Liebert XDF Water-Cooled Product Application Guidelines

advertisement

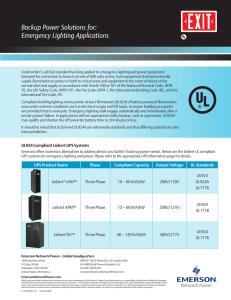

Liebert® XDF Water-Cooled Product Application Guidelines To ensure successful installation and proper operation of the Liebert XDF water-cooled unit, please adhere to the guidelines below. If questions remain after reviewing these guidelines, please contact Emerson Network Power, at 1-800-222-5877 to speak with an application specialist. Application Question If water is used as the coolant, what type of system/loop should be used? Requirements Liebert recommends employing a closed-loop system (e.g. a cooling tower). Comments This model employs a brazed plate condenser. A closed water supply system protects the Liebert XDF from particles and other contaminants that might reduce cooling efficiency and damage the XDF. Will any external piping be required with this system and what are the requirements? The unit will have to be connected to a water source with a flow of at least 15 gallons per minute (GPM) through the condenser to ensure the system’s ability to operate at its full capacity. The correct piping size must be selected to ensure proper flow. The installing contractor will determine the appropriate piping size. Can a water-based coolant be used if the building doesn’t have a closed-loop water source? Yes, a drycooler and pump package is available to create a closed-loop split system. The drycooler will require installation on a solid surface (typically a concrete pad or roof; refer to local code). Please reference the Liebert Drycooler user manual (SL-10058) available at www.liebert.com for additional detail. If the drycooler and pump package are employed, how far can the drycooler be installed from the Liebert XDF? The distance between the Liebert XDF and drycooler will be impacted by the piping size and number of bends. Utilizing 1¼” L copper tubing, the drycooler could be placed up to 150 ft from the XDF. The installing contractor will determine the appropriate piping size and drycooler location. What is an acceptable coolant temperature range for the Liebert XDF? A fluid temp between 50-85°F is recommended. The unit is designed for a maximum inlet temp of 115°F, but temperatures above 85°F will begin to reduce the Liebert XDF’s capacity. If glycol is desired, the percentage of glycol is determined by the local winter ambient design requirements. Please reference the Liebert XDF user manual (SL-17010) available at www.liebert.com for additional detail. At what ambient temperature can the Liebert XDF operate effectively? The ambient temperature should be between 35°F and 104°F. Ambient temperature will affect the capacity of the Liebert XDF. Temperatures above 95°F begin to reduce the XDF’s capacity. Liebert XDF Water-Cooled Product Application Guidelines 1 SL-17008_Rev1_06/08 Liebert® XDF Water-Cooled Product Application Guidelines Application Question Can the unit be operated in a highhumidity environment? Requirements The unit may be operated anywhere from 20% RH to 80% RH. Comments High humidity will impact the cooling capacity of the Liebert XDF. Conditions with a dew point above 60°F (31% RH at 95°F, or 60% RH at 75°F) will begin to reduce the XDF’s sensible cooling capacity. How will condensate be removed? Condensate created via the cooling process should be fed into a gravity drain or pumped away with an optional, factoryinstalled condensate pump. The condensate pump will increase the distance the condensate can be run from the unit to approximately 30 horizontal feet and/or 12 vertical feet. Should cable entrances be sealed? Yes, cables entrances should always be sealed. If cable entrances are not sealed, air infiltration will adversely affect unit performance and allow contaminants inside the cabinet. What is the minimum room size in which the Liebert XDF should be operated? The smallest acceptable room dimensions based on 36” service clearances on the side, top, front and rear are: • 10’D x 5’10”W x 9’10”H • 574 cubic feet The volume of the room will impact the back-up ventilation time. Refer to the table on page 3 for more information. In what type of environment can the Liebert XDF be operated? Environments containing caustic or explosive vapors are not acceptable for this product. The backup ventilation mode of the Liebert XDF will circulate room air through the cabinet. What equipment heat load can this unit accommodate? The equipment load should be between 3 kW and 14 kW. Equipment load will also impact back-up ventilation time. Refer to the table on page 3 for more information. What is the power requirement for this unit? Two power connections are required: • 120/208V 3-ph (NEMA L21-30P), and • 120V 1-ph (NEMA 5-15P) Please ensure 3-ph power (4 wires + ground) is available to the room in which the Liebert XDF will be located. How much sound will the Liebert XDF make? The sound level of the Liebert XDF water cooled unit is 79 dBA (quieter than a fully configured IT rack). The water-cooled Liebert XDF has a lower sound level than the self-contained, air-cooled Liebert XDF (79 dBA compared to 86 dBA) and is recommended for applications in which people are working full-time in the same area. How will I be able to control and monitor my Liebert XDF? Liebert XDF comes standard with an iCOM monitor and control module. An optional webcard can be ordered for remote viewing and control via SNMP. Liebert XDF Water-Cooled Product Application Guidelines 2 SL-17008_Rev1_06/08 Liebert® XDF Water-Cooled Product Application Guidelines Application Question What type of backup power is recommended to be used with this unit? Requirements A true on-line, doubleconversion UPS is recommended. Comments It is recommended that the Liebert XDF 1-ph power connection be plugged into UPS backup power to ensure the backup ventilation system allows ample time for safe automated shutdown of IT equipment in the event of an outage. Backup Ventilation System The back-up ventilation system in the Liebert XDF circulates room air through the XDF cabinet in case of a power failure or interruption of cooling inside the XDF. The size of the room, the temperature of the room, and the heat load inside the XDF all affect the amount of back-up ventilation time available. The table below contains estimates of the time until the internal rack equipment reaches 95°F (with back-up ventilation running and XDF cooling off). Room Volume (Cubic Feet) 1,200 2,400 5,000 7,500 10,000 6 kW Load 2 minutes 4 minutes 8 minutes 12 minutes 15 minutes 10 kW Load 1 minute 2 minutes 5 minutes 7 minutes 9 minutes 14 kW Load 45 seconds 1.5 minutes 3 minutes 5 minutes 6 minutes NOTE - The following assumptions apply: • Liebert XDF controls and internal fans continue to run during back-up ventilation. This may require that they be powered from a separate back-up power source. This back-up power source must have sufficient run time. • The temperature in the room is 75° F when back-up ventilation begins operating. • No cooling is done by the building system during the back-up ventilation. If the building cooling system continues to run during backup ventilation, the time to reach 95°F will be longer. Additional Information Additional information related to specifying, engineering, and installing a Liebert XDF cooling solution is available in the following documents. The documents can be accessed at www.liebert.com by entering the SL number listed below into the search bar: • Liebert XDF User Manual, SL-17010 • Liebert XDF Guide Specification, SL-17015 • Liebert Drycooler User Manual, SL-10058 Liebert XDF Water-Cooled Product Application Guidelines 3 SL-17008_Rev1_06/08