New DC grid access solution New DC grid access solution –

advertisement

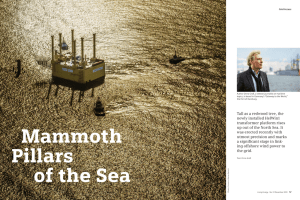

New DC grid access solution The high potential of wind power far offshore calls for cost-effective solutions for grid connection. Our experience along the supply chain from generation to the grid access of wind power, including references for DC offshore grid access projects, AC platforms, and wind turbines, enables us to meet this challenge by creating the next generation of DC grid access solutions. New DC grid access solution – saving weight, space, and costs with • Encapsulated, rugged equipment • Biodegradable and flame-retardant insulation • Simple and robust power electronics The new second-generation DC grid access solution is a breakthrough in simplifying today’s offshore AC/DC converters, making them smaller and easier to install and to maintain in an offshore environment. Combined with the benefits of DC cables like their high power density, the new DC grid access becomes the most cost-effective solution for large-power offshore wind farms. The breakeven distance versus AC is reduced to about 80 km. • Easy transport and installation The new innovation uses compact, robust, encapsulated power electronic devices. It is the simplest and most robust AC/DC converter the electrical engineer can imagine at all: a diode rectifier. The insulation liquid used is flame retardant and biodegradable. The DC switchgear is encapsulated as well, so there is no longer any high voltage in open air. • Flexible offshore installation options due to modular rectifier concept This allows us to reduce platform size and weight sub­ stantially and to provide small, modular, and flexible DC platforms easy to install and maintain. • High reliability, minimal maintenance • No offshore DC converter as single point of failure • Shorter delivery times • Stepwise offshore installation feasible • Fast commissioning of WTG aux power • Up to 1,200 MW DC Best solution for long distances and high rated power The new DC grid access concept does not require any AC offshore substations. The turbine strings can be connected directly to one of three DC platforms. These are of similar size to today’s AC offshore substations. The total topside volume is reduced by 80 percent. The weight is reduced from approximately 26,000 tons to only 9,000 tons. siemens.com/energy/grid-access-solutions Current status New concept Distributed small DC platforms OSS Large central DC platform Onshore HVDC converter station Onshore HVDC converter station Siemens’ new and cost-efficient DC grid access solution basically relies on distributed transformers and diode rectifiers. They are located on small, distributed DC platforms and connected in series by a DC cable. A central DC transmission platform is not required. The system can also operate with a reduced number of DC platforms, and a platform can even be bypassed. This feature ensures outstanding availability and enables the stepwise construction and commissioning of the power transmission system following the progress of installed turbine capacity. The operation costs are reduced as well, since there is no complex control and no maintenance-intensive auxiliary equipment like seawater cooling and large air conditioning. DC grid access, general data Finally, the small platform size allows fast erection: approximately 28 months till first power transmission. Auxiliary power supply for the turbines can be commissioned even faster, if the cables are in place. According to Siemens analysis, the 2nd generation DC grid access is the largest single lever to achieve the target of reducing the cost of energy to €0.10/kilowatt hour commonly set by the industry for the levelized cost of electricity (LCoE) of offshore wind in 2020. Rated power Up to 1,200 MW (3 x 400 MW) Rated DC voltage +/– 320 kV Distance Up to 250 km Rated AC voltage 66 kV (or 33 kV) Platform weight Approx. 3,000 t per platform The new DC grid access solution will be open to all wind turbine suppliers. Remark: The wind turbine control has to be modified to ensure proper power flow control and stability of the weak offshore AC grid with high cable capacitances present. For full converter machines this is a software update only. Siemens is ready to support all interested turbine manufacturers. Published by and copyright 2015: Siemens AG Energy Management Sector Freyeslebenstrasse 1 91056 Erlangen, Germany For more information, please contact our Customer Support Center. Phone: +49 180/524 70 00 Fax: +49 180/524 24 71 (Charges depending on provider) E-mail: support.energy@siemens.com 200 MW di-rectifier unit Power Transmission Solutions Order No.: E50001-G610-A139-X-7600 Dispo: 30003, fb6627 MA 473222 WS 03151.0 Printed in Germany siemens.com/energy/grid-access-solutions