Grid Access

advertisement

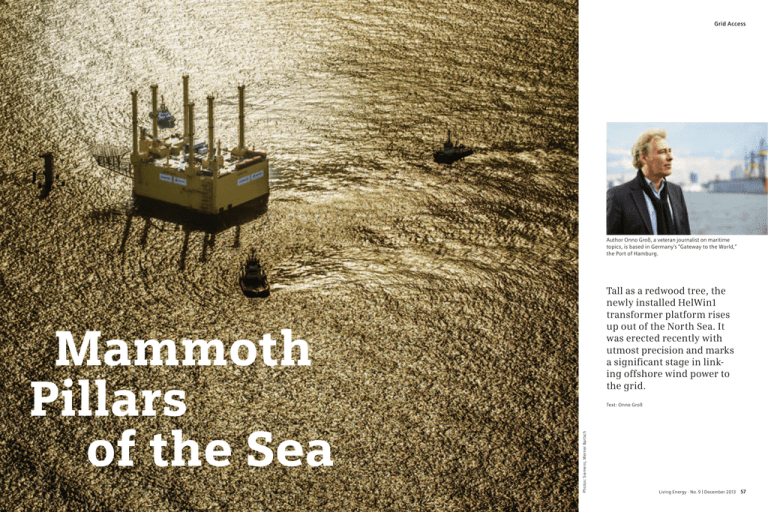

Grid Access Author Onno Groß, a veteran journalist on maritime topics, is based in Germany’s “Gateway to the World,” the Port of Hamburg. 56 Living Energy · No. 9 | December 2013 Text: Onno Groß Photos: Siemens, Werner Bartsch Mammoth Pillars of the Sea Tall as a redwood tree, the newly installed HelWin1 transformer platform rises up out of the North Sea. It was erected recently with utmost precision and marks a significant stage in linking offshore wind power to the grid. Living Energy · No. 9 | December 2013 57 Grid Access Kolumnentitel Grid Access A Crucial Link A 58 Living Energy · No. 9 | December 2013 1. Offshore wind turbine plants generate mediumvoltage AC power mately 85 kilometers off the coast. Siemens was commissioned to construct the platform by grid operator TenneT in mid-2010. With the Italian cable specialist Prysmian, the consortium is implementing a total of four North Sea grid connection projects: HelWin1 and HelWin2 off Heligoland, BorWin2 off Borkum, and SylWin1 off Sylt. The substructure and platform were constructed at the Nordic Yards 2. Wind energy generated by the wind farm turbines transformed to higher AC power at the substation platform 3. HVDC platform converts the alternating current from several substation platforms to direct current for transmission shipyard in Wismar and at Warnemünde on the Baltic Sea. Pilings as Tall as Big Ben The installation of the HelWin1 platform northwest of Heligoland began in April 2013, and started with the anchoring of the substructure, which weighs 1,000 tonnes. Ten steel pilings, which formed the structure’s jacket, had to be rammed into the seabed. Graphic: Siemens s anyone who has ever stood in a forest in front of a giant redwood tree knows, it is virtually impossible to escape the lure of these mighty giants. Firmly rooted in the earth, the trunk may have a diameter of several meters. In California, a road has actually been hewn through one of these arboreal mammoths. The pilings of the newly erected transformer platform HelWin1 in the North Sea rival the redwoods in height and stability. The platform, which lies just off the Heligoland archipelago, fills a significant gap in the grid connection of offshore wind farms. “The steel structure and complex construction made the HelWin1 project a real technical challenge. Now, the platform has been raised safely,” comments Marc Becker, lead project manager for all offshore grid connections at Siemens, with visible relief. His elation at the success of the weather-dependent venture is audible. What has been achieved is much more, after all, than the pioneering installation of a colossus in the North Sea, which had to be completed within a narrow time frame. Becker also relates other factors, such as the discovery of unexploded ammunition from World War II and a complex approval procedure. It is clear that the project faced a number of initial hurdles that had to be negotiated. The HelWin1 converter platform serves as a mainland link for the energy generated by the offshore wind farms “Nordsee Ost” (North Sea East) and “Meerwind” (Sea Breeze). The alternating current power generated by the wind turbines is transformed into low-loss direct current for transmission onto land, known in technical jargon as highvoltage direct current (HVDC). Siemens is one of the leading suppliers of this technology, the market for which is set to double its present volume of €3 billion globally over the next five years. Particularly stable and versatile HVDC platforms were developed for the German North Sea wind farms being erected approxi- The acoustic emission was minimized with the aid of an impact shell (cofferdam) designed to protect marine mammals from the pile-driving noise. At up to 3.2 meters in diameter and boasting a wall thickness of 8 centimeters, the pilings are true steel giants, whose length of up to 100 meters makes them as tall as the famous London landmark Big Ben. The platform stands at 22 meters 4. Subsea cables, some more than 100 kilometers in length, transport the low-loss direct current onto land above sea level, perched significantly higher than the maximum recorded wave height of 19.32 meters. The second step of the construction phase involved the platform’s transportation to its final position 20 kilometers off the coast of Heligoland. HelWin1 was converted into a floating vessel for this purpose, before being towed out into the North Sea by three tugboats. The outer doors were welded shut, 5. A converter station on land transforms the direct current back into alternating current for feeding into the high-voltage grid and for further transmission while inside, all the bulkheads were closed in order to create something resembling an ocean-going “ship.” World War II Legacy This special form of transport was selected in order to ensure that as much of the fabrication as possible took place on land, thus avoiding the exorbitant costs incurred by construction at sea. Accordingly, the complete HVDC u Living Energy · No. 9 | December 2013 59 Kolumnentitel Grid Access Siemens is currently testing three different methods in connection with the platforms’ installation. The self-floating transport used for HelWin1 and BorWin2 is one option, while, in the case of the SylWin1 project, the platform lies on a towed pontoon and is positioned in situ. Finally, the platform used in the HelWin2 project is lowered onto the prefabricated jacket structure via a large floating crane. Besides pioneering spirit, offshore installations require technical backups to safeguard against malfunctions and sufficient margins of tolerance. “These days, when we assess a project, we evaluate it on the basis of the transport and installation processes. We have learned from experience and now know which challenges are involved,” emphasizes Becker. Installing an offshore platform depends on a series of controllable factors, but the weather cannot be influenced so easily. All components must be robust, as the costs at sea are ten times as high as on land, while the cost in terms of time is five times as high. The learn- ing processes involved in cooperation with the sanctioning authorities are another factor. A New HVDC Platform Each Year In the wake of the successful anchoring of HelWin1, 100 engineers and employees are finalizing the installation. The platform must be fully functional in time for the commissioning in November 2014. “With the installation of our platform at sea, we have successfully mastered the most critical part of this project and are now on the final stretch for commissioning in 2014,” states Karlheinz Springer, CEO of the Power Transmission Division within the Energy Sector of Siemens AG. With a transmission rate of 576 megawatts, HelWin1 will eventually supply electricity to over 500,000 households on the German mainland. “We are certainly confident of our ability to execute new offshore projects,” says Becker. “We’re now familiar with the installation process, we have reliable suppliers, and we know how to cope with heavy swell – in short, the expertise is now on hand.” Europe remains the most important market for offshore HVDC technology. Germany has developed clear expansion targets for renewable energies: Network operator TenneT will be issuing one invitation to tender for platforms with a capacity up to 900 megawatts each year up to and including 2020, in order to comply with the grid expansion obligation. Wind power installation is also making rapid progress in Great Britain. In Germany, 33 plants amounting to a capacity of over 2,250 megawatts have been approved to date, while a further 8,000 megawatts are planned by 2020, and a total of 25,000 megawatts are envisaged by 2030. In England, installation of up to 51,000 megawatts is anticipated. Many more mammoth offshore pillars will thus be required in future. p Onno Groß, a science journalist from Hamburg, writes regularly on maritime issues for newspapers and magazines such as National Geographic and Handelsblatt. platform was constructed in the shipyard. An impressive seven stories high and with a surface area of 75 by 50 meters, it is as big as half a soccer field. Transporting the 11,000-tonne platform from the Baltic Sea around the tip of Denmark ultimately took seven days, and a further four were planned for the installation. Although the environmental conditions in the North Sea, which is 23 meters deep at this point, are a more predictable aspect of the project, the ambitious schedule was threatened by the discovery of two World War II torpedoes some distance away from the platform. “The seabed surrounding Heligoland is full of unexploded ammunition, which first had to be removed,” explains project manager Marc Becker. Although the discovery was not made directly in the construction area, the detonation 60 Living Energy · No. 9 | December 2013 would have affected the acoustic measurement equipment that is needed for piling operations, with the result that the latter had to be retrieved from the water and later replaced. This took a week. The Art of Picking a Weather Window The platform was eventually positioned precisely above the pilings with a deviation of just a few millimeters. In a second step, it was connected to the pilings within the jacket, a phase whose completion depended on the weather. “The process of threading the platform onto the legs can only be performed when the wave swell is less than 70 centimeters,” explains Randolph Schmid, Siemens Project Manager Offshore. The final phase involved the platform being hoisted onto the pilings via hydraulic power. As it was raised up with excruciating slowness, centimeter by centimeter, the faces of all Siemens participants lit up with delight and relief. The window of opportunity had been chosen with pinpoint accuracy: one day’s journey to the location, two days’ positioning, and two days for the threading. Raising the platform required a further day. Says Schmid: “It’s primarily a matter of checking the weather forecast and not losing one’s nerve.” The August deadline for the installation of HelWin1 had been agreed a year before, and Siemens was therefore able to stick to the schedule. Although the completion was preceded by a steep learning curve, it did result in HelWin1 overtaking BorWin2 on the installation timetable. Photos: Siemens In order to transport the platform to its final location 20 kilometers beyond Heligoland, HelWin1 had to be converted into a floating vessel towed by three tugboats. As the main land conversion and transmission node for energy gathered by offshore farms “Nordsee Ost” and “Meerwind”, HelWin1 plays a crucial role in the integration of renewables into Germany’s grid. Living Energy · No. 9 | December 2013 61