Improving Sales and Operations Planning in an Engineer-to-Order

Environment

by

Andreas Christogiannis

Diploma in Mechanical Engineering, National Technical University of Athens, Greece, 2006

I

Submitted to the MIT Sloan School of Management and the MIT School of Engineering in Partial

Fulfillment of the Requirements for the Degrees of

Master of Business Administration

HNES

and

Master of Science in Mechanical Engineering

MASSACHU SET7S mNTTf .TE.

OF TECHNOLOGY

In conjunction with the Leaders for Global Operations Program at the

Massachusetts Institute of Technology

JUN

June 2014

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and

electronic copies of this thesis document in whole or in part in any medium now known or

hereafter created.

Signature redacted

MIT School of Engineering, MIT Sloan School of Management

May 09, 2014

Certified by:

Siignature redacted

Donald Rosenfletd, Thesis Supervisor

Senior Lecturer, MIT Sloan School of Management

Signature redacted

Certified by:

Michael Triantafyllou, Thesis Supervisor

William 1. Koch Professor of Marine Technology

Professor of Mech * al and Ocean Engineering

Signature redacted'

Accepted by:

David Hardt, Mechanical Lidffieering Education Committee

Ralph E. and Eloise F. Cross Professor of Mechanical Engineering

Accepted by:

Signature redacted

V r tL

%

F'

MIUar+"erson

Director, MBA Program

MIT Sloan School of Management

1

201

LIB RARIES

© 2014 Andreas Christogiannis. All rights reserved.

Signature of Author:

18

Page Intentionally Left Blank

2

Improving Sales and Operations Planning in an Engineer-to-Order

Environment

by

Andreas Christogiannis

Submitted to the MIT Sloan School of Management and the MIT School of Engineering on May

09, 2014 in Partial Fulfillment of the Requirements for the Degrees of Master of Business

Administration and Master of Science in Mechanical Engineering

Abstract

A pragmatic approach is taken at analyzing and improving Sales and Operations Planning in a

project based, engineer-to-order product line. Variability of product and components configurations

and long lead times of the sales process and of material procurement during project execution place

additional planning challenges in comparison with a standardized high volume product business.

The study focuses on improving the visibility on future customer orders and on reducing the

procurement lead time of project material.

Due to the nature of the market and the customers of the studied product line, incoming orders

timing is very uncertain when viewed on a project by project basis. However, there is a specific

dynamic when the sales pipeline is analyzed on aggregate: Tenders that end up converting into a

customer order will do so sooner rather than later. Historical data and observations are used to

develop and propose a probabilistic model that connects today's open tenders to the expected

new business out of those tenders.

The organization is able to use this model to estimate what the current activity of the sales force can

produce in terms of new business. The expected benefit is that the organization can act proactively

if there is an expected reduction in incoming business from a specific region or major customer; it

can also make targeted efforts to increase sales activity towards that region or customer.

To increase its competitiveness when bidding for new projects, the organization has embarked on

an effort to reduce the overall project execution lead time. A significant portion of this lead time

is waiting time for project specific material (which comprises the biggest part of the BOM in money

terms).

A supplier flexibility scheme is proposed, under which a material order is placed in two phases:

first the desired delivery time and the component rough specification are specified, and later on the

exact specs are given to the supplier. An optimization model that utilizes the above concept is

developed and offers the organization an optimal way to plan the project material procurement,

given a desired reduction in procurement lead time.

The expected benefit is that there is a justified and optimal method to reduce procurement time

without building excessive material stock; it also sheds light to the "constraints" (specific materials

or suppliers) that need to be lifted for further lead time reduction.

Thesis Supervisor: Don Rosenfield

Title: Senior Lecturer, MIT Sloan School of Management

Thesis Supervisor: Michael Triantafyllou

Title: William I. Koch Professor of Marine Technology, Professor of Mechanical and Ocean

Engineering

3

Page Intentionally Left Blank

4

Acknowledgements

ABB

I want to thank my project sponsor and supervisor, Haitao Liu, for his valuable support throughout

my time at ABB. I also want to thank Aija Mankkinen for helping me kick start the ATPE study, and

Rudolf Wieser for his support within the OPS CH team. I am also particularly thankful of the teams

at: ATPE Sales, ATPE Engineering, ATPE Project Management, ATPE Product Management, BU

DMPC Sales Management, BU DMPC Supply Chain Management, Turgi Supply Chain Management,

Turgi Production and Purchasing for welcoming me into the ABB world and for their support and

insights.

MIT

Particular thanks go to my two advisors, Don Rosenfield and Michael Triantafyllou, for providing

vital guidance and advice, both while I worked on the project and while writing this thesis. I am also

very thankful of the LGO office staff for all their responsiveness and the seamless support I received.

Last but not least, my experience at MIT would not be nearly as memorable and unique without my

LGO and MBA classmates.

Finally, I thank my family for being present and supportive during my two-year LGO adventure.

5

Page Intentionally Left Blank

6

Contents

A b stract .............................................................................................................................................................................................. 3

A ckn ow led gem en ts ...................................................................................................................................................................... 5

C on ten ts ............................................................................................................................................................................................. 6

A bb reviation s ............................................................................................................................................................................... 10

1-

In trod u ction ................................................................................................................................................................... 1 1

1.1

Pu rp ose an d Scop e of Project ............................................................................................................................... 1 1

1.2

M otivation , C h allen ges, O bjectives .................................................................................................................... 1 1

1.3

H yp othesis an d Exp ected R esu lts ....................................................................................................................... 12

1.4

A p p roach ......................................................................................................................................................................... 13

1.5

Th esis outlin e ................................................................................................................................................................ 13

1.6

C on clu sion ...................................................................................................................................................................... 14

2 -

C om p any b ackgroun d ............................................................................................................................................... is

2.1

In trod u ction to A B B G roup .................................................................................................................................... is

P ow er p rod u cts ...................................................................................................................................................................... is

P ow er Sy stem s ....................................................................................................................................................................... is

Low V oltage P rod u cts ......................................................................................................................................................... is

P rocess A utom ation ............................................................................................................................................................. 16

D iscrete A utom ation an d M otion .................................................................................................................................. 16

2.2

D iv ision of D iscrete A utom ation an d M otion ............................................................................................... 16

2.3

Business Unit Pow er Conversion and new structure ............................................................................... 17

2.4

Product line Excitation and Synchronizing Systems (ATPE) ............................................................... 18

3-

Literature Review ....................................................................................................................................................... 2 0

3.1

In trod u ction ................................................................................................................................................................... 2 0

3.2

Sales an d O p eration s Plan n ing ............................................................................................................................. 2 0

D em an d Plan n in g .................................................................................................................................................................. 2 1

Su p p ly Plan n in g ..................................................................................................................................................................... 2 1

3.3

Forecastin g ..................................................................................................................................................................... 2 2

Forecastin g b u sin ess that fl ow s in regu larly .......................................................................................................... 2 2

Forecastin g b u sin ess that fl ow s in sp orad ically ................................................................................................... 2 2

3.4

M aterial Procu rem en t an d Flexibility .............................................................................................................. 2 3

Q u an tity fl exib ility su pp lier agreem ents .................................................................................................................. 24

Classification of supplier relationships between ABB and suppliers ........................................................ 24

7

4-

B en ch m arking S& O P across other P G 's an d B U 's..................................................................................

26

4.1

Introduction ...................................................................................................................................................................

26

Scop e of b enchm arking ......................................................................................................................................................

26

M eth od of b en ch m arking ..................................................................................................................................................

26

4 .2

B en ch m arking R esults..............................................................................................................................................

27

In tern al B e nchm arking ......................................................................................................................................................

27

E xtern al Ben chm ark ing .....................................................................................................................................................

30

4.3

A ssessm ent of ben chm ark ing results...............................................................................................................

31

4 .4

Su m m ary .........................................................................................................................................................................

31

5

Stu dy at A T P E O PS CH ..............................................................................................................................................

33

5.1

Introd uction ...................................................................................................................................................................

33

5.2

Fu nctions and operation of A TP E.......................................................................................................................

33

A T P E O P S C H sales dep artm ent ....................................................................................................................................

33

ATPE Global Product and Technology M anagem ent .....................................................................................

35

-

A T P E O P S CH Project M anagem ent.............................................................................................................................35

A T P E O PS CH E lectrical & M echanical E ngineering ............................................................................................

35

A T P P (Purchasing and Production) .............................................................................................................................

36

ATPE's Gate Model: from sales to project execution and delivery to customer ............

36

5.3

Study of sales forecastin g .......................................................................................................................................

37

Cu rrent forecasting m ethod ............................................................................................................................................

37

Sales Pipeline Analysis .......................................................................................................................................................

38

5.4

S tudy of p roject material procurem ent...........................................................................................................

55

Challen ges in p rocurem ent of p roject m aterial.................................................................................................

55

Proposed approach to improve project material procurement...............................................................

55

O p tim ization of p roject m aterial purchasin g ...................................................................................................

58

5.5

Sum m ary .........................................................................................................................................................................

66

6

Conclusion ......................................................................................................................................................................

67

6.1

Sum m ary of m otivation, challenges, and objectives............................................................................

67

6.2

Su mmary of Recom m endations to A T P E ........................................................................................................

67

6.3

Major lessons learned for the BU and recommendations for further work............................68

-

Exhibit 5.3.1 .............................................................................................................................................................................

69

Exhib it 5.3.2 .............................................................................................................................................................................

70

8

Exhibit 5.3.3 ............................................................................................................................................................................. 71

Exhibit S.3.4 ............................................................................................................................................................................. 72

Exhibit S.3.S ............................................................................................................................................................................. 73

Exhibit S.3.6 ............................................................................................................................................................................. 74

A PPEN D IX S.4 ............................................................................................................................................................................... 7S

Exhibit S.4.1 ............................................................................................................................................................................. 7S

Exhibit S.4.2 ............................................................................................................................................................................. 76

R eferences ...................................................................................................................................................................................... 77

9

Abbreviations

ABB

ASEA Brown Boveri

ATO

Assemble to Order

ATPE

ABB Excitation and Synchronization Equipment Product Line

ATPE OPS CH

Swiss Operation of ATPE

ATPP

ABB Turgi Production Organization

AVR

Automatic Voltage Regulator

BOM

Bill Of Material

BTO

Build to Order

BU

Business Unit

B2B

Business-To-Business

CHF

Swiss Francs

CRM

Customer Relationship Management (software)

CTO

Customize to Order

ERP

Enterprise Resource Planning

ETO

Engineer to Order

GPG

Global Product Group

GPL

Global Product Line

LEC

Local Engineering Center

MNC

Multinational Corporation/Company

PG

Product Group

PL

Product Line

PRU

Product Responsible Unit

R& D

Research and Development

ROW

Rest of World

SES

Static Excitation System

S&OP

Sales and Operations Planning

10

1 - Introduction

1.1

Purpose and Scope of Project

The purpose of this project and thesis is to perform a deep, data-driven study on aspects of Sales

and Operations Planning in an Engineer-to-Order industrial context. This study proposes

1)

a forecasting model whose inputs are business-to-business sales data and

2)

a material procurement model that optimizes material ordering schedule taking advantage of a

supplier flexible ordering concept

The project is carried out within a six and a half months period at the Turgi location of the ABB

Group. The study outlined above is aligned with the Division-wide drive of ABB's Discrete Motion

Division for Operational Excellence.

Since ABB has a hands-on, engineering driven culture, the project scope is deliberately narrowed

down and focused on one Product Line of the Group (Excitation Systems), so that recommendations

are specific and practical.

It is hoped though that the insights and recommendations can serve as examples for wider

improvements on a Business Unit or Division level.

1.2

Motivation, Challenges, Objectives

Organizations with a focus on engineering and product innovation traditionally compete on

superior product performance, long customer relationships, and solutions tailored to customers'

needs.

However, they also face pressures to become more responsive to a more volatile and fast paced

business environment. This creates the need to better anticipate and plan for future business intake

and to better plan to have the right resources at the right place at the right time.

11

The Excitation Systems Product Line of ABB often faces related external and internal pressures:

"

customers that demand faster delivery times for complex engineered systems

*

project opportunities that shift unpredictably to the future

"

projects that have to be delayed because of missing or delayed material

"

an engineering workforce that is frequently overloaded because of spikes in demand

The objectives of the project are to offer improvement recommendations in two key areas:

*

business forecasting

*

material planning

The deliverables consist of high level insights that point out the key items that affect the planning of

the organization and of a set of recommendations and tools that will help the management of the

Product Line drive improvements on those items.

1.3

Hypothesis and Expected Results

A typical Engineer to Order organization is expected to not be as mature in S&OP as a typical Make

to Stock or Make to Order organization; the reason being the low volume-high mix nature of an ETO

operation.

However, the hypothesis is that a deep study driven by data can reveal opportunities for improving

organizational coordination and responsiveness and creating competitive advantage.

The expected results from this project is that Excitation Systems will take action on improving the

key points pointed out by the study, utilizing the methods and tools developed. This will enable the

organization to:

12

"

understand the dynamic of the sales pipeline and manage the sales force efforts to create

demand that is satisfactory in volume and to mitigate expected unwanted demand volatility

throughout the year

"

drive down the lead time of project execution by reducing the lead time of material purchasing,

by utilizing a cost optimal method that balances material uncertainty risks with flexible ordering

policies and lead time reduction.

1.4

Approach

The approach taken throughout this project consists of the following pillars:

"

stakeholder interviews: understanding the context, strategy, culture, functions and internal and

external interrelations

"

relation building: during a busy time it is important to effectively make the case for the project

and its benefits so that busy stakeholders invest their time in supporting and buy in on the

recommended methods

"

data collection: data collected daily and in parallel for forecasting and material planning.

Sources range from databases to interviews, daily observations, lunch discussions, media

coverage

"

data analysis: data driven development of recommendations and models

*

pilot project: case study of supplier lead time reduction and effort to drive immediate

improvements

1.5

Thesis outline

Chapter 2 provides background to the ABB group, and the organizational belonging of the Product

Line Excitation Systems.

13

Chapter 3 explores the current literature on ETO S&OP and on supplier flexibility contracts.

Chapter 4 describes the method and results of benchmarking planning methods in other Product

Groups and Business Units within ABB. The analysis of the benchmarking results drives the

priorities for the study of S&OP at ATPE.

Chapter 5 provides more detailed information on ATPE's operation and on internal and

collaborating functions. It then proceeds with the actual study of sales forecasting and project

material procurement planning, outlining for each part of the study the current processes; the

proposed approach for improvements; the methods and tools developed; and the results that can be

achieved from said methods and tools.

Chapter 6 summarizes the motivation and objectives of the project, as well as the key

recommendations to ATPE. It also summarizes the major lessons that are learned for the whole

Business Unit Power Conversion. Finally, it suggests areas for further work and future projects.

1.6

Conclusion

This thesis proposes a forecasting model for Engineer-to-Order organizations and a material

procurement model that uses supplier flexibility to optimize the ordering schedule. The thesis is

based on the project carried out at ABB Group's Product Line Excitation Systems. The

recommendations and tools proposed here are developed in the context of this Product Line's

forecasting and material procurement.

14

2 - Company background

2.1

Introduction to ABB Group

ABB is a global provider of power and automation products and technologies. Based in Zurich,

Switzerland, the company operates in approximately 100 countries. At year-end 2012, ABB group

employed 145,000 people in all its locations, and reported revenues of $39.3 billion.

ABB's business is comprised of five divisions that are in turn organized in business units in relation

to the customers and industries that are served.

Those divisions are:

Power products

The product offering across voltage levels includes circuit breakers, switchgear, capacitors,

instrument transformers, power distribution and traction transformers, as well as a complete range

of medium voltage products. The division's main customers are electric and other infrastructure

utilities, industries across the spectrum and commercial enterprises.

Power Systems

Power Systems division provides turnkey solutions for traditional and renewable energy based

power generation plants, transmission grids and distribution networks. The division's main

customers are power generation, transmission and distribution utilities, other infrastructure

utilities, industries across the spectrum and commercial enterprises.

Low Voltage Products

Low Voltage Products and solutions are used in electrical applications from residential home

automation to industrial buildings, including low-voltage circuit breakers, switches, control

products, wiring accessories, enclosures and cable systems. LV Products are mainly sold to

15

distributors, installers, panel builders, OEMs, system integrators, contractors, architects and end

users.

Process Automation

The Process Automation division provides products, systems and services to be used in industrial

processes. Solutions include turnkey engineering, control systems, measurement products, life cycle

services, outsourced maintenance and industry specific products (eg, electric propulsion for ships,

mine hoists, turbochargers and pulp testing equipment). The main customers are the process

industries such as oil and gas, petrochemicals, mining, metals production, marine, pulp and paper,

and cement.

Discrete Automation and Motion

This division produces motors, generators, drives, mechanical power transmission, robotics,

programmable logic controllers (PLCs), wind converters, solar inverters, voltage regulators,

rectifiers, UPS systems, excitation systems, traction converters, fast DC chargers. Its main

customers are manufacturers, OEMs in a variety of industries, utilities, end users in a variety of

process industries.

2.2

Division of Discrete Automation and Motion

The division of Discrete Automation and Motion comprises four business units:

Drives and Controls

- Indicative products: low voltage AC drives, medium voltage drives, DC Drives

Motors and Generators

16

- Indicative products: low voltage motors, high voltage motors and generators, wind power

generators, diesel generators, gas and steam turbine generators, hydro generators, tidal

waves generators

Robotics

- Indicative products: industrial robots, robot controllers and software, industrial software

products, robot applications and automation systems for automotive, foundry, packaging,

metal, solar, wood, plastics, etc. industries

Power Conversion

- Indicative products: advanced power electronics, converter products, excitation and

synchronizing systems, high power rectifiers, power quality and power protection products

(including UPS),

traction converters,

wind turbine drives, solar inverters, charging

infrastructure for electric vehicles

2.3

Business Unit Power Conversion and new structure

The project focuses on the Excitation Systems Product Line, which belongs to the Power Conversion

Business Unit. The BU underwent restructuring in 2012-2013 and its product groups as of February

2014 are shown in figure 1.

17

BU Power Conversion

Overview Product Groups

of

I

16

-

Solar inverters for

residential,

commercial and

utility-scale use

. Micro inverters

- String inverters

- Central inverters

- LV wind turbine

converters

- MV wind turbine

converters

Fuel cell inverters

Tidal energy and

river converters

- Tumkey inverter

solutions

Figure

2.4

1-

- AC-DC

converters

Product Groups of

DC-DC

converters

Network power

systems

Three-phase

modular UPS

systems

Three-phase

standalone UPS

systems

Single-phase

standalone UPS

systems

BU

i

LV and MV power

converter products

Mass transit

propulsion and

and systems

auxiliary

Excitation and

converters

High power

synchronizing

propulsion

systems

High power

for locomotives

rectifiers

h

s

t

DCwyiepwrhigh-speed trains

s DC wayside power

solutions

DC fast chargers

and systems

AC chargers

(systems

applications)

Power Conversion - source: ABB Group

Product line Excitation and Synchronizing Systems (ATPE)

The Product Line (PL) Excitation and Synchronizing Systems will be referred to from here onward

as ATPE, in line with ABB's internal naming system. This product line primarily provides a range of

automatic voltage regulators (AVRs) and static excitation systems (SES) used with synchronous

generators and motors. Figure 2 shows the product families offered, ranging from the small UN 1000

AVR which is made to stock (and upon sale is configured to order and delivered to customer), up to

the larger UN6080 and UN6800 SES's which are sold on an engineer-to-order (ETO) business model.

UN1000 makes up a small fraction of ATPE's overall business, and the project focuses solely on the

larger, ETO systems.

18

It should be noted that ATPE has embarked on an effort to make part of its business customize to

order (CTO, see (Lenis, 2013)), however the bigger part of the business still operates under the ETO

model.

It should also be noted that, throughout the project, both the ETO and the CTO models were kept in

mind for the approaches taken and the tools developed.

Product family

UNITROL* product portfolio

I

UNITROL 6800

50/60Hz

SES, Thyristor type

50/60 Hz

UNITROL 6080

SES, Thyristor type

UNITROL 6080

823

31

16 2/3 . 50/60 ... 400 Hz

AVR, Thyristor type

4cnetr

DC, AC: 16 2/3 ... 50/60 ... 400 Hz

AVR, IGBT type

UNITROL 1000

I

3

I

10

I

15

I

I

I

40

100

400

I

I

800 1000

I

I

I

2000

4000

10000

Excitation current I

[ADC]

Figure 2 - ABB Excitation Systems product offering - source: ABB Group

I

19

3 - Literature Review

3.1

Introduction

This chapter describes the concept of Sales and Operations Planning, both for Volume Businesses

and for Low Volume-high mix environments. Then it addresses the specifics of Planning related to

this project and discusses the current literature on forecasting and material procurement and

supplier flexibility.

3.2

Sales and Operations Planning

Sales and Operations Planning ("S&OP", or also "Integrated Business Planning", IBP) answers the

fundamental question: "Are we doing what's needed in the 2-3 years ahead to achieve our strategy?"

To answer these questions, S&OP prescribes a business process that brings together all

stakeholders in the development and execution of a company's strategy:

*

Sales

*

R&D

*

Product Management / Marketing

*

Engineering

*

Supply Chain and Procurement

*

Production

*

Finance

The main parts of the process are usually repeated on a monthly basis and consist of business

forecasting and demand planning, and of supply review and planning. The demand plan and supply

plan are reconciled and specific actions are agreed on to ensure proper execution of these plans.

20

Throughout the cycle all stakeholders are able to and required to offer their input - this

involvement brings the sought-after buy-in which is essential for the agreed actions to actually be

carried through. According to (Wallace, 2004), S&OP enables people to view the business

holistically and to make solid, informed decisions. Viewing different parts of the business separately

can lead people to make suboptimal decisions.

(Sousa, Thome, & do Carmo, 2014) show that S&OP practices have a broad impact across several

performance dimensions and are a powerful lever for generating manufacturing performance.

Demand Planning

An organization implementing S&OP should recognize that:

1)

Customer demand is the result of the firm's marketing and selling activities

2)

Because the marketing and selling activities create the demand, the demand plan should be a

reflection of marketing and selling activities.

3)

The demand plan numbers are the expected results of the planned marketing and sales efforts.

Therefore, the organization needs first to be able to understand how its marketing and sales

activities affect demand in terms of both business volume and timing (Oliver Wight, 2013).

Supply Planning

Supply Planning covers the planning for the required resources to be available at the right quantity,

in the right place, and at the right time. In the case of an ETO organization, these resources are

Engineering, Materials, and Production and Testing Capacity.

A reconciled demand and supply plan will ensure that the above capabilities are managed in

anticipation of the upcoming demand, rather than reactively.

21

3.3

Forecasting

Forecasting business that flows in regularly

The current forecasting method employed by ATPE is a bottom-up aggregation of demand estimates

from different geographical regions, different products, or different channels into an overall

forecast. Although this method is straightforward and intuitive, it is also subject to a great deal of

uncertainty and an aggregate forecast will be more accurate on a percentage basis (Rosenfield,

1994). Therefore, it is attempted to build an aggregate forecasting model. Furthermore, the

forecasting scope can include several different breakdowns of an aggregate forecast (Rosenfield,

1994):

*

by geographic region

*

by product group or item

"

by customer group or channel

*

by shorter time period

It is chosen to perform the first level of disaggregation at the shorter time period (month) in order

to facilitate the development of the monthly S&OP cycle.

Forecasting business that flows in sporadically

In cases of intermittent demand it is not possible to work with typical demand arrival distributions

(e.g. Poisson). A method usually employed by computerized inventory control systems to forecast

sporadic demand items is the Croston method, which has certain shortcomings- (Snyder, 2002)

proposes improvements to this method with use of bootstrapping. Smart Software Inc. (Smart,

2002) also markets a bootstrapping technique that creates brings two main benefits: more accurate

evaluation of the probability of zero demand, and more accurate representation of a heavy tail (i.e.

rare occurrences of demand that is much higher than the mean).

22

In this project there is an example where data showed that new business arrives in a sporadic way

(India and China end customers) and where such methods could be proposed. However, according

to stakeholders on sales data collection, actual arrival of new business is less sporadic than data

implies, mainly due to a sporadic maintenance of the database. Therefore it was chosen to model

incoming business with a best fit probability distribution and to recommend that data collection is

improved (improvements are already being made with the introduction of global sales opportunity

monitoring).

3.4

Material Procurement and Flexibility

(C. Hicks, 2000) touches on the important but not commonly treated issue of ETO procurement.

Procurement in ETO companies obtains the specifications for components and sub-systems from

the design function. According to (C. Hicks, 2000), engineering design may specify items during the

detailed design process. This may cause a delay in the availability of detailed specifications. Parts

that have long lead-times should be considered early in the design process. Special supplier

relations are required to handle the remaining uncertainty in the exact specification. Furthermore, if

there is only limited re-use of engineering designs across orders unnecessary variety can be

introduced. This variety increases the complexity of procurement and introduces uncertainty and

risk. In general, the use of standard designs allows sourcing decisions to be made later.

(van Kampen, van Donk, & van der Zee, 2010) also discuss two alternative approaches to coping

with uncertainties in demand and supply: safety stock (company maintains stock of all required

components in anticipation of future demand) and safety lead time (company orders components

earlier, often with uncertainty on their specification).

To tie back to S&OP, (Sousa, Thome, & do Carmo, 2014) show that integration with suppliers

amplifies the effect of internal S&OP on performance.

23

These above concepts are leveraged in this project and a supplier flexibility framework is proposed;

an optimization model is built based on this framework in order to minimize the costs of ordering

under specification uncertainty.

Quantity flexibility supplier agreements

(A. A Tsay, 1999) discuss the quantity flexibility contract as "a method for coordinating materials

and information flows in supply chains operating under rolling-horizon planning". These contracts

feature a maximum revision in material quantity per planning iteration which effectively defines a

quantity range for each planning period. The supplier is obliged to cover any quantity increases

within that range and the customer is obliged to purchase at least the minimum quantity within that

range.

In an analogy to QF contracts, the flexibility framework proposed in this thesis will look ask for

specification flexibility. In collaboration with the supplier, the customer is asked to commit to

ordering a component as early as possible during planning of a project, but is only required to

provide the basic specification of this component at this point in time. The supplier, on the other

hand, is required to honor its lead time commitment (i.e. to reserve materials and capacity) with

time starting at this early order stage. At the next step, the customer is required to provide the

supplier with full specification, not later than a time stipulated by the supplier, so that on time

delivery of the component is possible.

Classification of supplier relationships between ABB and suppliers

The feasibility of supplier flexibility agreements will depend on where a company lies on the

spectrum of its relationships with suppliers. (Rosenfield S. L.-D., 2006) discusses this spectrum. On

the lower end of the spectrum are arm's-length relationships (level 1), which are cost-based and

purchase-order driven, followed by modified vendor relationships (level 2), where value-added

services are offered to customers (e.g. supplier managed inventories). Moving more toward vertical

24

integration, a company may sign long-term contracts with a supplier (level 3), and even further on

the relationship spectrum can be found R&D consortia, joint purchasing agreements (level 4), and

cross-investments in minority equity stakes (level 5).

ABB seems to operate in levels 1 through 3, at least with regards to ABB Turgi. Project material

procurement for ATPE is executed largely on a level 1, cost based basis. However, vendor managed

inventory was quite a common practice on the shop floors in Turgi (level 2), and sourcing managers

usually liaise with major suppliers to agree on yearly quantities (or, at least, on a range of yearly

quantities- approaching the logic of level 3).

In conclusion, although no special supplier relationsare required to handle the remaining uncertainty

in the exact specification were reported, ABB Turgi has gone in many cases beyond the arm's length

supplier relationships.

25

4 - Benchmarking S&OP across other

PG's and BU's

4.1

Introduction

Benchmarking across different groups of the organization is an essential first step in establishing

the organization's current maturity level and identifying transferable best practices and areas for

improvement for ATPE.

This chapter describes the parts within ABB where benchmarking was performed, the method and

targets of this benchmarking, and the results and how they can be used at ATPE.

Scope of benchmarking

*

Internal benchmarking: performed across product groups and product lines of BU Power

Conversion.

0

External benchmarking: a different Business Unit (BU Drives) was chosen for external

benchmarking. This BU is already implementing S&OP and is expected to feature a higher level

of S&OP maturity.

Method of benchmarking

Internal benchmarking is done by interviewing stakeholders of each product group to identify

existing procedures related to S&OP and more generally to forecasting and production planning.

The information collected is analyzed with the target:

1) to understand current best practices that can be transferred to ATPE

2) to understand current challenges, and identify areas for improvement that can have

26

practical impact in an ETO operation like ATPE.

External benchmarking with BU Drives is done at a higher level by interviewing the process

owners of S&OP for the whole BU. The information collected is analyzed with the same target as

in the case of internal benchmarking.

The main method for collecting information is one-on-one interviews, supplemented by

teleconferencing and video conferencing for stakeholders based outside Switzerland.

4.2

Benchmarking Results

This section discusses the best practices and challenges identified in each group where

benchmarking was performed.

Internal Benchmarking

PG Renewables (now split into PG Wind and PG Solar)

This product group provides converters for solar and wind power installations, operating mainly

on an MTO model. It used to belong to BU Drives (the BU used for external benchmarking) and

before being transferred to BU Power Conversion it started implementing S&OP. Therefore it

features an established monthly S&OP cycle.

The following practices were identified:

"

A demand plan is built from forecasts provided by all LECs.

"

The PRU (Product Responsible Unit) centrally manages the procurement of "noble

parts" (critical components with long supplier lead time). For this, the PRU receives local sales

forecasts from the LECs, validates and consolidates forecasts, and sources the noble parts and

distributes them accordingly.

0

For the noble parts, sourcing managers negotiate each category once per year on aggregate.

27

*

For manufacturing & factory-to-factory communication a specific Share-point and meetings

are run between LECs and the PRU with a monthly meeting as part of the S&OP process.

Furthermore, the following challenges were identified:

*

Lack of parts is the most typical and critical problem causing delivery delays rather than lack

of production capacity

"

One of the LECs sends their production master plan to the PRU instead of their forecast as an

input to S&OP. The LEC has a business forecast and a sales forecast but they don't share

those with the PRU.

"

Some customers not always take delivery when supposed to; this makes demand forecast

less trustworthy.

PG Power Control

Within PG Power Control, benchmarking is performed at PL High Power Rectifiers. This is an

ETO operation with many potential customers but very few large projects every year. Market

demand for its products is highly dependent on capital investment on smelter plants (e.g.

aluminum smelter plants) which, in turn, depends on macroeconomic trends.

*

With regards to demand planning, forecasting is considered a difficult task, and as

mentioned, is highly susceptive to trends in capital investment.

"

Another challenge is collecting reliable forecasts from some of the group's LECs (Local

Engineering Centers) abroad.

*

Operations planning falls into project management; the group primarily mobilizes resources

(project management, engineering, material procurement, project logistics) for few, large

projects after a customer order is signed.

28

PG Power Protection

This Product Group provides power protection solutions to corporate and industrial customers. The

business is high volume- low mix and the operating models range from MTS to ATO and MTO.

"

The group collects forecast information from its sales channels partners every August and

compiles a yearly forecast that drives frame contracts with their key suppliers.

"

The group also monitors actual demand on a monthly basis and makes adjustments.

*

A challenge being faced is excess raw material stock levels at the local units of the PG.

PG Transportation

Product Group Transportation provides traction converters that are used in the traction control

of trains. Its customer base consists of a few train manufacturers. The group operates with a mix

of ETO fulfilment (when a new converter is designed, produced, and commissioned) and MTO

fulfilment (after its first few ETO iterations, a converter is subsequently made to order,

according to the customer's quantity needs). Because PG Transportation only sells to a few large

customers, they work closely with these customers and have very good forward visibility into

upcoming demand; also such demand primarily consists of repeat orders for the same type of

converter, therefore material and production resources planning is simplified.

A challenge the group sometimes faces is having inadequate testing capacity, as this resource is

shared with other products.

PG Vehicle Charging

This group was added to BU Power Conversion after a vehicle charging company was acquired by

ABB. The PG currently operates in a more unstructured and entrepreneurial way and does not lend

itself well to S&OP benchmarking.

29

External Benchmarking

External benchmarking was performed with BU Drives S&OP stakeholders, and an effort was made

to get inputs that are more relevant to project based business, such as is ATPE's business.

The following practices were identified:

"

The demand forecast is built by combining a project demand forecast and a baseline demand

forecast.

"

The project demand forecast is built based on signed orders and submitted project quotations

with high enough probability of being won ("high enough" here is rather empirical than strictly

quantified). The probability is multiplied with the project value to give the expected project

value.

"

The baseline demand forecast is built with heuristics that take into account data such as PMI

across countries, seasonality patterns, and historical order intake across industries, regions, and

countries.

"

The further into the future, the project demand forecast constitutes an increasingly smaller

percentage of the total forecast, and the baseline demand forecast constitutes an increasingly

higher percentage of the total forecast.

*

Forecast accuracy is monitored by tracking the past 3 month bias divided by the past 12 month

mean absolute deviation (MAD).

Furthermore, the following challenges were identified:

"

Project information is dispersed across many locations and in offline spreadsheets, so it is

harder to frequently collect updated information.

*

The method for assigning probabilities to projects is empirical and dependent on personal gut

feeling and experience of sales managers.

30

4.3

Assessment of benchmarking results

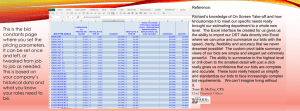

Figure 3 summarizes the practices and challenges identified through internal and external

benchmarking. Practices and challenges are phrased in a simplified way, and recurring themes are

only included once. Figure 3 serves to prioritize the capabilities and challenges that the project will

focus on at ATPE. A scoring system is used that takes into account for each item in the table: its

relevance to the ATPE project, the level of maturity at ATPE (expressed as immaturity to facilitate

adding up the scores), the potential impact of developing such practice or solving such challenge at

ATPE, and the practicality of doing so within the project's timeframe.

The items that should be prioritized, according to the assessment, are:

*

developing the demand plan based on project information

*

addressing missing parts

*

improving probability assignment methods

4.4

Summary

This chapter described the benchmarking performed, within and outside the BU Power Conversion,

with the objective to identify practices and challenges that can be relevant to the project at ATPE.

Also, a scoring assessment was discussed, which was performed in order to prioritize the items the

project will focus on. According to the assessment, priority has to be given to: developing the

demand plan based on project information, improving probability assignment methods, and

addressing missing parts and excess raw material stock.

As a final note, the study at ATPE takes into account the above results and their assessment, but also

remains flexible in case further opportunities are identified and/or stakeholder analysis shifts the

weight of the study toward a subgroup of the items.

31

Relevance to

ATPE project

ATPE

immaturity

potential

impact if

developed

practicality

OVERALL

PRIORITY

demand plan from LECs forecast

high

medium

high

low

MEDIUM

PRU noble parts sourcing

high

low

high

low

MEDIUM

medium

low

medium

low

LOW'

Share point monthly coordination

high

medium

medium

high

MEDIUM

monthly monitoring of demand and

forecast adjustment

high

medium

medium

high

MEDIUM

demand plan built from projects

information

high

medium

high

high

HIGH

forecast accuracy tracked

high

high

high

low

MEDIUM

Relevance to

ATPE project

ATPE

immaturity

potential

impact if

addressed

practicality

OVERALL

PRIORITY

Lack of parts creates delays

high

high

high

high

HIGH

Challenging to collect reliable LEC

forecasts

high

medium

high

low

MEDIUM

Customers do not take delivery of

order when supposed to

low

low

low

low

LOW

Excess raw material stock

high

medium

medium

medium

MEDIUM

Inadequate testing capacity

low

low

low

low

LOW

Assigning project probabilities is

empirical

high

high

high

high

HIGH

Project information dispersed/offline

high

low

high

medium

MEDIUM

PRACTICES

yearly supplier negotiations

CHALLENGES

Figure 3 - Assessment of S&OP practices and challenges

32

5

5.1

- Study at ATPE OPS CH

Introduction

Based on the conclusions drawn from S&OP benchmarking, the study on S&OP at ATPE OPS CH

focuses on two key areas:

1)

understanding the current forecasting challenges and proposing an alternative forecasting

method using projects information

2)

addressing challenges related to material procurement (missing parts)

This chapter first provides a description of the key functions of ATPE and the way ATPE

currently operates. Next, it describes the study made on forecasting and material procurement.

5.2

Functions and operation of ATPE

ATPE OPS CH consists of a sales department, a project management department, and an engineering

department. Working tightly with OPS CH are the teams responsible for global product and

technology management of ATPE, and the ATPE international operations team. OPS CH also

collaborates with the purchasing and production organization of Turgi, which is called ATPP.

ATPE OPS CH sales department

The Salesforce of ATPE operates on a typical Business-To-Business (B2B) model: area sales

managers are responsible for a set of countries each, and serve as the connection between ATPE and

customers.

At the first step of the sales process, ATPE approaches a customer who is considering a project that

will require an excitation system. This step is called early pursuit.

33

Next, the Salesforce works with the customer and receives a request for quotation (RFQ). This step

is called lead generation.

After the RFQ submission, ATPE sales work to create a technical proposal and a commercial

proposal. The point at which the commercial proposal is submitted to the customer is referred to as

tender submission or bid submission.

The customer reviews the proposals and, if they decide to pick ABB as the excitation system

supplier, a purchase order is signed. This step is called "order booked", "order won", or "order

signed". If the customer does not move forward with their project then the project is considered

"cancelled"; if the customer decides in favor of a competitor, then the project is "lost".

Sales information databases

As described, the sales process passes through four main steps: early pursuit, lead generation, bid

submission, and order signing. To track the evolution of project opportunities, ATPE uses software

which are described here:

E!Base

ATPE has used for almost a decade an opportunity tracking database called E!Base. On E!Base, the

sales managers have been inputting opportunities primarily from the bid submission step and

onward. This database has been gradually phased out beginning of 2013 and replaced with

ProSales, an online opportunity tracking tool that is being deployed by ABB at a group level.

ProSales

Since ATPE switched to ProSales, the sales managers are required to "open" a new opportunity from

the point of early pursuit and onward. As the opportunity evolves to the next steps, the sales

manager overwrites the relevant opportunity status updates. For example, for an opportunity that

34

passes from lead generation to bid submission, the status is updated from "lead generation" to "bid

submitted". This way, the whole sales pipeline is monitored and updated. However, it must be noted

that currently only the date for the latest update is stored, because every status update is

overwritten on top of the previous status update.

In addition to the status updates, the sales manager inputs the expected value of the opportunity,

the expected date of order, and the probability of ABB winning the order. These inputs are based on

the specifics of the opportunity, market intelligence, customer input, and the sales manager's

experience and personal judgment.

ATPE Global Product and Technology Management

The Product Management department is responsible for the product and marketing strategy of

ATPE. In the context of S&OP they are important stakeholders as they are also responsible for

communicating ATPE's material needs forecast to ABB's stock management organization. To fulfil

this role, product management utilizes the sales information databases and builds the material

forecast.

ATPE OPS CH Project Management

The Project Management department takes over from Sales when an opportunity converts to an

order. The department plays a key role in coordinating the handover of project information from

Sales to Engineering and in managing the work of Engineering, Purchasing, Production, and Testing

for every project.

ATPE OPS CH Electrical & Mechanical Engineering

The engineering workforce of ATPE is responsible for adapting the design of each excitation system

sold to the customer's requirements. Mechanical engineering is also responsible for integrating each

system's electrical engineering design and mechanical layout into CAD format and generating the

35

Bill of Materials (BOM). The BOM is essential to the purchasing and production department for

ordering project material from suppliers.

ATPP (Purchasing and Production)

When engineering has finished the engineering work on a project, it hands over to ATPP a

production order for the respective excitation system, accompanied by the BOM. ATPP is

responsible for ordering the required project material from suppliers and for managing the

assembly and testing of the system.

ATPE's Gate Model: from sales to project execution and delivery to customer

ATPE organizes its project execution according to a gate (milestones) model, as shown in figure 4.

After Sales win a new order, they hand the project over to project management (GI). The handover

is completed at G2 and engineering can start working on the project. At G4, the engineering design is

finalized and project material is ordered. When the material arrives (G5), assembly starts, and is

followed by testing and then delivery to customer (G7). The time at which each gate is passed is T1

for GI, T2 for G2 etc.

0)

(D

time:1T

0)

G2

~

T2

__

N

G4 cu

T41ITS

T31I

Figure 4 -Gate model of ATPE project execution

36

G56'_1

TO,

T1

5.3

Study of sales forecasting

Current forecasting method

ATPE has developed a practical forecasting method that takes into account all open opportunities.

The forecast for incoming business is a weighted sum of all open opportunities. The weighting factor

for each opportunity is the probability that it will successfully convert into an order for ABB. The

time at which is opportunity is accounted for in the forecast is dictated by the expected order date.

By adding all weighed opportunities over the future months, ATPE builds the overall forecast.

This forecast is utilized by product management in building the demand plan for stock material.

However, the current practice of product management is to ignore the assigned opportunity

probabilities; instead they assign 100% to all opportunities and use internally developed heuristics

to make sure that material stock outs are avoided.

Two areas for improvement are identified here, which lead to two fundamental questions:

1)

Can the dynamic of ATPE's sales pipeline be better understood and analyzed?

The expected closing time of each opportunity is very uncertain and more often than not, it shifts to

the future before an order is finally placed.

2)

Can the win probability be assessed or benchmarked in a better way?

The win probability assigned to each opportunity is based on the sales manager's experience and

personal judgment, and there is a lack of trust on these probabilities as the forecast is passed on to

product management.

To answer these questions the historical sales data of ATPE are collected and used in order to

analyze the Sales Pipeline.

37

Sales Pipeline Analysis

Sales historical data

ATPE has used E!Base to track sales data and recently (2013) switched to ProSales. E!Base has been

used at a "steady state" (i.e. post ramp-up of tool use and pre phase-out) for 7 years, whereas

ProSales is still in the ramp-up phase. Therefore, it was deemed reasonable to use the E!Base

database as a source of historical sales data, and to ignore the first few months of sales data on

ProSales.

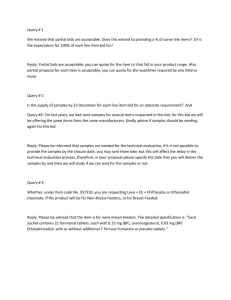

Figure 5 shows a small sample of the E!Base data that is relevant for analyzing the pipeline. For each

opportunity, there is a bid date and an expected order date. ATPE has been collecting sales

information consistently only from the point after an opportunity reached the "bid submitted"

status. After the bid submission, an opportunity is either won (Order), lost (Lost).

Bid No

Sale Status

Bid date

Order Date

1111

2222

3333

4444

5555

6666

7777

8888

9999

11110

12221

13332

14443

15554

16665

17776

18887

Lost

Lost

Bid submitted

Lost

Bid submitted

Order

Order

Order

Order

Order

Order

Bid submitted

Order

Order

Order

Lost

Order

2009-06-24

2009-07-01

2009-07-01

2009-07-02

2009-07-03

2009-07-05

2009-07-05

2009-07-05

2009-07-05

2009-07-05

2009-07-05

2009-07-08

2009-07-10

2009-07-10

2009-07-10

2009-07-14

2009-07-15

30.06.2010

01.04.2010

30.03.2012

31.10.2009

29.07.2009

29.07.2009

29.07.2009

29.07.2009

29.07.2009

29.07.2009

31.12.2013

29.07.2009

29.07.2009

30.07.2009

30.06.2010

Figure 5 - Sample data from E!Base, ATPE's legacy sales information database

38

A two-component forecasting model is built that utilizes the historical data of ATPE's sales

pipeline as follows:

component 1: The time at which a bid is submitted is considered the time when a "new

opportunity" arrives. The model considers the probability distribution of number of arrivals of new

opportunities with time. This is the model's first component.

component 2: Next, the model considers the way with which submitted bids (=new probabilities)

may evolve with time (won, lost, or remaining open). For the bids that are won, the model considers

the time to order (the time between the opportunity arrival date (= by definition bid submission

date) to the opportunity closing date), and the probability distribution which the time to order

follows.

The model will predict the number of bids that will close at time X in the future as follows:

# of bids that will convert to orders at period "X" =

current open bids Prob(closing

(component 1)

X - ti) +

X N(j) * Prob(closing X - j)

(component 2)

where:

ti= time of opening of each opportunity, i.e. bid submission date

X= time for which forecast is predicting, e.g. week 13 of current year

j= time between now and X at which new opportunities can open

N(j)= expected # of probabilities to open at time j

39

Based on interviews with stakeholders of the sales process and E!Base, it is chosen to segment the

global market for excitation systems as follows:

"

Opportunities with end customers in China & India

*

Opportunities with end customers in the Rest of the World (ROW)

The reason for this segmentation is the business culture in China: ABB Chinese sales representatives

are reported to delay reporting new opportunities until the representatives are almost certain that

these opportunities will convert to actual orders. Therefore, it is believed by ATPE that the data for

China end customers does not represent the true dynamic of the market and should be studied

separately. Because a significant amount of business to Indian end customers passes through

Chinese sales representatives, data on opportunities with Indian end customers is also part of this

segment.

End Customers in China and India

For end customers in China and India, the rate of new bid submissions per month is analyzed. A

probability distribution is fitted to the monthly number of new bid submissions. Figure 6 shows the

best fit, a geometric distribution. Figure 7 shows the cumulative frequencies of the data and the

respective cumulative distribution curves for the geometric distribution. Appendix 5.1, exhibit 5.1.1

contains the fitting results and the goodness of fit rankings. The best fit distribution is a geometric

distribution supported on the set {0,1,2,3...} with parameter p=0.227. The mean represents the

expected number of new bid submissions within any given month and is, by definition of the

geometric distribution:

E[monthly bid submissions]

-

p

=

3.405 new bids per month

40

ProbabsMy

Densdy Fumcuon

028

: 24

0

22

02

Die

01

1112

0,

00-

006

04

0

2

6

4

a

12

10

14

is

Is

20

22

Geonatflc

s&""

Figure 6 - X-axis: monthly number of new bids to CN & IN end customers; Y-axis bars: frequency of observation in

the data of respective number of bids. Curve: best fit probability distribution (geometric)

CumlOatwo Disnb01on

Fucion

09-

07

06-

0 5OA4

03

0,201

01

0

2

4

6

0

10

,-SaffOsl

12

14

10

10

20

22

-Oet

Figure 7 - Cumulative observation and probability distribution of previous figure. X-axis: new monthly bids to CN

& IN end customers; Y-axis: cumulative frequency of observation in the data of respective number of bids

The data and the corresponding distribution accurately reflect the stakeholders' remarks: There is a

27.5% probability that, in any given month, there will be no new bid submissions. Furthermore, the

analysis of the bid submissions inter-arrival times (performed with a daily resolution) shows that, if

41

a bid is submitted on any given day, there is a 64% probability that at least another bid will be

submitted on the same day (see figure 8 - Appendix 5.1, exhibit 5.1.2 contains the fitting results and

the goodness of fit rankings). This observation supports the claim that sales representatives "batch"

reporting of new opportunities. By observing figure 8, it can be deduced that the inter-arrival times

can be approximated by a combination of a spike at "0" days and a uniform distribution ranging as

high as 1-128 days (the arrival of new bids to India & China end customers is sporadic). Although

the distribution in Figures 6 and 7 will be used in the forecasting model, it is recognized that the

current data limits the model's ability to predict bid submission arrivals from India and China end

customers.

Probabiliy Density Function

0.64056048

04

032

0.24

016

008

0

40

6.

50

-Sample

-D.

Uniform -

s

70

Geom

90

100

110

120

130

etic

Figure 8 - X-axis: inter-arrival time of new bids in days; Bars (Y-axis): sample distribution of inter-arrival times of

new bids. Curves: best two fit probability distributions, uniform and geometric

Next, the distribution of the times from bid submission to order booking is studied. (for the bids that

ended up converting into orders). The objective is to model what fraction of successful bids converts

to orders within a given period in time. Figure 9 shows the frequencies and two best fit distributions

and figure 10 shows the cumulative frequencies and distributions. The best fit distribution is a

42

logarithmic distribution (can also be observed by visual inspection in figure 10). Appendix 5.1,

exhibit 5.1.3 contains the fitting results and the goodness of fit rankings. An important observation

drawn from the data is that the bids that end up converting to an order, are more probable to

convert very soon rather than later. For example, the cumulative distribution shows that, out of the

bids submitted this week which will convert to an order, 50% will have converted within the first 5

weeks from today and more than 70% will have converted within the first 20 weeks from today.

Probability Density

Function

0.16

0.14

0.12

0

20

40

60

60

100

120

-00mple

140

-GeOmetr0c

100

180

200

220

240

200

280

-- L0 gar1thm11

Figure 9 - X-axis: number of weeks from bid submission to order from CN and IN end customers; Y-axis bars:

frequency of observations in the data of respective number of weeks. Curves: best two fit probability

distributions, logarithmic and geometric

43

Cumulatie

Distibution Fonction

09

0.8

0.7

0.5

0.4

0.3

0.2

0.1

S

26

40

60

so

100

120

- Sam ple

140

160

180

200

220

240

260

280

- Geometric - Logarithmic

Figure 10 - Cumulative observations and probability distributions for previous figure. X-axis: number of weeks

from bid submission to order from China and India end customers; Y-axis: cumulative frequency of observation in

the data of respective number of weeks

End Customers in Rest Of World (ROW)

In a similar manner to the preceding analysis for China and India end customers, the rate of new bid

submissions per month is analyzed for ROW end customers. A probability distribution is fitted to

the monthly number of new bid submissions. Figure 11 shows the two best fits, a Poisson and a

negative binomial distribution. Figure 12 shows the cumulative frequencies of the data and the

respective cumulative distribution curves for the Poisson and negative binomial distributions.

Appendix 5.2, exhibit 5.2.1 contains the fitting results and the goodness of fit rankings. The Poisson

distribution ranks second, however it ranks more consistently than the negative binomial

distribution. The data is further studied by analyzing the inter-arrival times of new bid submissions.

In this case, the best fit distribution is a geometric distribution (see figure 13). Appendix 5.2, exhibit

5.2.2 contains the fitting results and the goodness of fit rankings.

By definition, if the inter-arrival times follow a geometric distribution, then the number of new bid

arrivals follows a Poisson distribution. Therefore, the new bids per month are modeled with a

Poisson distribution. The distribution has a parameter A = 9.843 , and, by definition, the mean of

44

the Poisson distribution is equal to the parameter A:

E[monthly bid submissions] = A = 9.843 new bids per month

PrObability

Densiy Function

0,15

014

013

012

Oi1

0.1

009

008

007

|

|

006

005

X\I N

IN

004-

003

0,02

0,01

2

4

6

a

-

Sample

12

-0

Un10,1r

-Neg

14

Binomial -

18

20

22

Poisson

Figure 11- X-axis: monthly number of new bids to ROW end customers; Y-axis bars: frequency of observation in

the data of respective number of bids. Curves: best two fit probability distributions, Poisson and negative

binomial

Cumnulati

Dstribution

Function

09

us

07

06

05

04

0302

U1

4

6

10

-

1Sample

-D

12

Un0orm

-Neg

14

16

18

20

22

Binomial -Poisson

Figure 12- Cumulative observation and probability distributions of previous figure. X-axis: new monthly bids to

ROW end customers; Y-axis: cumulative frequency of observation in the data of respective number of bids

45

Probability

Density Function

026

0224

022

0,2

0S18

0.16

0.14

0.12

0.1

0.08

0.06

0

8

16

24

32

40

56

48

64

72

80

Figure 13- X-axis: inter-arrival time of new bids in days; Bars (Y-axis): sample distribution of inter-arrival times of

new bids. Curve represents the best fit probability distribution (geometric)

Next, the distribution of the times from bid submission to order booking is studied. (for the bids that

ended up converting into orders). The objective with ROW end customers is again to model what

fraction of successful bids converts to orders within a given period in time. Figure 14 shows the

frequencies and two best fit distributions and figure 15 shows the cumulative frequencies and

distributions. The best fit distribution is a geometric distribution (can also be observed by visual

inspection in figure 15). Appendix 5.2, exhibit 5.2.3 contains the fitting results and the goodness of

fit rankings.

Similarly to the case with India & China end customers, the bids submitted to ROW end customers

that end up converting to an order, are more probable to convert very soon rather than later.

However, this is not as pronounced in the case of ROW end customers. For example, the cumulative

distribution shows that, out of the bids submitted this week which will convert to an order, 50% will