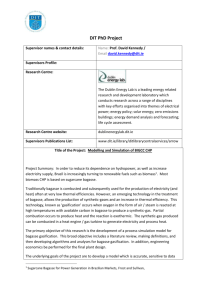

26 Bagasse handling. >tornge and drying 606 100 26.2.5 Baling I ! / ~0~~--~--~--7 8--~17 0--712~-1~~--~16 P>le heoghtln m Figure 26.4: 01) bulk dcnslly of bogas:.< .., • fun<:ll~n of heoghl ofoosa-'-"' piI< ((rom Mofll<m et aJ. 1974) i1 is preferable 10 con,ider dry bulk densities. A u..,. ful relationship becwcen dry bulk dcn>ily and pile heigh• was escublished by Morgtm ec ul. ( 1974) nnd is shown in Figure 26.4. Allhough chis dacn was ob· tnioed for wee bulk Mornge (di;.cu,sed in Section 31.2.1 on By-Product;). il appears 10 have more general applicability for baga>>e >tomge and ac the lower end conforms 10 other dal3 on bagasse packing den>ily. The Figure shows the dry bulk density increasing from 100 kglm' :11 a 2 m heigh• to 180 kglm' in a 14 m high pile. At 40 % moisturo. this im· plies a bulk density for moist bagasse varying from 166 to 300 kglm!. Because loose bagasse has such a low bulk den· sity. numerous in\'~Ligations have been made into baling baga'se 10 reduce the volume of stored ba· gnsse. Baling hns generally been proven to be better chan pelleti1jng. which re-quires costly equipment that is expcn<h·e to maimain. Baled bagasse tempemcurc< are also found to increa.sc in stomge as n result of mi· crobial activity. Temperatures rise co about60 •c after a few days and remuin there for about 30 days. They arc oflen M3ckcd with ajr pa.~g~ bclwccn them. to provide a means of dis;ipming che heat produced. Dawson et al. ( 1990) show that dried bag"""' of lcs; than 20 g water/I 00 g bagasse is obtained alter scor· age between 20 und 30 days. A' a re>uh the material is microbiologically and chemically inactive and mosc suitable for use in by-products or as a boiler fuel. Bales have a densicy. depending on the press used. of nboul 600 kglm' . i.e. roughly three time< that of loose bagasse (Section 32.2.2). However if bales are often scored with air spaces bee ween them. the ud,antage Of greater densities in >COring bagasse in bale> is lnrgely eliminated. Dtm·stm et ul. ( 1994) studied the populations of microorganisms in bales and in baga..e stored loose. They found that drying the baga>se prior to baling reduced the numbct'l> of >pore> de\'eiOped in stornge. buc concluded tbot baling of fresh and partially dried bagasse had liule advanwge over loose scoragc. 26.3 Baga.<sosis. There i' a potential heallh hazard associated with the scorage and handling of bagasse. namely bagasso;is. an allergic reaccion of lung ti,. !<IUC to I he ptC-i:>Cncc of T!Jemmactinomyc~s .wcclwri spores. These develop only in stored baga>se and are not u;u:clly present in sufficient quantity 10 cause problems in a normal mill environmem. Funher de· tails are given by Dawso11 et nl. ( 1995). Trnns port in bulk. In some cases baga>se is mnsponed from one mill 10 another '" road vehi· cles. It is imponant 10 design loading systems which contain the dust nod ensure thac the mocks are sealed before venturing ou1 on the road,. In general bulk storage of bagasse requires addi· tiona] environmental monitoring and management. Bagasse d rying Final bagasse ha.~ a high water content (48-52 g/1 00 g bagasse). which both reduces iiS heating value and i\ the cause of the largest energy loss in th• boiler>- because the fuel moisture carries the lacem heat of vaporization up the 'tack: The e-quation for the gross calorific \'alue of bagasse (equacion 27.1 ) shows a decren.e or 196 kJ/kg for C\"Cry increase or I 'k in the mobture comem. It i• shown in Section 27.3.2 thac ubout 95 % of the losses from a bagasse fired boi ler are st:tck losses and. for bagasse. the moisture loss is the most significant: the extent of the loss is propor· tionnlt<> the final gas tempernture. 26.3.1 Effect on boiler effi cie ncy and capacity Drying the bagasse is therefore beneficial to boiler efficiency for several reaso ns: (a) th e lower amount of water reduces the excess air required. at least down to a level of 40 '7c moi sture. below which there is no red uction in excess air required (Magasin er et al. 2002) : (b) it is possible to reach a higher adiabatic flam e temperature: (c) a smaller flow of gases passes to the stack. The ways in which bagasse moi sture and gas exit temperature affect boiler efficiency are illustrated in Figure 27.4. However. drying the bagasse with the flu e gas goes well beyond that as it effective ly reduces th e final gas temperature passing up the stack. usin g residual energy to effect the drying. This equates to returning some of the gas enthalpy to the boiler an d reducing losses accordingl y. Driers. mainl y rotary drum and fla sh types. have been insta ll ed in Am erica. Brazil, Philippines, Australia, China. Cuba and Indi a. bur consistent resul ts and concl usions have not always been obtained and the degree of success varies widely. 26.3.1 Effect on boiler efficiency and capacity The use of boiler exhaust gas to dry bagasse redu ces the stack temperature and hence from an effici ency point of view is eq uivalent to adding more boiler heat recovery surface . An economizer does not give an effic iency gain as high as a drier. but has been usuall y the prefened option because of lower initial costs. better reli ability and lower maintenance requirements. However bagas se driers can reduce stack temperature to a lower figure than either an air heater or economizer. The use of an economi zer enables a reliable and relatively cheap reduction in gas temperature to be obtained with simple heat exchange equipm ent with no additional fa ns. gas ducts or conveyors. With no moving parts. operational and maintenance costs are lower. The limit on outlet temperatures must be high enough to ensure that the conosion will be unimportant unless very abnormal conditions occur (Magasiner 1996). Drying of bagasse not only redu ces the effective boiler gas ex it temperature, but also reduces the amount of boiler gas produced, thu s improving the efficiency significantl y more than additi on al heat re- 607 covery eq uipment on a boiler can achieve. However it never mak es economic se nse to pay for the energy required to dry bagasse . Thi s only makes sense if waste heat in boiler flue gas is used for drying. An economic compari son of the two options is necessary to dete rmine which is the most cost effective alternative between economizers an d bagasse driers in each case. Maranhao (1986) reported that the cost of install ation of a bagasse drier represented around 12 'k of the value of the boilers. with a stack temperature of 135-140 oe, while Magasiner ( 1996) suggests that the cost of an eco nomi zer represe nts 6 to 8 '7c of the cos r of the boi ler with a stack temperature of 150 oe, Thus it appears that an economi ze r costs be tween 50- 65 'k of a bagasse dri er. Using info rm ation obtained in a prototype install ed at the Nun orco sugar mill, Argentina, Cardenas et al. (1994 ) pe rformed an evaluat ion concluding th at divertin g 50 'k of the stack gases to the bagasse drier increases th e boiler effi ciency from 7 1.4 to 84. 9 'k. large ly by redu cing stack losses. and with a smaller reductio n in furn ace loss. Dixon et al. ( 1998) show that reducing the moisture co ntent of bagasse has a substantial effect on the capacity of the boiler. However they estimate that a limit of 30 'k moisture is necessary for safe conditi o ns in conventi onal spreader firing. At this moi sture content an increase in steam output ofjusr over 10 '7c is expected. Narendranath and Rao (2002) report an increase in boiler capacity between 5 and 8 '7c following the installation of bagasse dri ers achieving bagasse moistu res in the 42-44 '7c ran ge . 26.3.2 Types of drier Initially. most driers were of the rotary type. Furines (1976) described some earl y installations in Florida. These were not always satisfactory and often gave considerable trouble. Subseq uentl y fla sh driers were developed. since it was established that very quick drying of the order of seconds. could be achi eved, particularly with good cane preparati o n. Thi s type has now been widely adopted. A re view of some of the bagasse dry ing plants used in several countries showing the rotary drum and the pneumatic suspension drier as the most popular alternati ves is give n by w 111 der Poe/ et al. ( 1998:458). Most of them have ach ieved a drop in moisture content of References p. 6 16 608 26 B agas se handling. storage a nd drying bagas se from 50 ck or just over to somewhere in the range of 30 to 40 'k . The swirl burner deve loped by SRI in Australia dri es bagasse being fed to th e boilers usi ng fu rn ace gases. This falls into a so mewha t differe nt category to the driers considered here. in that it is an integral part of the boiler and does not benefit ti·o m using resid ua l flue gas energy which would otherwi se be lost. Rotary drum driers. This type of equ ipmen t has bee n widely used fo r various drying duties. co nsisting of a rotating cylindrical drum. prov ided w ith internal deflectors and cocurrent fl ow of bagasse a nd hot gases . Airl ock sys tems must be us ed on the ends of the cylinder feeding and disc harging bagasse . to avoid air ingress which may cause a fi re. These driers have often proved troubleso me. they are mechanicall y cumbe rsome. a nd the ri sk of fires is hi gh. A number of driers installed in the past have bee n decommissioned and re moved. Pneumatic flash driers. Direc t contac t with ho t flu e gases gi\·es hi gh heat tran sfer rate s. short residence times and uniform dryi ng. Although differe nt des igns are availabl e. in general a fu el feeder is used at the bagasse inle t. which simultaneously ac ts as a seal preve nting the entrance of air. Bagasse is transported in the hot gases in long heating tubes and direct contact heat transfer take s pl ace. The bagass e is subseque ntly separated fro m the gas in a cyclone. The wet gases go to the stack. while th e bagasse separated in the cyclo ne is discharged via a rotary air-lock v-alve onto a conv-eyor or directly into the combustion chamber. ~a u st Cyclones Sid e view Moisture contents down to 35-40 'k can be achieved. in the process reducing the gas stack temperature to 80 cc_ just above the dew poi nt. The installation at Zai o mill in Morocco is reported to have inc reased the bo il er efficiency fro m 72 to 78 '7c and the steam production from 1.6 to 2.7 kg steam/kg bagasse (mn der Poe/ et al. 1998:459). gas 137 'C Gas return figure 26.5: Pneumatic su spension countercurrent bagasse drier at Sa nto Antonio (Maranha,· 1986) 26.3.3 Operatio nal issues The plant described by Maranhao (1986) involves the use of an auxiliary fan to direct part of the gases before or after th e ai r preheater to the front of the boiler through an underground pipe, to the drier located ju st before the bagasse feeding system (Figure 26.5). Bagasse is separated from the hot gases in cyclones, from which it discharges into th e boiler furn ace. The advantage of this system is the absence of additional conveyors. However wear on most of the components in the system is significant. requiring ongoing maintenance . A limit is imposed on the temperature of the gas leavi ng the drier. whic h is in contact with metal and therefore must be kept below the de w point of the co mbustion gases to avoid the form ation of acids that cause conosion. As bagasse has a lov..sulfur content. the temperature is lower than in the case of boi lers which use foss il fuels. For conventional bagasse boilers the dew point is below 90 oc (Magas iner 1996). After 7 years of experience with three pneumatic bagasse driers installed in the Santo Antonio sugar mill, M ara nhao ( 1986) described briefiy the units and results observed. summarized in Table 26.1. The initial boiler effic ie ncy was low and so signifi cant gai ns were possible with only an air hea rer. The comparison shows how much more the efficiency can be improved with a drier. with the best perform ance obtained with a co mbination of air preheater + bagasse drier. The reduction in excess of air from 93 'K to 35 'k has a considerable inftuence on the efficiency. apart from the reduction in stack temperature. The main concerns with bagasse driers are the maintenance, reliability and susceptibility to blockages. Careful design can minimize these problems. This req uires that all parti cle impacts occur at a shallow angle to minimi ze erosion . Erosion is not an issue on bends on vertical up-ftow. but all other bends 609 need to be very long radius or have easily replaceable wear plates at the bends. It is also important to have oversi1ed rotary va lves. It is reported that the valves have a working life of four seasons. A potential environmental advantage of bagasse driers in a well-designed system is the retention in the moist bagasse of small particles entrained wi th the flue gas. reducing the particulate emission through the stack (1·an de r Poe/ et a!. 1998) . In India it is reponed that the gas exiting the cyclones has a part iculate loading of< 100 mg/m 3 (Na rendranath and Rao 2002). Thi s also means a smaller quantity of sa nd in the gases , which together with lower velocities (because excess air is reduced) has resulted in a longer service life of exhaust fa ns and stacks (Maranhao 1986). 26.3.3 Operational issues The main operational issue is the mai ntenance of equipme nt. particularly related to wear. Even though the concept has been around for man y yea rs, so far the tec hnol ogy has not proved reliabl e and drier projec ts have not bee n consistentl y successful. Reports of successful installations of bagasse driers exist. but none of the se riously failed experie nces have bee n published. In Colombia for example. a bagasse drier was installed in the late 1980s. whi ch led to a smooth and efficient operation of the boiler, eliminati ng suppleme ntary fuel consumpti on. However. serious \Vear of some elements and problems wi th the rotary seal valves were so severe that the drier became a mainten ance problem and jeopardized the reliab ility of the plant. Finally it was dismantled. Popular opinion in places like Brazil and South Afric a suggests that an economi ze r is better than a bagasse drier beca use of few er problems. even though the efficiency is inferior. Whilst bagasse driers can reduce stack temperature Table 21i.l: Results v. ith bagasse driers in San Anton io sugar mill. to a lower figure than either an air heater or Brazil (Maranhao 1986) economi zer. they are expensive. mechanicalBo il er +Air +Dri er +Air ly complicated, use additi onal powe r and are alone preheater preheater difficult to integrate successfully into a con+Drier ventional boiler station. Indepe ndent of the Stack temperature in '' C drying technology selected , conveyors to and 217 260 140 330 Bagasse moisture in '1c 52.7 52. 7 40 from the bagasse driers are usuall y required, 35 Excess air in '7c 78 41 which may represent a signi fica nt additional 93 35 46.5 Boiler efficiency in cost. 55.6 64.3 69.3 Re(em1cesp. 616 610 26.3.4 Other alternati\es ror bagasse drying Or)ing using superheated ~t ea m. A lluidozed hed dner fur heet pulp ha' hecn de,crihed CJ•nsm 2003). whoch is in use on n number nf liuropean beet 'u~ur fnctorie,. Es'ientially. 'uperlteuted 'team (e.g. 2.g \1Pa. 250 Cl " u\ed to e\aporate moi,ture. )teldon~ a \tream of \apor l<a,in~ the drier with ell<>Ugh energ) to he u>ed "' the heaung media in the toN cfln'l of the C\3)10011<"' ce.g. 370 I..Pa. 150 C). The \apor generated on the drier " fe\.'0\ered on the fuctO<). In tho; \\3). nlm<"t all the energ) and wntcr " recO\ered. but the energy lc,cl ol the Steam i, lov.cred. The main complicatoon with hosh pre»ures is the feeding and o.ealing of the dncr. "hich in the ca\C of beet pulp has been wl'ed by employing I"N3<) \ ahe' u\ed in the paper pulp tndU>Il'). The ~Njor change required "ithon the IO<.'I<") " the 'Piit of the lir\t effecJ e>-apon~tor '"'" '"" h<llhts. or the addouon of a Mt:un uan,forrntr or anolher effa:t. to 3\oicJ ctmt.unuwlloo of the extuu't "-ondcn\Mc v.lth the 'ap<>r comong from the drier. Other dc"gn> lor heet pulp lxl\ed on the pnnco· pie <>I 'uperhcaung drying ure pre\Cnted by •wo der f'o<'i e t ul. ( 1998). The>C rely on lluid11ution of the beet pulp. but for sugureane mill,, lluidituuon of bn· 1!3!11\C " 11tlf10"ible. and initial trial' ha\C rnud~ u~ Of \Upcrbeated >I~ flO\\ through <t4110na<) poleked bed\, at atlll<hphenc pres<ure t.lfon:nonl/11 ond Bat· rmnt 10051. A further problem \\til he corong ""h \\Car due to ""'din the OOg3'"'· Boiler\ "<!Old aho 1\a'e l<l he modohed to operate \\ith IS<; mol\turc. Ng"'"' at tO to Solnr dr)ing. Solar energ) hn' hecn u.ed for the drying of beet pulp in Cnhfomoa nnd other ngricullurol products (e.g. coffee). and ;, an opuon for ba~.l\\C. A pil<ll plant '""in the Domonocan Repul>hc 'ho\\ed a reduction on m<ll,ture I rom SO'< to 36-1-1 <;, but 11 ·~ 1101ed that on a larger .,.;ale the tC\Uih can \at) coru.idernbl) Iran Jcr l'r'<'l ct al. 19981. It could he an interNinJ! option '" the ri~ht can.:um,tJn\..~' 26.4 :I ,\ hne fmcllon of OO£a>\C t<ml(J b~acollo 1> u\ed ._, a hlter :ud to the filter <t311t>n It " gcncr· 311) con..-eded that ltne " better than '"tl.lr\C lxlga.:illo: a e<>mm<lnl) 3CCqlled quaht) cntenon " that at lea'l K5 '• of the material ,houJd P"" through a 20 mc'h '<recn (0.83 mm open•ngl. Cullm ( 19671 recommended that 80-90 '.f <houhJ P"" through a 14 mc'h ,crcen ( 1.19 mml nnd nm more tlmn S <; 'hould P"" through a 36 me'h .ereen Uom~<t !1984! ha\ '"'"'n that the fincr lxlgacolln ornpro'·" filtrate ljUaht) but ~ not impro'c the rate of ltltrauon The t>agacillo '>hould he lrec Ill l;>ng tiber\ . "hoch do 0<>1 help achi.-e good filtrauoo Baga.ollo p.utocle\ foliO\\ a log·oormal \IIC dov tribuuon The t)pocal range of p.utoclc encoon- 701 60 ~ 50 ! 20 t J .,. 40 30 101 :!I 0 I '"e' 02 03 0405 Partldt loaM tn mm ll~urt Bagacillo collection 26.6: s"~ dosmbuoon ol "''""'lin I0 zo tcred " 'h<)Wil 111 Figure ::!6.6. B••sncillo i> ..epuroted from the b.'l'"'"' produced by performed screens in the b<Jttoon deck of a bagn'"' carrier. or b) pneumatic ..epnrauon throu11~ lou\er or perforated \CI"eeO,, or by \UCkutg hoe par· licit, out uf a bal;3'\e \tream.