and processing the test specimens. The authors would also like to thank George Fillari and Ronald Fitzpatrick of the Hoeganaes Corporation for their contribution to mechanical testing and data collection. REFERENCES 1. James, W.B, Causton, R.J., Baran, M.C., and Narasimhan, K.S., “New High Performance P/M Alloy Substitutes for Malleable and Ductile Cast Irons,” Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 2000. 2. Baran, M.C., Chawla, N., Murphy, T.F., and Narasimhan, K.S., “New High Performance P/M Alloys for Replacing Ductile Cast Irons,” Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 2000. 3. “Ductile Iron Data for Design Engineers,” Section 3, QIT-Fer et Titane Inc., 1990. 4. Salak, A., Ferrous Powder Metallurgy, Cambridge International Science Publishing, Cambridge, England, 1995, p.235. 7