QUICK SPEC METAL – UNISIL & UNISIL HS Method Requirements

advertisement

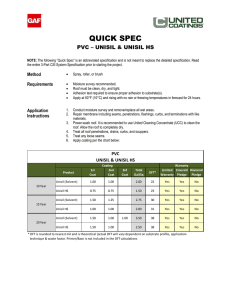

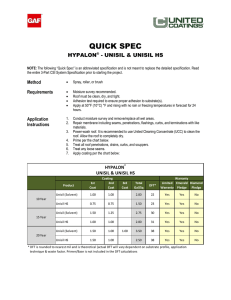

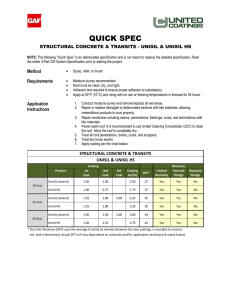

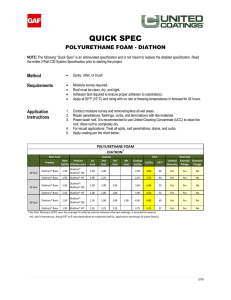

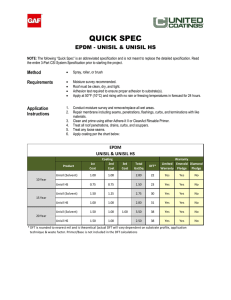

QUICK SPEC METAL – UNISIL & UNISIL HS NOTE: The following “Quick Spec” is an abbreviated specification and is not meant to replace the detailed specification. Read the entire 3-Part CSI System Specification prior to starting the project. Method Spray, roller, or brush Requirements Roof must be clean, dry, and tight. Adhesion test required to ensure proper adhesion to substrate(s). Apply at 50°F (10°C) and rising with no rain or freezing temperatures in forecast for 24 hours. Application Instructions 1. 2. Tighten and/or replace existing fasteners. Power-wash roof to ensure it is free of dirt, debris, oil, and other contaminants that could negatively affect adhesion. It is recommended to use United Cleaning Concentrate (UCC) to clean the roof. Allow roof to completely dry. Install crickets to divert water and complete other necessary sheet metal repairs. Prime rusty areas as needed. Treat all metal seams. Treat all roof penetrations, skylight curbs & rake edges. Encapsulate fasteners with Roof Mate Butter Grade Flashing. Apply coating per the chart below: 3. 4. 5. 6. 7. 8. METAL UNISIL & UNISIL HS Coating Warranty Limited Emerald Diamond 1st 2nd 3rd Total Product DFT* Coat Coat Coat Gal/Sq Warranty Pledge Pledge Unisil (Solvent) 1.00 1.00 2.00 22 Yes Yes No 10 Year Unisil HS 0.75 0.75 1.50 23 Yes Yes No Unisil (Solvent) 1.50 1.25 2.75 30 Yes Yes No 15 Year Unisil HS 1.00 1.00 2.00 31 Yes Yes No Unisil (Solvent) 1.50 1.00 1.00 3.50 38 Yes Yes No 20 Year Unisil HS 1.50 1.00 2.50 38 Yes Yes No * DFT is rounded to nearest mil and is theoretical (actual DFT will vary dependent on substrate profile, application technique & waste factor. Primer/Base is not included in the DFT calculations