Full migration to the state-of-the-art

SPPA-T3000 Control System makes

Tent A5 future-proof

Reference – Control System

Instrumentation, Controls & Electrical

Full migration from SPPA-T2000 to

SPPA-T3000 Control System

which is the latest control system generation

and makes unit A5 of the Nikola Tesla A power

plant fit for future operation.

The Result

■ Smooth migration to the

latest control system

generation SPPA-T3000

■ Simplified plant operation

thanks to easy-to-use and

flexible HMI

■ Maximum investment

protection through

retaining existing control

system components

■ Reuse of the replaced

SPPA-T2000 components

as spare parts for Tent A3

and TEK A5

The Plant

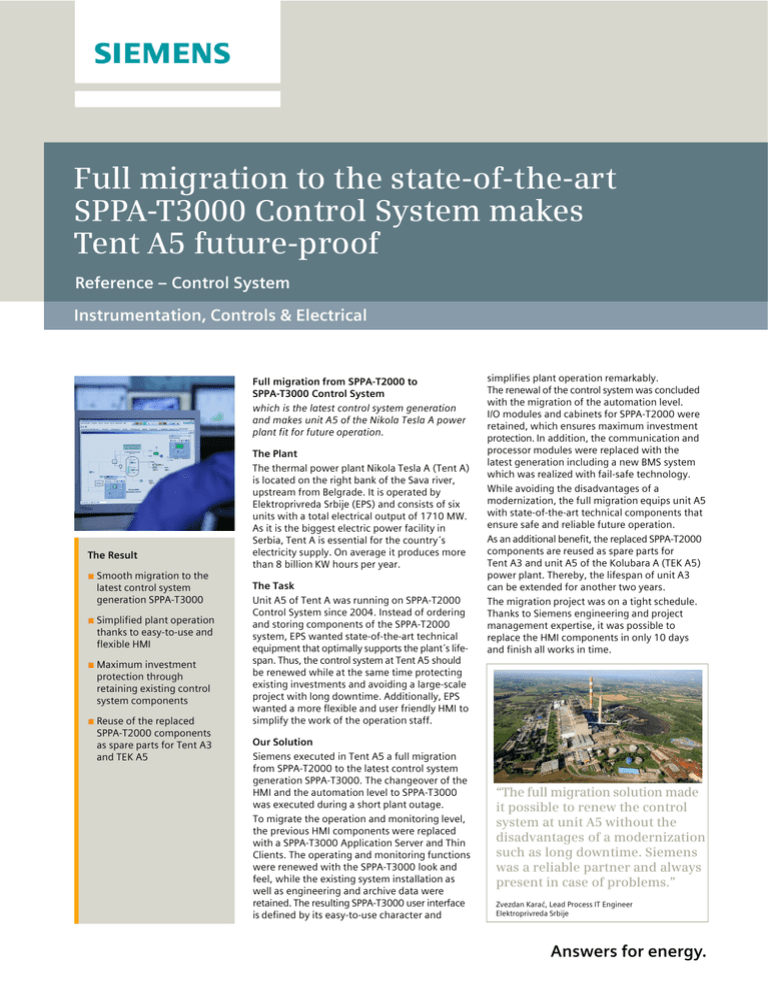

The thermal power plant Nikola Tesla A (Tent A)

is located on the right bank of the Sava river,

upstream from Belgrade. It is operated by

Elektroprivreda Srbije (EPS) and consists of six

units with a total electrical output of 1710 MW.

As it is the biggest electric power facility in

Serbia, Tent A is essential for the country´s

electricity supply. On average it produces more

than 8 billion KW hours per year.

The Task

Unit A5 of Tent A was running on SPPA-T2000

Control System since 2004. Instead of ordering

and storing components of the SPPA-T2000

system, EPS wanted state-of-the-art technical

equipment that optimally supports the plant´s lifespan. Thus, the control system at Tent A5 should

be renewed while at the same time protecting

existing investments and avoiding a large-scale

project with long downtime. Additionally, EPS

wanted a more flexible and user friendly HMI to

simplify the work of the operation staff.

Our Solution

Siemens executed in Tent A5 a full migration

from SPPA-T2000 to the latest control system

generation SPPA-T3000. The changeover of the

HMI and the automation level to SPPA-T3000

was executed during a short plant outage.

To migrate the operation and monitoring level,

the previous HMI components were replaced

with a SPPA-T3000 Application Server and Thin

Clients. The operating and monitoring functions

were renewed with the SPPA-T3000 look and

feel, while the existing system installation as

well as engineering and archive data were

retained. The resulting SPPA-T3000 user interface

is defined by its easy-to-use character and

simplifies plant operation remarkably.

The renewal of the control system was concluded

with the migration of the automation level.

I/O modules and cabinets for SPPA-T2000 were

retained, which ensures maximum investment

protection. In addition, the communication and

processor modules were replaced with the

latest generation including a new BMS system

which was realized with fail-safe technology.

While avoiding the disadvantages of a

modernization, the full migration equips unit A5

with state-of-the-art technical components that

ensure safe and reliable future operation.

As an additional benefit, the replaced SPPA-T2000

components are reused as spare parts for

Tent A3 and unit A5 of the Kolubara A (TEK A5)

power plant. Thereby, the lifespan of unit A3

can be extended for another two years.

The migration project was on a tight schedule.

Thanks to Siemens engineering and project

management expertise, it was possible to

replace the HMI components in only 10 days

and finish all works in time.

“The full migration solution made

it possible to renew the control

system at unit A5 without the

disadvantages of a modernization

such as long downtime. Siemens

was a reliable partner and always

present in case of problems.”

Zvezdan Karać, Lead Process IT Engineer

Elektroprivreda Srbije

Answers for energy.

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-t3000.energy@siemens.com

www.siemens.com/energy/sppa-t3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

T3_FR_Full Migration-T2-T3_Tent A5_e_V1-0

Order no. E50001-G230-A366-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.