e2e Materials, Inc. CNY Biotechnology Symposium June 3, 2011

e2e Materials, Inc.

CNY Biotechnology Symposium

June 3, 2011

Upstate Heritage

• Awards:

• Most Innovative Technology , UNYTECH, 2006

• First Prize , Essential Connections $100K Business Competition,

2007

• First Prize , Cornell Johnson School Business Idea Competition,

2007

• Grants:

• NYSTAR; NYSERDA; Grants for Growth, CenterState CEO; CAP

Grant, Syracuse COE

• Investors:

• Cayuga Venture Fund, Seed Capital Fund – CNY, Excell Partners,

Rochester Angel Network, ESD – SBTIF

• Employees (23):

• Cornell University, RIT, U of R, Syracuse University, Ithaca

5

Global Recognition

# 37 !

Grant Awards Investor Base

USDA, NSF,

USB,

California,

Seattle, Florida,

D.C.

Proprietary and Confidential 6

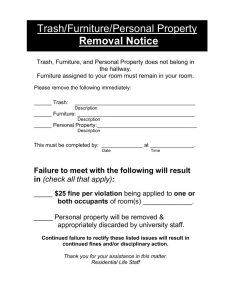

• Stair components

• Residential furniture

• Chair seats

•

Residential cabinets

• Mattress foundations

• Hand rails

• Mattress specialties

• Shelving racking systems

• Attic decking

• Automobile load floors

• Speaker boxes

• Window blinds

• Trade show displays

• Ad specialties

• Commercial furniture

• Musical instruments

• Healthcare interiors

• Packaging

• Shipping boxes

• Concrete forms

• Plant potting

• Roofing underlayment

• Engineered lumber

• Siding

• FRP (fiberglass reinforced panels)

• RV cabinets

• Heavy truck panels

• Automobile door panels

• Transit railcar interiors

• Work surfaces

• Flooring

• Speaker boxes

• Children’s furniture

• Sub-floor assemblies

• Wall assemblies (SIPS)

• Millwork

• Window frames

• Ceiling fan blades

• Countertops

• Molding

• Doors

• Educational furniture

• Acoustical abatement products

• Shingles

• Caskets

• Table legs

• Sporting goods

• Furniture framing

• Pallets

• Toys

• Architectural details

Over $65B in Market Opportunity

$5B Market Focus to achieve both near-term production volume and prove viability across all markets

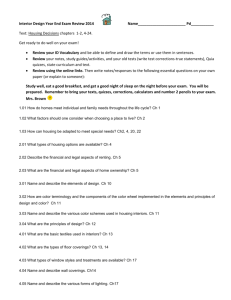

First Product - Desktop

• $310K Joint development agreement with $6B Tier 1 supplier to develop load floors and additional components for transportation markets

• Interest from 3 major OEMS

• Higher strength/lighter weight creates value through higher MPG and adds to overall cost effectiveness

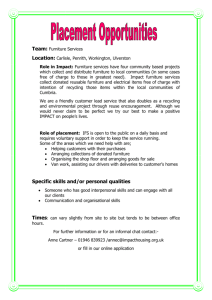

• Indian sugar cane producer an investor

• Developing use of waste fiber (Bagasse) currently burned

• 4 lbs fiber waste for 6lbs sugar produced

Highly respected partner for Indian market applications with bagasse.

112 tons of waste bagasse produced globally

REGIONALLY INTEGRATED

MANUFACTURING

IT’S HOW WE DO IT.

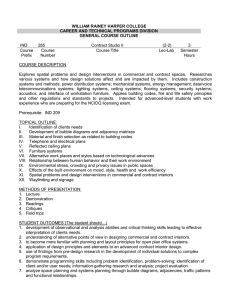

Established volume processes

Baled natural fibers processed into continuous web on conventional nonwoven equipment.

Soy resin blended and impregnated into fiber web (pre-preg) and conditioned for forming

Prepregs formed on conventional compression molding equipment with heat and pressure

Particleboard

4x8 Sheet ¾” Basis

222lbs of CO2

US Market

Total:

22.7B lbs CO2

Energy Story e2e Materials

Comparative