Panel Evaluation of Headspace Odors of Different Animal Manures J.H. Kim

advertisement

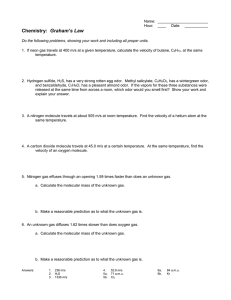

Science and Technology Journal, Vol. 3 No. II ISSN: 2321-3388 Panel Evaluation of Headspace Odors of Different Animal Manures 1 2 J.H. Kim1, H.L. Choi2, Y.J. Heor1, H. Ahn3 and H. Kim1,* Department of Environmental Engineering, University of Seoul, Seoul–130743, Korea School of Agricultural Biotechnology, Seoul National University, Seoul–151742, Korea 3 School of Nursing, Korea Bible University, Seoul–139791, Korea E-mail: *h_kim@uos.ac.kr Abstract—Odor intensity, hedonic tone, and odor characters of chicken, pig, and cow manure were evaluated by a sensory panel. Two snif ing methods were applied and compared in this study; one was the conventional direct snif ing method and the other was the dilute gas snif ing method where a small lux chamber was used to dilute headspace odor from manure before introduce it to the panel. Since animal manures usually produce strong and offensive odors, when the direct snif ing method applied, the odors could not be easily differentiated; in addition, between panel members, there were considerable deviations in odor intensity and hedonic tone for the same sample. On the other hand, when the dilute gas method applied, the difference between panel members could be reduced. The odor panel evaluation using the dilute gas method could be further improved by letting the panel members discuss about the odor intensity and hedonic tone of a sample. Finally, in order to precisely describe the odor characters of a manure sample, “two-stage odor descriptor wheels” were developed in this study. Keywords: Small Flux Chamber, Direct Snif ing Method, Dilution Method using a Flux Chamber, Two-stage Odor Descriptor wheel INTRODUCTION The public complaints about odors from waste treatment plants, and composting and concentrated animal feeding operations (CAFOs) have been increasing [1–2](Schiffman et al., 2000; Esteban, 1997). Especially, people living near CAFOs are physiologically and aesthetically affected by the odors from the facilities [3] (Shusterman, 1999). In fact, the odors from the CAFOs can affect the health of animals and animal production, too [4–5] (Wing and Wolf, 2000; Donham, 2000). Therefore, much effort has been made to control offensive odors from the facilities [6–7] (Stéphane, 1999; McCrory and Hobbs, 2001). For the proper control of odors, however, an accurate and objective odor measurement is required. In general, the odors from a CAFO are assessed in two ways; one is based on a human sensory panel, and the other is based on an analytical instrument, such as a gas chromatograph (GC) [8-9] (Davoli et al., 2003; Fakhoury et al., 2000), and a liquid chromatograph (LC) [10] (Uchiyama and Hasegawa, 1999). Since the instrumental analysis can quantify individual odorants from a sample with high reproducibility and accuracy, it will be more useful in determining odor generation mechanism. Since most odor sensation is caused by a number of chemicals, however, results from instrumental analysis often cannot be compared to the odor intensity evaluated by a human panel [11] (Gostelow, 2001). The odor evaluation using a sensory panel is often performed because it can represent what people actually smell. In an odor evaluation by a human sensory panel, odor threshold (the lowest odor concentration to which human can sense), odor intensity (degree of odor strength), hedonic tone (degree of disgust), and odor characters (words describing the feelings caused by odors) are measured [12] (Gostelow et al., 2003). The currently-applied sensory odor evaluation methods include ‘the direct snif ing method’ using a certain range of odor category, a dynamic olfactory method where odors are indirectly measured using a sophisticated device to dilute odorous gas with odor-free air Kim, Choi, Heor, Ahn and Kim in a odor free laboratory and a supra-threshold referencing method [13] (Sweeten and Akabani, 1994). Of the various sensory methods for odor measurement, the direct snif ing method has been the most frequently used since it does not require sophisticated equipment and can be easily applied in any cases. In addition, odor measurement can be inished within a short period of time [12,14] (Koe, 1989; Gostelow et al., 2003). Therefore, the method can be useful in preliminary odor assessment. However, the direct snif ing method often fails to provide consistent and informative results because panel members often showed large difference in the odor intensity and hedonic tones [14] (Koe, 1989), especially when sample odor is very strong as in the case of animal manures. In this study, odor panel evaluation of chicken, pig, and cow manure was performed using a small lux chamber where a manure sample was placed and its headspace gas was diluted with odor-free nitrogen. The panel evaluation also adopted supra-threshold referencing method in which each panel member was asked to compare the odor intensity of a sample to a reference odor source at a known concentration. Sweeten and Akabani suggested n-butanol solution can be used a reference odor source [13]. Then the results were compared with those from the direct snif ing method. Finally, “two-stages odor descriptor wheels” were proposed to precisely describe the odor characteristics of animal manures. MATERIALS AND METHODS EĝĕĊėĎĒĊēę DĊĘĎČē A small lux chamber was designed to dilute the headspace gas of animal manure and to introduce it to each odor panel member (Fig. 1). The chamber consists of a 1 L glass jar where an animal manure sample of 600 mL was placed. After the manure was placed, the jar was sealed with a cap and its headspace was lushed with pure N2 gas at 100 mL min-1. The headspace was remained lushed for 12 min before the headspace gas was introduced to panel members for their evaluation. The direct snif ing method is applied to the same manure samples. For the evaluation, a manure sample of 600 mL was placed in a 1L glass jar and the jar was sealed. Then, each panel member was asked to open the cover of the jar and to directly smell the odor. The result from the dilute gas method was compared with the one from the direct snif ing method. N2 in Sniff port Gas Flow meter Diffuser Sample Sample 1L Glass Jar Fig. 1: Schematic Diagram of Small Flux Chamber SELECTION AND TRAINING OF PANEL Sensory sensitivity to odor is variable between different individuals, which often causes accurate assessment of odor intensity of a sample impossible. Therefore, an odor panel should be made of individuals with similar olfactory sensitivity. Thus, screening of odor panels was performed to exclude individuals with exceptionally low or high olfactory sensitivity [15] (Ferriera et al., 2003). The screening was conducted using the so-called odor pen kit (St. Croix Sensory, Inc, U.S.A), which is commercially available [16] (Lay and McGinley, 2004). The method using the odor pens follows the 3-Alternative Forced Choice Method [17] (ASTM, 1997); in each test, a potential panel is asked to sniff three different pens (two are blank and the third release odor), and to distinguish the odorous pen [16] (Lay and McGinley, 2004). The panel size is also an important issue in a sensory test of odor. Typically, a panel is made up with 4–10 individuals [18] (Brennan et al., 1996). In this study, therefore, seven individuals with similar odor sensitivity (4 men, 3 women) were selected through the screening procedure. In an odor evaluation using the panel, 6 discrete categories scale of 0~5 was used; 0 for no odor and 5 for the odor with the highest intensity [19] (Frechen, 1994). The selected panel members were trained to distinguish odors with different intensity using a six category scale method, in which n-butanol solutions with 6 different concentrations were prepared and used as references (Table 1) [19, 20] (Cheremisinoff, 1988; Frechen, 1994). Training each member was continued until he or she could distinguish odor intensity of three randomly chosen n-butanol solutions. Speci ic procedure can be found in Zhang et al. [21]. Before any odor test, panel members were not allowed to have any meals, snacks or drink. They were not allowed to smoke or use cosmetics or perfumes, either. In addition, any 120 Panel Evaluation of Headspace Odors of Different Animal Manures panel member with a cold or allergy symptom was excluded from the odor evaluation. All the panel evaluations were based on the blinded test [22] (Cain, 1980). Table 1: A Six-scale n-butanol Odor Intensity Reference Level 0 1 2 3 4 5 n-butanol(ppm) in Air/in Water 0/0 25/250 75/750 225/2250 625/6250 2025/2250 Category Description No odor perceivable Barely perceivable Faintly perceivable Clearly perceivable Strong Very strong Fig. 2: Odor Intensity/ Hedonic Tone Using Direct Snifϐing Method PRECEDURE FOR THIS STUDY An odor evaluation form was made to measure the odors from manures of three different animals. i.e., chickens, pigs and cows (Table 2). Although the panel was trained to distinguish odors of 6 different intensities, they were asked to evaluate odors from the samples with 11 categories scale; from 0 (for no odor) tp 10 (for very strong odor). Hedonic tone of each sample was also evaluated on 11-point scale; from-10 (for very offensive odor) to 0 (for non-offensive odor). The panel evaluation using the dilute gas method was performed in two different ways; in the irst way, each member individually rated odor of a sample, while in the second the members were allowed to discuss the intensity of odor of a sample to reach a consensus. The second method was designed to reduce the difference between individual measures and to obtain more precise results [23] (AWWA, 1993). RESULTS AND DISCUSSION PĆēĊđ EěĆđĚĆęĎĔē–CĔĒĕĆėĎĘĔē ćĊęĜĊĊē DĎėĊĈęĎěĊ SēĎċċ Ćēĉ DĎđĚęĎĔē SēĎċċ MĊęčĔĉ Figures 2–4 show the odor intensities and hedonic tones of different animal manures measured by both direct snif ing and dilute gas methods, respectively. When the direct snif ing method was used, odors from different animal manures could not be distinguished; odors from all the manures were simply evaluated as having high odor intensities and low hedonic tones (much offensive) (Fig. 2). However, when the dilute gas method was used, the differences in odor intensities and hedonic tones of different animal manures were more clearly identi ied. Comparing to other manures, chicken manure produced much more strong and offensive odors (Fig. 3). Fig. 3: Odor Intensity/ Hedonic Tone of Using Dilution Sniff Method The average standard deviation of odor intensities and hedonic tones between panels evaluating odors of animal manures using the dilute gas method based on a small lux chamber was 1.5 and 1.7, respectively. On the other hand, it was 2.2 for odor intensity and 1.9 for hedonic tone when the direct snif ing method was used. The result implies that the natural odor characteristics of animal manures (e.g., string odor intensity and offensiveness) makes it hard to identify difference between them by the sensory panel evaluation (especially when direct snif ing method is applied). From this point of view, the sensory panel evaluation with the dilution method using small lux chamber can be advantageous, since panel members can avoid being overwhelmed by strong and offensive odor and can more accurately distinguish the difference between odors from different materials (especially the ones with strong and offensive odors). Fig. 4: Odor Animal Manure 121 Intensity and Hedonic-Tone of Kim, Choi, Heor, Ahn and Kim COMPARISON BETWEEN DIRECTIVE SNIFFȃINDIVIDUAL AND CONSENSUS METHOD THE ODOR CHARACTERISTICS OF ANIMAL MANURES After each panel member individually evaluated the odors from animal manures, he or she was allowed to discuss others about the odor strength and offensiveness of the samples and to reach a consensus. Then, the result from this speci ic test was compared with the one from the evaluation without post-discussion. In the individual evaluation, the average standard deviations of odor intensities and hedonic tones between panels were 1.5, and 1.7, respectively. However, the standard deviations between panels were lowered to 1.2 for odor intensity and 1.3 for hedonic tone, when they were allowed to discuss. The reduced differences in odor intensity and hedonic tone were attributed to the possibility of excluding potential outliers though the discussion between panel members. Table 2: Evaluation Results of Odor Intensity/ Hedonic Tone by Dilution Sniff and Directive Sniff Method Sample Cow Swine Chicken Cow Swine Chicken Cow Swine Chicken Method Dilution sniff (individuals) Dilution sniff (consensus) Directive Sniff Average (Standard Deviation) Intensity Hedonic Tone 3.5 (1.3) -4.2 (2.1) 5.4 (1.6) -5.3 (1.5) 7.9 (1.4) -8.0 (1.5) 3.8 (1.0) -5.3 (1.6) 5.7 (1.5) -5.3 (0.8) 8.0 (1.1) -8.3 (0.8) 6.3 (2.4) -6.6 (2.1) 8.0 (1.3) -8.0 (1.5) 7.1 (2.8) -7.0 (2.8) Cow Odor characteristics are usually reported using odor descriptors, i.e., words or phases of subjective and described by analogy [12] (Geostelw et al., 2003). However, since each individual can describe the odor of a sample in various ways or he does not ind a right word for it, it is often hard to evaluate the descriptors. To overcome this problem, recently, the so-called visible odor descriptor wheel was introduced to allow easy understanding of odor characteristics of a material [24] (Rega et al., 2003). Although this approach has been successfully applied to several studies, it is not suf icient to help a panel to describe the subtle odor characteristics of a sample. In fact, it is dif icult to describe ‘odor characteristics of a sample’ with one or two sentences or words. In this paper, therefore, “two-stage odor descriptor wheel system” was proposed and applied to discriminate the odor characteristics of different animal manures. “Two-stage odor descriptor wheels” are made of two odor descriptor wheels; irst wheel indicates 10 main descriptors (i.e., loral, fruity, vegetable, food, earth, offensive, stimulant, ishy, chemical, and medicinal) and each main descriptor has its own odor descriptor wheel which has 5 subsequent descriptors that a panel can choose to assess odor characters of a material in detail. In the beginning of the assessment with the animal manures, each panel member was asked to choose descriptors representing odor characteristics of different animal manures. Most of the members expressed odors from the three different manures all offensive by choosing the descriptor, offensive (Fig. 5). However, when they were Pig Fig. 5: Two Stages Odor Descriptors Wheels of Cow, Pig and Chicken Manure 122 Chicken Panel Evaluation of Headspace Odors of Different Animal Manures asked to choose descriptors from the second odor wheel 3. belonging to the descriptor, i.e., offensive in the irst wheel, the characteristics of the manure odors were distinguished 4. each other. The panel described that odor of rotten trash and stale odor were dominant in cow manure odors, while 5. pig manure smelled like sour milk and rotten trash. Finally, they described chicken manure produced odor of spoiled food, rotten trash, or excremental odor. 6. 7. CONCLUSION 8. For the olfactory evaluation of chicken, pig, and cow manures, which naturally have high odor intensities and 9. low hedonic tones, odor panel tests were performed with the dilute gas method using a small lux chamber. The result from the test was then compared with that from the direct 10. snif ing method. The dilute-gas method showed lower standard deviations in odor intensity and hedonic tone of different manure samples. The deviation was further lowered when the panel members were allowed to discuss and reach a consensus on the odors from the manures. 11. 12. If odors from different manures compared, odor from chicken manure was the most strong and offensive, followed 13. by odors from swine and cow manures. Finally, the proposed two-stages odor descriptor wheel system enabled panel members to visually compare odor characteristics of different materials. If it is further studied, 14. it will help assessing different odor sources. 15. ACKNOWLEDGEMENT Authors greatly appreciate the support of the R&D program of MOTI/KEIT (R&D program number: 10037331, 16. Development of Core Water Treatment Technologies based on Intelligent BT-NT-IT Fusion Platform). 17. REFERENCES 1. 2. Schiffman, S. S., J. M. Walker, P. Dalton, T. S. Lorig, J. H. Raymer, D. Shusterman and C. M. Williams. 2000a. Potential health effects of odor from animal operations, wastewater treatment, and recycling of byproducts. J. Agromedicine.7, (in press). Esteban, E., 1997. The conϔinement animal feeding operation workshop, Centers for Disease Control and Prevention. National Center for Environmental Heath. Atlanta, GA. 18. 19. 123 Shusterman, D., 1999. The health signi icance of environmental odour pollution revisited. J. Environ.Medicine. 1(4):249-258. Wing, S., and S. Wolf. 2000. Intensive livestock operations, health, and quality of life among eastern North Carolina residents. Environ. Health Perspect. 108(3):233-238. Donham, K. J., 2000. The concentration of swine production effects on swine health, productivity, human health, and the environment. Food Anim. Pract. 16(3):559-597. Stéphane, P. L. 1999. Barn management and control of odours. Adv. Pork Production, 10:81-91. McCrory, D. F., and P. J. Hobbs. 2001. Additives to reduce ammonia and odor emissions from livestock wastes: A review. J. Environ. Quality, 30(2):345-355. Davoli, E., M. L. Gangai, L. Morselli and L. Tonelli,. 2003. Characterisation of odorants emissions from land ills by SPME and GC/MS. Chemosphere. 51(5):357-368. Fakhoury, K. J., A. J. Heber and J. Q. Ni. 2000. Correlation of odor detection thresholds with concentrations of Hydrogen Sulϔide, Ammonia and Trace Gases emitted from swine manure. ASAE Annual international Meeting. ASAE, 004047. Uchiyama, S., and S. Hasegawa. 1999. A reactive and sensitive diffusion sampler for the determination of aldehydes and ketones in ambient air. Atmos. Environ. 33:1999-2005. Gostelow, P., S. A. Parsons and R. M. Stuetz. 2001. Odour measurements for sewage treatment works. Wat. Res. 35 (3):579-597. Gostelow, P., P. Longhurst, S. A. Parsons and R. M. Stuetz. 2003. Sampling for the Measurement of Odours. IWA Publishing, pp. 3-20. Sweeten, J. M. and M. R. Akabani. 1994. Approaches to Odor Measurement for Dairy and Cattle Feedlots: A State of the Art Review. In: Final Report: Preliminary research Concerning the Character, sources and Intensity of Odors from Dairy Operations in Earth County, Texas; Texas Natural Resources Conservation Commission Of ice of Air Quality. Koe, L.C.C. 1989. Sewage odors quantiϔication. In: Cheremisinoff, P. N. (ed) Encyclopedia of Environmental Control Technology, Vol 3: Wastewater Treatment Technology, Houston, Gulf Publishing, pp. 423-446. Ferreira, V., Ja´n Pet’ka, M. Aznar and J. Cacho. 2003. Quantitative gas chromatography–olfactometry. Analytical characteristics of a panel of judges using a simple quantitative scale as gas chromatography detector. J. Chromatogr. 1002:169–178. Lay, A. M. and C. M. McGinley. 2004. A Nasal Chemosensory Performance Test for Odor Inspectors. Water Environment Federation Odors and Air Emissions 2004 Bellevue, WA: 1821 April 2004. ASTM International (1997), Standard Practice for Determination of Odor and Taste Thresholds by a ForcedChoice Ascending Concentration Series Method of Limits, E679-91 (97), Philadelphia, PA, USA. Brennan, B. M., M. Donlon and E. Bolton. 1996. Peat bio iltration as an odour control technology for sulphur based odours. J. Chart. Inst. Wat. & Environ. Managt, 10:190-198. Frechen, F. B., 1994. Odour emissions of wastewater treatment plants: recent German experiences. Wat. Sci. Technol. 30(4):35-46. Kim, Choi, Heor, Ahn and Kim 20. 21. 22. Cheremisinoff, P. N., 1998. Industrial Odour Control. Oxford, Butterworth-Heinemann. Zhang, Q., J. J. R. Feddes, I. K. Edeogu. and X. J. Zhou. 2002. Correlation between odour intensity assessed by human assessors and odour concentration measured with olfactometers. Can. Biosyst.Eng. 44:6.27-6.32. Cain, W. S., 1980. The case against threshold measurement of environmental odors. J. Air Pollut. Control Assoc. 30:1295-1296. 23. 24. AWWA, American Water Works Association, 1993. Flavor Proϔile Analysis: Screening and Training of panelists. American Water Works Assoc, Denver, CO. pp. 2.19-2.23. Rega, B., Fournier, N., and Guichard, E., 2003. Solid Phase Microextraction (SPME) of Orange Juice Flavor: Odor Representativeness by Direct Gas Chromatography-Olfactometry (D-GC-O). J. Agr. Food Chem. 51:7092-7099. BIOGRAPHY Professor Hyunook Kim is the Dean at the School of Environmental Engineering, University of Seoul, Seoul, Korea and the Director of the R&D Center of Core Technology for Water Treatment. His major ield is water & wastewater treatment processes, especially, modeling or process control of them. He also has an expertise in analysis of trace organic compounds in water and odorants from various sources and advanced oxidation processes. He currently serves an Associate Editor of Chemosphere, Critical Review in Environmental Science and Technology, Frontiers of Environment Science & Engineering, and Energy, Ecology and Environment. He received a few Honors and Awards from Korean government. He has more than 70 publications in peer-reviewed journals and more than 200 reports in international and national conferences. 124