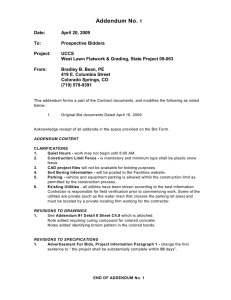

ADDENDUM No. 01 TO THE BIDDING AND CONTRACT DOCUMENTS FOR

advertisement

ADDENDUM No. 01 TO THE BIDDING AND CONTRACT DOCUMENTS FOR THE PROJECT: UCCS University Hall Remodel, Simulation Lab LKA PROJECT NO. 09.028 DATE: 05 December 2011 THE ARCHITECT: THE LKA PARTNERS, INC. 430 NORTH TEJON STREET - SUITE 208 COLORADO SPRINGS, COLORADO 80903 THE FOLLOWING shall become as fully a part of the above named Bidding and Contract Documents as if included and shall take full and complete precedence over anything stated or shown to the contrary in them. ACKNOWLEDGMENT: Each bidder shall indicate in the place provided on the Bid Form acknowledgement of receipt of this Addendum. EACH AND EVERY BIDDER, subcontractor and material supplier shall be responsible for reading each and every item in this Addendum to ascertain the extent and manner it affects the work in which he is interested. The Addendum items may not be listed in the same order that they occur on the Drawings or in the Project Manual. 1 A. PROJECT MANUAL.BIDDING REQUIREMENTS, CONTRACT FORMS AND CONDITIONS OF THE CONTRACT No Changes B. PROJECT MANUAL / SPECIFICATIONS SECTION 08 81 00 Glazing 2.02 GLASS TYPES Delete existing paragraph 2.02 in its entirety and replace with the following TYPE DESCRIPTION AT 1/4“ clear tempered BT 1/4“ Viracon “Optigray” monolithic tempered glass with perforated window film. Film shall be Koroseal Perforated Vinyl Window Film, or equivalent of other manufacturer. 1. Thickness: 5.8 mil. 2. Open area: 30% 3. Adhesive: Removable acrylic based clear adhesive 4. Flammability: M1 and B1 certified. 5. Pattern and Color: patterns shall be from digital image provided by the Owner. Color of film shall be white on image side, black side applied to glass SECTION 23 81 29 VARIABLE REFRIGERANT FLOW AIR-CONDITIONING Add the following paragraphs: 2.06 E 3. The following operation/settings shall be provided by the Campus EMCS: Request all Off (Emergency Stop) Request On/Off Setpoint Request Lossnay Mode Request Fan Speed Filter sign reset Request Local Prohibit On/Off, Mode, and Filter Sign Filter Sign Reset Request Limit Temperature Setting Range Ventilation Mode 2 2.06 E 4. The following points shall be measured/monitored by the Campus EMCS: Emergency state On/Off run state Mode state Setpoint state Lossnay mode state Fan Speed state Filter status Space Temperature Alarm state Error Code Ventilation Mode C. DRAWINGS SHEET TS1.1 Title Sheet At the Door Elevation, at the word “glazing” add the words “type AT” SHEET A2.1 Partial Floor Plan Add the note: NOTE: SEE SHEET P1.1 FOR THE LOCATION OF SANITARY SEWER PIPING. IF PENETRATION OF THE EXISTING LOWER 4” CONCRETE SLAB IS REQUIRED, PATCH AND REPAIR EXISTING VAPOR BARRIER AND SLAB TO MATCH EXISTING CONDITIONS, REINSTALL GRAVEL AND INSTALL NEW 4” SLAB ON TOP TO MATCH EXISTING. At MED ROOM/170F and at AV ROOM/1S-2 delete the finish schedule remark (2) SHEET A3.1 Reflected Ceiling Plan Ceiling Legend: revise the note, “AREAS OF CEILING PANEL REPAIR: PROVIDE (N) GRID & ACOUSTICAL CLG PANEL TO CMPLETE CLG.” To read, “AREAS OF CEILING REPAIR: PATCH WITH CEILING WITH SALVAGED, EXISTING GRID AND ACOUSTICAL TILES.” SHEET A8.1 Casework and Interior Elevations At the Equipment Schedule, item <E29>, change the manufacturers name from Metro to Pocket Nurse and change the item number from 02-25-257W to 02-25-257M SHEET A9.1 General Building Details At the Hollow Metal Frame Elevations, at the note “glazing type BT” to frame elevations HM2 and HM3 Replace detail 18/A9.1 with the attached detail 18/A9.1 on sheet A9.1.1 3 SHEET M1.1 MECHANICAL PLANS Add General Note 3 as follows: Tie variable refrigerant flow air-conditioning and ventilation control systems into existing Setpoint Systems Corporation (303-733-2300) building management system via BACnet interface. SHEET E0.1 Electrical Legend Remove General Note #8. See attached sheet E0.1.1 SHEET E1.1 Lighting & Fire Alarm Plan Add ceiling mounted occupancy sensors/relays in Simlab control rooms. See sheet E1.1.1 Specify a circuit number on panel L for the new lighting circuit as L-30. See sheet E1.1.1 Edit Keynote #5 to provide a new breaker for the new lighting circuit. See sheet E1.1.1 SHEET E2.1 Power & Signal Plan Change receptacles in Sim 1 to GFCI near sinks. See sheet E2.1.1 Change receptacles in Sim 3 to GFCI near sinks. See Sheet E2.1.2 Add receptacle for EMS monitor on west wall of control room. See Sheet E2.1.1 Add junction box for automatic sink power in Sim 3. See Sheet E2.1.2 Remove monitor receptacle on southwest wall in Briefing Room 135. See Sheet E2.1.2 Edit Keynote #6 to include specific information regarding transformer size and fusing. See Sheet E2.1.2 SHEET E4.1 Electrical Schedules Add the new lighting circuit information into existing Panel L; add note to provide new circuit breaker. See sheet E4.1.1 SHEET T0.2 TECHNOLOGY SCHEDULES/LEGENDS SHEET Add the following Project Notes: X REFER TO SHEET ED.1, PARTIAL ELECTRICAL DEMOLITION PLAN, FOR LOCATIONS OF EXISTING DATA OUTLETS TO BE REMOVED. REMOVE EXISTING FACEPLATE, BOX, CONDUIT, AND CABLING. REMOVE CABLING ALL THE WAY FROM OUTLET BOX BACK TO EXISTING TELECOM ROOM. REFER ALSO TO SPECIFICATION 27 17 30, COMMUNICATIONS – DEMOLITION. Y REMOVE ALL UNUSED COMMUNICATIONS HANGERS, CABLE TRAY, AND SUPPORTS ABOVE EXISTING CEILINGS IN ALL AREAS OF DEMOLITION. DO NOT REMOVE ANY WHICH MAY BE SUPPORTING EXISTING CABLING THAT WILL REMAIN TO SERVE ADJOING SPACES THAT ARE OUTSIDE THE AREA OF WORK. 4 D. APPROVAL OF MATERIALS AND MANUFACTURED ITEMS SECTION 23 72 00 ENERGY RECOVERY VENTILATORS Add paragraph 2.02.A.8. Daikin AC (Americas), Inc. END OF ADDENDUM No. 01 5