FUNCTIONAL NANOSTRUCTURES FROM CLUSTERS

advertisement

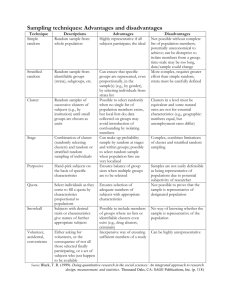

FUNCTIONAL NANOSTRUCTURES FROM CLUSTERS A. PEREZ, P. MELINON, V. DUPUIS, B. MASENELLI, L. BARDOTTI, B. PREVEL, J. TUAILLON-COMBES, E. BERNSTEIN, F. TOURNUS, I. WANG, A. TAMION, D. NICOLAS, C. RAUFAST, D. TAINOFF, N. BLANC Laboratory of Condensed Matter Physics and Nanostructures University Claude Bernard-Lyon 1 and CNRS Lyon - France Particles 2007 – Toronto-Canada – 19-21 july 2007 ¬ GENERAL CONTEXT Two main approaches to nanostructure preparation " Top Down " " Bottom Up " Elementary Bricks : - atoms, molecules Functionalized film Substrate ¬ Nano-Engraving Technique : - Nano-lithography, - Nano-imprint, - FIB… ¬ Deposition : - Nucleation - Growth Clusters preformed : - i.e. in the Gas-phase ¬ Deposition : - Nucleation - Growth Substrate Couche Fonctionnalisée Substrate Substrat Substrate OUTLINE ¾ Free cluster production and deposition on substrates using the : Low Energy Cluster Beam Deposition technique (LECBD) characteristic examples of functionalized cluster-assembled ¾ Some nanostructures : - Magnetic from TM (i.e. Co, Fe,…) and mixed TM-X clusters (i.e. Co-Sm, Co-Pt) - Optical from photoluminescent sesquioxide clusters (i.e. Gd2O3:Eu3+) ¾ Preparation of 2D–organized arrays of cluster-assembled dots on FIB-functionalized substrates - Application to very high integration-density devices (~ Gbits/in2 -Tbits/in2) ¾ Conclusion and prospects NANOSTRUCTURE PREPARATION FROM CLUSTERS Pulsed valve (He : 4 – 6 bars) Laser-vaporization cluster Source He ¬ Typical cluster sizes : a few tens to a few thousands of atoms (~ 1 to 4 nm) YAG Laser N° 1 ¬Very high cooling rate : ~ 108 - 1010 K/s YAG Laser N° 2 Target rod Supersonic expansion TOF- mass spectrometer Mass spectrum UHV-Deposition chamber à à Neutrals Ions Free cluster studies RHEED Diffractometer ¬ LECBD regime : clusters are not fragmented upon impact on the substrate Evaporation cell XPS-ISS Analyzer Substrate STM-AFM Microscope Eximer Laser OUTLINE ¾ Free cluster production and deposition on substrates using the : Low Energy Cluster Beam Deposition technique (LECBD) characteristic examples of functionalized cluster-assembled ¾ Some nanostructures : - Magnetic from TM (i.e. Co, Fe…) and mixed TM-X clusters (i.e. Co-Sm, Co-Pt) - Optical from photoluminescent sesquioxide clusters (i.e. Gd2O3:Eu3+) ¾ Preparation of 2D–organized arrays of cluster-assembled dots on FIB-functionalized substrates - Application to very high integration-density devices (~ Tbits/in2) ¾ Conclusion and prospects FUNCTIONAL MAGNETIC NANOSTRUCTURES (*) To overcome the superparamagnetic limit ¬ High magnetic anisotropy nanoclusters , High magnetic-blocking Temperature ( ≥ 300 K) , Application to high density data-storage systems (~ Tbits/in2) 1,5 Normalized Magnetization M/Ms Cobalt-Samarium System 300 K 20 K 1,0 SmCo5-clusters 0,5 20 K 0,0 300 K -0,5 -1,0 2 nm 2 nm -1,5 -3 Cobalt-Platinum System CoPt _ L10-Phase CoPt _ A1-Phase (fcc) [ -2 -1 0 1 2 3 Magnetic Field (kOe) CoPt3 _ fcc-Phase ] 2 nm 2 nm (*) see : "Functionalized cluster-assembled magnetic nanostructures for applications to high integration-density devices", A. Perez et al., Adv. Engineer. Mat., 7(6), 475 (2005). FUNCTIONAL MAGNETIC NANOSTRUCTURES ¬ Size control Without mass-selection : , size dispersion ~ 40 % Mass-selected cluster deposition using an electrostatic mass-analyzing system : , size dispersion ~ 5 % As deposited CoPt-clusters on a-C substrates at 300 K. CoPt _ A1-Phase (fcc) Fit Log-normal Diameter (nm) Size Histogram Number of particles Number of particles Size Histogram Ø = 2 nm Diameter (nm) OUTLINE ¾ Free cluster production and deposition on substrates using the : Low Energy Cluster Beam Deposition technique (LECBD) characteristic examples of functionalized cluster-assembled ¾ Some nanostructures : - Magnetic from TM (i.e. Co, Fe…) and mixed TM-X clusters (i.e. Co-Sm, Co-Pt) - Optical from photoluminescent sesquioxide clusters (i.e. Gd2O3:Eu3+) ¾ Preparation of 2D–organized arrays of cluster-assembled dots on FIB-functionalized substrates - Application to very high integration-density devices (~ Tbits/in2) ¾ Conclusion and prospects FUNCTIONAL OPTICAL NANOSTRUCTURES (*) ¬ Preparation and characterization of novel photoluminescent nanostructures exhibiting : - A high-emission efficiency - A good stability under high-power excitation - Emission wavelength adjustable in a wide range of visible - Potential applications to nano-optics devices - Alternative to photoluminescent semiconducting-nanostructures ¬ Rare-earth doped sesquioxyde nanoparticles, i.e. : - Gd2O3:Eu3+, Y2O3:Eu3+ (red emission) - Gd2O3:Tb3+ (green emission) - GdBO3:Pr3+ (blue emission) Luminescent materials commonly used for TV-screen coatings ¬ In such materials, the doping element is responsible of the light emission and not the sesquioxide matrix ¬ Fundamental aspects : - Confinement effects in strongly ionic nanocrystals ? ? ? - Comparison to the well known effects in semiconducting nanoparticles (*) See : "Quantum confinement effect on Gd2O3 clusters" B. Mercier et al., J. of Chem. Phys., 126, 044507 (2007). PHOTOLUMINESCENTE NANOSTRUCTURES FROM Gd2O3:Eu3+ - CLUSTERS HRTEM-image of a Gd2O3:Eu3+ cluster deposited on an a-C coated grid at 300 K d22-2 d400 = 2,67 Ǻ 30 Number of particles d222 = 3,08 Ǻ Size distribution <d> = 3,2 nm 25 20 2.5 nm ≤ 80% ≤ 3.6 nm 15 10 5 0 0 2 4 6 8 Diameter (nm) 2,7 nm Cubic structure with : a = 10.7 Å Bulk phase (bixbyite, bcc, Ia3) : a = 10.8 Å O2Gd3+ Composition ¾Target-rod mounted in the cluster source : Gd2O3 doped Eu3+ (10 %) ¾ Average composition deduced from XPS-measurements on a thick clusterassembled film : Eu3+ ≈ 13 % Rhombic dodecahedron 10 PHOTOLUMINESCENCE PROPERTIES OF Gd2O3:Eu3+ - NANOCLUSTERS CB Red emission : transition between the 4f-levels of Eu3+-impurities Laser excitation : λexc Variation of the gap of the Gd2O3-matrix as a function of the size (*) ΔEg ΔEg (eV) (eV.) 1 CdS - Krishna et. al - Ledoux et. al - Viswanatha et. al - Nanda et. al CdS - Our results Si 0,1 0,01 α= ZnO ΔE g = α Gd2O3 dγ CuBr Gd2O3 with γ = 1.39 (**) 2 5 10 α= 20 1,0 0,8 - Bulk Gd2O3:Eu3+ (5 %) - Cluster film (<Ф> = 3.2 nm) - Cluster film (<Ф> = 2.8 nm) 0,6 0,4 8.7 8 0,2 3 .7 3 α= 1 α = .67 1 .4 α= 7 0.5 6 nanocrystals diameter (nm) Intensity (a.u) VB 0,0 580 600 620 640 660 680 700 720 Wavelength (nm) 50 Nanocrystal diameter : d (nm) (*) Deduced from excitation measurements in VUV on cluster films (Gd2O3:Eu3+ (10 %), at 10 K) using the synchrotron radiation at DESY (**) See : C. Delerue et.al., Phys. Rev. B 48, 11024 (1993). OUTLINE ¾ Free cluster production and deposition on substrates using the : Low Energy Cluster Beam Deposition technique (LECBD) characteristic examples of functionalized cluster-assembled ¾ Some nanostructures : - Magnetic from TM (i.e. Co, Fe…) and mixed TM-X clusters (i.e. Co-Sm, Co-Pt) - Optical from photoluminescent sesquioxide clusters (i.e. Gd2O3:Eu3+) ¾ Preparation of 2D–organized arrays of cluster-assembled dots on FIB-functionalized substrates - Application to very high integration-density devices (~ Tbits/in2) ¾ Conclusion and prospects DIFFUSION OF DEPOSITED CLUSTERS ON THE SUBSTRATE EXPERIMENTAL EVIDENCE (*) : ⇓⇓⇓⇓⇓⇓ Two extreme cases depending on the cluster-surface interaction Easy diffusion of clusters : No cluster diffusion : i.e. Gold clusters (Au750) on HOPG at 300K i.e. Gold clusters (A750) on Au(111) at 300K t=0.01 nm t=0.03 nm t=0.08 nm t=3.4 nm 100 nm 1μm 150 nm (*) See : L. Bardotti et al., Phys. Rev. B, 62, 2835 (2000). 150 nm ISLAND DENSITY NUCLEATION AND GROWTH PROCESS OF LECBD FILMS : SUMMARY Nucleation Growth Coalescence COVERAGE RATE PREPARATION OF 2D-ORGANIZED ARRAYS OF MAGNETIC CLUSTER-DOTS(*) ¬ Application to high integration-density devices (~ 100 Gbits/in2 - 1 Tbits/in2) for data storage systems and spintronics TMAFM images Nano-craters (2,5 μm x 2,5 μm) Nano-hillocks Functionalized HOPG-substrates using the FIB-nanoengraving technique - Ga+-ions 30 keV - Periodicity 300 nm 50.103 ions/point 10.103 ions/point 5.103 ions/point 2D-arrays of magnetic CoPt-cluster dots on FIB-HOPG substrates nm 300 - Periodicity : 300 nm , ~ 10 Gbits/in2 3,5 μm 2 μm 0,5 μm (*) See : "2D arrays of CoPt nanocluster assemblies" A. Hannour et al., Surf. Sci., 594, 1-11 (2005). CONCLUSION ¾ The preparation of original / functional nanostructures from clusters preformed in the gas phase using the LECBD technique seems promising : ¬ Model nano-systems well suited for fundamental studies, as well as functionalized ones well suited for applications are easily synthesized. ¾ The control of the nucleation and growth process of cluster- assembled nanostructures on functionalized substrates is used to prepare 2D-organized arrays of cluster-dots ¬ Applications to high integration-density devices (, Tbits/in2). PROSPECTS ¾ Control/modification/combination of core/surface/interface effects to realize functional nanostructures with unique properties : ¬ mixed clusters : alloying effects, surface effects, segregation effects… ¾ 2D-organized arrays of functionalized nanoclusters on functionalized substrates : ¬ Study of the organization-properties relationship ¬ very high integration densities ( ≥ Tbits/in2) RESEARCH GROUP ON CLUSTERS AND NANOSTRUCTURES AT LPMCN – Univ. Lyon 1 O. BOISRON Engineer V. DUPUIS P. MELINON B. MASENELLI G. GUIRAUD Engineer L. FAVRE PhD L. BARDOTTI A. PEREZ J. TUAILLON B. PREVEL F. TOURNUS E. BERNSTEIN 2D-PERCOLATION THRESHOLD OF CLUSTER - ASSEMBLED FILMS PREPARED BY LECBD V Cr - electrode A Corning-glass substrate Electrical-conductivity measurements in situ during cluster deposition 1.5 mm 2 mm -6 10 current intensity (A) , Coverage rate ≈ 50 % current intensity (A) Equivalent deposited thickness at the percolation threshold : t ≈ 2 nm 0.001 -4 10 1.8 nm -8 10 -10 10 Co-clusters T = 80 K -12 10 -14 10 0 2 4 6 8 10 Deposited thickness (nm) -5 10 2.5 nm -7 10 -9 10 Ni-clusters T = 300 K -11 10 -13 10 0 2 4 6 8 10 12 Deposited thickness (nm) 14 NUCLEATION AND GROWTH MECHANISM CHARACTERISTIC OF LECBD(*) incident cluster, size Ni ≈ 102 to 103 atoms (a) (c) (e) (b) (d) (a) Deposition (b) Diffusion (c) Nucleation (d) Coalescence (e) Growth Substrate Clusters are not fragmented upon impact on the substrate in the LECBD - regime Coalescence is limited ⇒ 2D-Growth (*) Review article : P. JENSEN, Rev. Mod. Phys., 71, 1695 (1999). NANOSTRUCTURED MORPHOLOGY OF A THICK CLUSTER FILM Sb-cluster Film Si-substrate TEM cross section view of a thick (~80 nm) antimony-cluster film deposited on a silicon substrate at room temperature : ¬ density ≈ 50 to 60 % of the bulk phase MD-SIMULATIONS OF THE CLUSTER DEPOSITION C28-Fullerenes on a semiconducting substrate Mo1043-Clusters on Mo(001) surface LECBD regime A. Canning et al, Phys. Rev. Lett, 78, 4442 (1997). H. Haberland et al., Phys. Rev. B, 51, 11061 (1995). MD-SIMULATIONS OF THE CLUSTER DIFFUSION ON A CRYSTALLINE SURFACE(*) Top view Cross section view D=f(Misfit) D=f(Size N) , D~Nα -0.66 < α < -1.4 D=f(Temperature) (*) P. Deltour et al., Phys. Rev. Lett., 78, 4597 (1997) EXPERIMENT-SIMULATION OF THE CLUSTER-ASSEMBLED NANOSTRUCTURE MORPHOLOGIES ¬ DDA - model (Deposition - Diffusion - Aggregation)(*) ¬ Kinetic Monte Carlo (KMC) model Experiment : Sb2300-clusters on HOPG at 400 K DDA - Simulation : h Incident clusters can diffuse on the HOPG-surface. h Dcluster ≈ 10-8 cm2/s χ χ Nislands ~ (F/D) = (F/D0) exp(χ Ea /kT) h with χ = 1/3, Ea ≈ 0.7 eV and D0 ≈ 104 cm2/s Cluster fluence (F) and Temperature (T) allow to control Nislands (*) See : P. JENSEN, Rev. Mod. Phys., 71, 1695 (1999). CARACTERISTIC EXAMPLES OF FUNCTIONALIZED CLUSTER-ASSEMBLED NANOSTRUCTURES 1- Preparation of original semiconducting nanostructures ¬ from silicon and mixed silicon-carbon cage like clusters : (*) C59Si Si-Fullerenes Si stuffedFullerènes C58Si2 Si-C Heterofullerenes (C60)13 - Si2 Icosahedral edifice Ä Original electronic structures, différent from the bulk-Si one, mainly due to the presence of large numbers of pentagonal rings Ä Large quasi direct gap (~ 1.6 to 2 eV) , photoluminescence Ä Applications to nano electronics / opto-electronics (*) See : P. Mélinon et al., in "Clusters as precursors of nano objects", Eds C. Brechignac et al., Comptes Rendus de Physique, 3 (2002) pp. 273-288. CLUSTER DIFFUSION AND TRAPPING AT DEFECTS ¬ Application to the preparation of 2D-organized arrays of cluster-assembled dots Au750-clusters on HOPG at 300K Trapping at step edges 1μm 1μm Au750-clusters on ion-irradiated HOPG at 300 K * Ar+-1,5 keV 25 nm 1μm ¬ KINETIC MONTE CARLO (KMC) SIMULATIONS Ballistic model DDA (Deposition – Diffusion – Aggregation)(*) Experiment : ¬ 10-2 ML of Au750-clusters deposited on FIB-functionalized HOPG at 373 K Distance between defects : 300 nm KMC-Simulation considering : ¬ Diffusion of incident clusters and compact islands with sizes up to 20 clusters. ¬ No evaporation ¬ Introduction of specific trapping sites (¦) with irreversible sticking (ideal traps) (*) See : P. Jensen, Rev. Mod. Phys., 71, 1695 (1999). SUMMARY OF KMC-SIMULATIONS Nislands / functionalized substrate (Nisl/fs) Ndefects / functionalized substrate (Ndef/fs) 100 1 Existence of islands between defects All islands are Created on defects N isl / fs / N def / fs No creation of Cluster - islands between defects 10 100 80 60 40 1 20 0.1 0.01 0.1 1 N isl / non-fs / N def / fs 10 0 Mean size of of islands (number of clusters) All defects must be occupied COMPETITION BETWEEN 2 KINETIC PROCESSES ¬ capture at defects and nucleation outside of defects Lisl / non-fs h 2 characteristic lengths : Mean distance between islands on virgin substrates (non-functionalized) , Cluster-cluster aggregation kinetic ~ (F/D)Х with Х = - 1/6 Ldef / fs : Mean distance between defects on functionalized substrates , define the mean time for a diffusing cluster to be captured at a defect ~ (Ldef / fs)2 / D h "Growth on defects" regime (Ldef / fs << Lisl / non-fs) , A diffusing clusters is captured at a defect before meeting another cluster to form an island , filling of defects by a Poisson law , Lowest island-size = 5 clusters h Other regimes (Ldef / fs >> Lisl / non-fs) , Nucleation outside of defects is preponderant ADJUSTMENTS OF THE PARAMETERS OF THE 2D - ARRAYS ¬ Lattice parameter : Ldef / fs h Adjustment of Ldef / fs , Adjustment of Ndef / fs h Adjust. of F (cluster fluence) h Adjust. of D (diffusion coeff., T-dependent) Adjust. of Nisl / non-fs ~ (F / D) Nisl / non-fs Ndef / fs χ (χ= 1/3) << 1 ¬ Mean Island size h Defects = exclusive nucleation centres h Above tc, islands grow by capture of clusters t = tc t > tc ¬ Nanoparticle morphology h Compact rather than ramified Annealings : activation of the ramified / compact transition i.e. Au-clusters – 150 °C 1 hour in situ in the TEM ¬ Nature of the clusters h General behaviour of LECBD films whatever is the nature of the clusters Au-clusters / HOPG Sb-clusters / HOPG Co-clusters / HOPG MAGNETIC NANOSTRUCTURES FROM CLUSTERS 1- Pure cobalt clusters(*) X-rays diffraction at grazing incidence on a 80 nm thick Co-cluster film deposited on a Si-substrate at 300K * Incident free clusters : Co300 ⇒ Φ ≈ 2 nm TEM-image fcc-Co fcc-Co 1 nm Fourier transform of the X-rays absorption spectrum (EXAFS) Nearest neighbours fcc-cobalt cluster * Truncated octahedron * Diameter ≈ 3 nm ⇒ 1388 atoms 1 → Co-Co core (d ≈ 0.25 nm) [001] 2 → Co-Co surface (d ≈ 0.26 nm) 3 → Co-0 surface (d ≈ 0.22 nm) [100] [010] (*) See i.e. J. TUAILLON et al., Phil. Mag., 76, 493 (1997). MAGNETIC PROPERTIES OF ONE INDIVIDUAL Co-CLUSTER (*) Using the microSQUID technique developed at LLN - Grenoble μ0 Η y Highest sensitivity obtained with the Co-cluster embedded in the Nb-film at a micro-bridge : ⇒ ≈ 10-17 emu ⇒ ≈ 103 Bohr-magneton ⇒ ≈ One Co-cluster with Φ ≈ 3 nm Hz (T) Hx (T) Hy (T) 1 μm 1 μm μ0 Η x 1 μm micro-bridge junctions cluster Cluster 20 nm 200 nm Niobium loop 9 3D-switching field distribution measured at 35 mK for a Co-cluster : Φ ≈ 3 nm ⇒ ≈ 1000 Co-atoms ⇒ 2 anisotropy axes : - Hard // Hy - Easy // Hz Hz (T) Simulation using the StonerWohlfarth uniform rotation model : E(m)/V = - K1mZ2 + K2mY2 ⇒ K1 = 2.1 105 J/m3 ⇒ K2 = 0.5 105 J/m3 Hx (T) Hy (T) (*) See : M. JAMET et al., Phys. Rev. Lett., 86, 4676 (2001). EVOLUTION WITH TEMPERATURE 2D-switching field distributions in the yz-plane measured at different temperatures 0.3 0.04 K T B - 14 K 1K 0.2 2K 0.1 8K 12 K μ0 μ0Hz (Tesla) 4K 0 -0.1 -0.2 -0.3 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 μ0Hy (Tesla) ⇓⇓⇓⇓⇓ Blocking temperature TB ≈ 14 K for a Co-cluster (Φ ≈ 3 nm) MIXED COBALT – SAMARIUM CLUSTERS(*) h High magnetic anisotropy Ä High blocking temperature (~ 400 K) h Applications to high density memory devices and spin electronics Deposited on a-C at 300K Annealed in UHV at 570 °C 1.27 Å 2.09 Å 2.92 Å 1.07 Å 1.82 Å 2 nm 15 nm 100 Φ ≈ 3.5 nm 80 60 40 20 0 0 1 2 3 4 5 Diamètre (nm) 6 Diameter (nm) 7 8 Nombre de particules 120 Number of particles of particles Number Nombre de particules 10 nm 80 70 Φ ≈ 6 nm 60 50 40 30 20 10 0 0 2 4 6 8 10 12 14 Diamètre (nm) Diameter (nm) (*) See M. NEGRIER et al., Europ. Phys. J. D, 9, 475 (2000). MAGNETIC PROPERTIES OF MIXED Co-Sm CLUSTERS Magnetization measurements As deposited at 300 K Annealed at 770 K 1.5 300 K 20 K 1 0.5 20 K 0 300 K -0.5 -1 -1.5 -3 -2 -1 0 1 2 3 Magnetic field (kOe) Normalized magnetization : M/Ms Normalized magnetization : M/Ms 1.5 300 K 20 K 1 0.5 20 K 0 300 K -0.5 -1 -1.5 -3 -2 -1 0 1 2 3 Magnetic field (kOe) Annealed at 840 K Normalized magnetization : M/Ms 1,5 Nanosize clusters (Φ ≈ 5 nm) magnetically blocked at T > 300 K. 300 K 20 K 1,0 0,5 20 K 0,0 *Problem of the segregation of 300 K -0,5 -1,0 -1,5 -3 -2 -1 0 1 Magnetic field (kOe) 2 3 samarium at the cluster surface. *Recrystallisation after annealings (Sm-Nb non-miscible). SURFACE CONTAMINATION XPS-measurements (O1s-level) on Gd2O3:Eu3+-cluster films Intensity (a.u.) 5 Presence of hydroxide pollution (c) - Bulk hydroxide sample : Gd2(OH)3 4 (b) - Cluster film transferred in air and subsequently annealed for ½ hour at 300 °C 3 2 (a) - As deposited cluster-film transferred in air 1 0 526 528 530 532 534 Binding energy (eV) 536 STRUCTURE ¬ Phase transition in the low cluster-size range as observed from cathodoluminescence spectra of Eu3+-impurities Cathodoluminescence measurements (using e- 4 keV) in situ in UHV on 10 nm-thick Gd2O3:Eu3+-cluster films deposited on Si-passivated substrates Mean cluster-size 3.2 nm Mean cluster-size 2.5 nm 0,8 0,8 0,6 0,6 Cluster film (Ф ≈ 2.5 nm) u.a. 1,0 u.a. 1,0 Cluster film (Ф ≈ 3.2 nm) 0,4 0,4 Bulk cubic-phase 0,2 0,2 0,0 0,0 Bulk monoclinic-phase 600 610 620 630 640 600 610 w avelength (nm ) 620 630 640 w avelength (nm ) Cubic monoclinic Transition pressure at room temperature for the bulk phase ~ 2 GPa ¬ Possibility of a phase transition at low cluster-size (~2 nm) SIZE EFFECT ON THE PHOTOLUMINESCENCE PROPERTIES Particular Case of Y2O3:Ce3+ Nanocrystals Bulk materials ¬ e--delocalization ¬ Confinement effects F Widening of the gap No luminescence ¬ Luminescence of Ce3+ ? CB Ce 5d CB Ce 5d X Ce 4f ? Ce 4f VB M.Raukas et. al. Appl. Phys. Lett. 69, 3300 (1997). D.Jia et. al. Phys. Rev. B 69, 235113 (2004). VB PHOTOLUMINESCENCE MEASUREMENTS ¬ VUV-Synchrotron radiation at DESY ¬ Sample : Y2O3:Ce3+ (1 %) ¬T = 10 K Appearance of an emission band probably due to Ce3+-impurities Nanocrystals Ce 5d Emission spectra Normalized intensity (a.u.) CB ? Ce 4f VB Excitation spectra Intensity (a.u.) 1,0 <d> = 3 nm 0,8 <d> = 30 nm 0,6 Bulk 0,4 0,2 0,0 <d> = 9 nm 0,8 1,0 250 <d> = 30 nm 0,4 0,2 0,0 180 Bulk 190 200 210 220 Wavelength (nm) 230 350 400 450 500 550 600 650 Wavelength (nm) <d> = 15 nm 0,6 300 240 Excitation at 200 nm Type : Self-Trapped Exciton emission