siemens.com/transformer-insulation

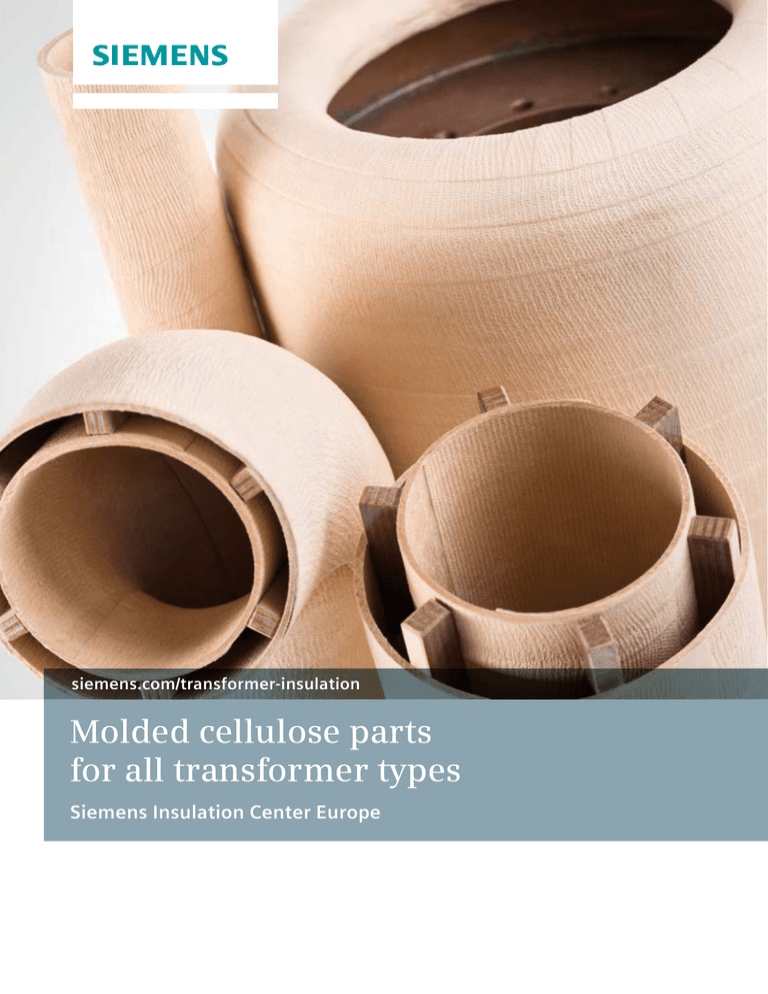

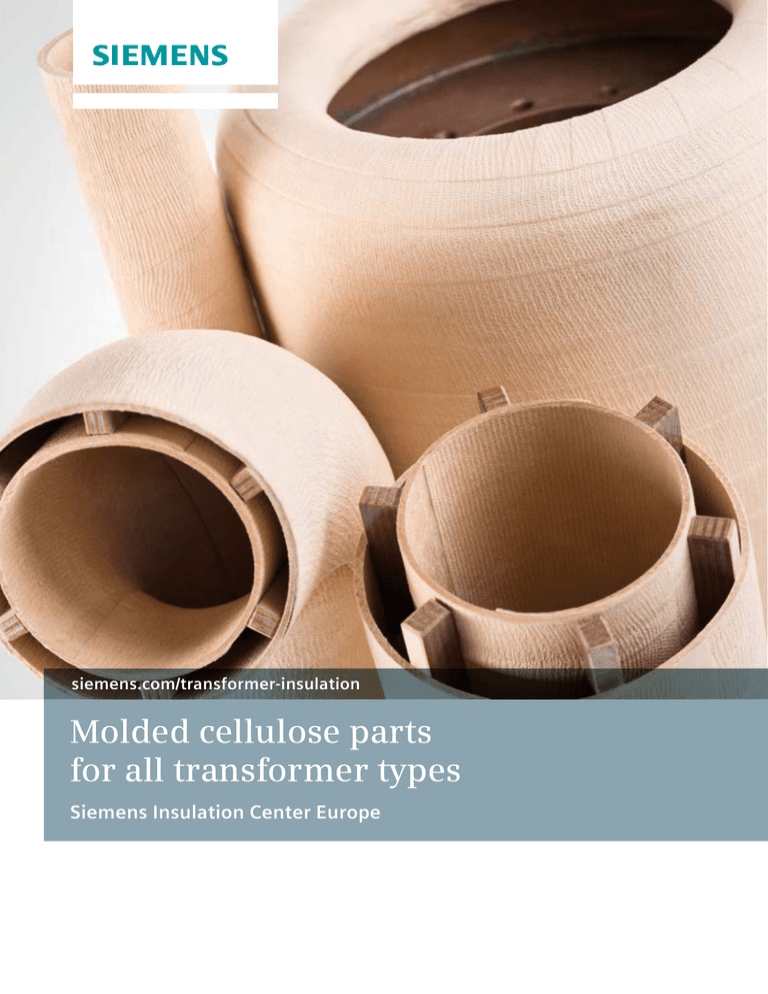

Molded cellulose parts

for all transformer types

Siemens Insulation Center Europe

DNV BUSINESS ASSURANCE

MANAGEMENT SYSTEM CERTIFICATE

Certificate No.: 148738-2014-AHSO-GER-DAkkS

This is to certify that

Siemens Insulation Center GmbH & Co. KG

Werner-von-Siemens-Str. 1

08297 Zwönitz - Germany

»Quality is

in our DNA

and begins

with each

employee.«

has been found to conform to the Management System Standard

ISO 9001:2008

ISO 14001:2004

BS OHSAS 18001:2007

This certificate is valid for the following product or service ranges:

Sales and Production of Insulation Parts for Transformers

16.12.2013

15.12.2016

Timo Michel,

CEO

Siemens Insulation Center Europe (SICE) –

the alternative for your molded parts

In addition to the advanced transformer materials of

­copper, electrical steel, and insulating oil, molded parts

made of cellulose are one of the critical components for

the service life of transformers. It is no surprise that trans­

former manufacturers from around the world consider

quality to be the key criterion for the purchase of molded

parts made of cellulose.

The Siemens Insulation Center (SICE) based in Zwönitz

(Saxony) was founded in 2007 and is a wholly owned

­subsidiary of Siemens AG.

Today SICE is the secure bank for all AC and DC voltage

classes that are used in the Siemens transformer group.

We are a recognized manufacturer outside of Siemens

as well. Along the entire range of power transformers

and in all corporate processes, we embody the highest

quality “made in Germany.” We likewise stand for com­

petitive prices and flexible delivery times.

Place and date:

Initial Certification date:

This certificate is valid until:

Essen, 16.12.2013

for the Accredited Unit:

DNV ZERTIFIZIERUNG UND UMWELTGUTACHTER GMBH

The audit has been performed under the

supervision of

Volkmar Rändler

Lead Auditor

Nikolaus Kim

Management Representative

Lack of fulfilment of conditions as set out in the Certification Agreement may render this Certificate invalid.

DNV ZERTIFIZIERUNG UND UMWELTGUTACHTER GMBH, Schnieringshof 14, 45329 Essen, Tel: +49 201 7296 222 Fax: +49 201 7296 333 - www.dnvba.de

Quality as the fundamental principle

Quality is in our DNA – that is our leading principle.

This quality begins with the selection of the wet material.

In this regard, we can count on the Krempel Group as

a reliable and well-known business partner. The starting

material for all our products is Transformerboard IV

Type B 3.1 per IEC 60641‑3. A careful 100 percent inspec­

tion of all our parts at different points of the production

process is an added factor that ensures that our customers

will view us as the quality leader in the industry.*

Our highest quality requirement is evident in our prepara­

tions to build our insulating parts. The tactile properties

are as important as a high-quality and functional packaging.

In line with our guiding principles, our processes are

­certified in accordance with ISO 9001, ISO 14001,

and OHSAS 18001.

Whether in Europe, America, or Asia, we enjoy the trust

of our customers from around the world. For the operators

of transformers, safety and reliability are the key criteria

for making decisions. This is also reflected in the purchases

made by transformer manufacturers.

As a supplier of molded parts to one of the largest trans­

former manufacturers worldwide, we are conscious of

our unwillingness to compromise on quality. As a Siemens

subsidiary, we are as familiar with the challenges of this

business as if it were our own: The efficiency, weight, and

service life of transformers are as important to us as they

are to our customers.

* 2014 customer satisfaction survey representing 80% of our customers

»Both in terms of

technology and quality,

SICE […] has become

a force to be reckoned

with among the best

molded parts manu­

facturers in the world

[…].«

L. Berger,

Siemens transformer factory

Nuremberg

Production facility in Zwönitz

Molded parts for every use

Our molded parts are as diverse as where they are used

in a transformer: We manufacture angle and cap rings

and segments; U-ring segments and U-channels as well

as angle-, caps- and U-ring segments with snout in

­accordance with customer specifications. Snouts, tubes,

and elbows are additionally available in a wide range

of ­designs. Our strengths also include complex terminal

lead systems including electrodes.

Partner for new challenges

We have experience in all voltage levels, particularly

in the area of HVDC transformers. With our component

and system expertise, we are a partner to trust when it

comes to new developments. Even at the highest voltages

and the highest DC load, our customers can rely on our

expertise.

We provide milestone support in transformer

construction

We manufactured the insulating parts for the first 800 kV

HVDC transformer: with a thickness of up to 4 mm at a

­diameter of over 3,000 mm. The milestone for us in the

next step became a milestone for our customer.

Even in the AC range, we can handle the highest voltage

levels. For example, we have already manufactured the

lead exit for an 1100 kV AC transformer at our facility in

Zwönitz.

Product range

Diameter

Radii

Degree

Neck and

flange size

Division

Angle rings

400 to 1700

up to 25 mm

up to 360°

Default

max. 200 mm

Single part or

multiple parts

Cap rings

600 to 1630

up to 50 mm

up to 360°

Default

max. 200 mm

Single part or

multiple parts

Angle and cap segments

580 to 3280

up to 65 mm

up to 60°

Default

max. 195 mm

Single part

U-ring segments/U-channels

In accordance with

customer specifications

In accordance with

customer specifications

up to 90°

Default

max. 200 mm

Single part or

multiple parts

Angle-, caps- and U-ring

­segments with snout

400 to 3000

up to 65 mm

default

45° & 60°

Default

max. 200 mm

Single part or

multiple parts

Flange tube

In accordance with

customer specifications

–

–

–

Single part or

multiple parts

Tubes and elbows

In accordance with

customer specifications

–

In accordance with

customer specifications

–

Single part or

multiple parts

–

–

Electrodes and outgoing leads In accordance with

customer specifications

In accordance with

customer specifications

Additional sizes and shapes can be manufactured upon request

Published by and copyright © 2015:

Siemens AG

Energy Management Division

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Transformers

Katzwanger Strasse 150

90461 Nuremberg, Germany

Phone:+49 (37754) 33795-0

E-mail:sales-zwz.de@siemens.com

www.siemens.com/energy

For more information, please contact

our Customer Support Center.

Phone: +49 (0) 180/524 70 00

Fax:

+49 (0) 180/524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Printed in Germany

TH 101-150106 DB 0915

Printed on elementary chlorine-free bleached paper.

Subject to change without prior notice.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

The information in this document contains general descriptions

of the technical options available, which may not apply in all cases.

The required technical options should therefore be specified in the

contract.