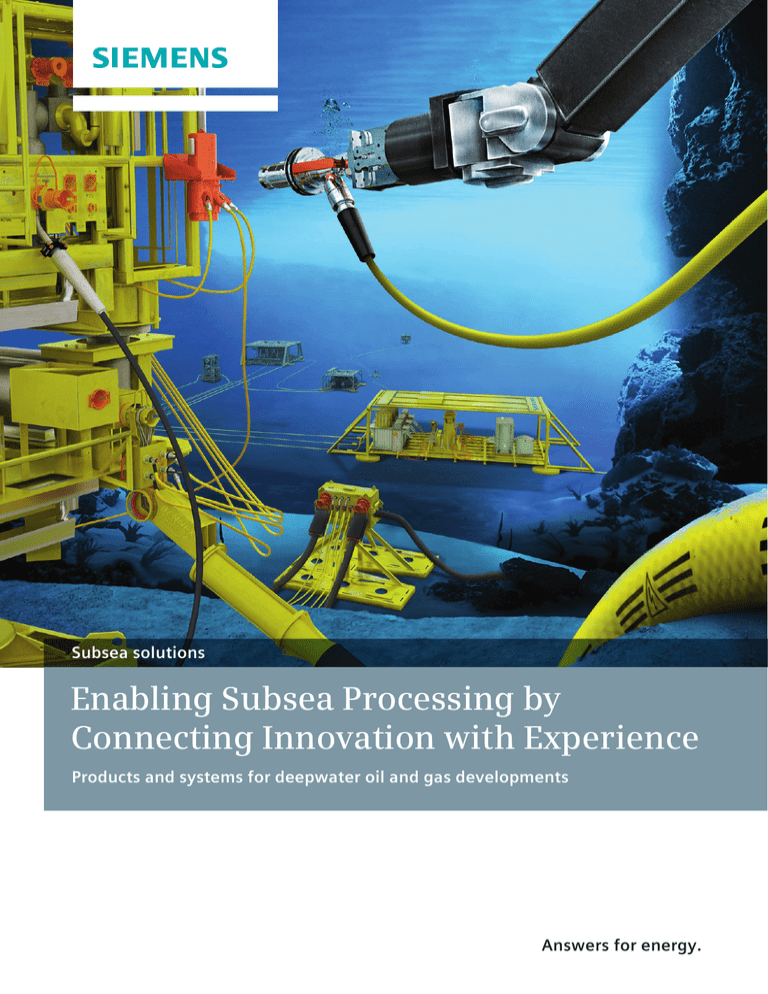

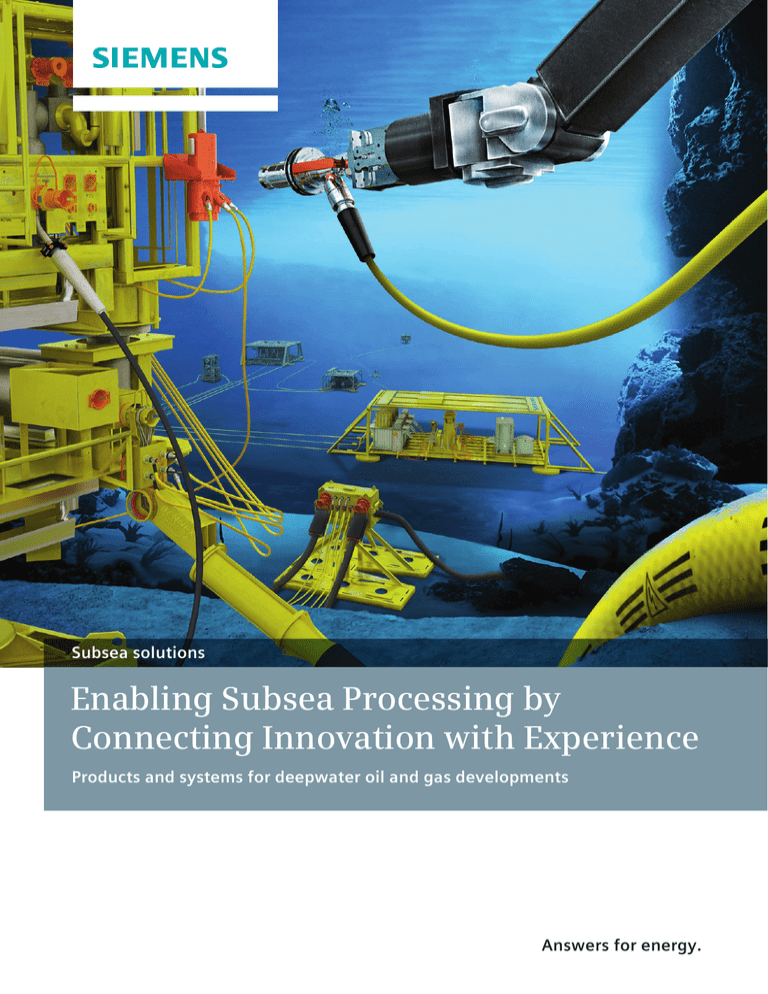

Subsea solutions

Enabling Subsea Processing by

Connecting Innovation with Experience

Products and systems for deepwater oil and gas developments

Answers for energy.

Enhancing oil and gas

recovery in challenging

environments

The future of oil and gas recovery involves accessing increasingly complex reserves.

Most importantly, our unique subsea offering is backed by a tireless commitment and

It involves cost-efficient subsea processing developments, especially for long step-outs,

dedication to our customers and to the industry as a whole. That is reflected in the

marginal and dispersed fields frequently located in deep and ultra-deep waters. And it

quality of our subsea solutions and in the innovation, excellence and concern for safety

involves advanced supporting power supply and distribution technology.

and sustainability that has gone into their development. And it is also documented by

our track record. Case in point: our Tronic products. As the most widely sold connectors

That‘s where Siemens comes in. As the technology leader for land-based power

in the industry, their reliability speaks for itself.

generation, transmission, distribution, drives and automation, we supply complete in-field

subsea distribution systems, including the solutions experience, expertise and capabilities

Enabling subsea installations – even in the most challenging environments.

for configuring complex power transmission to multiple subsea consumers.

Subsea Products

Subsea Systems

Lifecycle Management

Enhancing subsea developments

Enabling large-scale subsea processing

Fully backing our subsea commitments

Our subsea products and systems portfolio covers a broad spectrum of applications. Going

far beyond power and distribution, it comprises everything from pioneering technologies

for subsea control and surveillance to exemplary service and support based on extensive

marinization expertise. As a result, we are able to provide answers over the entire life

of the field.

2

3

Subsea products

Extending your

recovery scope

Siemens offers subsea products for customized solutions

with a portfolio of market-leading brands such as Tronic,

Matre and Bennex. The reliable Tronic line of DigiTRON,

SpecTRON, FoeTRON and ElecTRON products provides

electrical and fiber-optic connector systems for subsea power

and communications. Our Matre products, in particular,

the wellhead pressure sensors (WEPS), pressure temperature

(PT) sensors and differential pressure (DP) transducers,

are renowned for delivering optimum performance and

reliability. The Siemens subsea offering also includes

high-performance Bennex equipment for power solutions,

fiber-optic and seismic applications.

Recognizing the challenges facing the global oil and gas industry for

deepwater prospects, we have initiated an extensive qualification program.

We continuously review market requirements to improve our product range

and to meet new and evolving industry demands. Our aim is to keep developing

high-integrity products and solutions to aid and enhance hydrocarbon recovery.

8

9

Products for

customized solutions

Subsea distribution:

Enhancing subsea developments

With a solutions lineup that comprises subsea

distribution units, a high-power changeover switch as

well as pressure-compensated electrical, fiber-optic and

hydraulic connectors and jumpers, Siemens has the

capabilities needed for safe and reliable subsea power

and signal distribution. Our Anguila jumpers, cable

terminations and Anguila Cobra Head – which terminates

hydraulic and electrical umbilicals to various subsea

structures – continue to set the industry standard for

subsea oil and gas activities.

Making the right connection

Our advanced and highly reliable Tronic

connector systems have been used for

subsea oil and gas applications since

1979. In 1994, we installed the world’s

first subsea electrical submersible pump

(ESP) system together with Petrobras,

complete with wet-mate connectors to

power a downhole pump. Since then,

ESPs for subsea wells have become a

widely accepted solution.

Approximately 150,000 connectors in service

in over 500 projects worldwide are testament

to the proven and trusted quality of our DigiTRON

(DigiTRON+ and DigiTRONe), SpecTRON, ElecTRON

and FoeTRON range of subsea connectors. In fact,

our Tronic connectors define subsea performance

and reliability, combining cutting-edge technology

and advanced testing results.

Monitoring your operational

conditions

Our Matre sensors and transmitters have been delivering

excellent performance with a high level of dependability

for over 20 years. In addition to our renowned wellhead

pressure and temperature sensors, available both as single

and dual units, we also offer a wide assortment of proven

and tested instruments for monitoring the conditions of

subsea operations.

Matre subsea sensors were first used in the TOGI (Troll-Oseberg

Gas Injection) project in 1988, performing superbly throughout the

23-year lifespan of the subsea installation. Our high-quality sensors

and transmitters, which also include various sensing products for

numerous applications, ensure reliable measurements throughout

the lifetime of a subsea field.

10

11

Subsea systems

Enabling large-scale

subsea processing

Dependable power supply and distribution is vital for subsea

production facilities. Siemens has the know-how and ability

to configure complex power transmissions to multiple subsea

functions. We offer a sizeable assortment of specialized

systems for reliably supplying electricity to numerous

consumers across the seabed and downhole ESPs from an

onshore power plant or platform.

As operators are faced with ever stricter health, safety, security and

environmental (HSSE) guidelines, control and surveillance play an increasingly

important role for subsea oil and gas processing. Reliably monitoring well

performance is crucial for ensuring maximum availability and oil recovery –

as well as for cost savings, maintenance reduction and system life extension.

Siemens has a variety of subsea systems and solutions for condition, performance

and environmental monitoring as well as operation control and communication,

including direct electric heating (DEH) power systems designed to prevent hydrate

formation in pipelines.

With our long-standing expertise in power, distribution and control technology,

we are able to provide customers with smart systems specifically tailored to their

subsea applications and demands. We can assist you with everything from the

studies, design, procurement and assembly to the testing and installation.

12

13

Powering installations

on the seabed –

down to 3,000 meters and more

With the Siemens Subsea Power Grid, a supply and distribution system, we are combining

Subsea switchgear

our high R&D focus and broad subsea power concept experience with our extensive

The subsea switchgear has a modular design. Its main bus

bars, wet-mate connectors and measuring transformers

are housed in the fluid-filled and pressurized base module.

marinization expertise. Currently undergoing the detail design and test phase, it

incorporates proven high-quality Siemens industrial components, including subsea

transformers, switchgear and variable-speed drives. All power components can be installed

on a common structure located on the seabed. As such, the Siemens Subsea Power Grid

marks another milestone in powering large-scale seabed processing facilities.

Subsea transformers

The step-down transformer is the main interface

between the subsea transmission line and the power

distribution. As a hermetically sealed, fluid-filled and

pressure-compensated unit transformer for variablespeed drive of pump motors, it enables step down

to a wide range of consumers as well as longer

step-outs. Its natural convection cooling

reduces maintenance requirements.

Variable-speed drives

The variable-speed drive (VSD) features a fault-tolerant

multi-cell topology with built-in component redundancy.

Designed specifically for sea floor operation, its fluid-filled

enclosure and all power electronics can be exposed to full

pressure, thereby reducing maintenance requirements.

14

15

Electrical heating

for flowline control

and installation monitoring

Surveillance

and control

Our broad subsea surveillance and controls

portfolio covers everything from well

performance and gas leak detection to

reservoir, integrated environmental and

condition monitoring – including seabed

seismic and oceanology applications.

Operators face several challenges – the need to enhance recovery, follow strict regulations

as well as comply with health, safety, security and environmental (HSSE) requirements.

There is an ever greater demand for control and surveillance of assets and the environment

to ensure that subsea oil and gas operations are successful. With our extensive subsea

monitoring experience, our topside process control as well as industrial IT and database

systems, we can offer superb assistance in this area.

Direct electric heating

(DEH) power systems

Deepwater reservoirs induce hydrate

and wax formation, which can cause

flow assurance challenges such as

reduced capacity or even flowline

and pipeline blockage.

Our direct electric heating (DEH)

power systems are designed to

prevent wax and hydrate formation

and secure flow assurance. They allow

for OPEX savings through reduced

chemical injection and dumping into

the sea, in addition to low CAPEX and

maintenance costs while also avoiding

depressurization during shutdown.

What’s more, they can be retrofitted

onto operating pipes. Combined with

our customized power design and

components, they help to further increase system reliability and lifetime

performance.

16

Permanent reservoir monitoring (PRM)

PRM is a key technology for improving reservoir

imaging. Siemens designs, builds and delivers PRM

systems that can be easily connected to existing subsea

installations and expanded. Our state-of-the-art digital

sensing technology and associated systems ensure

reliable monitoring of operations and enable increased

oil recovery while preventing harm to the environment.

Subsea hydraulic power unit (SHPU)

Combining our electrical and hydraulic system expertise,

we deliver hydraulic power units for permanent subsea

installation. As an alternative to umbilical replacement,

the SHPU can be operated in several ways – for example,

as a repair unit for subsea hydraulic supply failures

such as leakage or blockage that may result in a well

production stop. Or as a building block in green field

hydraulic infrastructure developments – a particularly

viable alternative for long step-outs. With its low peak

power consumption, the SHPU helps to maximize the

utilization of the subsea electrical infrastructure and

standard interfaces for universal application.

Subsea control unit (SCU)

Large-scale subsea oil and gas processing requires

sophisticated instrumentation that ensures failsafe

communication with operational equipment. Our

subsea control units allow you to add a wide variety

of instruments to your fields that you can influence

and adjust. They can be connected to cameras, sand

detectors, multiphase meters, hydrocarbon leak

detectors, pressure and temperature sensors, electrical

actuators and directional control valves.

17

Lifecycle management

Fully backing our

subsea commitments

Subsea oil and gas recovery comes with many challenges.

In order to adequately meet steadily growing customer

demands, to optimize operational efficiency, extend field life

and increase output, Siemens fully backs its commitments

with a variety of service support offers – at every phase of

the development.

Lifecycle management from Siemens comprises a range of

post-sales support services. Our dedicated team of trained and

qualified field service experts around the world fully back our

products and systems – with world-class support, both onshore

and offshore, rapid response and strategic life of field solutions.

In addition to installation, inspection, maintenance, spare parts, refurbishment,

modification, technical and repair services, the comprehensive Siemens subsea

service offerings include a variety of agreements that can be individually tailored

to specific customer requirements. We also provide onsite trainings as well

as partial and complete project management. In addition, we possess a large

equipment pool for offshore exploration and ROV/diving.

18

19

Published by and copyright © 2014:

Siemens AG

Energy Sector

Freyeslebenstr. 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Power Generation Division

Oil & Gas Solutions

Wolfgang-Reuter-Platz

47053 Duisburg, Germany

siemens.com/energy/subsea

For more information, please contact:

Siemens AS

Østre Aker vei 88

0596 Oslo, Norway

Phone: +47 22 63 30 00

subsea.energy@siemens.com

Printed on paper treated with chlorine-free bleach.

Power Generation Division

Order No. E50001-G440-A148-V2-4A00

Printed in Germany

and in the United Kingdom

Subject to change without prior notice. The information

in this document contains general descriptions of the

technical options available, which may not apply in all

cases. The required technical options should therefore

be specified in the contract.

All rights reserved.

Trademarks mentioned in this document are the

property of Siemens AG, its affiliates, or their

respective owners.