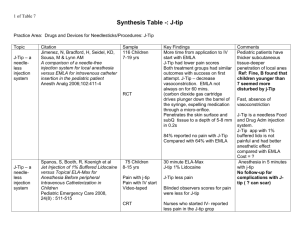

Intradermal Needle-Free Powdered Drug Injection John Liu

advertisement

Intradermal Needle-Free Powdered Drug Injection

by

John Liu

Submitted to the Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

Master of Science in Mechanical Engineering

at the

ARCHIVES

FMASSACHUSESI INSThTE

OF TECHNOLOGY

JUN 28 2012

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

L_

June 2012

LIBRARIES

© Massachusetts Institute of Technology 2012. All rights reserved.

Author ..

. .....

. ...

.....................

A .. 'Department

. ...

of Mechanical Engineering

May 21, 2012

C ertified by ................. ...........................

Ian W. Hunter

Hatsopoulos Professor of Mechanical Engineering

Thesis Supervisor

Accepted by .

David E. Hardt

Chairman, Department Committee on Graduate Theses

2

Intradermal Needle-Free Powdered Drug Injection

by

John Liu

Submitted to the Department of Mechanical Engineering

on May 21, 2012, in partial fulfillment of the

requirements for the degree of

Master of Science in Mechanical Engineering

Abstract

This thesis presents a new method for needle-free powdered drug injection. The

design, construction, and testing of a bench-top helium-powered device capable of

delivering powder to controllable depths within the dermis is presented. This device uses a jet of gas undergoing choked flow to entrain powder and subsequently

penetrates through the skin for delivery of the powder. Different nozzle designs and

orifice geometries are also explored. In vitro injection of polymer beads (1-5 pim in

diameter) into porcine tissue demonstrate the device's capability of drug delivery to

depths of 260 to 5000 pm. The jet parameters of nozzle orifice diameter and applied

pressure are shown to affect injection depth, shape, and success rate. The presented

device has the potential to be implemented with stabilized formulations of vaccines

to address the cold chain problem-the cost and risk of transporting temperature

sensitive vaccines to developing countries.

Thesis Supervisor: Ian W. Hunter

Title: Hatsopoulos Professor of Mechanical Engineering

3

4

Acknowledgments

First, I would like to express my heartfelt gratitude towards my advisor Professor Ian

Hunter for giving me the opportunity to research in his lab. The scientific development

I have experienced in these past two years would not have been possible without the

guidance and encouragement he has given me.

I would also like to thank Dr. Cathy Hogan for her dedication and support.

Dr. Hogan spent countless hours guiding my next step in experimentation, providing

advice on biology, and training me in the biological experiments necessary for my

research. Thank you to Ms. Kate Melvin for helping me manage my lab materials so

that my research could continue without unnecessary hitches.

I would like to thank Bryan Ruddy and Yi Chen for their invaluable advice, ideas,

and optimism. When faced with an engineering problem, they had the uncanny ability

to turn on just enough light for me to start moving again. I would also like to thank

other colleagues in the Bioinstrumentation Lab: to Jean Chang for her commitment

and care in editing this thesis, to Brian Hemond, Adam Wahab, and James White

for insightful discussions, and to Ashley Brown, Alison Cloutier, Ashin Modak, and

Adam Spanbaeur for all of the heartfelt laughter in lab. I would like to thank a UROP

in the lab, Rachel Dias Carlson, for helping me with the tissue sectioning work.

This research was supported in part through the NSF Graduate Research Fellowship and Sanofi S.A.

Thank you to my friends in the Christian community at MIT and Park Street

Church for displaying to me what love looks like. They have been to me a home away

from home.

To Elizabeth and Esther, a cord of three strands is not easily broken. I thank

God for blessing me with two of the loveliest sisters in this world.

To Dad and Mom, words simply cannot express my gratitude. It is hard to imagine

a set of parents more loving, godly, and dedicated than you are.

And lastly to Jesus Christ, You are my soul's glory, joy, and crown.

5

6

Contents

1

15

Introduction

15

............................

1.1

Global Vaccination ......

1.2

Needle-Free Vaccine Delivery Systems . . . . . . . . . . . . . . . . . .

16

1.3

Description of Chapters

. . . . . . . . . . . . . . . . . . . . . . . . .

20

21

2 Background

2.1

Mechanics of Liquid Jet Delivery

. . . . . . . . . . . . . . . . . . . .

21

2.2

A Prior Art: Powder Ballistic Delivery . . . . . . . . . . . . . . . . .

23

2.3

Calculations for a Jet Composed of Gas and Powder . . . . . . . . . .

24

. . . . . . . . . . . . . . . . . . . . . . .

24

2.3.1

Gas Flow M echanics

2.3.2

Comparison of Ballistic Powder Delivery to Powder Delivery by

aGas Jet ......

3

27

.............................

29

Device Development

. . . . . . . . .

. . . . . . . . . . . . .

29

. . . . . . . . . .

. . . . . . . . . . . . .

29

3.3

Carrier Gas . . . . . . . . . . . . .

. . . . . . . . . . . . .

30

3.4

Electronics . . . . . . . . . . . . . .

. . . . . . . . . . . . .

30

3.5

Powder . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

31

3.6

N ozzle . . . . . . . . . . . . . . . .

. . . . . . . .

31

3.1

Design Parameters

3.2

Bench-top Setup

3.6.1

Stereolithography Produced Nozzle

. . . . . . . .

31

3.6.2

Composite Nozzle . . . . . .

. . . . . . . .

33

3.6.3

Aluminum Alloy Nozzle

. .

. . . . . . . .

36

7

4 Device Characterization

4.1

4.2

Profile of the Pressure in the Nozzle . . . . . . .

. . . . . . . .

39

4.1.1

Strain Gauge Measurements . . . . . . .

. . . . . . . .

39

4.1.2

Theoretical Prediction of Pressure Decay

. . . . . . . .

40

. . . . . . . .

43

. . .

. . . . . . . .

43

Volume of Gas Injected . . . . . . . . . . . . . .

. . . . . . . .

44

Velocity of Injection

4.2.1

4.3

5

39

. . . . . . . . . . . . . . .

High Speed Camera Measurements

In Vitro Injection Experiments

47

5.1

Experimental Procedures . . . . . . . . . . . . . . . . . . . . . . . . .

47

5.2

Successful and Unsuccessful Injections

. . . . . . . . . . . . . . . . .

48

5.3

Inflation of Tissue during Injection . . . . . . . . . . . . . . . . . . .

49

5.4

Quantity of Powder Delivered . . . . . . . . . . . . . . . . . . . . . .

49

5.5

Dispersion Pattern in Tissue . . . . . . . . . . . . . . . . . . . . . . .

50

5.6

Depth of Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

5.6.1

Diameter Dependence Trials . . . . . . . . . . . . . . . . . . .

53

5.6.2

Pressure Dependence Trials

. . . . . . . . . . . . . . . . . . .

58

5.6.3

Jet Power Dependence . . . . . . . . . . . . . . . . . . . . . .

59

5.7

Success Rate of Injections

. . . . . . . . . . . . . . . . . . . . . . . .

6 Conclusion and Future Work

61

63

6.1

C onclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

6.2

Future Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

64

Bibliography

65

A MATLAB Script for Tissue 3D Reconstruction

69

A .1 hsvtest.m

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A .2 injectionshape.m

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B CAD of the Aluminum Alloy Nozzle

8

69

75

79

List of Figures

1-1

Various current methods of cutaneous immunization. Taken from Mitragotri, et al. [8]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

18

a) Picture of the Biojector 2000. Taken from the Bioject website [11].

b) Picture of the Injex. Taken from the Injex website [12]. Cutaway

view of the linear Lorentze-force actuator of the MIT Bioinstrumentation JI. Taken from Taberner, et al. [13]. . . . . . . . . . . . . . . . .

19

2-1

The sharp-tipped punch model. Figure taken from Shergold, et al. [18].

22

2-2

Jet power describes liquid jet injection behavior well: a) Dependence

of the depth of the erosion hole that a liquid jet creates, on jet power.

b) Dependence of Lm, the depth corresponding to the maximum width

of dispersion in the tissue, on jet power. Figures taken from SchrammB axter, et al. [20]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

23

Picture of the Powderject device for epidermal powder immunization.

Figures taken from Chen, et al. [16] . . . . . . . . . . . . . . . . . . .

24

. . . . . . . . . . .

25

2-4

Diagram of the nozzle for compressible fluid flow.

3-1

Block diagram of the bench-top powder injector and (inset) photograph

of the device: gas flows from the gas tank through the hose (1) to the

solenoid valve (2) and to the nozzle (3) (scale bar = 30 mm). ......

30

3-2

Electronic layout of the timer circuit. . . . . . . . . . . . . . . . . . .

32

3-3

A CAD drawing and picture of the SLA produced nozzle. In the nozzle

in the foreground of the picture, the minuten pin has not yet been

removed and can be seen (scale bars = 5 mm). . . . . . . . . . . . . .

9

34

3-4

The outer housing of the compression fitting houses an acrylic disk and

a custom-machined aluminum piece to mate to the compression fitting

su rface.

3-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

Compressed acrylic disks act as rigid o-rings to seal the composite

nozzle. The observable blue color on top of the disk is the residual

powder that remains on top of the disk after injection.

3-6

. . . . . . . .

35

Microphotographs of acrylic disks of different diameter orifices (scale

bars = 100 pm ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

3-7 The 7075 aluminum alloy nozzle. Scale bars in the picture and its inset

are 10 mm and 5 mm, respectively. . . . . . . . . . . . . . . . . . . .

4-1

37

Two strain gauges are installed perpendicular to each other to infer

the pressure inside the nozzle. . . . . . . . . . . . . . . . . . . . . . .

40

4-2 Pressure profile of the nozzle at varying applied pressures: 2.5, 5.0, 7.5,

10.0, and 12.5 M Pa . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3

Pressure decay in the nozzle of a 5 MPa ejection due to gas escaping

the nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4

4-5

41

42

6420 fps, 155.8 pis exposure, leading edge: 9.367 m/s, following plume:

12.130 m/s (scale bar = 5 mm). . . . . . . . . . . . . . . . . . . . . .

43

Setup to measure volume of gas ejected.

44

. . . . . . . . . . . . . . . .

4-6 Volume of gas injected from the nozzle (mL) as a function of applied

pressure (MPa). Ejections into air served as the control.

5-1

. . . . . . .

45

Representative tissue midline cross-sections of two types of injection

trials: (a) an erosion hole with no dispersion in tissue which is considered unsuccessful and (b) an erosion hole with powder dispersion

considered to be successful.

Frozen OCT in the erosion hole has a

bluish white appearance. In (b) an air bubble in the frozen OCT appears as a darkened hole in the middle of the erosion hole. . . . . . .

10

48

5-2

Time-lapse photograph series of pre-, mid-, and post-injection using

the SLA produced nozzle. Note the inflation in the second picture

(0.05 s) and deflation in the third (1.22 s) (scale bar = 10 mm).

5-3

.

. .

49

Change of tissue mass (g) due to dehydration at ambient humidity

and temperature. The mass of these tissue samples used for dehydration experiments were comparable to tissue samples used for injection

experim ents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4

50

The figure output of a MATLAB script assists the user in determining

the appropriate hsv values by defining a border around the superposition of thresholded hue, saturation, and luminance images according to

a hsv value that the user inputs. The image displays: 1) the original

image, 2-4) each image after thresholding according to a given hue,

saturation, or luminance value, 5-8) histograms of the hue, saturation,

luminance, 9) a superposition of the image and the defined border, and

10) an isolated plot of the defined border.

5-5

. . . . . . . . . . . . . . .

52

3D MATLAB reconstructions of the tissue injection shape. Three primary shapes were observed (a) upside down cone, (b) right side cone,

and (c) sphere. The powder dispersion depth corresponding to each

shown 3D reconstruction is 441, 810, and 1125 pum, respectively (scale

bars = 1 mm ).

5-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Photograph of a representative 20 im section of porcine tissue stained

with Mayers hematoxylin (scale bar = 1 mm). . . . . . . . . . . . . .

5-7

53

54

Dependence of Dh on average nozzle diameter at constant pressure.

Solid markers represent successful injections, while open markers represent unsuccessful injections. . . . . . . . . . . . . . . . . . . . . . .

5-8

55

Dependence of Dd on average nozzle diameter at constant pressure.

The injection depth of an unsuccessful injection is considered to be

zero (Dd

=

0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

56

5-9

Depth data for 25 ptm ranges of average orifice diameters at injections

at 8.9-9.0 MPa of applied pressure. Depth of both erosion hole and

powder dispersion generally increases with applied pressure.

. . . . .

57

5-10 Dispersion depth versus pressure for successful injections. Each plotted

point represents the average of a set of successful injection experiments

(n

=

1-3) at given pressure settings: 2.5, 5.0, 7.5, 10.0, and 12.3 MPa.

58

5-11 Dispersion depth versus initial jet power for all successful injection trials. 60

5-12 Success rate of injections of diameter dependence trials using the composite nozzle. Note that average nozzle diameters are presented because the expansion of orifices during injection. Data is grouped into

50 pm ranges (n = 1-6).

. . . . . . . . . . . . . . . . . . . . . . . . .

61

5-13 Success rate of injections of pressure dependence trials using a 136 pm

diameter aluminum alloy nozzle (n = 4-5). . . . . . . . . . . . . . . .

12

62

List of Tables

5.1

Compilation of the ranges of orifice diameters, Dh, and Dd for Sets 1-3. 54

13

14

Chapter 1

Introduction

1.1

Global Vaccination

Vaccine immunization saves more than three million lives worldwide each year [1] and

is considered to be one of the most cost effective measures of addressing disease on a

global scale. Over 100 million children below the age of one are immunized against

measles, polio, and other diseases [2,

3].

There remain areas for great improvement,

namely the cold chain-the temperature controlled supply system of vaccines stored

at temperatures of 2-8 'C-which is one of the most vulnerable aspects of vaccine

delivery for the developing world. Numerous studies across different countries [4] show

frequent refrigeration malfunction that leads to drug waste, vaccinations administered

with compromised vaccines, and an increased financial cost of 200-300 million dollars

a year

[5].

Furthermore, vaccination using a needle and syringe poses serious global

health problems. When compared to health workers in the United States and Canada,

the average number of sharps injury per worker per year is over 26 times higher (4.7

sharps injuries per healthcare worker per year compared to 0.18) in countries such as

Egypt and Pakistan [5].

To alleviate the problems currently associated with the cold chain, different approaches have been investigated. Efforts such as the World Health Organization's

vaccine vial monitor (VVM) and new refrigeration and temperature monitoring technologies have offered some improvement [6]. Lyophilization of vaccines is well doc15

umented and has improved the shelf life of many formulations but the lyophilized

drug still needs to be refrigerated. Reformulating drugs to be thermostable between

the temperatures of freezing and 45 'C by methods such as spray drying and spray

freeze drying are currently being developed. In particular, a recent study showed that

spray-dried formulations of the Hepatitis B vaccine were stable for at least 24 months

at 37 'C [7]. The development of the delivery of thermostable powder vaccines leads

to the potential of eradicating the need for cold chain supply and transportation.

1.2

Needle-Free Vaccine Delivery Systems

Needle-free vaccine delivery systems have garnered a heightened interest in the past

few decades. The advantages of needle-free delivery are numerous. Elimination of

the needle eliminates the risk of sharps injury and cross-contamination through reuse of the needle while removing the need for sharps disposal, solving the issue of

needle phobia, and increasing patient compliance. Numerous methods of needle-free

drug delivery have drawn the interest of research and commercial groups and can

be grouped into two general types based on the location of delivery: mucosal and

cutaneous administration.

Administration of drug to the mucous membranes covering the aerodigestive or

urogenital tracts (e.g. to oral, nasal, pulmonary, vaginal, or rectal sites) intuitively is

an effective method of vaccine delivery since pathogens of major diseases such as HIV

or the influenza virus enter the body through mucosal tissue. The mucosal immune

system contributes nearly 80% of a healthy adult's immunocytes and is therefore sensitive to antigens. Thus, many methods to target sites in the mucosal immune system

are in development. However, delivery via each route currently has major constrictions that limit its usage. For example, while oral delivery of drugs has a high patient

compliance rate, because of the poor stability of proteins in an acidic and enzyme-rich

environment, non-living vaccines tend to break down in the gastrointestinal tract [8].

Similarly, aerosolized vaccines delivered to the nasal site are less likely to break down

due to lower enzymatic activity, but there are still constraints on the size of the ac16

tuated droplet and medicinal agent for proper placement of the deposited drug and

avoidance of inflammatory responses [9].

To offer an alternative to the needle and syringe, other methods of cutaneous delivery are being developed: topical application, microneedles, and needle-free injection.

Topical delivery of vaccines (Figure 1-1c) is attractive because of the high density of

antigen-presenting cells in the superficial layer of the skin, but permeating through

the stratum corneum has traditionally been a challenge. To alleviate this problem,

hydration, mechanical (e.g. abrasion to physically disrupt the stratum corneum), and

chemical methods (adjuvants or permeabilizing agents) are used to increase the permeability of the stratum corneum to drug molecules. Each of these methods comes

with its unique advantage and disadvantage [5,8]. Microneedles (Figure 1-1h) (solid

and hollow arrays of silicon projections 25 to 1000 pm long) are designed to specifically penetrate the stratum corneum into the epidermal and dermal layer, yet are

designed to be short enough to avoid contacting nerves found in the fat layer. The

joint usage of the microneedle and transdermal patch show promising results in recent clinical trials [10] but may still not be appropriate for mass immunizations due

to their two-step application of microneedle and patch.

Finally, needle-free injection is a technology that propels the drug in a highvelocity stream of fluid to penetrate the tissue, effectively replacing the needle with

the drug itself. In the 1950s to the 1980s, the United States military used multi-usenozzle jet injectors (MUNJIs) to administer mass immunizations to its personnel [8].

However, injector tips were not changed upon each injection, leading to the exchange

of bodily fluids from one recipient of the vaccine to another. This practice led to

a widespread cross-contamination of Hepatitis B [8]. In the last two decades, independent health care groups, non-governmental organizations, and biotech companies

have been independently developing a variety of different devices, such as the commercially available Biojector 2000 [11] and Injex [12] (Figure 1-2 a and b). However

these devices offer low controllability of the depth of delivery due to their actuation

mechanisms' (spring and gas, respectively) inabilities to shape their pressure profiles.

A recent improvement of this technology took place in MIT's Bioinstrumentation

17

Figure 1-1: Various current methods of cutaneous immunization. Taken from Mitragotri, et al. [8].

Lab. A highly controllable Lorentz-force actuator called a "jet injector" (JI) (Figure 1-2c) was developed to use a two-phase pressure profile to repeatedly deliver a

pre-determined volume of drug to controllable depths in the tissue [13].

Virtually all current needle-free injection systems use aqueous solutions, which require reconstitution of the powdered drug. Because a reconstituted drug is thermally

unstable, unused reconstituted drugs must be disposed of after 24 hours, leading to

drug wastage [14]. If powdered vaccines can be delivered directly, there will be no

need for diluent and reconstitution, further cutting costs in storage, transportation,

and human training and error.

To date, few powder injection systems have been developed. A helium-powered

needle-free technology [15] is able to perform epidermal powder immunization (EPI)

[16]. However, because particle penetration is governed by the ballistics of individual

particles, constraints exist on the size and density of each particle for it to achieve

momentum density sufficient for penetration. Because of these constraints, standard

pharmaceutical formulation techniques may need to be modified [17] and this tech18

a)

b

b)

c)

Ampoule -.

Figure 1-2: a) Picture of the Biojector 2000. Taken from the Bioject website [11]. b)

Picture of the Injex. Taken from the Injex website [12]. Cutaway view of the linear

Lorentze-force actuator of the MIT Bioinstrumentation JI. Taken from Taberner, et

al. [13].

19

nology may not be ideal in situations where financial resources are limited.

This thesis describes the design, construction, and testing of a needle-free drug

delivery device used to inject powder to controllable depths. The development of this

new method of drug delivery could find its application in the developing world and

help alleviate issues associated with the cold chain.

1.3

Description of Chapters

This thesis is organized as follows:

Chapter 2 lays a framework for understanding a jet composed of gas and powder

by elucidating the jet mechanics and choked flow of compressible fluids. These

calculations are also compared to previous work in powder delivery.

Chapter 3 describes the development of a helium-powered device to perform powder

injection. Various nozzle designs are also developed.

Chapter 4 describes the characteristics of the helium-powered device.

Chapter 5 reports the results of powder injection in vitro. The device's ability to

control injection depth, shape, and success rate are presented.

Chapter 6 presents a brief summary of the work presented in this thesis and future

areas of work.

20

Chapter 2

Background

We hypothesize that if entraining powder into a gas jet is possible, the subsequent

two-phase mixture could be delivered into the tissue. We would like to draw from

both an understanding of aqueous drug delivery by a liquid jet and powder ballistic

delivery by a carrier gas to motivate powder delivery by a gas jet.

2.1

Mechanics of Liquid Jet Delivery

Shergold, et al. [18] hypothesized two phases in liquid jet injection: the initial penetration of the skin by a jet at high velocity and subsequent delivery of the bulk of the

liquid. They described skin penetration by liquid jet using the "sharp-tipped punch

penetration model" [18]. This model describes that penetration of a soft solid by a

sharp-tip solid object involves cracking the soft solid, and upon the removal of that

object the tissue undergoes reversible deformation to close the crack. This model

predicts that for liquid jets of diameters ranging from 100 to 500 pm, a peak pressure

of 14 MPa is sufficient for skin penetration, though other literature has suggested

that the critical yield stress for the stratum corneum has a larger range: 3.2-22.5

MPa [19].

Based on the observation that both exit velocity and nozzle diameter influenced

the depth of drug delivery in jet injections, Schramm-Baxter, et al. [20] used the

concept of "jet power" (Po) to describe a jet of fluid. For a liquid jet accelerated

21

-Punch,

diameter D

D1

Opened crack

x

(b)

Closed crack

Figure 2-1: The sharp-tipped punch model. Figure taken from Shergold, et al. [18].

some distance away from the surface of the tissue, they found that increasing the jet

power of a jet injection increases both the depth of the erosion hole created by the

injection and depth of the fluid dispersion in the tissue (Figure 2-2).

Assuming a constant velocity profile across the orifice,

Po =

1

-hu,

2

(2.1)

where rh is the mass flow rate, and uo is the exit jet velocity.

The mass flow rate is related to uo by

m

=

pAouo,

(2.2)

where p is the fluid density and A0 is the area of the nozzle orifice. Then

Po = -7rpD 2U3

8

00

where Do is the diameter of the jet [20].

22

(2.3)

b)

a)

13.5

10

3 -

8

2.5

E

4) -

1.5 -

2

0.5

4

0

1

10

I

100

TJ

0

1000

1

10

100

1000

Power at nozzle exit (W)

Power at nozzle exit (W)

Figure 2-2: Jet power describes liquid jet injection behavior well: a) Dependence of

the depth of the erosion hole that a liquid jet creates, on jet power. b) Dependence

of Lm, the depth corresponding to the maximum width of dispersion in the tissue, on

jet power. Figures taken from Schramm-Baxter, et al. [20].

2.2

A Prior Art: Powder Ballistic Delivery

In ballistic drug delivery as used in epidermal powder immunization (Figure 2-3),

individual particles are accelerated by a carrier gas, which is typically helium. Upon

skin impact, the gas is deflected, leaving the individual particles to penetrate the

stratum corneum and deposit into the viable epidermis. The depth of an individual

particle's successful penetration into the viable epidermis is dependent on the conversion of its kinetic energy into the kinetic energy of the tissue (the inertia of the

particle transferring to the tissue as it bends) and the subsequent plastic deformation

of penetration into the tissue [21].

Three parameters of the particle have been found to affect the penetration depth:

the particle's density (pp), diameter (rp), and impact velocity (vi). To combine the

information of these three parameters, they are multiplied together (pVirp) to form

" momentum density," the impact momentum per cross-sectional area of the particle.

In successful penetrations, typical momentum densities of particles are in the range

23

Silencer

Powdered Vaccine

cassette

Helium Gas

Acuton

BuLon

Chamber

Nozzle

Figure 2-3: Picture of the Powderject device for epidermal powder immunization.

Figures taken from Chen, et al. [16].

of 7 to 14 kg/m -s, below which particles do not penetrate the stratum corneum [21].

2.3

Calculations for a Jet Composed of Gas and

Powder

We would like to answer two questions:

1. What parameters are needed for a jet composed of gas and powder to be "similar" to a jet composed of liquid?

2. If one can deliver powder via a jet of gas and powder, how does it compare to

ballistic delivery?

2.3.1

Gas Flow Mechanics

To gain some intuition about how a jet composed of gas and powder might behave,

we first analyze the mechanics of the gas, and perform an analysis of compressible

fluid flow from a convergent nozzle (Figure 2-4) into atmospheric surroundings (no

load is placed against the nozzle).

We start by assuming a peak pressure of 10 MPa, a pressure on the order of

common peak pressures found in liquid injections. We note that the ratio of the back

24

P = Pt

P = Pt

U= 0

PI= Pe

P = Po

P = Pb

Figure 2-4: Diagram of the nozzle for compressible fluid flow.

pressure at atmospheric (Pb = 101,325 Pa) to total pressure at peak (pt = 10- 106

Pa), Pb/Pt, is less than the ratio of the critical pressure to total pressure at peak,

p*/pt [22]. That is,

0.010133

101325

=

101

10106

p

_Pb

-

Pt

<

-

Pt

2

= (

)

-

= 0.488,

(2.4)

7+1

where y is the adiabatic constant (5/3 for helium). Equation 2.4 is the criteria for

choked flow (Pb/Pt < p*/pt) and because it is met we know that the velocity of the gas

jet at the nozzle orifice is "choked" at the speed of sound (uo = Vsonnd). In fact, for

an ejection of gas into the surroundings held at atmospheric pressure, any increase

of applied pressure beyond p, = 101,325/0.488 = 207,633 Pa, will not increase the

velocity of the gas.

The speed of sound is described by,

_

Vsund =

25

RT

M ,

(2.5)

where R is the gas constant (R = 8.314 J/mol -K) and M is the molecular mass

(4.04. 10-3 kg/mol for helium). Then at T = 293 K the speed of sound for helium

(voonnd) is:

1.66 -8.314 -293

M

I

Vsound

=

When the gas velocity is choked, the equation for the mass flow rate (m4)

m =

CA

I

p1pt(2

(2.6)

1007 m/s.

[23]

)( +1/(y-l),

is:

(2.7)

where pt is the gas density at the source. Because of compressible flow, we must

make a distinction between the gas density at the source pt and gas density at the

orifice exit po. To find pt, we apply the ideal gas law:

Pt

=

PtM

T

(2.8)

RT

10. 106. 0.0040026

8.314.293

16.43 kg/m 3 .

(2.9)

To find po, we combine Equations 2.2 and 2.7:

PtPt(

Po =

Vspeed

7

+1

)(+1)/(m-),

(2.10)

where C is the coefficient of discharge (0.60 for a sharp edge orifice) and keeping

in mind that nO

= Vspeed

for choked flows.

Then combining the expression for exit density (po) from Equation 2.10 and jet

power (Po) from Equation 2.3, we obtain an expression for the jet power of a compressible fluid jet experiencing choked flow:

P

=p8t(t

DOVS,fldC

)(+3/1),

or substituting the expression for pt from the ideal gas law (Equation 2.9):

26

(2.11)

P

= T

V

=DvonCptj(

7M

8 0 oRT

22)(y1)/(y-1)

-7+ 1

(.2

(2.12)

The rupture of skin by a macroscopic object is dependent on attaining critical

yield stress [18] and thus the application of sufficiently high pressure and jet power

using any medium would rupture the tissue. However, because of the dependence of

delivery depth on the jet power of a liquid jet as elucidated in Section 2.1, we will

use jet power as a metric for performing similar injections by a jet composed of gas

and powder.

The jet parameters of a typical jet injection are: p = 1000 kg/m

3

Do = 200 pm,

and uO = 200 m/s. From Equation 2.3 this yields a jet power of:

Po

=

1

-7r(1000)(200. 10-6)2(200)3

8

=

125.7 W.

(2.13)

Then given Equation 2.11, we see that the jet power of a gas jet of the same

diameter experiencing a peak pressure of 10 MPa is:

P

=

=

8

.(200. 10-6)2. (1007)3. (0.60).

2

(1.66)(16.43)(10 - 106)( 1.66+ 1 )(1.66+1)/(1.66-1)

88.84 W,

(2.14)

(2.15)

which is similar to the jet power calculated for liquid injection (Equation 2.13).

2.3.2

Comparison of Ballistic Powder Delivery to Powder

Delivery by a Gas Jet

If typical polystyrene beads (1-5 pm, 1500 kg/m 3 ) can be entrained in the gas jet

described in Section 2.3.1 (v = 1007 m/s), this yields a range of momentum densities

from 1.5 to 7.5 kg/m -s, in general lower than the range of momentum densities of

ballistically delivered particles.

27

Since skin puncture would be solely dependent on the stress induced by the jet,

if a device can entrain powder into the gas jet to form a jet composed of gas and

powder, then delivery of solid particles of lower momentum density (and therefore

less restrictions on the formulation of the drug) can be delivered.

28

Chapter 3

Device Development

3.1

Design Parameters

The main purpose of this research was to develop a new method of injecting powder

into tissue to controllable depths. The device was developed according to the following

guidelines:

1. The method would not use liquid in any phase of the injection.

2. Gas would be used to entrain the powder in its stream.

3. The powder would be accelerated to sub- or sonic speeds.

3.2

Bench-top Setup

To fulfill this purpose, a high-pressure pneumatic valve system was conceived and

implemented in a bench top setup. The bench top setup (Figure 3-1) is composed

of a high-pressure stainless steel solenoid valve (Parker model 71216) connected to

a tank carrying industrial-grade helium (Airgas HE40) by a smooth-bore stainless

steel gas hose (Unisource 4TSC-11-11-36.0) and outfitted pressure regulator (Airgas

E13-N115H). A pressure sensor is attached between the pressure regulator (Omega

model PX303-4KG5V) and hose to determine the applied pressure at the nozzle.

29

Figure 3-1: Block diagram of the bench-top powder injector and (inset) photograph

of the device: gas flows from the gas tank through the hose (1) to the solenoid valve

(2) and to the nozzle (3) (scale bar = 30 mm).

3.3

Carrier Gas

Helium was chosen as the carrier gas because of its comparatively high diffusivity

in tissue and low solubility in blood [24].

We conjecture that injection of helium

into the upper layers of tissue poses minimal risk of enducing embolism. This issue

is addressed by qualitative observation in Section 5.3 though further quantitative

studies are needed to verify such a hypothesis.

Because previous needle-free liquid injection experiments utilized peak pressures

of 10-20 MPa to penetrate tissue, it was decided to use a standard helium tank,

yielding maximum pressures of 14 MPa.

3.4

Electronics

A timer circuit (Figure 3-2) designed by Bryan Ruddy, a PhD candidate in the lab,

was used to control the solenoid valve. In its deactivated state, the coil inputs (W3

30

and W4) are both kept at the constant voltage of 24 V. When the circuit to the

power supply is connected via an external switch (W1 and W2) it introduces a voltage

difference across the Precision Timer (SE555), which sends a timed pulse of control

current to the MOSFET driver (TC4420). The MOSFET driver then sends a timed

pulse of amplified current to the MOSFET (IRFB3077) which connects the negative

terminal of the coil input (W4) to the ground rail for a pre-determined time. The

solenoid valve is connected to the coil inputs and is thereby energized by a timed

voltage pulse of 24 V from the power supply. A voltage pulse width of 15 ms was

used as the duration of the voltage pulse to be analogous to the widths of the pressure

peaks in typical liquid needle-free injections.

3.5

Powder

White glass beads (1000 kg/m 3, 2-10 im) and colored fluorescent beads (1500 kg/m 3,

1-5 pm) were chosen to simulate drug delivery as they have similar densities and

particle sizes to that of lyophilized drug [17,25].

3.6

Nozzle

At the time of this research, no commercial nozzles were easily adaptable for powder

injection; thus various attempts were made to custom-design and create nozzles for

powder injection. The purpose was to machine nozzles that withstood high levels of

pressure (up to 14 MPa) with orifice diameters ranging from 50-200 jm.

3.6.1

Stereolithography Produced Nozzle

A nozzle was fabricated by stereolithography (SLA) using the Viper Si2 [26] and is

shown in Figure 3-3. During the fabrication process, the nozzle tip was found to be

without orifice before curing. It is likely that the resin does not vent from the orifice

because of its narrowness. In order to form the orifice, a 150 pm minuten pin (shown

in Figure 3-3b) was manually inserted into the soft resin, cured, then removed post31

-l

C

C-)

-I

C

C-)

Figure 3-2: Electronic layout of the timer circuit.

32

cure to form a hole approximately 150 pm in diameter. The nozzle was then fitted

into a compression fitting to connect to the solenoid valve.

In addition to the ease of use and ability to rapid-prototype, one advantage to a

nozzle fabricated by stereolithography was its optical clarity, which permitted one to

qualitatively observe the powder (e.g. for powder clogging) by visual confirmation.

A second advantage was the the lower elastic modulus of the cured resin (when

compared to metal). When strain gauges were installed to infer the internal pressure

of the nozzle during injection (Section 4.1.1), a lower amplification of the voltage

output was therefore required (compared to what would be necessary for a metal

nozzle) thus leading to a higher signal to noise ratio.

One of the difficulties associated with fabricating nozzles in this manner was the

requirement that minuten pins be manually inserted through 2 mm of resin; during

this process these pins often bent and permanently deformed in the middle of the

insertion. It was also deemed impractical to use thinner pins to fabricate nozzles

of smaller diameter orifices.

Furthermore, it was found by experimentation that

orifice diameters expanded with each injection due to the erosion of the orifice by the

injectable and deformation under pressure.

3.6.2

Composite Nozzle

Because of the fabrication difficulties and limited use of nozzles fabricated via stereolithography, a method to rapidly prototype nozzle orifices of different diameters was

developed. By modifying the power and cut parameters of a laser machine, acrylic

disks having a range of different sized holes could be quickly fabricated.

A carbon steel compression fitting (Parker Yor-Lok) was used to house one acrylic

disk and a machined aluminum piece was used to mate to the surface of the inside of

the compression fitting (Figure 3-4). When the pieces were assembled and tightened

in the compression fitting, the acrylic disk and aluminum piece were compressed

together to form a gas-tight seal in the fitting (Figure 3-5), resulting in a composite

nozzle that could house acrylic disks of different orifice geometries. Acrylic, 1.7 mm

thick, was laser machined to yield orifice diameters ranging from 20 to 200 pm (Figure

33

Figure 3-3: A CAD drawing and picture of the SLA produced nozzle. In the nozzle

in the foreground of the picture, the minuten pin has not yet been removed and can

be seen (scale bars = 5 mm).

3-6).

While the ability to rapidly prototype a range of orifice diameters was advantageous for experiments that varied jet power, the disadvantages eventually outweighed

the advantages. First, because the laser machine was only accurate to within 30 pam,

many acrylic disks had to be fabricated before obtaining a disk with the desired orifice diameter. Secondly, orifices of smaller diameters were tapered more than those

of larger diameters. This variation of 3D geometry was an uncontrollable variable

that may have affected the behavior of the fluid flow in the nozzle. The gravest issue

however was the increase in orifice diameter during injection due to plastic deformation under pressure and abrasion by the injectable. Orifice diameters often expanded

more than 40 pm during a single injection and therefore represented an uncontrollable

variable in experimentation.

34

15 mm

Figure 3-4: The outer housing of the compression fitting houses an acrylic disk and

a custom-machined aluminum piece to mate to the compression fitting surface.

Figure 3-5: Compressed acrylic disks act as rigid o-rings to seal the composite nozzle.

The observable blue color on top of the disk is the residual powder that remains on

top of the disk after injection.

35

I

Figure 3-6: Microphotographs of acrylic disks of different diameter orifices (scale bars

-

100 pm).

3.6.3

Aluminum Alloy Nozzle

To ensure a constant orifice diameter during the injection, a one-piece nozzle was

designed and machined out of 7075 Aluminum alloy (Figure 3-7).

This alloy was

chosen for its high yield strength.' To achieve a range of diameters, the nozzle was

micro-drilled using drills of diameters 50, 75, 100, 125, 150, 175, and 200 pm, yielding

nozzles with orifice diameters of 61, 81, 107, 136, 162, 197, 195 pm. Orifice diameters

were measured by observation under the microscope.

36

Figure 3-7: The 7075 aluminum alloy nozzle. Scale bars in the picture and its inset

are 10 mm and 5 mm, respectively.

37

38

Chapter 4

Device Characterization

Three main metrics were chosen to characterize the needle-free gas-powered injector:

the internal pressure the nozzle experiences during an injection, the speed of the

powder as it leaves the nozzle, and the volume of gas delivered per injection.

4.1

Profile of the Pressure in the Nozzle

To measure the profile of the pressure in the nozzle, strain gauge measurements were

performed to infer the internal pressure in the nozzle. These measurements were then

reconciled with theoretical predictions.

4.1.1

Strain Gauge Measurements

In order to obtain optimal strain gauge measurements, stereolithography (SLA) produced nozzles were chosen. The cured resin formed by SLA has a lower Young's

modulus than aluminum, which yields a larger strain per unit of induced stress. Two

strain gauges were installed on the SLA-produced nozzle (Figure 4-1): one having its

main axis along the nozzle's circumference and the other having its main axis along

the length of the nozzle. These two strain gauges were placed in a dual wheatstone

bridge configuration to minimize thermal effects of the strain gauges. The voltage

measurements were calibrated to pressure values by sealing the nozzle from the sur39

roundings, opening the valve directly to the gas regulator and comparing the voltage

output of the strain gauges to the measurements of the pressure sensor at different

values of applied pressure.

Figure 4-1: Two strain gauges are installed perpendicular to each other to infer the

pressure inside the nozzle.

Figure 4-2 shows the pressure profiles of the nozzle (with no load) with a valve

opening time of 15 ms at varying applied pressures: 2.5, 5.0, 7.5, 10.0, and 12.5 MPa.

4.1.2

Theoretical Prediction of Pressure Decay

The Bird, Stewart, Lightfoot (BSL) source-term model [27] predicts choked gas flows

from a pressurized gas system:

t = [F(t)(1y/

_1](

2 )(V

7 - 1 CA

where:

. t = time after leak flow starts

40

gyPo

2

do

y+ 1

(4.1)

4

j

I

I

I

I

I

I

I

121-

-

10

-

2.5 MPa

5.0 MPa

7.5 MPa

10.0 MPa

12.5 MPa

0O 8

6

(D,

CD,

ICL

4

2

0

0

0.2

0.4

0.6

1

0.8

1.2

1.4

1.6

1.8

Time (s)

Figure 4-2: Pressure profile of the nozzle at varying applied pressures: 2.5, 5.0, 7.5,

10.0, and 12.5 MPa.

* F(t) = fraction of initial gas weight remaining in source vessel at time t

* V = volume of the source vessel

* C = coefficient of discharge, (0.60)

" A = area of the source leak

*

*

Y = the adiabatic constant, cp/c

gravitational conversion factor

c=

" Po

=

initial gas pressure in source vessel

d = initial gas density in source vessel

The isentropic expansion of an ideal 'gas is described by,

P(F) = PoF(t)-.

Then rearranging Equations 4.1 and 4.2 we obtain an expression for P(t):

41

(4.2)

P(t) = Po[-t

a + 1]',

(4.3)

where,

a = (2

-1

V Yg.YPo

CA

do

2 ) +/Y-0)-

(4.4)

+ 1

Making the assumption that the nozzle is completely filled with gas stored at the

peak pressure until an opening at t = 0, we use the BSL source model to make a

theoretical prediction of the decay of pressure in the nozzle and compare it with the

experimental data of the decay of a 5 MPa ejection (Figure 4-3). We see that the

theoretical prediction agrees well with experimental results. Therefore, choked flow

accurately describe the behavior of the gas flow of an ejection.

M 3

C.

1

1L

0

1.5

0.5

Time (s)

Figure 4-3: Pressure decay in the nozzle of a 5 MPa ejection due to gas escaping the

nozzle.

42

4.2

4.2.1

Velocity of Injection

High Speed Camera Measurements

To determine the speed of an ejection, a series of ejections into air were recorded

using a high-speed CMOS video camera (Phantom v9, Vision Research [28]) fitted

with a 65 mm macro photo lens (Canon MP-E 65). The ejections were captured at a

resolution of 1440 x 720 and a frame rate of 6420 fps. The pressure of ejection was

10 MPa and the speed of the front of the powder jet when already diverged was 12.13

m/s.

0.0 ps

623.1 PS

155.8 pts

778.8 pts

311.5 pis

934.6 pts

467.3 pis

1090.3 ps

Figure 4-4: 6420 fps, 155.8 ps exposure, leading edge: 9.367 m/s, following plume:

12.130 m/s (scale bar = 5 mm).

43

4.3

Volume of Gas Injected

To determine the volume of gas injected in a single trial, the nozzle setup was placed

in a sealed Buchner flask, and the difference in pressure within the chamber before

and after an injection trial was measured using a pressure sensor (Vernier GPS-BTA)

(Figure 4-5). The volume of helium delivered in a porcine tissue injection was found

to increase with pressure, from 4.9 mL at 2.1 MPa to 10.4 mL at 10.2 MPa (Figure

4-6). Comparison of injections into tissue to control ejections into air demonstrates

that the presence of a load greatly decreases the volume of gas delivered.

Figure 4-5: Setup to measure volume of gas ejected.

44

140

E 120-

10080-

0

)

0

E

.-

60-

* Control

* Porcine Tissue

.

*

40-

A

20-

-

rO '

2

0

4

6

8

10

12

Pressure (MPa)

Figure 4-6: Volume of gas injected from the nozzle (mL) as a function of applied

pressure (MPa). Ejections into air served as the control.

45

46

Chapter 5

In Vitro Injection Experiments

Design verification was carried out by performing injections into porcine tissue, a

close analog to human tissue.

5.1

Experimental Procedures

Post mortem porcine tissue was obtained through the MIT Tissue Harvest Program

using procedures approved by the IUCAC and in accordance with the NIH Guide for

the Use and Care of Laboratory Animals. Tissue was harvested from the abdomen

of Yorkshire pigs (approximately 6 months in age) immediately after euthanasia and

included muscle, subcutaneous fat, and skin. The tissue was trimmed, immediately

vacuum sealed, and stored at -80 'C. Prior to injection, each sample was thawed at

4 'C and equilibrated to room temperature. All injections were done by placing the

nozzle in direct contact with the tissue sample. Injected tissue was placed in plastic

containers (22 mm x 22 mm x 18 mm) containing optimal cutting temperature

compound (Tissue-Tek OCT Compound) and frozen in liquid nitrogen. Tissue slices,

15 pum thick, were then successively removed from each sample using a Vibratome

Ultra Pro 5000 cryostat. A Canon EOS-7D camera, fitted with a 65 mm macro photo

lens (Canon MP-E 65) was used to photograph the tissue after removal of each section,

yielding a series of photographs that when compiled, imaged through the entire block

of tissue. To view the different layers of porcine tissue, tissue was embedded in OCT

47

and microtomed using the cryostat to yield 20 pm sections, which were captured on

microscope slides. These sections were consequently fixed in cold acetone and stained

with Mayers hematoxylin.

5.2

Successful and Unsuccessful Injections

The jet once it has punctured the stratum corneum may produce two effects. In the

first case, an erosion hole is created but powder is not dispersed through the tissue

(Figure 5-la) while in the second case, an erosion hole is created followed by dispersion

of drug into the tissue (Figure 5-1b). These two cases were carefully differentiated

by visual assessment. When an erosion hole is created without powder dispersion,

the powder resides only on the exposed surface of the erosion hole. For the purpose

of analysis, an injection yielding an erosion hole with no powder dispersion is not

considered to represent a successful injection. As such injection profiles have been

quantified using two measurements: Dh the depth of the erosion hole and Dd the

depth of powder dispersion.

Figure 5-1: Representative tissue midline cross-sections of two types of injection trials:

(a) an erosion hole with no dispersion in tissue which is considered unsuccessful and

(b) an erosion hole with powder dispersion considered to be successful. Frozen OCT

in the erosion hole has a bluish white appearance. In (b) an air bubble in the frozen

OCT appears as a darkened hole in the middle of the erosion hole.

48

5.3

Inflation of Tissue during Injection

In successful injections, it was often observed that the helium inflated the tissue sample. Figure 5-2 shows a time-lapse series of photographs demonstrating tissue inflation

at 0.05 s after the start of injection and deflation within 1.22 s. The observation of

tissue deflation and the observation that the vast majority of powder injections are

delivered to the upper region of the dermal layer (Section 5.6) (where major arteries

and veins are not located), are consistent with the conjecture that injection of helium

into the upper layers of tissue poses minimal health risk (Section 3.3). Still, deflation

could primarily be attributed to gas escaping through the fat layers of the sides of

the tissue sample, a mode of escape that would be unavailable in an in vivo injection.

Further experiments would need to be carried out to verify whether gas deflation still

occurs when its only mode of escape is diffusion back through the skin layer.

0.05s

0.00 s

1.22 s

Figure 5-2: Time-lapse photograph series of pre-, mid-, and post-injection using the

SLA produced nozzle. Note the inflation in the second picture (0.05 s) and deflation

in the third (1.22 s) (scale bar = 10 mm).

5.4

Quantity of Powder Delivered

Percent yield of delivery is an important metric when assessing the efficacy of an

injection method. While mass measurement before and after injection is a common

method used in liquid injections to determine the volume of drug injected into the

tissue, this was found to be an impractical method for powder injections. In one or

two minutes, a piece of freshly exposed tissue (approximately 20 mm x 20 mm in area)

loses 2 to 5 mg of mass due to dehydration (Figure 5-3). Since the powder loaded into

49

the nozzle per injection is on the order of 1 mg (as opposed to approximately 25-200

mg for liquid injections) a mass measurement yields no usable information. Future

work would entail employing techniques such as measuring the levels of fluorescence

or radioactivity of the tissue after delivery of fluorescent or radioactive particles,

respectively.

0-4

-0.005-

Trial 1

Trial 2

Trial 3

o

A

+

+

+

0

-0.01-

0

0

C -0.015

()

C

00

-0.02-

0

+

U-0.025

-0.03 1.

0

0

200

400

Time (s)

- - -. . 1* . - - - - - - . . 8

600

800

Figure 5-3: Change of tissue mass (g) due to dehydration at ambient humidity and

temperature. The mass of these tissue samples used for dehydration experiments were

comparable to tissue samples used for injection experiments.

5.5

Dispersion Pattern in Tissue

Image processing and 3D reconstruction of the injection were performed in MATLAB

[29] (Appendix A) to determine the dispersion pattern of each tissue injection. Image

thresholding was performed on each picture according to its hue, saturation, and

luminance value (hsv) and a border was defined around the remaining area after

superposition (Figure 5-4). Each picture's border of the powder in the tissue was

then successively 3D plotted to its corresponding depth on the z-axis. Finally, a

50

surface was defined around the series of borders to yield the 3D dispersion pattern of

the powder injection.

Reconstruction of successful powder injections into porcine tissue revealed that

the dispersion patterns were quite varied.

The most common shapes observed in

successful injections could be classified as an upside down cone (Figure 5-5a), an

upright cone (Figure 5-5b), or a sphere (Figure 5-5c).

These injection shapes are associated with the development of the actual injection.

An upside down cone was observed with the most shallow of injections, whereas the

sphere was commonly observed with the deepest of injections. Fluid and powder

dispersion within tissue originates from what can be thought of as a point source of

radially outward flowing fluid [14]. As dispersion depth increases, the point source

also increases in depth and a greater section of the sphere is realized; in a shallow

injection, this point source can be thought of as resting on the surface, hence only

the bottom part of the sphere is realized. The intermediate stage between the upside

cone and sphere may be thought of as an underdeveloped sphere, and thus the shape

more closely resembles a right side cone. These observations are similar to those for

needle-free injections using aqueous solutions and are consistent with the point-source

hypothesis for incompressible fluid injection. A deeper understanding of the tissue

mechanics that predict dispersion pattern could be beneficial to further optimize

delivery of drugs to specific depths in the tissue.

5.6

Depth of Injection

To test the controllability of the device, two parameters of jet power, nozzle orifice

diameter and applied pressure, were varied to observe the consequent depth of injection. Depth of injection was determined by measurement after medial section or 3D

reconstruction of the dispersion pattern. In addition, the specific layer of tissue that

powder had been delivered to was inferred by comparison with a representative tissue

section counterstained with Mayers hematoxylin. A typical section of tissue stained

with Mayers hematoxylin is shown in Figure 5-6 and shows a dermal layer 2.5 mm

51

F,

4

OVI"UG322

10

4Hstopa.

SOMB

.(Lumnc Vu

7j ofgw

logram of sdurdion

10

[1.

3

I2

0S

I

02

04

0.6

Gry Lels

OS*

12

I

0

Gray LeVels

Powderire*K

Lun*aanceVehae

W

10

1r0

%SYLsV*

M0

2M

o

w

100 ISO

Gray tals

O

M

Shpe 7

hmage + Border: thresh =0.05

3000

2000

lawn

ure 5-4: The figure output of a MATLAB script assists the user in determining the appropriate hsv values by definin

der around the superposition of thresholded hue, saturation, and luminance images according to a hsv value that the u

uts. The image displays: 1) the original image, 2-4) each image after thresholding according to a given hue, saturation,

inance value, 5-8) histograms of the hue, saturation, luminance, 9) a superposition of the image and the defined bord

10) an isolated plot of the defined border.

a)

c)

b)

Figure 5-5: 3D MATLAB reconstructions of the tissue injection shape. Three primary

shapes were observed (a) upside down cone, (b) right side cone, and (c) sphere. The

powder dispersion depth corresponding to each shown 3D reconstruction is 441, 810,

and 1125 pm, respectively (scale bars = 1 mm).

thick and a fat layer that is at least 3 mm thick.

5.6.1

Diameter Dependence Trials

Because the composite nozzle (Section 3.6.2) could easily house acrylic disks having

orifices of a range of diameters, it was used to perform injections to determine the

effect of varying orifice diameters on injection depth. Three sets of trials at different

applied pressures were performed: 8.9-9.0 MPa, 10.1 MPa, and 13.7-13.8 MPa. The

depths of erosion hole and dispersion of these single trials are plotted in Figure 57 and Figure 5-8, respectively. Given the expansion of the orifice during injection,

the average of orifice diameters before and after injection is presented on the x-axis.

Injection success and failure is also differentiated in each data set. The ranges of nozzle

orifice diameters, depths of erosion hole, and depths of dispersion are summarized in

Table 5.1.

In general, we observed a correlation of both erosion hole depth and

dispersion depth with increasing orifice diameter.

To observe more clearly the correlation of both erosion hole depth and dispersion

depth with nozzle diameter, the data was grouped into 25 pm ranges (n = 2-4) and

the respective depths were averaged (Figure 5-9).

For an applied pressure of 8.9-9.0 MPa, trials were unsuccessful in the 25-75

53

Epidermis: 100 prm

MI Dermis: 2.5 mm

Fat: 3+ mm

'1~

Figure 5-6: Photograph of a representative 20 pm section of porcine tissue stained

with Mayers hematoxylin (scale bar = 1 mm).

Set

Pressure (MPa)

Range of Orifice

Diameters (pM)

Range of Dh (pm)

Range of Dd (Pm)

1

2

3

8.9 - 9.0

10.1

13.7-13.8

33 -173

54 - 159

74 -265

91 - 860

313 - 585

210-1890

260 - 1090

441 -1125

585 -5310

Table 5.1: Compilation of the ranges of orifice diameters, Dh, and Dd for Sets 1-3.

54

2 0 0 0 -,

e-

a)

a)

C:

0

- .--.-.--.-.-.-.-.-.-.-.

-

.

-.

* Trial 1: 8.9-9.0 MPa (success)

o Trial 1: 8.9-9.0 MPa (failure)

* Trial 2: 10.1 MPa (success)

o Trial 2: 10.1 MPa (failure)

A Trial 3: 13.7-13.8 MPa (success)

A Trial 3:13.7-13.8 MPa (failure)

1500-f

1000+- - -

-{

500-|

LU

V

0

50

I

100

I

150

I

200

Average Nozzle Diameter (pm)

2

250

300

Figure 5-7: Dependence of Dh on average nozzle diameter at constant pressure. Solid

markers represent successful injections, while open markers represent unsuccessful

injections.

55

bUUU

I

*

*

5000-

A

I

I

Trial 1: 8.9-9.0 MPa

Trial 2: 10.1 MPa

Trial 3: 13.7-13.8 MPa

4000-

-3000-

0

-0

2000-

Q.

1000 -

O0100

150

20

Average Nozzle Diameter (pm)

250

300

Figure 5-8: Dependence of Dd on average nozzle diameter at constant pressure. The

injection depth of an unsuccessful injection is considered to be zero (Dd = 0).

56

jm range: erosion holes and powder dispersion were not observed in the 25-50 Pm

diameter range and erosion holes but not powder dispersion were observed in the 5075 pm range. Both erosion holes and powder dispersion were observed (successful) in

the 75-175 pm range.

1200

- -

10 0 0 -

800 -

-

-

-

-

--

--

Erosion Hole

Dispersion

-

-- - - - -

- -- - -

-

-

-

-

-

-

-

-- - --

-

-

E

.c

600

-

40 0

-

-

-

-----.- -

.

.

-

--

-.

.

-

-.

--

200.

25-50

50-75

75-100

100-125

125-150

150-175

Range of Average Nozzle Diameter (um)

Figure 5-9: Depth data for 25 pum ranges of average orifice diameters at injections at

8.9-9.0 MPa of applied pressure. Depth of both erosion hole and powder dispersion

generally increases with applied pressure.

Thus we see more clearly the trend of increasing erosion hole depth and dispersion

depth with increasing nozzle orifice diameter.

The inherent limitation in interpreting the results of the experiments performed

using the composite nozzle lies in the expansion of the orifice during an injection.

Orifice expansion was generally in the range of 20-60 tm depending on the initial

nozzle diameter and pressure setting. Across all trials, the average expansion during an injection was 47 pm. Because the time progression of the orifice expansion

during an injection is unknown, the actual diameter of the powder jet the tissue is

experiencing at a given point in time during an injection is also unknown. This lack

57

of knowledge leads to an inability to make any statement on the injection depth's

dependence on nozzle orifice diameter beyond correlation.

5.6.2

Pressure Dependence Trials

Because the orifice diameter of a composite nozzle was not fixed, an aluminum alloy

nozzle (Section 3.6.3) was chosen to evaluate the relationship between injection depth

and applied pressure. Injections were performed using a nozzle having a fixed orifice

diameter of 136 pm at five different pressure settings: 2.5, 5.0, 7.5, 10.0, and 12.3

MPa.

At least one injection failed at every pressure setting in this set of experiments.

We decide to address the success rate of injection separately (Section 5.7) and select

only successful trials to plot the average dispersion depths (Figure 5-10).

5000

1

4500-

0-*c

E

40003500300025002000-

C

1500 1000 -

C,,

-

500 -

6

8

10

12

14

Applied Pressure (MPa)

Figure 5-10: Dispersion depth versus pressure for successful injections. Each plotted

point represents the average of a set of successful injection experiments (n = 1-3) at

given pressure settings: 2.5, 5.0, 7.5, 10.0, and 12.3 MPa.

58

We observe a trend of increasing dispersion depth with increasing pressure, consistent with the previously stated theory of jet power.

5.6.3

Jet Power Dependence

To compare together all sets of in vitro injection trials presented in this thesis, we

would like to use jet power (see Section 2.3.1) as a metric. As this variable includes

jet parameters of both applied pressure and orifice diameter, it is appropriate then to

combine the sets of diameter dependence trials (Section 5.6.1) with the set of pressure

dependence trial (Section 5.6.2).

There are two challenges in calculating the jet power of a jet composed of gas and

powder.

First, given the observation that the tissue sample inflates and deflates during

injection (Section 5.3), we know then that the internal pressure of the tissue will be

greater than atmospheric pressure during the injection, but we do not know how much

greater the pressure will be without experimental measurement. Thus we do not know

whether the criteria for choked flow (Equation 2.4) holds during the duration of the

injection and Equation 2.12 may therefore not be a proper expression for jet power

during the injection. However, at the instant the injection begins, the tissue is still at

atmospheric pressure, and therefore the initial flow can be characterized as choked.

Thus, we can use initial jet power as a metric.

Secondly, it is currently unclear how the entrainment of powder affects the behavior of the jet. Powder entrainment in the gas jet could greatly increase the effective

density of the jet. Given a peak pressure of 10 MPa, the exit density of a jet whose

volume is composed of 0.5% powder would be more than double the density of an

equivalent jet without powder. However, the inertia of powder a gas is able to impart

likely increases with the inertia of that gas. If so, then the effective density of powder

entrained in the gas would also increase with the exit density of the jet of gas. Then

observed trends with calculations of jet power neglecting powder entrainment would

still be consistent to calculations of jet power taking into account powder entrainment. Experimental work to measure the effective density of a jet composed of gas

59

and powder would be required to verify this hypothesis.

Having qualified the use of Equation 2.12 as an expression for the initial jet power

of an injection, we plot the dispersion depth of all successful trials against the calculated initial jet power (Figure 5-11).

60001

1

a

5000-

/o 4000-

}

3000-

0a-

2000-

aCd

1000-

4

OL

0

50

+ Set 1: 8.9-9.0 MPa, 33-173 gm diam

- Set 2: 10.1 MPa, 54-159 sm diam

A Set 3: 13.7-13.8 MPa, 74-265 gm diam

x Set 4: 2.5-12.3 MPa, 136 gm diam

Initial Wet Power ( , (W)

200

250

Figure 5-11: Dispersion depth versus initial jet power for all successful injection trials.

There is a general increase in dispersion depth with an increase in initial jet power.

Given our knowledge of the thicknesses of each tissue layer (Figure 5-6) we note that

all injections except for two have delivered powder to the dermis.

60

5.7

Success Rate of Injections

The data suggests that the success rate of an injection increases with increasing orifice

diameter. A graphical representation of the success rates of injections using orifice

diameters grouped by 50 pm ranges is shown in Figure 5-12.

The data also suggests that the success rate of injections is optimized by a certain

value of pressure. We see that within both the 50-100 pm and 100-150 pm groups,

the success rate of injection decreases with increasing pressure (pressure increases

from the 8.9-9.0 MPa set to the 13.7-13.8 MPa set). In the 150-200 pm group, a

similar relationship is observed between experiments performed at 8.9-9.0 and 10.1

MPa. The deviation from this trend at 13.7-13.8 MPa represents a single injection

(n

=

1) and as such may not be representative.

100- 90 90

C 80-

0 60 - 50

-

-

. ...

Set 1: 8.9-9.0 MPa . .

Set 2: 10.1 MPa

Set 3: 13.7-13.8 MPa

- - --- - --

-

--

- -- --

- - ----

- --

--

--

--

...

..

-.-

4-

020

-..

.....

- ..

-.

-....... --..

-..

....-..

Cn)

500020-10

0

50-100

15-0

100-150

150-200

Range of Average Nozzle Diameter (pm)

Figure 5-12: Success rate of injections of diameter dependence trials using the composite nozzle. Note that average nozzle diameters are presented because the expansion

of orifices during injection. Data is grouped into 50 pm ranges (n = 1-6).

To further demonstrate the hypothesis that success rate is dependent on pressure,

we plot the success rate of injections in pressure dependence trials in Figure 5-13. We

note that the highest success rates are observed at P = 7.5 MPa and P = 10 MPa.

61

For the orifice diameter of 136 pm used in this set of trials, there seems to exist then

an optimal pressure of injection between 7.5 and 10 MPa. This conjecture would also

be consistent with the trend observed in Figure 5-12: within the 100-150 pm group

there is a 100% success rate for the 9 MPa set which subsequently decreases to 33%

for the 13.7-13.8 MPa set. The decrease of success rate for injections that use higher

peak pressures is possibly due to the mass flow rate of the gas exceeding the maximum

absorption rate of the tissue, forcing the gas to splash back out of the created hole

instead of delivering the powder into the tissue. This "splash back" phenomenon has

been observed in injections using aqueous solutions and can be improved by pressure

pulse shaping [30].

100

-

~90C

0

80 -

--

-.-

-.--........... ....

-IC

6 0

...... . .... ...

....

- - - .. ...... ......... ..- ..... . .

.4-

0

01

2.5

5.0

7.5

10.0

Applied Pressure (MPa)

12.3

Figure 5-13: Success rate of injections of pressure dependence trials using a 136 pm

diameter aluminum alloy nozzle (n = 4-5).

We thus conjecture that injection success rate increases with increasing orifice

diameter and is optimized by a certain pressure value. The presented data suggests

that a set of injection parameters that may optimize injection success rate is an orifice

diameter of 150 pm and an applied pressure of 9 MPa.

62

Chapter 6

Conclusion and Future Work

6.1

Conclusion

A new method of powdered drug delivery has been developed and demonstrated.

The developed device is a simple and inexpensive bench-top helium-powered device

capable of delivering particles into porcine tissue to depths of 260 to 5000 pLm. Because

penetration of the powder is not dependent on ballistics but the jet mechanics of the

carrying gas, penetration of particles of lower momentum density than has previously

been attained is made possible.

The device presented offers an alternative method for the intradermal delivery of

powdered drug and has the potential to be implemented with stabilized formulations

of vaccines to address the cold chain problem. While the device uses a compressible fluid for jet injection, the penetration, success of injection, injection depth, and

injection shape are consistent with previous results obtained using essentially incompressible fluids (aqueous solutions). It is shown that the depth of the powder's

dispersion in the tissue is dependent on the jet power of injection, which can be varied by changing applied pressure or nozzle orifice diameter. It is conjectured that

the success rate of injection could also be optimized by the jet parameters of applied

pressure and nozzle orifice diameter. Further development of this type of technology

could provide a platform for the delivery of a variety of powdered drug formulations

and deliver to the subcutaneous and muscle layers of tissue.

63

6.2

Future Work

Future experimental work will include delivering thermo-stabilized formulations of

vaccines, verifying their stability under high pressure and physical impact, and exploring parameters required for successful injections and bioavailability of the delivered

drug.

Future device development will explore optimal nozzle geometries and development of a hand-held device, of which the design parameters are as follows:

1. be a handheld device

2. operate on battery power

3. be automatically reloading

4. use disposable nozzles

5. employ a controllable pressure waveform

6. be able to reliably inject drug to dermal, fat, and muscle layers of tissue

64

Bibliography

[1] M. Kane and H. Lasher. (2002) The case for childhood immunization. [Online].

Available: http://www.unicef.org/immunization/index-coverage.html 1.1

[2] T. L. P. Project. (2009) Progress toward immunization: Winning the fight

against deadly diseases. [Online]. Available: http://www.gatesfoundation.org/

livingproofproject/Documents/progress-towards- immunization.pdf 1.1

[3] W. B. WHO, UNICEF, "State of the world's vaccines and immunization," WHO,

2009. 1.1

[4] D. M. Matthias, J. Robertson, M. M. Garrison, S. Newland, and C. Nelson,

"Freezing temperatures in the vaccine cold chain: A systematic literature

review," Vaccine, vol. 25, no. 20, pp. 3980 - 3986, 2007. [Online]. Available:

http://www.sciencedirect.com/science/article/pii/S0264 4 1 0X0700 2 2 89 1.1

[5] E. L. Giudice and J. D. Campbell, "Needle-free vaccine delivery," Advanced

Drug Delivery Reviews, vol. 58, no. 1, pp. 68 - 89, 2006, challenges

in Pediatric Drug Delivery: the Case of Vaccines. [Online]. Available:

http://www.sciencedirect.com/science/article/pii/S169409X0600007X 1.1, 1.2

[6] PATH. (2012) Not too hot, not too cold.

//www.path.org/projects/cold- chain.php 1.1

[Online].

Available:

http:

[7] D. Chen, S. Kapre, A. Goel, K. Suresh, S. Beri, J. Hickling, J. Jensen,

M. Lal, J. Preaud, M. LaForce, and D. Kristensen, "Thermostable formulations

of a hepatitis b vaccine and a meningitis a polysaccharide conjugate vaccine

produced by a spray drying method," Vaccine, vol. 28, no. 31, pp. 5093 5099, 2010. [Online]. Available: http://www.sciencedirect.com/science/article/

pii/S0264410X10006699 1.1

[8] S. Mitragotri, "Immunization without needles," Nature Reviews Immunology,

http: