ARTICLE IN PRESS

Journal of Physics and Chemistry of Solids 68 (2007) 866–872

www.elsevier.com/locate/jpcs

Ag-photodoping in Ge-chalcogenide amorphous thin films—Reaction

products and their characterization

M. Mitkovaa,, M.N. Kozickib

a

Department of Electrical & Computer Engineering, Boise State University, Boise, ID 83725-2075, USA

b

Center for Solid State Electronics Research, Arizona State University Tempe, AZ 85287-6206, USA

Abstract

We make a brief review on the effect of silver photodiffusion in Ge-chalcogenide glasses and report some of our recent results in this

aspect. Using Raman spectroscopy and X-ray diffraction analysis we demonstrate that the hosting backbone undergoes depletion in

chalcogen due to the specific conditions of photodiffusion and the diffusion products are silver chalcogenides. While in the Ge–Se system

preliminary binary Ag—chalcogenides are forming, in the Ge–S system formation of Ag2 GeS3 is evidenced. This effect is related to the

ability of the Ge–S glasses to form ethane—like structure at much lower Ge concentration than the Ge–Se glasses. For this type of

structures is known that Ag replaces Ge to form homogeneous material, hence formation of Ag-containing ternary occurs.

r 2007 Elsevier Ltd. All rights reserved.

Keywords: A. Chalcogenides; A. Nanostructures; C. Raman spectroscopy; C. X-ray diffraction

1. Introduction

2. Nature of the photodoping process

Silver photodiffusion—accelerated silver diffusion under

the action of light is a unique feature of chalcogenide

glasses. Ever since this effect was first encountered [1] it has

been profoundly investigated because it can be used in

many applications of chalcogenide glasses. We are using

this process to form the active material—the solid

electrolyte based on silver doped chalcogenide glass—for

the programmable metallization cell (PMC) two terminal

memory devices which have an electrode made from Ag

and the other being electrochemically inert (W, Ni Pt, etc.)

[2]. At application of a bias with positive voltage towards

the Ag electrode formation of a robust but reversible

conducting pathway by way of electrodeposition at low

voltage and current reduces the resistance of the electrolyte

by several orders of magnitude. In this manner non-volatile

memory is realized in elements that are highly electrically

and dimensionally scalable.

Our understanding is that the process of photodiffusion

is driven by the formation of charged defects in the

chalcogenide glass, which form by illumination with light

and create an electrical potential. The light that is critical

for metal photodissolution is absorbed at or near the

interface between the reacted and unreacted (doped and

undoped) chalcogenide layers [3,4]. In this process,

electrons are trapped by silver ions [5,6], while holes move

further into the chalcogenide film and are trapped there.

The electric field formed by the negatively charged

chalcogen atoms and positively charged silver ions can be

sufficient for the silver ions to overcome the energy barrier

at the interface. Therefore the penetration of the metal into

the chalcogenide during photodoping is due to the

difference in electrochemical potentials and the process

was considered to be similar to that occurring in a galvanic

cell, where the more electropositive metal is dissolved into

the electrolyte [7].

Kluge [8] considered the process of photodiffusion of

metals in chalcogenides as an intercalation reaction. The

main reason this can be realized in chalcogenide glasses is

the fact that they possess relatively rigid covalent bonds

Corresponding author. Tel.: +1 208 426 3395; fax: +1 208 426 2479.

E-mail address: MariaMitkova@boisestate.edu (M. Mitkova).

0022-3697/$ - see front matter r 2007 Elsevier Ltd. All rights reserved.

doi:10.1016/j.jpcs.2007.01.004

ARTICLE IN PRESS

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

mixed with soft van der Waals interconnections. This type

of structure ensures formation of voids and channels where

the diffusing ions can migrate and can be hosted. The

reaction can be efficient when the reversible transport of

ions and electrons can be achieved, accompanied by

formation of bonds with the host matrix, according to

the reaction:

suggest that the kinetics of the diffusion process is highly

influenced by free space availability in the chalcogenide

matrix and the chemical reaction between S and Ag in the

case of sulfur-rich glasses. When Ge rich glasses are

considered, the photodiffusion rate could be related to the

formation of the number of chemically active photo excited

localized centers [20].

(1)

This reaction describes the transition of an initially twofold

covalently bonded chalcogenide atom ðC02 Þ into a C

1

charged unit possessing only a single covalent bond and an

excess electron that establishes an ionic bond with

Agþ ðMþ Þ. Eq. (1) shows the importance of the potential

þ

in forming the new C

bonds of the intercalation

1M

product. The possible number of these bond-units is fairly

high as the chalcogenide glasses are capable of forming a

number of single C

1 centers under the influence of light

illumination. Once silver is introduced into the chalcogenide glass, its further migration into the chalcogenide glass

continues.

The photodiffusion kinetics depends on a number of

factors such as light intensity [9], light wavelength [10],

temperature [11], pressure [12], external electric field [13],

composition of the hosting glass [14], and the atmosphere

in which the diffusion process is performed [15]. Many

details in this respect are given in the work of Kolobov and

Elliott [16]. In this review, we will specifically discuss the

data concerning Ge-chalcogenide systems.

3. Silver photodiffusion in the Ge–S system

3.1. Basic data

The most profound investigation of silver diffusion in

sulfur-rich Ge glasses has been made by Oldale and Elliott

[17]. They have found that the Ag photo-dissolution rate in

a-Ge29 S71 has no induction period and the process has 2

stages—phase 1, which is an acceleratory stage leading to a

maximum in the photodissolution rate, and phase 2, a final

deceleratory stage. As the time to develop the acceleratory

stage shows a spectral dependency, it is obvious that the

absorption of actinic radiation in the photodoped film is

responsible for this stage of the photodissolution kinetic

profile. Maruno and Ban [18] reported that when the silver

film is deposited on previously illuminated Ge30 S70 film, the

diffusion process proceeds very slowly. Speculations are

made upon the changes in the structure of the chalcogenide

film due to the light illumination. However, we assume that

oxidation of the chalcogenide film during the initial

illumination could also be responsible for the occurrence

of this effect. The defects that can be created by

illumination are indeed the driving force for the oxidation

process.

Kawaguchi and Maruno [19] obtained very important

data about the compositional dependences on the initial

photodoping rate and photodoping kinetics. Their data

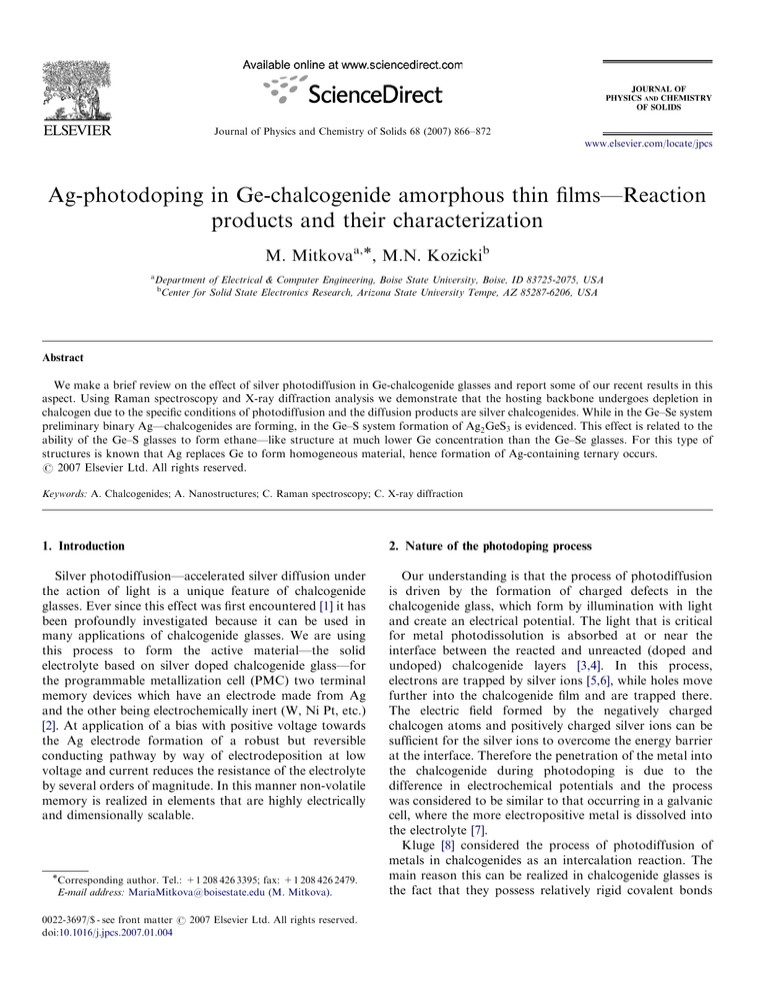

3.2. XRD data generated in our research

We contributed with some research related to GeS2

photodiffused with Ag [21] towards further understanding

of what the diffusion products are and how diffusion

affects the hosting backbone, combined with data about

the influence of annealing at 150, 300 and 430 C since in

the real world of application, the glasses are usually

processed at similar temperatures. The X-ray diffraction

(XRD) spectra of photodiffused films are shown on Fig. 1

(a)–(d). As shown on the figure diffusion products are Ag2 S

and Ag2 GeS3 and only during annealing at 430 C

Ag8 GeS6 forms. The most impressive result of this

experiment is the fact of a fast growth of the diffusion

products during annealing. The studies of the density of

Ge–S glasses show that the stoichiometric composition

GeS2 is expected to have the highest density [22]. However,

the real composition of the backbone after introduction of

Ag is much more Ge rich because of the reaction of Ag

with the negatively charged defects and it is expected to

have much lower density. This easily allows formation of

channels, which, because of the low polymerization, can

offer substantial space where the Ag containing phase is

located. Numerical simulations of the structure also suggest

their existence [23]. Therefore, we believe this enables

introduction of high amount of Ag and the rapid growth

^

+

+

Intensity (Arb. units)

þ

C02 þ e þ Mþ ! C

1M .

867

430 C

300 oC

*

20

d

+

*

*

+

*

150oC

RT

*

* ^ *

o

+

* **

30

+

+

+

+

+

40

2 Theta (Deg.)

+

c

+

b

**

**

a

50

Fig. 1. XRD data for: (a) photodiffused Ge–S film; (b) photodiffused

Ge–S film annealed at 150 C; (c) photodiffused Ge–S film annealed at

300 C; (d) photodiffused Ge–S film annealed at 430 C; * denotes

appearance of Ag2 GeS3; þ denotes appearance of Ag2 S; ˆ denotes

appearance of Ag8 GeS6 . Figure taken from Balakrishnan et al. [21].

ARTICLE IN PRESS

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

Ge-Ge bond vibration

(ethane-like structure)

1.0

d

0.5

0.0

1.0

c

0.5

Intensity (Arb. units)

Intensity (Arb. units)

symmetric stretch of Ge(S1/2)4

tetrahedra

clu

mo ster

de ed

g

1.0

e

Sclu S str

ste etc

r e h fr

dg om

ed

im

ers

868

0.0

200

400

300

Rel. Wavenumber (cm-1)

0.5

0.0

1.0

b

0.5

500

Fig. 2. Raman spectra for pure Ge–S films at room temperature. Figure

taken from Balakrishnan et al. [21].

0.0

1.0

a

0.5

of the diffusion products through agglomeration of the

nanoclusters as established by the XRD data—Fig. 1(a)–(d).

3.3. Raman data generated in our research

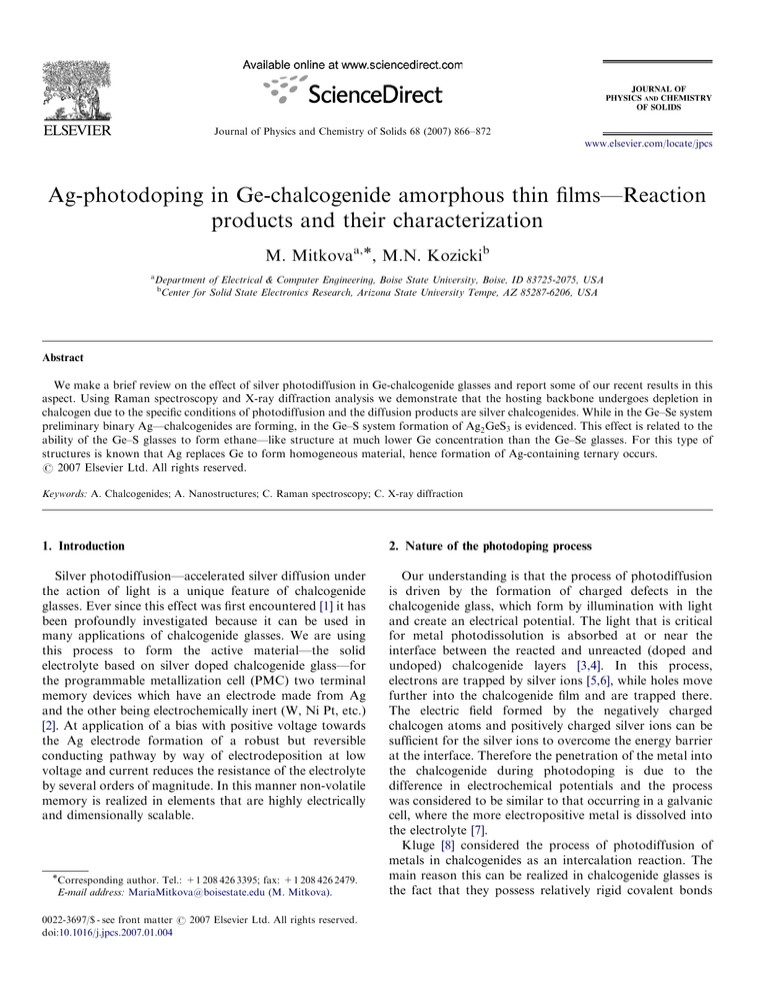

The Raman results for pure Ge–S films Fig. 2 taken from

[21] show appearance of relatively high intensive mode at

343 cm1 of the A1 symmetric stretch of GeðS1=2 Þ4 [24]

combined with scattering at 370 and 427 cm1 from the

edge sharing structures. There is a well resolved peak at

252 cm1 corresponding to the vibrations coming from the

ethane like structures available in glasses containing more

than 33 at% Ge [25]. The deconvolution of the Raman

modes between 340 and 440 cm1 manifests formation of a

peak at 427 cm1 . We believe that this signal occurs from

the vibrations of the S chains available due to formation of

wrong bonds in these glasses. The variety of building

blocks forming this film is indication for the specific

structure that develops in the Ge–S system. Boolchand

et al. [26] have demonstrated that the formation of ethanelike structural units containing Ge–Ge bonds starts at the

stoichiometric composition GeS2 . On grounds of stoichiometry an equivalent number of S–S bonds are available.

This is a very rare case in chalcogenide glasses in which

almost all possible building blocks emerge in one composition. The implication of this effect is that upon illumination

metastable states [27] occur on sulfur atoms with different

surroundings.

When Ag is photodiffused in the Ge–S glass, well

expressed changes occur in the Raman activity of the newly

formed material, (Fig. 3(a)). One observes intensity growth

of the mode at 250 cm1 , indicating formation of a higher

number of ethane like structural units. Meanwhile, the

relative intensity of the mode at 343 cm1 is reduced, and

the vibrations at 370 and 400 cm1 strengthen. We

attribute the latter modes to development of thiogermanate

0.0

200

300

400

500

Rel. Wavenumber (cm-1)

Fig. 3. Raman spectra for: (a) photodiffused Ge–S film at room

temperature; (b) photodiffused Ge–S film annealed at 150 C; (c)

photodiffused Ge–S film annealed at 300 C; (d) photodiffused Ge–S film

annealed at 430 C. Solid lines are fitted results. Figure taken from

Balakrishnan et al. [21].

bonds ðGe2S Þ forming metathiogermanate tetrahedra

ðGeS2

3 Þ and dithiogermanate tetrahedra ðGeS2:5 Þ as

suggested by Kamitsos et al. [28]. Illumination with light

causes formation of defects not only on S atoms forming S

chains but also on S that is part of other structural units. It

is for this reason that we observe formation of both Ag2 S

and Ag2 GeS3 after Ag diffusion by which the Ag ions react

with the photoinduced defects in the chalcogenide glass as

suggested by Eq. (1). The growth of the mode at 250 cm1

indicates significant sulfur depletion of the initial composition (Fig. 3) of the hosting backbone after Ag is

photodiffused in the Ge–S film (Fig. 3) and a large number

of ethane-like structures are formed.

After annealing of Ag diffused films, we realize that their

structure keeps the initial character and the intensity of the

ethane like structures increases with annealing temperature

(Fig. 3(b)–(d)). The decreasing ratio between the intensity

of the mode at 252 cm1 and the mode at 334 cm1 could

be related to some continuing reaction between the three

elements at annealing. Note that the peak at 252 cm1 is

very stable due to a higher rigidity of the structure and

better filling of the intercluster space with introduction of

Ag in the film. This prevents incidence of intercluster

changes. In fact, due to the low dimensional nature of the

clusters, the Ge–S host is expected to be less strained

ARTICLE IN PRESS

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

compared to its isoionic counterpart, Ge–Se glass. This,

along with the bond strength of the covalent bonding in the

studied glass accounts for the lower polymerization relative

to the Ge–Se system. As a result a more relaxed structure is

formed where the Ag-containing products experience much

lower pressure from the surrounding backbone and only

the low-temperature forms of the respective compositions

occur that are known to have larger volume than the hightemperature forms. The dramatic decline in the scattering

intensity of the edge and corner sharing tetrahedra during

annealing at 430 C (Fig. 3(d)) can be related to formation

of a new ternary composition—Ag8 GeS6 (Fig. 1(d)). For

this composition the structure is formed by isolated GeS4

tetrahedra as well as S atoms that are not bonded to the Ge

atoms [29]. The anion parts GeS4 and S are connected by

Ag atoms to form 3D structure. The Ag atoms are bi-,

three- and fourfold coordinated with S [30]. In other words,

formation of Ag8 GeS6 brings about a serious depolymerization of the structure and hence decreases the intensity of

the modes related to particular structural coordination of

the Ge–S tetrahedra. This effect can be also accompanied

with high concentration of Ag on the surface at the highest

annealing temperature that would be the most natural

effect considering the highest number of wrong bonds that

are related to the surface defects. The scattering coming

from this Ag rich medium with a narrow band gap will

significantly reduce the scattering from the Ge–S host.

However, note that the second order Si substrate mode at

303 cm1 yields almost consistent intensity in all the fits,

indicating that the laser beam reaches with ample energy

the studied material and the sample penetration depth

through the films is not influenced by Ag clustering near

the surface.

4. Silver photodiffusion in the Ge–Se system

4.1. Basic data

Most extensive data about Ag diffusion in Ge–Se glasses

have been reported by Kluge et al. [31]. They have found

that the diffusion kinetics and the total amount of diffused

Ag are very closely related to the composition of the

hosting backbone. While for a backbone containing

75290 at% Se there is almost no induction period for the

diffusion process, at lower Se concentration this period

grows with decreasing Se content. This is somewhat

correlated with the depth profile of the Ag diffusion. At

high Se concentration, for GeSe5:5 , a step-like profile is

found [32,33] by which a Ag-depleted layer lies over the

Ag-enriched layer situated just above the substrate. Leung

et al. [34] also confirm that surface diffusion is much

smaller than the bulk diffusion. Indeed, some irregularities

and discontinuity of the silver doped film with formations

of islands have been found also by Rennie et al. [35]. For

GeSe2 glasses, the process is slower and follows the

classical distribution [36]. Wagner et al. [37] established a

significant difference in the diffusion profiles of laterally

869

diffused Ag in Ge20 Se80 and Ge40 Se60 glasses, with sharp

edge diffusion for the Se-rich glass and a classical diffusion

profile for the Ge-rich glass. Their interpretation of this

effect is related to the existence of two glass-forming

regions in the Ge–Se–Ag system. While for the Ge-rich

glasses the diffusion process goes through compositions

characteristic only for one of the sub regions, in the case of

Se-rich glasses the composition of the diffused product

resembles those of the two regions. This requires some

structural rearrangements that affect the diffusion profile.

Structural investigations on the photodiffused material

reveal formation of a heterogeneous structure after

photodiffusion [38,39]. Chen and Tai [38] report formation

of bcc Ag2 Se, Ag2 SO4 and small amounts of orthorhombic

Ag2 Se when Ag is diffused into GeSe2 glass and bcc Ag2 Se

and traces of free Ag when the diffusion process is

conducted in Ge0:1 Se0:9 glass. We assume that these

differences in the diffusion processes are closely related to

the availability of space and channels for the diffusion of

Ag in the particular hosting glasses. Formation of Ag2 Se

has been submitted also by Zembutsu [39]. Considering the

existing results, Kawaguchi et al. [40] proposed a schematic

model for the evolution of the structure of the chalcogenide

glasses during Ag diffusion that depict the formation of the

two phases—Fig. 4.

4.2. XRD data generated in our research

We studied [41] the diffusion products in the Ge–Se

system and their growth during annealing at 85, 110, 125

and 150 C in hosting materials with composition Ge20 Se80 ,

Ge30 Se70 , Ge33 Se67 and Ge40 Se60 . Fig. 5 gives representative curves of the XRD spectra of the photodiffused glasses

for an initial composition of Ge33 Se67 . In all cases, the

hosting Ge–Se glass remained amorphous during the

annealing while the silver containing species formed

nanocrystals. We found orthorhombic, bAg2 Se, as well as

cubic, aAg2 Se with Ag8 GeSe6 appearing only when Ag is

introduced in a host containing 33 at% and higher

concentration of Ge. The crystals forming after diffusion

a

b

c

Ag-poor phase

Ag-rich phase

d

e

f

Ag particles

Fig. 4. Schematic illustration of the change of structure of

ðGex SeðSÞ1x Þ1y Agy deposited films with increasing Ag content: (a)

shows the initial glass in which the amount of Ag gradually increases

(b)–(e) until Ag particles phase separate (f). Figure taken from Kawaguchi

et al. [40].

ARTICLE IN PRESS

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

870

*

+

+ + ^

+

* *

d

Intensity (Arb. units)

*

*

*

+ + ^

*

+

*

+

+

+ +

^+

+

+ ^ + +

* *

*

c

*

b

* *

30

50

40

2 Theta, Deg.

60

b

Ge30Se70

c

Ge33Se67

d

Ge40Se60

e

after Ag diffusion

Film resulting after photodiffusion

a

100

20

Ge20Se80

a

Intensity, Arb. Units

*

70

Fig. 5. Representative XRD plots of Ge33 Se67 glass photodiffused with

Ag annealed (a) at 85 C for 15 min, (b) at 85 C for 120 min, (c) at 150 C

for 15 min and (d) at 150 C for 120 min; * peaks characteristic for

Ag8 GeSe6 ; ˆ peaks characteristic for aAg2 Se; þ peaks characteristic for

bAg2 Se. Some peaks were reduced to fit on a single graph. Figure taken

from Mitkova et al. [41].

are relatively small because they can only form in the free

interspaces available in the matrix of the hosting glass.

Although in the case of Ge20 Se80 glass the initial structure

is floppy, following the initial silver inclusion and formation of Ag2 Se, the glass structure becomes depleted in Se

and stiffer. The internal space limitation produces the same

effects as elevated pressure, stabilizing some clusters in the

high temperature form which has the closest packing. With

Ge-enrichment of the hosting backbone, the intensity of

the peaks of aAg2 Se becomes higher, suggesting reflectance

from a larger number of planes. At the same time,

Ag8 GeSe6 clusters are formed and we assume that these

occur at terminal defects on the Ge–Se tetrahedra in the

case of the Ge33 Se67 host or develop within the volume of

the films when Ag is diffused in a Ge40 Se60 host. Indeed,

Mössbauer spectroscopy definitely shows that replacement

of Ge by Ag occurs in Ge-rich glasses [42] so a combined

effect could be the reason for the development of the

ternary composition.

4.3. Raman data generated in our research

Raman features of initial hosts closely match those of

bulk materials with the same composition, as illustrated in

Fig. 6(a)–(d). However, after diffusion, the spectra of all

samples show a vibrational band at 180 cm1 and a higher

frequency band at 200 cm1 independent of the composition (Fig. 6(e)), suggesting the formation of a structure

containing ethane-like units with Ge–Ge bond as well as

the Ge–Se tetrahedra. These spectra remained unchanged

following the moderate annealing.

200

300

400

500

Raman shift, cm-1

Fig. 6. Raman spectra of the undoped Ge–Se glasses and spectrum of the

photodiffused material. Compositions are noted in the figure. Figure

taken from Mitkova et al. [41].

We assume that as in the case of Ge–Se glasses, the

illumination with light causes formation of charge defects

that can react with Ag and form the diffusion product. This

fact has important consequence since some Se is extracted

from the initial Ge–Se backbone to react with the diffused

Ag. So the remaining chalcogenide glass backbone

becomes Se deficient, as demonstrated by the appearance

of a Raman signature that is characteristic of a Ge-rich

glass, independent of the initial composition of the host. In

this composition the underlying molecular phase consists

of face-sharing quasi one-dimensional ethane-like

Ge2 ðSe1=2 Þ6 chain fragments whose presence is manifested

on the Raman spectra by the appearance of the mode at

180 cm1 [43] depicted in Fig. 6(e). The Raman spectrum of

the resulting material shows a lower intensity ratio between

the modes at 180 cm1 and the mode of the Ge-tetrahedral

units at 200 cm1 when compared to the intensity ratio of

these modes for a Ge40 Se60 initial glass film indicating that

the number of ethane like units is lower than in Ge40 Se60

glass. However this structure still contains Ge–Ge bonds.

They are the result of the spontaneous reaction of Ag with

charged metastable states on the chalcogen initiated by

light illumination and with charged defects occurring at

bond conversion [44]. This reaction will be preferred since

the energy that it requires is less than the energy for the

Ge–Se bonding (48.4 vs. 113 kcal/mol). We suggest that

this, together with space organization in the material is the

reason for the extraction of some Se from the Ge–Se

backbone for the formation of Ag2 Se in addition to the

reaction of Ag with the initially available free Se chains.

The structure of Ge–Se backbone formed after photodoping is depolymerized to some extent due to the extraction of

Se and formation of crystalline products. It is for this

reason that the organization of the photodiffused hosting

glass does not change with the moderate annealing applied,

ARTICLE IN PRESS

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

as happens with pure Ge–Se films [45] where the local

stressed configurations with a high free energy relax

through breaking of the Ge–Ge bonds and formation of

Ge–Se corner-sharing units due to reaction with Se–Se

wrong bonds.

5. Conclusions

In this work we gave a brief review with extended

references of the published results about the Ag photodiffusion in Ge–S(Se) chalcogenide glasses and combined

them with our recent results. We demonstrate that the

photodiffusion effect can be well characterized by XRD

method which gives direct evidences about the diffusion

products that are crystalline and by Raman spectroscopy

which supplies data about the structure of the hosting

Ge–S(Se) backbone. We found out differences in the

photoinduced effects in the investigated systems which

can be summarized as follows:

For the Ge–S system:

The diffusion products are nanocrystals of Ag2 S and

Ag2 GeS3 which grow via agglomeration with increasing

the annealing temperature. At 430 C Ag8 GeS6 forms

which is product of reaction of agglomerated Ag2 S with

the hosting backbone.

The Raman data about the hosting Ge–S backbone

show that it becomes more rigid and Ge-rich after the

act of Ag photodiffusion in it.

The intensity of the Raman mode characterizing the

formation of Ge–Ge bond after introduction of Ag

grows with the annealing temperature up to 430 C. At

this temperature the intensity characterizing the Ge–S

tetrahedra decreases drastically because of structural

rearrangement and formation of Ag8 GeS6 ternary which

is build up by isolated GeS4 tetrahedra and this

essentially affects the structure of the host.

For the Ge–Se system:

Regardless of the initial composition of the hosting

glass, the photodiffused material shows Raman features

characteristic for Ge-rich material. The glassy component becomes Se-deficient due to consumption of Se in

the formation of the diffusion products.

The diffusion products are nanocrystalline regions

dispersed into the glassy matrix and their composition

is dependent upon the hosting glass composition and

develops from Ag2 Se to a combination of Ag2 Se and

Ag8 GeSe6 with enrichment of the host in Ge.

The cluster size of the crystalline products depends on

the molar volume of the host in close relation to its

rigidity.

Isothermal annealing at moderate temperatures results

in diffusion limited slow growth of the Ag2 Se clusters

and homogeneous growth of the Ag8 GeSe6 clusters.

871

References

[1] M.T. Kostyshin, E.V. Mikhailovskaya, P.F. Romanenko, Fiz. Tverd.

Tela 8 (1966) 571 (Sov. Phys. Solid State (1966) 451).

[2] M.N. Kozicki, M. Park, M. Mitkova, IEEE Trans. Nanotechnol. 4

(2005) 331.

[3] T. Wagner, M. Frumar, V. Suskova, J. Non-Cryst. Sol. 128 (1991)

197.

[4] J.H.S. Rennie, S.R. Elliott, J. Non-Cryst. Sol. 97&98 (1987)

1239.

[5] A.V. Kolobov, S.R. Elliott, M.A. Taguirdzhanov, Philos. Mag. B 61

(1990) 859.

[6] I.Z. Indutni, V.A. Danko, A.A. Kudryavtsev, E.V. Michailovskaya,

V.I. Minko, J. Non-Cryst. Sol. 185 (1995) 176.

[7] A.V. Kolobov, G.E. Bedel’baeva, Philos. Mag. B 64 (1991) 21.

[8] G. Kluge, Phys. Stat. Sol. (A) 101 (1987) 105.

[9] A. Urena, M. Fontana, B. Arcondo, M.T. Clavaguera-Mora, J. NonCryst. Sol. 320 (2003) 151.

[10] S.A. Lis, J.M. Lavine, Appl. Phys. Lett. 42 (1983) 675.

[11] M.T. Kostyshin, V.I. Minko, Ukr. Fiz. Zh. 29 (1984) 1560.

[12] Ke. Tanaka, Phys. Rev. Lett. 65 (1990) 871.

[13] G.E. Bedel’baeva, A.V. Kolobov, V.M. Lyubin, Fiz. Tech. Polupr.

25 (1991) 197.

[14] P.J. Ewen, A. Zakery, A.P. Firth, A.E. Owen, J. Non-Cryst. Sol.

97–98 (1987) 1127.

[15] A.V. Kolobov, V.M. Lyubin, J. Troltzsch, Phys. Stat. Sol. (A) 115

(1989) K139.

[16] A.V. Kolobov, S.R. Elliott, Adv. Phys. 40 (1991) 625.

[17] J.M. Oldale, S.R. Elliott, J. Non-Cryst. Sol. 128 (1991) 255.

[18] S. Maruno, S. Ban, Jpn. J. Appl. Phys. 19 (1980) 97.

[19] T. Kawaguchi, S. Maruno, J. Appl. Phys. 71 (1992) 2195.

[20] R. Ishikawa, Sol. State Comm. 30 (1979) 99.

[21] M. Balakrishnan, M.N. Kozicki, C.D. Poweleit, S. Bhagat, T.L.

Alford M. Mitkova, J. Non-Cryst. Sol. (2007), to be published in

spring.

[22] H. Takebe, H. Maeda, K. Morinaga, J. Non-Cryst. Sol. 291

(2001) 14.

[23] M.F. Thorpe, private communication.

[24] G. Lucovsky, F.L. Galeener, R.C. Keezer, R.H. Geils, H.A. Six,

Phys. Rev. B 10 (1974) 5134.

[25] K. Jackson, A. Briley, S. Grossman, D.V. Poresag, M.R. Pederson,

Phys. Rev. B 60 (1999) R14 985.

[26] P. Boolchand, J. Grothaus, M. Tenhover, M.A. Hazle, R.K.

Grasselli, Phys. Rev. B 33 (1986) 5421.

[27] K. Shimakawa, A. Kolobov, S.R. Elliott, Adv. Phys. 44 (1995) 475.

[28] E.I. Kamitsos, J.A. Kapoutsis, G.D. Chryssikos, G. Taillades,

A. Pradel, M. Ribes, J. Sol. State. Chem. 112 (1994) 255.

[29] P. Armand, A. Ibanez, J.-M. Tonnerre, B. Bouchedt-Fabre,

E. Philippot, Phys. Rev. B 56 (1997) 19852.

[30] D. Carre, R. Ollitrault-Fichet, J. Flahaut, Acta Cryst. B 36 (1980)

245.

[31] G. Kluge, A. Thomas, R. Klabes, R. Grötzschel, P. Süptitz, J. NonCryst. Sol. 124 (1990) 186.

[32] R. El Ghrandi, J. Calas, G. Galibert, Phys. Stat. Sol. (A) 123 (1991)

451.

[33] J. Calas, R. El Ghrandi, G. Galibert, A. Traverse, Nucl. Instrum.

Meth. Phys. Res. B 63 (1992) 462.

[34] W. Leung, N. Chung, A.R. Neureuther, Appl. Phys. Lett. 46 (1985)

543.

[35] J. Rennie, S.R. Elliott, C. Jeynes, Appl. Phys. Lett. 48 (1986) 1430.

[36] J.H.S. Rennie, S.R. Elliott, J. Non-Cryst. Sol. 77&78 (1985) 1161.

[37] T. Wagner, R. Jilkova, M. Frumar, M. Vlcek, Int. J. Electr. 77 (1994)

185.

[38] C.H. Chen, K.L. Tai, Appl. Phys. Lett. 37 (1980) 605.

[39] S. Zembutsu, Appl. Phys. Lett. 39 (1981) 969.

[40] T. Kawaguchi, S. Maruno, S.R. Elliott, J. Appl. Phys. 79 (1996) 9096.

[41] M. Mitkova, M.N. Kozicki, H.C. Kim, T.L. Alford, J. Non-Cryst.

Sol. 352 (2006) 1986.

ARTICLE IN PRESS

872

M. Mitkova, M.N. Kozicki / Journal of Physics and Chemistry of Solids 68 (2007) 866–872

[42] M. Mitkova, Yu. Wang, P. Boolchand, Phys. Rev. Lett. 83 (1999)

3848.

[43] P. Boolchand, in: P. Boolchand (Ed.), Insulating and Semiconducting

Glasses, World Scientific, Singapore, 2000, p. 214.

[44] N. Bondar, N. Davydova, V. Tishchenko, M. Vlcek, J. Mol. Struct.

555 (2000) 175.

[45] Y. Wang, K. Tanaka, T. Nakaoka, K. Murase, J. Non-Cryst. Sol.

299&302 (2002) 963.