Venture

into the world of industrial turbomachinery and oil and gas solutions

Issue 15 | May 2011

Focus

Drillships: Going deep with

trust and passion

Spotlight

Forging ahead with subsea

technology

Monitor

SGT-750 — What customers

asked for in a gas turbine

Venture_15_LY_RZ_1.indd 2

20.04.11 16:59

Dear Readers,

Welcome to a new Venture magazine. This issue will be distributed at the Offshore

Technology Conference in Houston, Texas, during the first week of May and therefore

reflects our offshore technologies business. From subsea to drillships and back

again, we visit a shipyard in Korea that has close cooperation with our oil & gas hub

in Singapore, meet the man who designed the cooling system for the STC-ECO

subsea compressor, and present some recent strategic business tie-ups, including the

acquisition of two Norwegian subsea specialist companies who will enrich our

portfolio and extend our competence. Our recently launched SGT-750 industrial gas

turbine also makes a guest appearance: already in the design phase this turbine

was marinized for the tough roll and pitch of offshore applications.

Enjoy reading and an open welcome to meet us in Houston!

Tom Blades, President

Siemens Energy Sector, Oil & Gas Division

Venture_15_LY_RZ_1.indd 3

20.04.11 16:59

Inside

Inside

06

14

04 News flash Around the world

Projects in Australia and Norway, and a boost of subsea competence

06 Focus Going deep with trust and passion

Delivering essential electric power packages to the worlds leading

manufacturer of drillships

14 Spotlight Forging ahead

18

Awarded “Siemens Innovator of the Year”, Wolfgang Zacharias

is the brain behind the cooling system of Siemens STC-ECO subsea

motor-compressor unit

18 Monitor SGT-750

With the latest SGT-750, Siemens developed the first of a whole new

breed of industrial gas turbines, based on extensive customer research

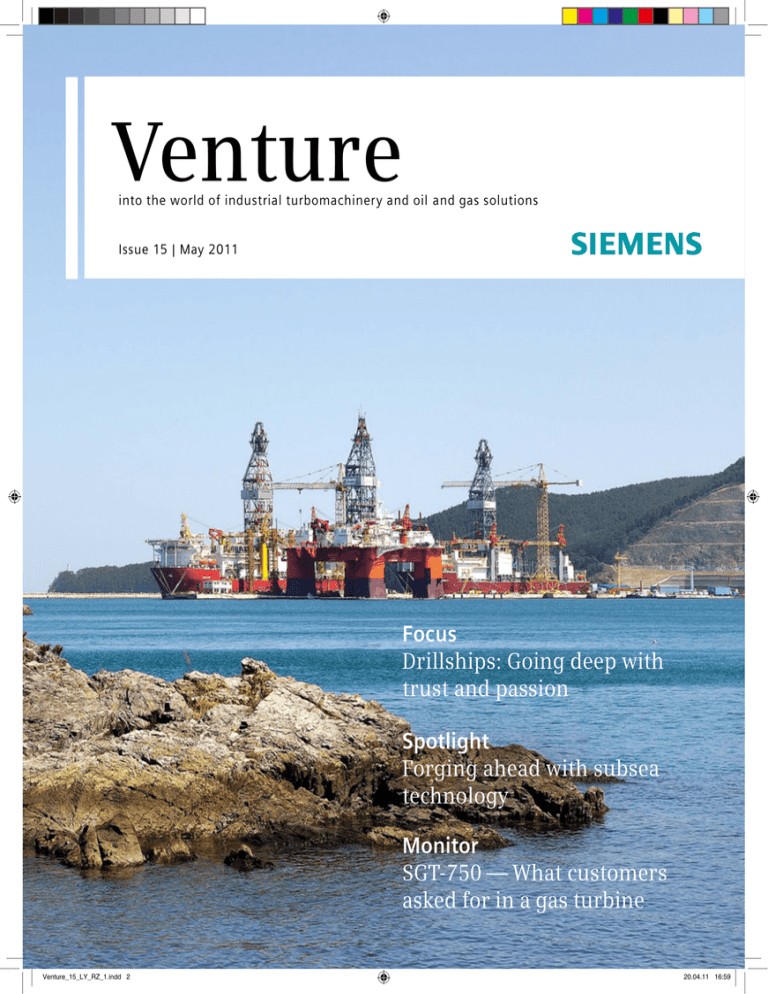

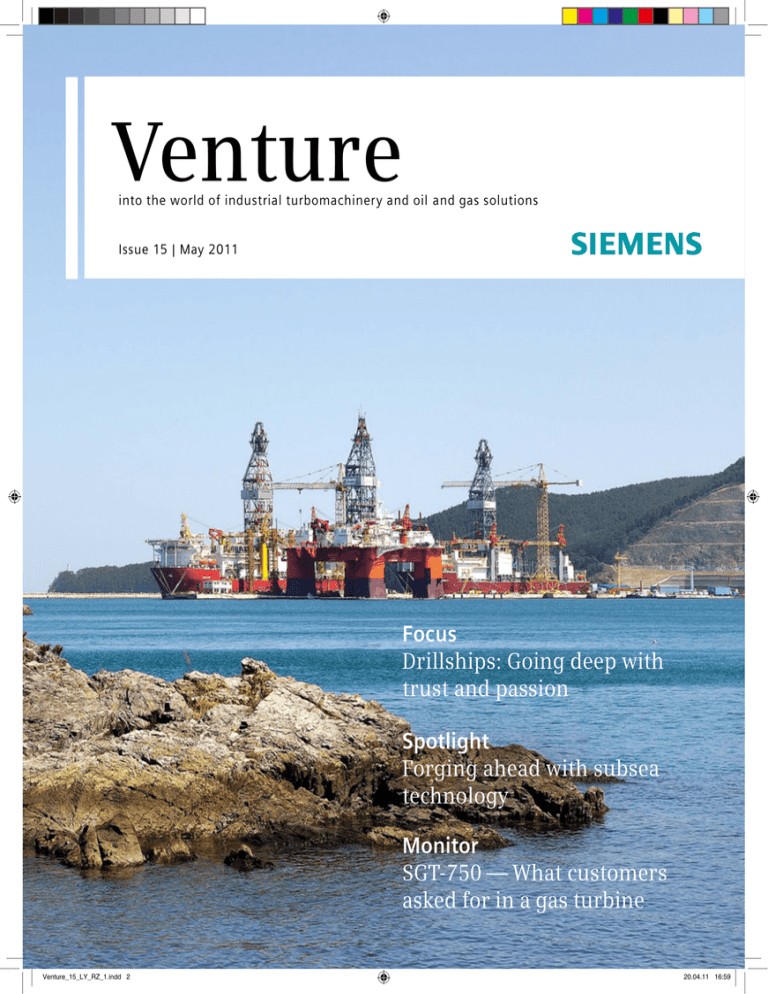

Cover photo: Drillships and a semi-submersible drilling rig at the Daewoo Shipbuilding and

Marine Engineering (DSME) in Okpo, South Korea

IMPRINT

Publisher: Siemens AG, Energy Sector, Oil & Gas, Wolfgang-Reuter-Platz, 47053 Duisburg, Germany Responsible: Dr. Uwe Schütz Editorial team: Lynne Anderson (Head),

Manfred Wegner Contact: lynne.anderson@siemens.com Contributing editor: Eric Johnson, Thomas Chatterton Design: Formwechsel Designbüro, Berlin

Photography: Jochen Balke, Florian Sander, Edgar Hendrassen Lithography: TiMe GmbH, Mülheim Printing: Köller+Nowak GmbH, Düsseldorf.

© 2011 Siemens AG. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical photocopying, or otherwise, without prior permission in writing from the publisher.

May 2011 Venture 03

Venture_15_LY_RZ_1.indd 4

20.04.11 16:59

Vista

A R O u N D T H E W A l l S — Engineering headquarters of Daewoos DSME shipyard at Okpo, South Korea, see article on page 6.

04 Venture May 2011

Venture_15_LY_RZ_1.indd 5

20.04.11 16:59

News flash

Around the world

1

Acquisition of subsea specialists Poseidon and

Bennex strengthens the Siemens Subsea Portfolio

Subsea processing is the most rapidly growing application in the

oil and gas industry as depletion of onshore reserves and a mounting

demand on the world market are forcing oil and gas companies to

exploit fields in remote places at ever greater water depths.

The strong strategic match between Siemens, Poseidon and Bennex

will enable quicker realization of the companies’ development plans

and the transaction will be very positive for employees, customers

and stakeholders. The subsea hydraulic and electrical subsea distribution systems, fiber optic, electromagnetic and seismic applications

supplied by Bennex add a decisive building block to the Siemens subsea

portfolio. The role of the Poseidon engineers will be to marinize the

proven Siemens offshore portfolio for subsea applications, including

subsea control systems, transformers, switchgears, electric motors,

automation and compressors along with other complementary

elements such as subsea cameras and subsea electric valve actuators.

“This acquisition brings new capabilities to Siemens in subsea engineering, equipment marinization and electrical connector penetrator

technology, the primary elements of solution based on in-house

products,” emphasizes Tom Blades, CEO of the Siemens Oil & Gas

Division.

2

Efficient solutions for unconventional gas gathering in Australia

Siemens Energy is to deliver up to 10 compressor trains to Australia

Pacific LNG (APLNG) in Queensland, Australia, a joint venture between

Origin Energy and ConocoPhillips. The project involves development

of coal-seam gas fields in south central Queensland over a 30-year

period. It includes construction of upstream gas-gathering and processing facilities, together with a 450-km main transmission pipeline

from the gas fields to the LNG facility, being built on Curtis Island near

Gladstone. The Siemens compression solution will be incorporated

into the upstream gas-gathering facilities to compress low-pressure

coal-seam gas for delivery to the LNG facility, where it will be compressed and cooled into liquefied natural gas (LNG).

Each compression train consists of two compressor skids, one lowpressure and one high-pressure, each skid carrying two compressors

with variable speed drives. Each train is designed to transport around

84 million standard cubic feet per day of gas. The compressors have

to demonstrate a high level of reliability and flexibility to suit the

LNG facility requirements.

Coal-seam gas is a natural gas which is mainly composed of methane.

It is a by-product of ancient plant matter that has formed over millions

of years by the same natural processes which produce coal.

3 Statoil and Siemens team up

Statoil and Siemens have agreed to team up to push forward

developments in subsea technology, electrical engineering technology,

energy efficiency measures and wind power.

Statoil said co-operation between the companies facilitates the

development of new technology. Halfdan Knudsen, senior vice

president for process and refining technology in Statoil, said: “Based

on complementary user needs and technological opportunities

we aim at developing technological solutions that contribute to more

environmentally friendly, effective production. This is a strategically

important agreement for Statoil.”

Siemens is an important Statoil supplier within several areas, and

the two companies already co-operate in the technology development

area. An umbrella agreement has therefore now been developed,

structuring the framework of the technology partnership within R&D

and technology development and facilitating the start-up of new

cooperation projects.

May 2011 Venture 05

Venture_15_LY_RZ_1.indd 6

20.04.11 16:59

Focus

Going deep

with trust and

passion

In an extremely competitive market for deep-water drillships, manufacturer

DSME is relying on electric power packages from Siemens. The simple secret

of success: Proximity of Siemens Oil & Gas to the South Korean shipyard.

Perhaps we all know that the earth is 40,000-km

round at the equator, but the practicality of

that really sinks in when a global project is on

deadline. Take the case of Daewoo Shipbuilding

and Marine Engineering (DSME), which sources

its shipyard off the southern tip of Korea with

components and services from 40 to 50 major

suppliers that are located — literally — all over

the world.

“Sometimes during the engineering, installation and commissioning of a new ship, we

can make mistakes or our supplier can make

mistakes,” notes DSME’s Tae-Young Kang,

Senior Engineer and in charge of electrical and

control system design. “This is unavoidable,

but to stay on schedule, we need to respond

quickly. Siemens Oil & Gas team is higly

dedicated so when we ask them for help,

they often come back with answers on the

same day.”

This, according to Eun-Kerl lee, Procurement

Manager Offshore with DSME, is where

Siemens towers above its competitors. “All the

suppliers must communicate,” he notes,

06 Venture May 2011

Venture_15_LY_RZ_1.indd 7

20.04.11 16:59

Focus

Venture_15_LY_RZ_1.indd 8

DRILLSHIP

OWNER

END USER

Platinum Explorer

TMT & Vantage

ONGC India

Dragon Quest

TMT & Vantage

Petrobras

NORBE VIII

Odebrecht

Petrobras

NORBE IX

Odebrecht

Petrobras

Cobalt Explorer

TMT

To be announced

Carolina

Petroserv

Petrobras

ODN I

Odebrecht/Delba

Petrobras

ODN II

Odebrecht/Delba

Petrobras

20.04.11 16:59

Focus

The lobby of DSME shipyard, with the corporate motto chiseled in marble.

“but none of them do it as well as Siemens.”

Of course the top-notch technical performance

of its equipment is highly valued by DSME,

but what sets Siemens apart from the crowd is

accessibility and prompt response.

and what role Siemens equipment plays in

them.

test of performance comes when swells and

tides join the action.

That’ll be the Daewoo

This is where dynamic positioning (DP) comes

into play. DP maintain a vessel’s position and

heading by use of propellers and thrusters. An

array of sensors — that measure geographic

position, wind and motion — coupled with gyro

compasses, tell a central computer the vessel’s

position as well as the outside forces affecting

that position. using a mathematical model that

includes all these inputs plus the vessel’s drag

and its propeller and thruster abilities, the

computer calculates the required steering angle

and output for each thruster. This allows operations in the deep sea where mooring or

anchoring is impossible, or in shallower areas

where anchors are forbidden due to pipelines

or other congestion on the sea floor.

That is fulsome praise — which so far has been

more than matched by deeds. From 2005 to

2010, the shipbuilder bought Siemens powerpackages for 13 drillship and semi-submersible

platform projects (see table for the most recent

ones) at a total value north of euro 300 million.

First things first: these ships are behemoths.

Stretching some 240 m long by 40 m wide and

20 meters below the deck, and wired by some

700,000 meters of data and power cables, their

operating gear — crowned by an unmistakeable oil derrick poking up from the middle

— reaches another 70 meters into the sky. They

weigh over 100,000 metric tons.

For Siemens this is an honour as well as a

sizable order. So to commemorate the occasion,

Venture took an onsite look at Daewoo’s

ship building operations at Geoje Island, to

learn more about what the vessels can do,

where they are deployed, how they are built

As is obvious from their name, drillships

are meant to drill the ocean floor for oil and

gas reservoirs, penetrating up to 10,000 ft

(3,048 m) of seawater followed by up to another

30,000 ft (9,146 m) of the earth’s crust. In calm

seas this is challenging enough, but the real

08 Venture May 2011

Venture_15_LY_RZ_1.indd 9

20.04.11 16:59

Focus

Trust, passion and mutual understanding — essential ingredients of a working relationship. From left to right: Tae-Young Kan, Senior Engineer for

offshore electrical and control systems, DSME; Myeong-Cheol Shin, Senior Manager offshore projects, DSME; Eun-Kerl Lee, Procurement Manager, DSME;

YeongJoon Jeong, Project Site Manager, Siemens; Cheol Chae, Director, Head of Busan branch, Siemens; P.K. Naik, Senior Project Manager, Siemens.

Not only drillers use dynamic positioning. It

also sees duty in semi-submersible units as

well as pipe layers and oceanographic research

vessels. In any case, the DP system is mission

critical. In drilling, DP is the failsafe that keeps

pipes from cracking or leaking under the stress

of movement. So it is no wonder that DSME and

Siemens treat it with such care. “DP3, the latest

and most stringent version of DP specifications,

requires the dynamic positioning system to

maintain the position of the ship during and

following any single fault, including loss of

compartment due to flood or fire,” explains P.K.

Naik, Senior Project Manager with Siemens

Singapore Oil & Gas Division. Tae-Young Kang

adds: “Basically, DP operates in island mode,

with completely redundant power supply. Even

in the event of maximum failure of the

11kV switchboard, we’ll lose no more than two

thrusters and two generators, but the remaining thrusters will keep the ship in position.”

The entire DP system is engineered based on

FMEA (failure modes and effects analysis)

procedures, and is subjected to more than

100 tests before final commissioning.

Industry experts estimate that more than

1,000 DP-able drillships are in action worldwide.

Most of them are run directly or indirectly by

the A-listers in the oil industry, companies such

as BP, ExxonMobil, Petrobras and Shell. Daewoo

vessels are on the job in all the major offshore

sites: Brazil, Gulf of Mexico, North Sea, Persian

Gulf and West Africa. Still to be drillshipped are

the final frontiers of the arctic, says DSME’s

Tae-Young Kang. “We have not yet mastered the

technology for drillships to handle extremely

cold climates.” Faced with the world’s unquench-

able thirst for oil, that barrier surely will fall,

and the number of drillships is sure to increase.

It’s about time

However, even as demand is climbing, thanks

to fierce competition, drillship prices are

actually in a modest decline. What currently

lists for uSD 500–600 million sold a few years

ago for nearer to uSD 750 million.

DSME’s response is to build them faster than

anyone else. Currently it takes a project

team, numbering some 500‒600 staff, about

30 months to deliver a ship: 12 months for

engineering and design topped by another

18 months of construction and commissioning.

“You cannot find this kind of speed elsewhere,”

assures Eun-Kerl lee who adds that the company is not resting on its laurels. “From cutting

May 2011 Venture 09

Venture_15_LY_RZ_1.indd 10

20.04.11 16:59

“To ensure faster response, since 2008 our

drillship project management is located in

the same time-zone as DSME. In addition,

were continuously increasing the number

of engineers available at our Busan and

Okpo offices.”

Cheol Chae, Director, Head of Siemens Busan branch

Venture_15_LY_RZ_1.indd 11

20.04.11 16:59

Focus

WHAT’S UNDER THE HOOD:

• Alternators (6 x 11kV, ~ 8MVA)

• 11kV Switchgear c/w synch panels

• HV transformers – 18nos.

• Thruster drives – 6nos.

• Drilling drives

• Thruster motors (6 x 4.5/5.5MW)

• UPS system

• NGT

• Local power management system

• Power system studies for complete ship

(including LV)

• FMEA study

• Class certification through ABS/DNV

steel to delivering the ship, we’re already down

to 17 months, and we’re aiming to cut that time

even further.”

This need for speed is where Siemens enters

the picture. As expected, DSME values Siemens’

excellent qualifications as well as its good-quality product and solutions. Its unique selling

principle, though, is Siemens’ ability to respond

rapidly to DSME’s needs, which is possible with

a competent and dedicated execution team

serving from (relatively) nearby Singapore. It

is from here, where Siemens has been present

for over a century and now has more than 2,000

employees, that DSME’s demand is satisfied.

Show me the goods

For each drillship, Siemens is supplying a power

package (see box) that supplies electricity from

the ships six massive diesel generators through

11-kV switchboards to the entire vessel, most

importantly its workhorses: the drill and the

ship’s thrusters which through guidance of

the dynamic positioning system, keep the drill

where it is meant to be.

The drillship Venture visited was the Norbe IX.

Currently under commissioning, it is the 8th

such project of cooperation between DSME and

Siemens since May 2006. Summarizing his past

experience with Siemens, lee says: “We believe

Siemens have a very good product — and a

good organisation as well. So, we have trust in

the product and the people, and we consider

Siemens a very good colleague for the success

of our drillship projects.” So, it wouldn't

surprise anyone if DSME wanted to continue its

successful cooperation with Siemens. What

does come as a surprise, however, is the sheer

number of future projects DSME wants to

realize together with Siemens. On April 6, DSME

issued an order for the supply of power

solutions for three more drillships, plus a letter

of intent for another seven drillships and —

a first for the Siemens Singapore team — a

semi-submersible drilling rig. Obviously, the

streak doesn’t stop here. So, watch this space!

TEXT

Eric Johnson P H O T O S

Jochen Balke

F u R T H E R R E l AT E D I N F O R M AT I O N

www.siemens.com/venture

May 2011 Venture 11

Venture_15_LY_RZ_1.indd 12

20.04.11 16:59

L O c at i O n

Okpo-dong area, Geoje island, South Korea

c O O r D i n at E S

34° 53' 17'' n, 128° 41' 37'' E

Dat E O f v i S i t

March 21 to 24, 2011

W E at h E r c O n D i t i O n S

fair, 7 degrees centigrade max.

PhEnOLOGy

unusually cold for time of year; cherry blossom

probably delayed by a week or two

Venture_15_LY_RZ_1.indd 13

20.04.11 17:00

Off Limits

May 2011 Venture 13

Venture_15_LY_RZ_1.indd 14

20.04.11 17:00

Spotlight

Wolfgang Zacharias — Awarded “Siemens Innovator of the Year” for his contribution to the STC-ECOs cooling system

14 Venture May 2011

Venture_15_LY_RZ_1.indd 15

20.04.11 17:00

Spotlight

Forging ahead

Imagination and fantasy are essential prerequisites when it comes to finding unconventional solutions

for unconventional applications. Add decades of experience and excellence in workmanship, and you’ll

get a fairly precise outline of Wolfgang Zacharias — Siemens Innovator of the Year and developer of the

cooling system of Siemens STC-ECO subsea motor-compressor unit.

The massive steel capsule would be the pride of any blacksmith. Not

that Wolfgang Zacharias — a trained blacksmith — is responsible for

the impressive shell: his job was to ensure the successful function of its

even more impressive contents. And he did such a good job, that this

engineer, based in Duisburg, was recently chosen as one of the Siemens

Innovators of the Year for his work with components for subsea equipment. In particular for the design of a cooling system for the compressor

and its motor, which are contained by the steel capsule in question.

They are part of the STC-ECO solution, a hermetically sealed integrated

motor and compressor unit for dirty-gas applications. Setting up such

equipment onshore is easy business and has been done many times. But

setting it up at the bottom of the sea is pioneers’ work.

Huge oil and gas finds off the coasts of Brazil and elsewhere in the world,

including the frosty north, call for equipment to be placed nearer to the

pockets of oil and gas — thus at the bottom of the sea, the potential

location for a flourishing subsea oil and gas industry.

“Conditions are rough down there, and maintenance is prohibitively

costly in the extreme environment encountered at 3000 meters

below sea level,” says Zacharias. The major challenge is thus to raise

reliability of the equipment even further to allow for maintenance

cycles of five years without intervention. One way of achieving this is

the reduction of inlet and outlet pipes and the use of a seal-less design.

The latter has the additional advantage that it reduces the probability

of leakage.

The revolutionary design of the STC-ECO which makes it suitable for

the extreme conditions encountered on the seabed, especially the high

pressure, creates its own challenges: conventional cooling designs do

not work. Motor and compressor are not separate units here, as they are

in onshore applications. Thus both produce process heat within a relatively small, tightly confined area. Cooling fins that would transport the

heat away from its source are not practical in this case, partly due to

the very compact design of the device. And as if this was not enough of

a problem, Zacharias had to deal with an additional complication: in

order to fit the motor into the same capsule as the compressor it must

be able to withstand the raised pressure inside. Also, the particularly

sensitive copper wiring of the motor must not come into contact with the

gas since this could cause corrosion or physical damage through sand

particles, which are sometimes found in raw gas.

“It was obvious that we would have to work with a separate cooling cycle

under these circumstances. Compressor and motor simply produce too

much waste heat. Even the cool waters at the bottom of the sea cannot

reduce the temperature sufficiently,” says Zacharias.

May 2011 Venture 15

Venture_15_LY_RZ_1.indd 16

20.04.11 17:00

to be higher than the pressure of the cooling liquid, therefore the shield

could break easily. To make matters worse: the pressure of the gas

changes constantly, due to natural conditions at the gas deposit or shifting patterns of production. “To avoid damage of the shield we have to

make sure that the pressure on both sides is about equal at any given

time,” explains Zacharias.

The inventor and the machine he co-fathered.

“Maybe a third of my inventions seemingly come out

of the blue. An idea, a quick

draft and it turns out that

it really works.”

For the cooling cycle Midel is used as cooling fluid. It transports the

excess heat from the copper wiring out of the steel capsule, to a heat

exchanger. Together with other auxiliary systems and the steel capsule,

the heat exchanger is located within a metal frame, which contains the

complete STC-ECO solution — in total measuring somewhat less than

five cubic meters.

However, for Zacharias, who claims 28 entirely own inventions, alongside 34 patents, work was not done simply by setting up a cooling cycle.

The wiring of the motor, which is surrounded by the cooling oil, must

be shielded from the process gas. This is done by means of a highly

resistant barrier. The resulting problem: the pressure of the gas tends

To achieve this, he and his team developed a sophisticated control system,

which constantly adapts the pressure of the cooling liquid to match the

pressure of the raw gas flowing through the compressor. “This control

system must work perfectly. The reason is simple: Once the device has

been brought to the bottom of the sea it will have to work without flaws

and without maintenance for years,” Zacharias adds.

Currently a long-term test with a pilot system is being carried out, one

aspect of this testing being to expose the system and its components to

extreme stress levels, to identify their respective breaking points. This

is an important part of the creative process of making a product out

of an invention. According to Zacharias there is more than one way to

spark ideas which lead to inventions. “Maybe a third of my inventions

seemingly come out of the blue. An idea, a quick draft and it turns out

that it really works,” he says. But most inventions are the result of the

continuing struggle of an engineer to make an incremental improvement

to an existing machine. If you’re lucky, the increment turns out to be

a leap rather than a step — and becomes an invention. “It is natural for

inventions to be the result of team work rather than the result of a

single man’s genius. There is frequently more than one name on a patent,” says Zacharias.

And sometimes the improvement was never even intended. The STC-ECO,

developed for subsea applications, could turn out to be an asset onshore,

too. Its seal-less design makes it particularly safe with regard to leakages.

This is particularly beneficial when it comes to the handling of hazardous and toxic gases, like those containing mercury, H2S or CO. The solution also allows for greater plant safety, due to its fully integrated, canned

design. Compared to solutions consisting of discrete components, this

means a substantial reduction of interfaces and thus of complexity. And

while space is not exactly a limiting factor on the seabed, it can be in landbased installations: The vertical, integrated concept of the STC-ECO reduces its footprint, thus requiring less space than conventional solutions.

The application of the solution in the context of a live subsea offshore

project might still be some years away, when the long-term testing has

16 Venture May 2011

Venture_15_LY_RZ_1.indd 17

20.04.11 17:00

Spotlight

Top left: Prototype of the STC-ECO at NAMs Vries-IV gas-gathering site south of Groningen, Netherlands. Top right: Tubing of the STC-ECOs Midel

cooling system. Bottom left: The ancient smithy of Wolfgang Zacharias father. Bottom right: Assembly of the STC-ECO at Siemens Hengelo workshop.

been concluded successfully. During this process new issues might come

up, calling for both the creativity and perseverance of Wolfgang Zacharias

and his team. But no doubt, he would come up with a solution. In spite

of all the modesty he displays when asked about the recognition as Innovator of the Year: “look at all those other guys who were awarded. They

tend to have a lot more patents than I do. In that sense I am only average,”

he says, half joking.

He has proven himself with his inventions, so does not need to prove

himself again with big words. In the near future Zacharias will retire,

looking back at a professional life full of increasingly sophisticated

engineering achievements. A career that had begun with a hammer and

an anvil and the hot fire in his father's smithy, where he had been trained

to become a smith himself.

The workshop still exists, although it is a little dusty now, having lain

idle for many years. “Who knows?” says Zacharias, “maybe I will take up

the hammer again when I retire.” He would then, once again, forge iron

rather than ideas.

TEXT

thomas chatterton P H O T O S

florian Sander, harry reusmann, Edgar hendrassen

F u R T H E R R E l AT E D I N F O R M AT I O N

www.siemens.com/venture

May 2011 Venture 17

Venture_15_LY_RZ_1.indd 18

20.04.11 17:00

Monitor

SGT-750 — Proven technology,

perfected results

What do customers really want, and what is the range that is

important for the next stage of development? Benchmarking gave

Siemens the answers for the SGT-750 industrial gas turbine.

18 Venture May 2011

Venture_15_LY_RZ_1.indd 19

20.04.11 17:00

Monitor

Voices are heard from the

control room:

ignition

sequence

start

Pressure

oK

oK,

let’s go

Power on

all

systems

green

Center in Norrköping. Fifty VIP guests — customers, partners and journalists — and as many

representatives from Siemens Energy, have

been welcomed by the head of Industrial Power,

Dr. Markus Tacke, to the inauguration of the

first industrial gas turbine for ten years, the

37MW SGT-750.

“Combining heritage with leading-edge design

and engineering, this piece of machinery is

designed to deliver maximized customer value

day in, day out” the narrator’s voice impresses

upon us.

Count on it

And suddenly there we are, revolving in space

and hurtling through the internals of the

SGT-750 gas turbine in a rollercoaster ride that

takes us into unbelievably intimate contact

with the newly designed turbine such as never

before experienced. We almost touch the

value words that loom at us on the full-surround

screen

customer Value — uPtime —

Performance — new Power

range — world class dry

low emissions — fleXiBility

The occasion is the November VIP launch of

the latest Siemens industrial gas turbine. The

venue is the recently inaugurated Visualization

Reliability was the big message that came back

from the customer survey which Siemens carried out before embarking upon the design of

its latest gas turbine. uptime and serviceability

were the criteria that were the backbone of

the turbine design. In order to assure that the

requirements were met, an innovative design

approach was used: a full-scale 3D studio was

used so that the turbine could ‘grow’ in natural

scale, based on sophisticated modeling techniques to indicate well in advance if there were

any pitfalls in the design. This technology

enabled close cooperation between designers

and service engineers from the very earliest

stages. This advanced 3D visualization program

enabled the engineers to check that the design

allowed full serviceability of important components and areas, without major disassembly

of the unit.

17 days in 17 years

Not only the core engine, but also the overall

package, is designed to provide owner confidence. The modular design supports easy

maintenance and maximized uptime. The

SGT-750 was designed for maximized serviceability and minimized load-to-load downtime.

To start with, the modular build-up facilitates

swift disassembly and parts replacement. If

the customer chooses the on-site 24-hour generator swap option, Siemens can schedule

as little as 17 days’ maintenance time over a

17-year service period. This 24-hour exchange

of the complete gas generator can is key to the

outstandingly high uptime capability.

Siemens’ solution-oriented approach has

resulted in a turnkey product that is fit for hard

work in many demanding applications, not

least in the oil and gas industry.

Filling the gap

SGT-750, as its name implies, will fill the gap

between the 32MW SGT-700 and 47MW SGT-800

gas turbines. With a launch output of 37 MW,

the Siemens SGT-750 fits perfectly into the

Siemens range of industrial gas turbines from

4 to 47 MW. It offers high output, marketleading efficiency and future-proof DlE emission control.

The SGT-750 is seen primarily as a fit for the

future mechanical drive market, following the

market trend for greater unit power. Since the

Mechanical drive 37.11 MW (49,765 bhp)

• Fuel: natural gas

• Efficiency: 40.0%

• Heat rate: 9,002 kJ/kWh (6,362 Btu/bhph)

• Turbine speed: 3050–6400 rpm

• Compressor pressure ratio: 23.8:1

• Exhaust gas flow: 113.3 kg/s (249.8 lb/s)

• Temperature: 462° C (864° F)

• NOx emissions (with DLE, corrected to 15% O2 dry): ≤ 15ppmV

May 2011 Venture 19

Venture_15_LY_RZ_1.indd 20

20.04.11 17:01

Monitor

entire design of the SGT-750 has been targeted

to meet the stringent requirements of the

oil & gas industry, the core engine is suitable

for operation in extreme climates, from arctic

to desert environments, from -60°C to +55°C.

Additionally, the gas turbine meets the pitchand-roll requirements for installations on FPSO

and marine applications, in accordance with

DNV rules and regulations.

However, the turbine’s high efficiency and rapid

start capability make it an equally competitive

machine for the power generation market.

SGT-750 sets a new standard of efficiency for

industrial gas turbines in this power range.

Reaching 38.7% in power generation applications and afull 40% in mechanical drive

applications helps push fuel consumption down to even lower levels, still

keeping — and improving — all the

benefits of

a robust, easy-to-service industrial

design.

well suited where grid requirements call for

maintained power output in the event of frequency drop.

and perfect adaptability to fixed or floating

installations, onshore and offshore, upstream,

midstream or downstream.

Mechanical drive

On upstream production facilities, it can be used

to drive pumps and compressors for various

applications such as associated gas reinjection,

water injection or export gascompressors to

forward produced gas to treatment facilities. In

midstream applications it can drive gas pipeline compressors, the refrigerant compressor

trains on mid-size lNG liquefaction plant (onshore or offshore) or on liquefaction processes

using cascade processes. Waste heat from the

turbine exhaust can also be recovered to provide

process steam or hot oil for oil and gas treatment and separation processes, or to raise steam

to generate additional p ower from steam turbine generators, increasing the overall energy

efficiency of a facility.

The sheer robustness and stability of the

37 MWs SGT-750 makes it a perfect option for

mechanical drive applications within the oil

and gas industry. The dual-fuel online switchover capabilities provide a unique built-in

flexibility when it comes to ambient climate,

A turbine for all seasons

Power generation /cogeneration

In power generation and cogeneration, SGT-750 demonstrates its

flexibility, being the perfect option

for base load, standby power and

peak lopping. The fast start-up and

cycling capability both support intermediate to continuous operation with

improved turndown capability, high

efficiency and low emission levels.

Through the use of a free power turbine, the 36 MWe SGT-750 is also

Power generation 35.93 MW(e)

• Fuel: natural gas

• Frequency: 50/60Hz

• Electrical efficiency: 38.7%

• Heat rate: 9,296kJ/kWh

(8,811 Btu/kWh)

• Turbine speed: 6,100 rpm

• Compressor pressure ratio: 23.8:1

• Exhaust gas flow: 113.3 kg/s

(249.8 lb/s)

• Exhaust temperature: 462° C (864° F)

• NOx emissions (with DLE, corrected

to 15% O2 dry): ≤ 15ppmV

20 Venture May 2011

Venture_15_LY_RZ_1.indd 21

20.04.11 17:01

Monitor

Siemens and Leon AB were awarded the regional annual marketing prize for their “Count on it” campaign of the year.

Keeping the turbine running

Reliability is always an important issue: never

more so than in the demanding environments

of oil and gas production and transport, where

surprises are to be avoided and rugged machinery and detailed planned maintenance are

essential. Operation of the rotating equipment

is critical for the operator: no power, no production, no revenue. So the longer the plant is

able to operate without interruptions, the better

the financial returns for the operator.

In the SGT-750 reliability is inbuilt. The turbine

is programmed to run for four whole years of

operation before a hot-section inspection is

advised. Remote, on-line check of the complete

engine is performed once a year from the manufacturing unit.

Where do we go from here?

The film ends with a breathless fly-in over deserts and high seas — the natural world of the

oil and gas markets. Time to test our orientation

as we leave our seats: I listen for reactions and

comments: “Impressive, very impressive!”

“Brilliant. Fun and informative.” These comments set the tone. Herbert Habersätter, SAAPI’s

gas turbine specialist and adviser, is more

specific: “I appreciated the opportunity to talk

directly to members of the development team,”

he says “and I won’t forget the 3D-presentation

and the trip through the turbine in a hurry!”

Now it is time to board the specially decorated

bus and visit the Finspong manufacturing site,

some 30 kilometers away. This is where the

SGT-750 is being built, and where it is being

presented today by the Finspong experts in the

context of the overall product family. News on

these products is also on the agenda.

The first two units will be produced for testing

at a specially designed rig. Testing will continue

until the first commercial unit begins operation

so that there is still time to make improvements

prior to a full global release. First delivery is

estimated for 2012. Siemens is currently in talks

with several interested customers.

It is anticipated that the SGT-750 will become a

standard in its range for power generation,

since Siemens has incorporated the best features

from its turbine range into this machine. The

power generation market is always in need of

reliable and economic power producers and the

SGT-750 is entering a new power range, increasing the company’s flexibility on the market.

Meanwhile the oil & gas market is facing its own

challenges: eliminating flaring of associated

gas; operating in more remote and harsher

environments; monetizing stranded gas assets;

and providing low carbon energy at the lowest

possible cost to consumers located long distances from the source of the oil and gas.

lNG (liquefied Natural Gas) is one of the

possible solutions for all these issues, onshore

or offshore. The lNG value chain uses a gas

turbine in several applications: as the driver for

the main refrigerant compressors in the liquefaction process; to provide power (and heat) for

the rest of the liquefaction plant, including any

gas treatment facilities; and to provide power,

and sometimes heat, for the regasification

process at the lNG receiving terminal. Whatever

the specific solution selected, reliable sources

of power and compression will be required and

the gas turbine will be there to fulfil these

needs.

The markets are there and the turbine will soon

be available: together with the other solutions

in the Siemens Energy total offer, the new

SGT-750 will contribute to generating power

and value for decades to come. Count on it!

TEXT

Elise chaplin P H O T O S

Siemens

F u R T H E R R E l AT E D I N F O R M AT I O N

www.siemens.com/venture

May 2011 Venture 21

Venture_15_LY_RZ_1.indd 22

20.04.11 17:01

E50001-E440-F156-V1-4A00

Deepsea Atlantic, a sixth-generation semi-submersible drilling rig

designed by GVA Consultants and owned and operated by Odfjell

Drilling, is ideally suited to operate in environmentally sensitive

3569_460x274_Oil_and_Gas_Ad_DrillShip.indd

1-2

Venture_15_LY_RZ_1.indd

23

areas. Along with its highly efficient design, the rig features electrical solutions with state-of-the-art technology ensuring safe

operation and high availability.

20.04.11 17:01

Availability is key at sea.

Highly reliable and high-performance electrical offshore equipment.

Solutions for the oil and gas industry

The entire electrical system, from the generation plant to the

drive systems, has been designed and supplied by Siemens.

As Deepsea Atlantic often operates in harsh climates, availability

is key, and Siemens technology has proven itself superbly here,

braving the elements and ensuring reliable operations – delivering the Siemens promise literally anywhere and anytime.

www.siemens.com/oilandgas

Venture_15_LY_RZ_1.indd 24

13.04.2011

10:07:01

Uhr

20.04.11

17:01

www.siemens.com

Venture_15_LY_RZ_1.indd 1

20.04.11 16:59