Architectural Framework to Support Integrated

Concurrent Engineering in an Academic Institution

By

Bruce J. Farnworth

B.E. Mechanical Engineering

The City College of New York, 1998

SUBMITTED TO THE DEPARTMENT OF AERONAUTICS AND ASTRONAUTICS

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

MASTER OF ENGINEERING IN AERONAUTICS AND ASTRONAUTICS

AT THE

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2000

@ 2000, Bruce J. Farnworth, All rights reserved

The author hereby grants to MIT permission to reproduce and to distribute publicly paper

and electronic copies of this thesis document in whole or in part.

Signature of Author:

Bruce J. Farnworth

Department of_.eronautics and Astronautics

May 18, 2000

Certified by:

i

Certified by:

bCharles

W. Boppe

Senior Lecturer, Department of Aeronautics and Astronautics

Thesis Supervisor

,Cory

R.A. Hallam

Lead Project Engineer, Department of Aeronautics and Astronautics

Thesis Supervisor

Accepted by:

Nesbitt W. Hagood

Associate Professor of Aeronautics and Astronautics

Chairman, Committee of Graduate Studies

SW 0 '7Z0O

(-.IBRARIES

Architectural Framework to Support Integrated

Concurrent Engineering in an Academic Institution

By

Bruce J. Farnworth

Submitted to the Department of Aeronautics and Astronautics on

May 19, 2000 in Partial Fulfillment of the Requirements for the

Degree of Master of Engineering in Aeronautics and Astronautics

Abstract

This thesis focuses on developing a recommended architecture for the next generation of

design centers for integrated concurrent engineering in an academic environment and

identifying and implementing an enabling sub-system for the architecture. During the

development of this architecture a systems engineering process was used to structure the

efforts of the team and maintain traceability to the customer needs throughout the design.

Site visits were undertaken to benchmark existing design centers. Customer needs were

compiled and analyzed to develop the system requirements that were input into a product

matrix. This enabled the team to generate a wide array of implementations to synthesize

multiple architectures. The recommended architecture should help to promote active

learning in a distributed design team environment. Further, a concept for an On-Line

Teaching Assistant (OLTA) was developed designed to help designers throughout the

process of developing complex systems. The OLTA may be considered an "expert

system" that will retain and filter an accumulating knowledge database of student work

entities. A proof-of-concept prototype was developed to demonstrate this concept.

Results of the architecture show a significant relative improvement over the currently

proposed architecture and preliminary responses for the OLTA are very positive with one

advisor stating "OLTA could revolutionize engineering education as we know it." Two

faculty members agreed to utilize a prototype in their upcoming classes and the

Aeronautics and Astronautics Department is very interested in implementing the system

in its capstone design classes.

Charles W. Boppe

Thesis Supervisor:

Title: Senior Lecturer, Department of Aeronautics and Astronautics

Thesis Supervisor:

Cory R.A. Hallam

Title: Lead Project Engineer, Department of Aeronautics and Astronautics

2

Table of Contents:

1. Abstract

2

2.

Introduction

7

3.

Background: The New Paradigm of Design Centers

9

4.

Methodology

12

5.

DE-ICE Mission Statement

17

6.

Needs, Expectations and Requirements

19

7.

Architectural Synthesis

38

7.1

Concept Development

45

7.2

Concept Evaluation

52

7.3

Baseline System Architecture

55

7.4

Baseline Product Development Process

58

8.

Prototype Development and Demonstration

59

9.

Assessment and Recommendations for Future Work

86

10.

Conclusions

90

11.

Acronyms

92

12.

References

94

13.

Appendices

97

3

List of Figures:

Figure 6-1 Hierarchy of User Need

20

Figure 6.1-3 Distribution of the Modeling Resources

27

Figure 6.1-4 Components of the DOME System Architecture

28

Figure 6.1-5 A Collaborative Framework

29

Figure 6.1-6 Conceptual Diagram of VSLCDE

30

Figure 6.2-1 DE-ICE QFD Requirements Matrix

32

Figure 6.3-1 System Use Case Diagram

36

Figure 6.3-2 Design Use Case Diagram

37

Figure 7-1 DE-ICE QFD Product Matrix Page 1

39

Figure 7-2 DE-ICE QFD Product Matrix Page 2

40

Figure 7-3 DE-ICE QFD Product Matrix Page 3

41

Figure 7-4 DE-ICE QFD Product Matrix Page 4

42

Figure 7-5 DE-ICE QFD Product Matrix Page 5

43

Figure 7-6 DE-ICE QFD Product Matrix Page 6

44

Figure 7. 1-1 Software and IT Architectural View for the Author's Architecture "A"

46

Figure 7.1-2 Equipment Architecture View for the Author's Architecture "A"

49

Figure 7.1-3 Physical Architectural View for the Author's Architecture "A"

51

Figure 7.3-1 Final DE-ICE SW/IT Architecture View

56

Figure 7.3-2 Final DE-ICE Equipment Architecture View

57

Figure 8-1 OLTA Vision

60

Figure 8-2 OLTA Use Case Diagram

65

Figure 8-3 OLTA Interface Relationship Diagram

66

Figure 8-4 Top-Level OLTA FFD

69

Figure 8-5 FFD for Blocks 3

71

Figure 8-6 FFD for Block 4

72

Figure 8-7 FFD for Blocks 9

73

Figure 8-8 FFD for Block I1

74

Figure 8-9 OLTA Preliminary Faculty User Interface

75

Figure 8-10 Preliminary Student Interface

76

Figure 8-11 OLTA Prototype Development Use Case

80

Figure 8-12 OLTA User Interface

82

Figure 8-13 Prototype Physical Implementation

83

Figure 8-13 OLTA Development Process

84

Figure 8-12 OLTA Production Server Architecture

89

4

List of Tables

Table 2-1 Priority of Classes for DE-ICE Development

8

Table 5-1 DE-ICE Mission Statement

17

Table 7-1 Product Matrix Architectural Evaluation

38

Table 7.2-1 Pugh Matrix

53

Table 8-1 Prototype Evaluation Matrix

61

Table 8-1 Prototype Work Package Descriptions and Break Down

68

Table 8-2 Content Type and Attributes

77

Table 8-3 Content Providers

78

Table 8-4 Content Consumers

79

Table 8-5 Access Control

79

5

Dedication:

This thesis is dedicated to my wife for her unending support, understanding and love.

Acknowledgements:

The author would like to thank the following people for their help and support on this

project: Mr. Cory Hallam, Mr. Charles Boppe, Dr. Dava Newman, Dr. Billy Fredriksson,

Mr. Gunnar Holmberg, Mr. Fred Donavan, Mr. David Mitchell, Dr. Robert Shishko, and

Dr. Joel Sercel. Additionally I would like to thank my teammates Mr. Alex Manka and

Mr. Simon Nolet for their support in pursuing this project and their professionalism

during the execution of this project.

6

2. Introduction

The

Massachusetts

Institute

of Technology's

Department

of Aeronautics

and

Astronautics has recognized a need for a revolutionary change in the way students are

taught [15]. Traditionally, instructors have taught with a discipline-specific methodology

which allow students few opportunities to understand the interactions of each discipline

in design, manufacturing, and systems integration processes.

In addition, industry has

indicated the desired attributes of graduating engineers to include [20]:

i)

A good base of engineering fundamentals

ii)

Understanding of the design and manufacturing process

iii)

Multi-disciplinary "systems perspective"

iv)

Good communication skills

v)

The ability to think critically and creatively

vi)

Flexibility to adapt to rapid and major change

vii)

Understanding of the importance of team work

Today MIT is embracing the Conceive-Design-Implement-Operate (CDIO) theme as the

context by which an engineering education is to produce graduates that address these

issues by designing and manufacturing a product in a team environment.

Examples of the changing pedagogy in the Aeronautics and Astronautics Department are

the implementation of the CDIO philosophy and the use of active learning methods in

design classes [15]. Development of the Design Environment for Integrated Concurrent

Engineering (DE-ICE) is part of the process to create active learning in a design

environment. This initiative seeks to "create a more stimulating hands-on environment

for students (thus improving student motivation, understanding and retention) [15]."

The Aeronautics and Astronautics Department is creating a "cultural shift" in education,

whereby students and faculty consider learning to be integrally linked with active

engagement and interaction instead of relying on passive learning through lectures [2].

7

This pedagogical shift aims to produce engineers that understand the complex and

iterative nature of holistic product design and also gain a deeper understanding of the

engineering fundamentals they have learned by using them.

To address this change the Aeronautics and Astronautics Dept. has planned to develop a

world-class Design Center (DC) enabling students to perform integrated concurrent

engineering. This center will be used by undergraduate (UG) and graduate (G) students

for lectures/presentations, large systems design, research design support, collaborative

design with external teams, design-based distance learning and teaching, and interactive

electronic classes.

Priority

1

Short Term

16.82 Flight Vehicle UG

16.83 Space Systems Engineering UG

2

16.89 Space Systems Engineering G

16.90 Aircraft Systems Engineering G

3

Long Term

16.684 Experimental Capstone

Subject UG

16.870 Master of Engineering

Project G

16.00 Introduction to Aerospace and Design UG

Table 2-1 Priority of Classes for DE-ICE Development

Table 2-1 shows the immediate priority of the classes targeted for the DC. The project

time frame is defined as short term (one week to one semester) or long term (1 to four

semesters). Please see Appendix H for active learning course descriptions.

8

3. Background: The New Paradigm of Design Centers

As aerospace systems become more complex with the constant need to produce quality

products faster and at lower life cycle cost, more and more industry organizations are

turning toward integrated concurrent engineering with the assistance of information

technologies. NASA, Saab AB, Boeing, and The Aerospace Corporation have developed

DC's and distributed integrated tools to support integrated concurrent engineering. At

these organizations a holistic design process stressing the complete process over time is

beginning to replace the traditional product development processes (i.e. the over the wall

process). This is accomplished through use of the appropriate tools key to their success

such as development methods, integrated modeling, and engineering management [16].

Generating designs for a complex system involves decomposing the design problem into

sub-problems that can be analyzed by a small team of engineers. This allows engineers

who possess the needed core competencies to solve specific areas of each sub-problem

[9].

However, generating a holistic design that addresses the trade-offs of cost,

performance, etc. and different goals of each sub-problem can be very time consuming,

and often involves multiple iterations of the design. Inferior decisions can also be made

if the sub-problem interactions are not fully understood. Additionally, experience has

proven that 70-80% of a system's cost is committed during the initial conceptual

development phase of the design, thus the conceptual development phase offers the

greatest opportunity to influence the life cycle cost of the system [17]. The current trend

towards integrated concurrent engineering is to enable aggregation of the sub-problem

analyses into a whole "system" for analysis and trade studies early in the design process.

This aggregated system model would consider the lifetime of the "system."

NASA has set out to meet these goals by initiating development of an Intelligent

Synthesis Environment (ISE) that integrates advanced computing with human interaction

(in the computer environment) to create a seamless environment enabling new levels of

productivity among distributed collaborative teams [1]. NASA's first step towards the

9

ISE vision is the Product Development Center (PDC). In developing the PDC, Integrated

Product Development (IPD) teams have been able to complete proposals and mission

analyses with "savings of up to ten times the previous cost" in dedicated week-long

sessions instead of during the span of several months [18].

Saab AB's goals sought to reduce life cycle cost, time and the number of defects by 50,

50 and 20 % respectively for the development of the two-seat version of the Gripen and

the Saab 2000 [17]. Aspects of the development process used at Saab are [4]:

e

Easy access to information and knowledge

e

Extensive use of modeling and simulation to provide knowledge

e

Support engineers in preliminary development stages to allow for mature

decisions as early as possible

e

Support and simplify communications

e

Provide a channel for engineers and experts to utilize their expertise in an

efficient manner

Saab AB has implemented a company-wide distributed database with integrated

engineering processes to allow collaborative and concurrent work. Design centers were

created which allow IPD teams to meet and actively work together to reach design

decisions. Designs can be accessed and viewed in their context by the team along with

additional information such as simulation and analysis results, scheduling information,

and Bill of Materials (BOM).

An application (DIP) was created to record meeting

minutes and to provide for "screen grabbing" opportunities of any information or

drawings. It allows engineers to add annotations into the system in real-time, enables

team leaders to assign responsibilities, and to retain and enhance knowledge of the

decision making process while fostering communication.

During the introduction of

Saab's change in engineering process, there was some hesitation from the engineers but

now the general consensus is that it is working "very well" was relayed during personal

interviews at the site visit in February 2000, and have met or exceeded their goals stated

above[17].

10

However, DE-ICE is driven by different goals and constraints than industry. With the

shift towards an active learning paradigm and the CDIO philosophy students will be

encountering real world design problems involving cross discipline knowledge. One goal

is to enhance core fundamental knowledge while introducing students to the iterative

nature of developing products that span a very wide range of complexity. A second goal

of DE-ICE is to promote active learning in a design environment by enabling students

and faculty to work in distributed design teams concurrently, along with external design

groups to develop and design complex products.

The primary distinction between industry and academia is that students cannot become

dedicated IPD group members spending all of their time on a single project due to the

requirements of other classes and the scheduling conflicts that this would impose.

Additionally, most junior students using the system may not have the expertise of

working engineers and may find it difficult to perform well in an unguided IPD

environment.

To overcome this problem the DE-ICE architecture must provide a robust

communication and collaboration infrastructure that allows students to work along with

the demands of their varying class schedules, and act as a resource to help students

accomplish their tasks.

11

4. Methodology

During the course of the team's research and design period, a process was used to

structure the effort and to provide a logical framework. The formal methodology used

during the DE-ICE architectural concept development is described in the following

sections.

During the course of the project, communication was integral as a means to

perform work and test technologies and ideas of the team which enhanced overall

interaction and spirit.

MS NetMeeting, group emails, Virtual Network Computing

(VNC), and Distributed Object Modeling Environment (DOME) were tested and

provided insight into some of the limitations of these applications and techniques (please

see Manka [30] for information on the testing of these tools).

Define Project Scope:

The first task undertaken was to define the scope of the project.

This project was

considered to be very complex, as pointed out by Mr. Gunnar Holmberg, manager of the

advanced technologies department. The team realized that boundaries must be set at the

beginning of the project to help guide and focus the design team. A mission statement

was developed that defined the project and set achievable goals for the team to work

towards [8]. The users of the system were defined, along with possible constraints and

stakeholders on the project.

Literature/Technology Search:

Literature and technology searches helped the team to develop a better understanding of

the problem undertaken.

Searching existing literature and technology ensured that the

system architecture developed would build on, but not repeat the efforts conducted by

other researchers and organizations.

This project utilized patent searches, Internet

searches, library and journal publications, and organizational best practices (i.e. site visits

to observe how others are meeting similar goals) to uncover and understand the state-ofthe-art in integrated concurrent engineering.

Data collected in this effort was also

important during the benchmarking phase of requirements definition. This process also

12

helped identify potential sub-system components that may be utilized in the system

architecture.

Survey Potential Users:

For this project the customers of the DE-ICE system were defined as the end users. This

would include internal and external students, faculty, guest lecturers, teaching assistants,

and the AA staff. Two surveys were used to gather the varied needs of the end users.

Students, staff and faculty were surveyed with issues such as system usability, ease of

accessing data, and team communication. In addition, faculty were surveyed on how they

plan to use the system to enhance their delivery of course material to help students gain a

better understanding of the course goals, and for the design team to understand the

teaching processes that may be used with the system.

The student and staff survey was more general so that the results would mark the

preference of the end users. Personal interviews were conducted for the faculty survey

while the general survey was Internet-based.

At the recommendation of Professors

Newman and Boppe the survey format was selected, due to i) possible low return rate

from the faculty, ii) the importance of getting feedback from the faculty. Copies of the

surveys may be seen in appendix C.

Needs and Requirements Analysis:

Key to the success of this project was the proper identification of the customer needs and

focusing on the ones most important. Correctly translating the customer needs allowed

for the generation of the systems technical requirements, a process matrix, and ultimately

the system architecture. To correctly capture the voice of the customer, Quality Function

Deployment (QFD) was used to help eliminate any personal biases that may be

introduced by the team members [26].

QFD helped the team to identify the highest

technical requirements of the system while minimizing personal biases of the design

team. Requirement conflicts were also identified and monitored.

13

Benchmarking Existing Systems:

Site visits provided information on state-of-the-art integrated concurrent engineering

design environments. System architectures and top-level design processes of the existing

facilities were gathered and analyzed for use in competitive benchmarking. Collected

data was used in the QFD matrix to allow the team to set goals to match or exceed the

systems benchmarked.

Use Cases:

Object-oriented methods such as Use Case Diagrams helped the team to understand the

context in which the system would be used and to identify possible operational

interactions that the team may have inadvertently neglected. Use cases identify the actors

using the system, the use instances and how functionality is extended. The Use Case

Diagram also showed the relationships between the actors and the use cases or

functionality of the system along with any interfaces [19].

Product Matrix:

The product matrix acted as a map of the highest technical requirements from the QFD

into implementations that can satisfy the requirement of the system. Use of a product

matrix allowed the team to characterize multiple implementations for each technical

requirement.

It can also allow for requirements traceability for future design

enhancements to the DE-ICE system.

Architectural Synthesis:

Architectural variants were generated from the product matrix by selecting subsets of the

implementations generated in the product matrix.

Multiple "views" (i.e. physical,

software/IT, schematic Block diagrams) of the architectural concepts were used along

with the product matrix for a convergent/divergent total design concept [5] that will meet

the user needs.

14

With the variants and baseline architecture identified, a Pugh matrix was used to identify

the concept, which as a whole met the selected decision criteria. Ranking was achieved

through engineering judgments of the increased, decreased or similar performance that a

particular architectural criterion would yield relative to the baseline.

A Pugh type

analysis was used because it could yield good results during the conceptual design phase

when detailed analysis of cost and functionality may not yet be adequately analyzed.

Baseline for the Pugh matrix was the existing and planned design center in the

Aeronautics and Astronautics Department. A Pugh matrix also allowed the design team

to identify aspects of each architectural variant that would show significant improvement

over the baseline.

Results from the Pugh matrix were used to synthesize additional design concepts that

capitalized on the increased performance aspects of each concept from the previous step.

The goal was to identify an architecture that would show increased performance when

judged against all of the decision criteria.

Prototyping:

Throughout the process of synthesizing the architectures the team maintained focus on

creating or combining elements that would prove to be critical and novel prototype

options. Prototype concepts were evaluated against the driving technical requirement to

provide a well-founded justification for the selected concept.

Due to the team's size and constraints of the term boundary, prototyping demonstrated a

sub-set of the enabling functionality.

Therefore, the prototype acted as a proof-of-

concept demonstration with follow-on work to be performed after the project.

Project Planning:

Initially, the team planned two days per week to meet and discuss individual work

accomplished during independent work time. Major tasks for the project were defined,

and the team tried to evenly distribute the workload. Using MS Project 98 helped to

15

facilitate project planning (see appendix G for the detailed project schedule).

Three

design reviews acted as choke points to keep the team focused. Industry representatives

were invited to attend and give feedback on the work completed and the direction of the

project.

16

5. DE-ICE Mission Statement

To launch the DE-ICE project a mission statement was drafted to identify the system

context along with a basic description and goals of the project. The mission statement

shown in Table 5-1 helped the team identify three of the six attributes of the DE-ICE

system [23], namely: why the system is being built, what the system should do, and who

will be doing it.

Description

"To develop an operational framework for a design center to enhance learning in

an academic environment."

Context

DE-ICE will be used in an academic environment to enhance the learning of the

process of conception, design, implementation, and operation of complex

aerospace systems.

To develop recommendations for To discover a key enabler of the system and

prototype a component.

the architecture of the design

environment.

Possible external users:

Internal:

Guest lecturers

MIT Students

Industry representatives

Teaching Assistants

External students

Faculty

Staff

The system will use existing computer

The system should utilize mature

hardware.

technologies.

Goals

Users

Assumptions

Stakeholders

End Users (MIT students)

MIT A/A Department

Microsoft Corporation *

Industry

Table 5-1 DE-ICE Mission Statement

The asterisk next to the Microsoft Corporation indicates that they were initially

considered a primary stakeholder, considering the substantial funds they provided to the

department for research. Microsoft showed interest in the project during the prototype

phase and was very helpful.

17

Using the mission statement helped the team remain focused and not get overwhelmed by

the scope of the task. Initial documentation of the design team goals clearly defined

project deliverables. Additionally, when presenting at the Architectural Design Review

(ADR) the team was able to show that it had successfully completed its first goal and had

identified a component of the system to prototype.

18

6. Needs, Expectations and Requirements

One of the most difficult processes undertaken during the project was discovering

customer needs. The customers for the system are defined as faculty, staff, and students

of the Aeronautics and Astronautics Department who will be the majority of the end

users. Difficulty in defining the needs was due to the fact that the ultimate uses of the

system were somewhat uncertain, teaching processes that would be used were undefined,

and there was a limited base of experienced end users.

During the initial stages of this project the highest level needs defined by the Aeronautics

and Astronautics department were:

1) The system should be scaleable for varying levels of user experience and training

2) Enable a distributed design team to concurrently design aerospace systems

3) Add value to the engineering project and enhance previously learned knowledge

Upon review and suggestions from the group advisors, the team tried to reassess the

system needs. Further consideration, refinement and iteration led the group to create a

hierarchy of system needs. A description of the system needs and weighting factors may

be found in Appendix A. The customer needs are as follows:

Pedagogical Needs

*

Capability to support MIT operational modes (system constraint)

e

Active learning in a design environment

" Holistic view of design

*

Improved knowledge of and experience with the design process

e

Support of life cycle analysis

Operational Needs

*

Improves the quality of student design work

19

e

Increases productivity for a given amount of time

*

Highly useable system

*

Support for team enablers

*

Flexible system (Sustainability)

The high-level needs are categorized as Pedagogical and Operational under which are

reflected the primary system needs.

A graphical hierarchy of needs was created to

indicate needs prioritization, and is shown in Figure 6-1.

DE-ICE Needs

Hierarchy

Capability to support

MIT operational

modes

Active learning in a

design

environment

Holistic view of

design

improve

knowledge of and

experience with the.

design process

Support of life

cycle analysis

Increase productivity

for a given amount

of time

Highly useable

system

Support for team

enablers

improve the quality

of student design

work

Sustainable system

Figure 6-1 Hierarchy of User Need

20

6.1

Survey of Existing Systems

Integrated concurrent engineering design environments evaluated for this study can be

classified into two groups, those used for:

i)

Conceptual design,

ii)

Product engineering/manufacturing

The following is a brief description of the systems surveyed. Additionally the team has

reviewed several core technologies that may be mature enough for system utilization.

Concept Design Centers (CDC) are mainly focused on developing conceptual designs

and proposals for complex space systems. Goals of the CDC's are to reduce the time and

cost needed to develop a design or proposal. To date, they have shown great success in

meeting their goals as will be explained in the following sections [18].

NASA JPL PDC:

NASA's Product Design Center (PDC) is used for generating and analyzing conceptual

designs for space missions. NASA has reduced the design cycle time to one-tenth the

traditional engineering process while reducing cost from 250K to 50K [18]. A dedicated

team of functional engineering leads for each sub-system is used during design sessions.

Preliminary work is undertaken off-line by each sub-system lead so they are fully

prepared when the design session begins. Design sessions are led by an overall team

leader and are highly scripted and timed. Sub-system models are integrated into one

Excel spreadsheet for global cost/performance optimization and decision-making.

System architecture for the PDC and top-level process can be seen in appendix D. For

more information on the PDC please see [30,31].

TRW/Aerospace Corp.:

TRW and the Aerospace Corp. concept design centers are very similar in usage and

functionality to the NASA PDC and are in fact outgrowths of the PDC. These newest

design centers use linked MS Access databases to increase flexibility. For a more in-

21

depth analysis of these facilities see Appendix D. For more information on the these

DC's please see [30,3 1].

California Institute of Technology:

Dr. Joel Sercel, who was one of the driving forces in the development of the NASA PDC,

is using the concept of integrated concurrent engineering to teach Space Systems Design

at CalTech.

The students are supplied with all the equations needed to design and

analyze a space system.

Students use UML to develop the system's top-level

requirements.

ICEMaker is used to identify subsystem interfaces early in the design process so that

students only create the models they need for their analysis [27]. ICEMaker is a LAN

distributed Excel spreadsheet and database. Subsystem groups log into ICEMaker and

build their models on a local sheet. When a model is complete the resulting outputs are

published to the "System Sheet" which integrates the multiple distributed sheets (or

models) [27]. ICEMaker incorporates a Product Attribute Database (PAD) that is used to

integrate the subsystem models.

It supports external interfaces with Excel, Matlab,

DrawCraft, and CAD STEP files.

The students spend twelve weeks building the system models and three weeks performing

design trade studies.

Saab AB:

The site visit to Saab AB focused mainly on the area of detailed design of airframe

structures and system integration. Saab AB has turned to simulation, modeling, and the

use of Digital Mock-Ups (DMU) to greatly reduce the time needed to verify the subsystems requirements to the allocated baseline requirements [24]. An organization-wide

product definition database serves as a baseline from which all IPD team members can

work using discipline specific tools. Simulation is used extensively during the design

22

process to verify manufacturing, assembly, maintenance, and later in the life cycle, for

customer support.

Three design centers and an application to capture meeting minutes were implemented to:

" Decrease the time from design to decision

e

Increase the rate of communication for the IPD team members

e

Move decision making down to the lowest level possible

*

Postpone generating drawings as long as possible

e

Capture the design knowledge and carry it forward with the design [32].

The meeting minutes application, known as "DIP" (a Swedish acronym), is a method for

carrying knowledge along with the design. DIP can also be thought of as a decision

database as it is accessible to all project engineers on-line before and after a meeting. It

is used to set the meeting agenda and to assign explicit responsibilities to team members.

DIP has also been found to be very useful in documenting the designs.

Please see

Appendix L for more information on the "DMU Rooms." The system architecture and

structural analysis and modeling process followed at Saab AB can be seen in Figures 6.11 and 6.1-2 respectively [23].

During the analysis of the data from the site visit it began to appear that Saab has

implemented many of the Lean Enterprise Model enabling practices [29]. Key practices

that were believed to be identified are:

e

Assure seamless information flow

e

Make decisions at the lowest level possible

e

Implement integrated product and process development

23

Video

Switching

Video

RGB

Video

eo

put

- Ii

I

L_

-I

Video

AUX Video

input

Design Centers

Unix Workstations

distributed throughout

FTP to external

vendors

Figure 6.1-1 Saab Design Center Architecture

24

A structural modeling process followed at Saab is an iterative loop that is used to verify

the sub-assemblies to the allocated baseline. Modeling analysis flows from a CATIA

model of the aircraft perimeter. Computational fluid dynamics is used to determine the

load distribution and a load case is defined for input into the structural models developed

in I-DEAS. NASTRAN is used for finite element analysis of the structure. Landing and

flight dynamics are then incorporated into the load cases and the process is iterated to

refine the detailed design and structural sizing. Additionally, as the program matures

load cells are incorporated into the test and production craft to continuously validate,

refine, and update the models and the load cases used in the simulations.

CATIA

CFD

1-DEAS

Loads

NASTRAN

Dynamics

Key to this

analysis is good

definition of load

cases

Detail design sizin(

Figure 6.1-2 Saab Structural Analysis and Modeling Process

25

Core Technologies:

Existing systems that could be utilized in the DE-ICE architecture were researched to

gain insight into their functionality, level of maturity and usability. DOME which was

developed in the MIT CAD-LAB, and IMAGE developed at Georgia Tech were

researched and are summarized below.

DOME:

Distributed Object-based

Modeling and Evaluation (DOME) enables the rapid

construction of integrated design models to improve product quality and reduce

development time. DOME allows different engineering applications and design models

to interact in a common environment [9].

Modules are created that encapsulate

engineering models, data, or software applications. These modules or objects can then

interact with each other through services over the World Wide Web (WWW) thus

allowing for the exchange of information. Interactions between modules are achieved by

publishing and subscribing to services that can be remotely provided through the WWW

[11].

DOME enables aggregation of the individual sub-problem objects, simulation execution,

and analysis of the whole system no matter where the objects reside or what disciplinespecific tool was used to create it. Further, since each sub-problem is a stand-alone

module there is a potential for model cataloging and reuse. Individual objects can be

integrated using relationships that define their interactions.

Figure 6-3 shows how

individual distributed objects are aggregated into sub-system modules and then into a

holistic system for a simple cordless drill.

A key feature of DOME is that it allows a design to evolve over time by allowing the

system designers to define modules (declaring the services it can provide) without

implementing the embedded model.

Initially a model can be defined by a simple

26

function that the sub-problem is expected to emulate [10] and can be further refined over

time.

Informtion Broker

Gear Manufacturer

\etwork Backbone

(i.e. internet, WWW, etc.)

Network Backbone

(i.e., Internet, Intranet. etc.)

Drill Division

Consuner Ekectronic Company

Figure 6.1-3 Distribution of the Modeling Resources

(From: Modeling and Evaluation of ProductDesign Problems in a DistributedDesign

Environment)

DOME includes design optimization tools for system evaluation. Evaluation models can

be embedded into the modules to provide evaluation services that facilitate observing

quality and evaluating alternates from different viewpoints. Evaluation services include

probability acceptance modeling, Design Structure Matrix (DSM), neural networks,

Genetic Algorithms (GA) for system wide optimization, and multi-dimensional spider

graphs to indicate the effects of trade-offs.

27

DOME uses a three-tier, distributed, object modeling architecture consisting of a client

GUI, DOME server, and model repository that interact using a standard CORBA

interface. Figure 6.1-4 shows the main system components of the DOME architecture.

DOME server interface

interrace/

pointer

pointer of an interface

requests for a service

Figure 6.1-4 Components of the DOME System Architecture

(From: A Web Based CollaborativeDesign Modeling Environment)

IMAGE:

Georgia Tech is currently developing a collaboratory framework called Intelligent

Multidisciplinary

Aircraft

Generation

Environment

(IMAGE).

Collaboratory

frameworks are defined as integrating disparate domain analysis tools, management of

complex systems, communication of design information, and human distributed decisionmaking [12].

IMAGE is a multi-media based, designer-oriented, collaborative

framework where simulations, teams, and teammates interact as shown in Figure 6.1-5.

28

Collaboratories

r ------------------------------------------------Domain

Analysis

A

<

Management

Domain

Analysis

<

C

Figure 6.1-5 A Collaborative Framework

(From: Enabling Advanced Design Methods in an Internet-Capable Framework)

Seven functional components which include database functionality, process management,

and advanced design functionality are designed to facilitate modeling, simulation, and

design along with a Lean-Server concept make up the backbone of IMAGE.

IMAGE

currently supports technology assessment, design method integration, and distributed

simulation [13].

IMAGE is currently used as the prototype architecture for the Virtual Stochastic Life

Cycle Design Environment (VSLCDE), which is designed to facilitate decision-making

over time. Figure 6.1-6 shows the relationships of the five major elements undertaken

when a design project commences [14].

"

Problem formulation

*

Life-cycle modeling

*

Integration

*

Decision support

29

e

Decision making

Please see Elements of an Emerging Virtual Stochastic Life Cycle Design Environment

for a more detailed description of VSLCDE.

Problem Formulation

Decision

MA ing

Figure 6.1-6 Conceptual Diagram of VSLCDE

(From: Elements of an Emerging Virtual Stochastic Life Cycle Design Environment)

Research Findings:

Site visits and research revealed that the IPD teams use dedicated team members and in

some instances functional team leaders in their integrated concurrent engineering

sessions. The NASA PDC sessions are highly scripted to maintain team focus. Meeting

notes and annotation are collected in real time during the design session.

30

Saab uses the DIP application to structure meetings, assign responsibilities, and to retain

organizational knowledge in the form of the decision database. The DIP meeting notes

also considered official design document. The design rooms allow interactive design

sessions of the IPD teams that increase the communication between team members. Saab

is mainly focused on communication of the design teams instead of integration of design

tools. This is due to the fact that as systems become more complex, a single engineer

may no longer comprehend the complexity.

*

Communication is a driving factor in all organizations studied

e

Communication and documentation are integrally linked in these systems

e

Team member with little initial stake in the design can make very good

documenters and will get drawn into the process

e

Need to consider the clock-speed of typical software packages used and support

from vendors (normally

-

1.5 years)

e

Plan for upgradability of the software systems

e

All ICE sessions are heavily dependent on a team leader to maintain focus, tempo

of meetings, consideration should be given to short training session for the team

leads

In academia possible problem that may arise are:

e

Inexperienced engineers may have difficulty developing good first order models

e

Maintaining balanced teams to help optimize globally may not be possible

e

Remembering that decisions are still made by humans

31

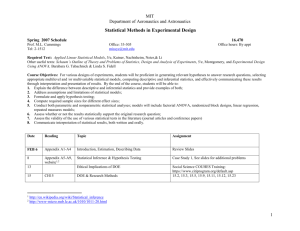

6.2

Technical Requirements

System Technical Requirements (TR) were filtered down from user needs through QFD.

A QFD requirements matrix was generated and iterated to properly capture the highest

technical requirements. Due to the limited time of this study only the highest priority

technical requirements were used to develop the system architecture.

The QFD

requirements matrix is shown in Figure 6.2-1.

2x

x'

<

X,

X

>

x

X

X,

x

Req

u Iremnt,

E

\Technica

Cu-1me Need.

Active Learning In

Environment

a

Design

Holistic View of Design1Kowldgeofand

Exeinewt h

eIgn Process

Support of Life Cycle Analysis

Quality of Student Design

Work

impove

Improved

10

9

9 19

3

9

9

9

8

5

3

3

39

1

3

1

8

1

3

increased Productivityfor Given

Arnount of Tirne

7

3

9

Support For Team Enablers

7

j

9

3

1

9

1

1

1

1

3

9

3

3

1

1

3 131

1

1

1

3

1

3

1

3

3

1

3

3

1

3

9

9

3

Capabilityto SupportMIT Operational

Modes

N/A

TR Importance W*_

RelativeWeight (%)

_t

1

3

1701

98

2

4

8

3

287 122

3

1

3 3

1112811271

3

3

Units

3

3

3

1

45

54

68

14

7

6

5

2

1

1

1

3

9

9

9

9

3

1

1

3

1

3

1

1

9

1

1

9

9

9

9

9

9

_4

1

32_

28

9

3

3

1

130

3

5

3

9

3

1

106

1

3

3

1

56

3

3

9 3

1

13

3

1

12

12

1

9

9

91

3

1

31

132 122 105 113 117 107

3

1

1

1

4

Highly Usable system

73 _98

5

4

1 1

1

3

54

84

54

45

6

4

6

7

.

3

74 i44

5

3

61

56

3

9

72

32

5

10

74

0

at

X

Target Values

-

Saab

>1

8

NASA, Aerospace, TRW

>2

7

CalTech

>4

DOME

1

1

3

9

Sustainable System

Constraint

3

>2?

_7

4

1

2

>4

1

0

161

0

1

1

6

1

1

2

inf

>6

3

>4

0

1 min

7

<1

4hr

11

1

2

IMAGE

Figure 6.2-1 DE-ICE QFD Requirements Matrix

User needs, categorized as pedagogical and operational are inserted on the left side of the

QFD matrix.

Ranking factors that were defined and agreed upon by the team and

32

representatives of the Aeronautics and Astronautics Department are listed just to the right

of the user needs. The main body of the QFD matrix is the relationship matrix area

where each technical requirement is assigned to a column and evaluated against a need.

Next, a decision is made as to the importance relationship of each TR. This determines

the relationship of a TR to a specific need. Relationships to the needs are weighed on a 9,

3, or 1 scale depending on a strong, medium, or low relationship respectively. Each TR

weighting factor is multiplied with the ranking factor of the needs and summed in the

bottom of the TR columns to give a total importance score for the TR. Directly beneath

the total score is the relative importance score of the TR.

Measurable units used to specify each TR are located at the upper portion of the lower

section. Under this is a benchmarking section where each existing system that contains a

comparable TR is rated to allow for a goal to be set for the DE-ICE system.

The QFD matrix generated seven TRs: four from the highest ranked and three that ranked

strongly against the single constraint. A sensitivity study conducted on the QFD matrix

revealed a borderline TR which was carried along with the original seven. The TRs for

the system are (in order of importance):

1. Design and analysis support

System should provide the hardwareand software tools the students need during

the design and analysisprocess.

2. Provide guidance throughout the design process

Give students access to information, examples, theory, etc. which should provide

a roadmap through the life cycle of a product design.

3. Planning and management of the design process

Help students define, schedule and monitor tasks, deliverables between tasks and

the progress of theirproject.

4. Experimentation support

33

Support of the design, implementation, analysis and integrationof results of

experiments, including resources and tools that will help students interface with

computers, machines, controllers,etc.

5. Operate on any platform

Give the students andfaculty the ability to work in any environment (UNIX, Mac,

PC operatingsystem).

6. Distance collaboration support

Provide remote capabilityto attenda class, easily interactwith remote teammates

and access external resources (specialists,professors, etc.).

7. Flexible system

Have the ability to adapt easily to different operationalmodes, subjects, projects

or new technology.

8. Presentation and reporting support

Provide students the capabilityto effectively presentand report theirprogress

and results.

These TRs were used in the QFD Product Matrix to synthesize possible architectural

variants for the DE-ICE system.

The top section or "roof" of the house of quality is the correlation matrix that was used to

determine the conflicts between the TRs (Boppe [25]). The main conflicting TRs are:

e

Design and Analysis Support vs. Operate on Any Platform

Due to the large variety of software tools and operatingsystems special care

would be needed to ensure that the system could operate on any type of platform.

e

Design and Analysis Support vs. Flexible System

Tight Integrationof design and analysis tools that will support the life cycle of a

design may tend to make the system highly inflexible and limit the evolution of the

34

system. The system should support the ability to "snap-in" new toolsfor design

and analysis as the system evolves.

*

Distance Collaborative Support vs. Flexible System

For teams to be able to effectively collaborate at a distance a mix of

communication, and distributeddesign and analysis tools are needed. If these

tools are not integratedwell they may be of little usefulness. Whereas integrating

these components into a useable sub-system may tent to limit the flexibility of the

system.

*

Distance Collaborative Support vs. Operate on Any Platform

Distance collaborativetools will need to operate on an inhomogeneous mix of at

least three majorplatforms. Selection and integrationof tools to support

distributedteams that are truly platform independent may not be possible.

These conflicts need to be managed and considered as the design progresses and any

systems that are built for the system should either support multi-platform use or

utilize a client -server architecture. Design and analysis tools should utilize a

standard application interface for tool integration.

35

6.3

Use Case Diagrams

Use Case Diagrams helped identify the need for an external user interface that would

determine levels of access privileges assigned to each external user, and to provide

services based on those privileges. A Use Case Diagram for DE-ICE is shown in Figure

6.3-1 and a "design" Use Case is shown in Figure 6.3-2. Use Case analysis showed that

there would be four main actors interacting with the system faculty/TAs, students, staff

and external users. Creating the Use Case diagram also showed that some of the DE-ICE

functionality extended beyond the system boundary. Use Cases for the faculty show the

main expected interaction with DE-ICE, but they should be able to use any functions of

the system.

Wind tunnel

Manufacturing lab

Figure 6.3-1 System Use Case Diagram

36

The design Use Case was evaluated separately because the functions can be used

separately or through an integrated instance from the "perform design work" function.

Figure 6.3-2 Design Use Case Diagram

The "manage data" function is shown as being able to be accomplished by students and

or a computer. This may put an unnecessary requirement on the users but it was felt to be

advantageous to give users the freedom to manage their own data if they so choose.

37

7. ArchitecturalSynthesis

The highest ranked TR's and their importance weightings were used in the QFD Product

Matrix.

Both were placed in the Product Matrix on the left side and multiple

implementations were created along the top to satisfy each TR. Use of the product matrix

enabled the team to quickly synthesize architectural concepts for the system while

maintaining traceability to the user needs. Another relationship matrix was used in the

body of the Product Matrix as defined in Section 4 and will not be repeated here. Total

importance rankings were used to compare the baseline architecture to the variants

generated by each team member. This gave a rough indication of the possible "overall

The Product Matrix may be seen in Figure 7-1 through 7-5.

relative" improvement.

Architectural implementations are grouped by functionality and a bold typeface indicates

a hardware-based implementation. Individual and groups of implementations considered

for prototyping are highlighted in the top of the Product Matrix.

Development of the Product Matrix occurred in an iterative fashion. Each time the team

met to discuss their concepts, new items "bubbled-up" and were added to the Product

Matrix.

Below the Product Matrix is a section where the architectural variants were analyzed.

When an implementation was selected for a particular architecture, its score from the

relationship matrix was carried down into this section allowing the team to evaluate the

percent improvement of each concept relative to the baseline. This may be seen in Table

7-1.

Architectural Variant Total Score Percent Improvement

A

165405

61.4%

B

81703

21.9%

C

120136

46.9%

Baseline

63781

0.0%

ABC'

116886

45.4%

Table 7-1 Product Matrix Architectural Evaluation

38

I

I

I

9

0

Technical Requirements

Design and analysis support

Provide guidance thoughout design process

Planning and management of design process

Experimentation support

Operate on any plaform

Distance collaborative support

Flexible system

Presentation and reporting support

Design priorities

TR Importance Weigh

eaive eig

Architecture A

297

170

149

145

143

122

98

32

-

1

3

3

3

3

3

3

1

1

756

8

l

512

11

Xi

496

11

I

1X

Architecture________

ArhtcueB7561

Baseline Architecture

Architecture ABC'

____________756_____________

3

3

3

1

3

1

1

1

3

9

3

3

1

9

3

3

3

3

3

9

3

9

1

1

3

3

*

1______________

756 1

Architecture C

Simulation Tools

Simulation Tools

Print~r~

Drintare

II

5~v~ta~m~

OnArs~tinn quntamc

fnarntinn

II

660

9

XI

1424

4

1100

5

2571

3

X lxiX_ Xi lx

X

1 11830 1 14241 11001 2571 1

XI

I

1

I

X~~.1

XEX

830

7

1

496 1 660

[

1616

4

I

X

116161

X I

___IT

____

I

X

__

9

9

1

9

1

1

1

1

1

1

1

*

*

*

*

1546

4

5277

2

2816

2

2771

2

3068

2

2850

2

2816

2

I___ I*

X ![

I

8301J5711

1

9

*

X__

I__

L

3

9

9

*

xI

XI

152771

I

257

x10

xX__

9

*

X1027

1 14241

9

7

1 5277

x

x

xX

IX

12771130681

1i

I

I1

1

1

1

III

__IX

I

I X1

1

I1 I

1527

1

1

I

1

Figure 7-1 DE-ICE QFD Product Matrix Page 1

39

Modeling & Model Management Tools

Math Tools

Discipline-Specific Design Tools

I\'9

-Z

3

1

3

1

1

3

9

1

1

9

9

3

3

1

891

7

3

3

1111

5

297

19

806

7

__x_

xX

3

3

9

9

1

9

3

1

3

1

1859

3

E

3

5352

1

I X

1 118591

F 1I

lx

1 x

53521

1034

6

I

1

x

9

9

9

9

3

1

1

1

1

1

3

I X [ _x

Ix

1

Ix

1

3091

2

x

13091

xiixi

__I__I__I__X__I__X

I

1

I

1

x

I

_

3663

I

3184

I

IXI

1 9231

3663

1

3369

IX

xi

Ii

1........L........L......

806 118591 53521 923 1

[

I

9

9

9

9

9

9

1

1

3

1

1

2771

2

3440

2

2771

2

9

1

1

2961

2

2961

2

2961

2

X I x

x

2961 296

11

2818

2

3992

2

x

x

xX I

12818

IX

1

1_1

Ix

Xx

2 77 1

]

13440

II

x

x)

344012771

1

x

x

Ix

x

x

129611 28181 39921 27711 28181 2771

-x[

111

Ix I-x I x[I_

3663130911 2961

2818

2

x_L _ J

3992

I x

129611

x

12961

2771

2

2818139921

Ilx- i ii

I--I ..._ I

2961 1

I

lxIx

1

9

1

1

3663

2

3184

2

12210

1 18591

x

3369

2

122101 33691

ii

(x[

J 806 118591

2210

3

I

806 '1859'

1

9

1

923

6

AC4jxO

C7

N

I_

[

x-39921

128181

I_ I

I

I

1I139912771j 1

I

1

1

x

12771

I x X

J344012771

Figure 7-2 DE-ICE QFD Product Matrix Page 2

40

Figure 7-3 DE-ICE QFD Product Matrix Page 3

41

Experimentation Support

Project management tools

Guidance

C cC3

c~

-~

Sq~Z,

Z'

I\N

613

91

1

1

1

9

1

9

3

1

1

9

9

9

9

1

2099

3530

2375

3

3 2

1714

4

370212873129661 196 840

112

2 12

1516134

4 14

J71

1

3h E

8E E

1732 1525

4435

2051 1305

2644

1337

5

3

1305

5

16021

4

1305

5

TI

I

1~ x72 x83 x 1

- I_

x I X

37021 28731 29661_ 196

531 2091372

3002

2

1511

4

1j56

x_

1_116_1_302

=

EE61 1

-02 172

lxx

1 300211732

1-

5161

xj

37021 28731

E

9

13

1

1

x

1 Ii

x

X Ix

287 74 27135301j 20991 3702 1 28731 29661

x

171

1~~ 1

50

xl

I 350

I2I7I1275 531

9

911

3

2817

2

3

1

1

9 1 19

9

9

9

16

1

9

2

c-

9_'V

9__99

1

c4

-

e~

511

I -

I

1 1

02

15251

lxx

1525 120

J05

__

1

1

126441

xI

1

I___ I I IX I

.1

17311525 1

110

J

I

J

30021 17321 15251

1

X

i-_

-x

11525j

x

1

- - 1 H

~732

1602

X__ I I

-

110

j

X....

-

~

1

9

Z162

Figure 7-4 DE-ICE QFD Product Matrix Page 4

42

Remote Presence

Cross Platform Communication

0

00

11b,

1C

1q1

3

3

3

3

1

3

9

3

1

1

_1

1

9

1

3

9

9

9

1

9

1

1

9

1

1

1

9

3

3

9

1

9

31

1

1424

1130

755

755

755

1804

2535

1783

1371

1228

2039

645

755

755

7

1804

2535

1783

1371

1228

2039

645

755

755

2535

X

1

~ 1371

~

1755

xl~

[12281

x

_

1

9

1

9

9

1

3

1

3

3

3

3

9

3

1

1

1_1

9

3

3

1228

1751 1751

803

1979

2775

1196

660

366

1484

1377

2385

1228

1751

803

1979

2775

1196

660

1

1

jxj_[__

1

1377

1

11

1783

6451

3

1424

_

x X

_

2385

11228751

I X1

[x

x

1228

I

X

1j

803 I 19791

X

I X

x I xX lxi

1751

[X

12281 17511

1

11424

171

_6

11377

12385 112281 1751 1

x32I27lli

1751

803

__

1

462

111961

9

1

3

756

3227

756

3227

7

3227

x X

_

1

1 756

X

_I_

_I_

1

4

X

x__~_

19791

3

3

3

3

3

3

3

2385

X

1121 231 645

9

3

1377

645

_5

9

9

1

9

1484

XX

1

75[ 1 1804 2551181

9

19

1645

X_ I 1424

XJ

I

x

3

366

S2535

1804

4

1p

01

11979

19791

1

1 160

li

J

3227

17132

J751

Figure 7-5 DE-ICE QFD Product Matrix Page 5

43

rresetiiaiionineporiin~

IPresentationepotig

I

Flexible

System

Flexible System

0

00

0OA0

1

1

340

91

1

1

1

1

1

83

-

111

9

9

3

3

9

3

9

3

9

9

9

1

1545

1392

5

4i

4

1990* 1-45- 1392

x

1424

........ 1

13 I- 1392

4

4

x

ii

x1

Ii

1392 13921109811098 1751

142

4

14

109

10815

5

2483

1036

803

1673

3

6

7

4

5.4

I

I

I

xxIx

x

x

10361 803

1 124831

X~14

X~

=55 =

155 1

14

j 1424

1

1

1

1

1

J

4831 1

X..4....... I

1 1J 43

9

3

9

1

9

1

1

1250

3

3

1

9

1680

4

Ix

I

9

3

9

3

9

978

1275

6

882

7

1x Ix

lxx

x____

116731 16801 978

4

9

3

1

3

1

3

3

3

857

1778

194

4+

3

1

1

1

9

9

36

U

14

x

x

Ix

826

I

7

I

*

1

9

9

529

11I

249

280

171

147

1683

A

x x Voalsco% improv

x I x I x 11ticEINipo

I x

Ixxj

16731 16801j 978 1j1751

38

197

17781

85

1

127

I

Ix

1

1

9

199

9

1

3

3

3

9

9

3

x I_ x

X

x

1

x I I X XI XI

0 63 60 7 25

1

117781

X

857

xI x

I

117781 1974 1

826 1529 11683117503511.93955

1

~tasoj/I

1I

scl -01

xIXI I

1J 678~j1.1 50

1 1826 1 529 1

Ix

I

1 826J 529f 1

x

Tota scor %improv

1861543

Figure 7-6 DE-ICE QFD Product Matrix Page 6

44

7.1

Concept Development

To develop architectures, each team member used the Product Matrix to identify

implementation combinations that were felt to produce "good" architectures. Each team

member generated conceptual drawings to convey the key features of the different

architectures. Interestingly, team members initially used a different "view" to describe

their architectures.

There was a physical, software/IT, and equipment Block diagram

(EBD) and each one conveyed different information. It was realized that to fully describe

the concepts all three views were needed (discussion, Boppe 3/15/2000). Figures 7.1-1

through 7.3-3 show the Software/IT, EBD, and the physical views respectively for the

author's architecture "A." Architectures "B" and "C" can be seen in Appendix E.

After development of the architecture consideration was given to the design principles

used that affected the concepts. Design principles [22] used sought to:

" Minimize the effect of the varying clock speeds of the student team members

" Maximize communication and design flexibility

" Maximize the useful life of the system

Software/IT Conceptual View:

The software and information technology (IT) view depicts the nested IT infrastructure

developed to support users working on a distributed laptop computing system within the

design room, the department and outside of the MIT physical boundaries. External users

may gain access to the design room server through a user authentication application (i.e.

AltaVista Tunnel or Tether), the DOME server, log onto the video bridge to receive

streaming audio/video over the World Wide Web, or onto individual user laptops through

NetMeeting or Virtual Network Computing (VNC). Users within the physical confines

of the MIT network will have the same access options but will be able to gain direct

access to the design room server and labs outside of the design room.

45

External Users:

Students

Faculty

Lecturers

Customers

Vendors

Extemal Users

Laptops:

Windows 2000 Workstation

Matlab

MS Office

Working Model

VenSim

Pro E

AutoCAD

VNC

CVV/NetMeeting

Instant Messaging

Group E-mail

ePost it notes

Software Through Pics

STK

Maple

Compilers

NASTRAN

Risk AnalysisVirtual WorkBench

PSM32

LabView

QFD-Capture

Latex

Visio Technical

Sample Design Processes

Fax Software

TRIZ Tools

MasterCam

Front Page

Stat-Ease

CFD

Figure 7.1-1 Software and IT Architectural View for the Author's Architecture "A"

46

A DOME server would be installed on the Aeronautics and Astronautics Department

servers which allows students and faculty users to access the integrated modeling

environment over the WWW. DOME will be used to integrate sub-system models and

costs that will allow the team to analyze and optimize the system globally. All software

needed for the student designs would be installed on the server and on each laptop; a set

of CDs should also be provided to each student using the system that contains all the

needed software.

An automated software installation server will act as a means of

software distribution that will enable students to install any applications not currently on

their systems. Software selected for architecture "A" contains all possible applications

that students could use in support of the life cycle of a design project, based on the

authors experience and the survey data collected.

Software grouped by class and the

recommendations for additional packages are listed in Appendix K.

Team communication is designed to support different modes (i.e. person-to-person,

person-to-group, group-to-group, and inter-group) is provided by NetMeeting, VNC,

telephones at each workstation, fax software on each computer, ViewStation FX, and

group emails in this concept.

A second eighteen-inch LCD monitor will provide additional audiovisual support with a

PC camera at each workstation to be used for communication and design work within the

room. View Station FX and a video bridge will provide support for the integration of PC

camera systems, PBX and IP video conferencing systems.

This will also provide the

capability to transmit streaming audiovisual over the Internet. Video conferencing will

be enhanced through the use of novel components called the Electronic White Board

(EWB) and the Round Table Virtual Presence (RTVP) system. Descriptions of the EWB

and RTVP can be found in the prototype section.

Dashed lines indicate possible concepts for prototyping and will be discussed in the

prototype section.

47

Equipment BlockDiagram View:

The EBD shows the components, their interfaces, and the types of interfaces specified.

Laptops are selected over workstations in architecture "A" to provide the following

benefits:

e

Remove the constraint of students needing to perform all design work in the

design center

e

Flexibility of the users to work and form groups anywhere is maximized

e

Frequency of communication between team members can be increased

e

Round table meetings and ICE sessions are easily facilitated using laptops at the

conference table

Architecture "A" utilizes wireless Ethernet cards in all the laptops to facilitate team

flexibility and ease of reconfiguring the design lab. Due to the limited throughput of

wireless Ethernet systems, it is required to reduce the traffic over the net in the design

lab. This can be accomplished if all user applications are installed on each laptop (as

described in section 11-1) and the network is used for communication and data exchange

only. A 100 Mbps Ethernet raceway will also run around the perimeter of the room so

that students can hardwire into the system to increase network speeds.

Laptops and

cameras should also be provided to each faculty member using the system to enable

sharing of data and communication tools. Tether should be supplied to all users free of

cost so that users can work at home with out penalty.

Color laser copiers, a digital

networked copy machine, a scanner, and a large format plotter will further enhance team

communication.

48

Video Projector

Overhead Projector

KEY:

Phone/computer cable

V

deo Recorder

Wireless Comm Link

--.-

UUUU

Rapid Prototyping

Vd

Video ridge

View Station FX

Video

Video Projector

-

100 base Ethernet

Scanner

PC Video

Wind tunnel

Internal Data Flow

-- -- -- --

Digital Copy Machine

Moitor

Faculty/TAs

Manufacturing Lab

PC Video

Other Labs

:Oather

LLaptop

Disk storage

C

--

Tel

IT!

hone

Monitor

Server

Win 2000Server

Dome

ProE SharedDatabase

VNC

Office

View Station Software

Personal Folders for Students

Shared Foldersfor Work

Auto InstallationSoftware Package

Cost Database

TetherMS

Tether

Athenal

l iOn-Line

ii

Sun

Laptops:

Windows2000 Workstation

Server:

Color Laser printer

Laserprinter

Lsrpitr

Laser

printer

Help

Ineatve IEEEStandards

16.870 SearchableNotes

GroupBrain Storming Tools

Star trek Vileo Terminal

ARC

S

e

Matlab

MS Office

Working Model

VenSim

Pro E

AutoCAD

STK

Nastran

Risk Analysis

PSM32

QFD-Capture

Visio Technical

Processes

TRIZToods

MasterCam

Front Page

Stat-Ease

CFD

VNC

CVV/NetMeeting

Instant Messaging

GroupE-mail

ePost it notes

Software Through Pics

Maple

Compilers

VirtualWorkBench

LabView

Latex

SampleDesign

Fax Softare

Plotter

In

PP e

PC Video

Monitor

PCommand

PC Video,

Laptopcomputer

PC Video

Telephone

Telephone

Monitor

Laptop computer Telephone

Monitor

Laptop computer

Telephone

Monitor

Laptopcomputer

Figure 7.1-2 Equipment Architecture View for the Author's Architecture "A"

49

Physical View:

The physical layout of the main design center area and the team rooms is shown in Figure

7.1-3. Rolling desks are used on three sides of the room, with the front of the room used

for whiteboards, printers, supplies, and the video screens.

Three video screens are

arranged to partially surround the meeting Table to enhance natural communication

during meetings. Three video projectors are permanently mounted in the ceiling and are

pre-focused. Video screen display is controlled through Meeting Suite 5000. This would

allow software control of the screen displays. The RTVPs have been placed to minimize

intrusion into line-of-sight discussions at the conference table while at the same time

enabling the local and remote team member to feel that they are in a normal face-to-face

meeting.

50

PBX

Video Bridge

AA Server

.2

gul-m

Figure 7.1-3 Physical Architectural View for the Author's Architecture "A"

51

7.2

Concept Evaluation

Evaluation of the architectural

variants and development of the recommended

architecture was accomplished through the use of a Pugh matrix.

Only the author's