Industrialisation of 3D printing (additive manufacturing) for gas turbine components repair and manufacturing

advertisement

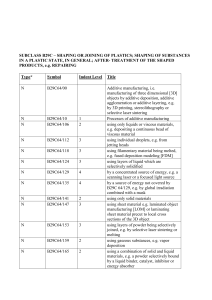

VGB PowerTech 12 l 2015 3D printing for gas turbine components Industrialisation of 3D printing (additive manufacturing) for gas turbine components repair and manufacturing VGB PowerTech - Autorenexemplar - © 2015 Vladimir Navrotsky, Andreas Graichen and Håkan Brodin Kurzfassung Introduction Industrialisierung von 3D Drucken (generative Fertigung) für Gasturbinenkomponenten-Reparatur und -Herstellung The recent advances in computing power and cheaper laser sources together with ITbased networking, open the door for a new design and manufacturing chain. 3D-CAD/ CAM models themselves contain information related to their manufacturing process, meaning that – ideally – only one file is needed to produce the component to the intended geometry, quality and material specification. Tooling and fixtures become obsolete in a blue sky scenario (F i g u r e 1). Formerly a complicated network of different competencies was needed in an advanced workshop, now it can be performed by one single “3D-printer”. In the coming years, we will see AM (additive manufacturing) as we are seing colour printing on paper, something that simply works, without much need for human intervention. There are many advantages for the designer and the supply chain: –– AM in the form of SLM (selective laser melting) gives an unprecedented freedom of design because geometries are possible that could not be accessed with traditional machining methods, –– many times, complexity of geometry comes for free, or costs the same as traditional simple geometries, –– this means that, for example, for gas turbine components cooling systems, vibration dampening and lightweight designs can be improved without extra cost, –– assemblies can be simplified and integrated, –– many manufacturing operations that earlier needed many logistical steps can be carried out on one single machine, In den letzten Jahren hat eine neuartige revolutionäre Art der Fertigung namens Additive Manufacturing (AM) in der Industrie Einzug gehalten. Diese wird tiefgreifende Veränderungen mit sich bringen. Im Gegensatz zur traditionellen Fertigung, bei der Material durch Fräsen, Bohren, Erodieren usw. abgetragen wird, wird bei diesem Verfahren Material durch den Einsatz von Laser- oder Elektronenstrahlenergie aufgetragen. Es gibt verschiedene AM-Technologien, von denen gegenwärtig das Selektive Laserschmelzen (Selective Laser Melting – SLM) das interessanteste Verfahren zu sein scheint. Das AM eröffnet eine neue Dimension der integrierten Konstruktion und Fertigung. AM ermöglicht eine schnellere Fertigung und Reparatur von Gasturbinenbauteilen bei gleichzeitig größerer Funktionalität und Leistungsfähigkeit der Bauteile. Siemens Power Generation setzt diese Technologie zur Herstellung von Prototypen (Prototyping) sowie in begrenztem Umfang für Reparaturarbeiten und die Fertigung von Gasturbinenbauteilen ein [1 bis 3]. Kürzlich setzte Siemens die SLM-Technologie zur Reparatur von Gasturbinenbrennern der Industriegasturbinenbaureihe SGT-800 ein. Die Ergebnisse zeigten, dass das Ersetzen konventioneller Reparaturverfahren durch die SLM-Technologie zu einer signifikanten Verkürzung der Reparaturzeit führt und die Bauteile bei der Reparatur darüber hinaus auf den aktuellen Brennertyp umgerüstet werden können. Ein weiteres aktuelles Beispiel für die Anwendung der SLM-Technologie bei Siemens stellt die Fertigung von verbesserten Brenner-Swirlern für Industriegasturbinen der Baureihe SGT-750 dar. In diesem Fall war SLM die einzige Technologie, die in der Lage war, diese Art von Swirler zu fertigen. Die Ergebnisse haben den Erfolg der Anwendung der SLM-Technologie in der Konstruktion, im Prototyping und in der Fertigung neuer, verbesserter Brenner-Swirler bestätigt. l Authors Dr. Vladimir Navrotsky Andreas Graichen Dr. Håkan Brodin Siemens Industrial Turbomachinery AB Finspong, Sweden 48 –– the transmission of CAD/CAM-files is not restricted by geography. 3D-printing can take place virtually anywhere as long as an internet connection exists (F i g u r e 2). As a result, the development and manufacturing time of some components and products will be significantly reduced. New products will enter the market, functionality and product upgrades could be improved and made more frequently. Further technology and AM equipment development will allow for reduced manufacturing cost for some components in the next 5 years. National programmes and public funds can speed up industrialisation of this technology and implementation of innovation into our daily lives. However, alongside the obvious benefits and opportunities there are threats and challenges: –– powder (e.g. specification, chemistry, cost, suppliers), –– AM equipment (e.g. process speed, equipment cost, components size), –– AM process parameters, –– very limited material data, –– qualification and validation of the process, –– design tools and design criteria, –– industrial standards and regulation for AM. Additive manufacturing technologies Powder-bed additive layer manufacturing Additive layer manufacturing (ALM) comprises a group of rapid manufacturing pro- 3D CAD Data Fig. 1. To manufacture a component by AM technology, the following is needed: 1 = 3D model of the component 2 = appropriate powder and 3 = laser sintering equipment. >>> VGB DIGITAL <<< VGB PowerTech - Autorenexemplar - © 2015 VGB PowerTech 12 l 2015 3D printing for gas turbine components in a pre-defined pattern, in order to create a minimum of internal stresses [14] and the best surface possible [15]. Each pass of the laser beam creates Faster technology Lead time reduction & a solidified band of matevalidation & product life cycle improvement for rial, producing a microdevelopment complex parts structure similar to how the material would look Fig. 2. Additive manufacturing (AM) enables quick realisation if being built up by a numof exciting new product features and highly customised ber of weld passes. Howsolutions. ever, due to differences in input energy and actual cesses that today can be used as alterna- melt pool size, the microstructure is not a tives to normal manufacturing routes for typical weld structure. metallic, ceramic and polymer components Building of a component is performed on in many applications, for instance tooling a substrate plate, normally manufactured mould inserts, automotive components from steel. The plate is attached onto a and also details for the aerospace industry processing table that can translate in the z[4 to 6]. Major drivers for the increased direction in a chamber with a controlled atinterest in ALM are: availability of differ- mosphere, typically nitrogen (often used for ent alloy powders [7] (aluminium, steel, steels) or argon (inert gas, for instance used cobalt base and also nickel base powders), for super alloys). A thin layer of powder (in increased production rate [8] (available the range of 20 to 60 µm) is distributed by a laser power and better understanding of so-called recoater onto the substrate plate. the manufacturing process) and high qual- After this, the laser beam travels over the ity of the manufactured components [9] first powder layer that will form the com(low amount of porosity, pure material, ponent. The process table is lowered, new homogeneous material). Also the number powder distributed and a new laser scan is of industrially available equipments has performed. Layer by layer, the process is reincreased over the past years [10]. peated and the component is built up. Most AM technologies for metals share the Different approaches are used for laser following procedures [11]: sources and laser beam positioning. For the –– produce the raw powder in fine particle SLM process, the laser source is normally fractions, an Nd-YAG fiber laser. During building , the –– spread powder in thin layers of 20 to 100 laser is moved by positioning of a reflectµm thickness, ing mirror or by moving the laser head. The –– join the powder particles – to form one laser beam is focused via a series of lenses. solid layer – using thermal energy such The current publication focusses on manuas laser or an electron beam that sinter, facturing of material with the SLM process. partially or fully melt and weld the particles or adhesive chemicals that are in- Electron-beam melting jected to glue the particles, With the electron-beam process, fully –– repeat the process to build stacked and dense metal components can be manufaccoherent layers, tured in the same way as described above –– post-process to increase strength, sur- regarding the SLM process. The main difface or other specific properties. ferences are: –– the material is being melted by an elecSelective laser sintering/melting tron beam, Within the group of additive layer manu–– chamber temperature is elevated up to facturing processes one of the processes around 1,000 °C (material dependent), is based on melting powder with a laser – – powder sieving fractions are coarser source. Two methods of laser sintering need than the powder used for SLM. to be mentioned here: selective laser sintering (SLS) [12] and selective laser melting (SLM) [13]. SLS is a method where a powder is partially melted and SLM is a method where the powder is completely remelted during the manufacturing process. Both the SLS and SLM processes are so-called powder-in-bed methods where a component is built up layer-by-layer. A directed laser beam is used to melt a thin layer of pre-placed powder into a slice that will represent a cross-section of the component to be built. Through addition of successive layers, the component is manufactured slice by slice. For each slice the laser will travel An EBM machine utilises a high power electron beam that generates the energy needed for high melting capacity and high productivity. The electron beam is managed and controlled by electromagnetic coils instead of mirrors in the laser-based system. If the SLM processes are using inert gas, the EBM process takes place in vacuum. Current status and expected trends of AM technology It has been stated that AM today is as advanced as computers were in the mid-80s. This is to say that a huge wave of progress >>> VGB DIGITAL <<< is expected in terms of improved speed, reliability, ease of use and operator friendliness, 3D-printing quality, standardisation of processes and components inside the 3D-printers, etc. A tremendous improvement of AM process capability can be noted. In 2009, laser sources of 200 W were considered to be the market standard. In 2011, the market standard became 400 W. In the same year, single providers of SLM equipment launched prototype 1 kW sources in their products. But maybe the most important effect on building speed must be expected by the introduction of multiple laser sources that work in parallel, independently from each other. Market introduction of a double beam SLM machine was announced in 2011. In this case, a 1 kW source for the melting of large cross sections was coupled together with a smaller 400 W source for achieving precise skin features. In 2015, 4-beams SLM machine are expected on the market. Equipment When comparing available brands of equipment for additive manufacturing, a number of European producers are available. European equipment manufacturers of selective laser melting systems are: –– Electro Optical Systems, EOS (Germany) –– ConceptLaser (Germany) –– SLM Solutions (Germany) –– Renishaw (UK) –– Phenix (France) –– Realizer (Germany) –– Sisma (Italy) For electron beam melting, the major equipment supplier today is Arcam (Sweden). Equipment manufacturers have so far focussed on development of equipment with successively larger laser capacities-up to 1 kW. With larger lasers and multiple lasers, the productivity will increase through faster scanning with constant heat input or application of thicker layers in each laser scan. Besides this, the equipment manufacturers face a number of challenges: –– increase of AM equipment productivity and size of the components that can be manufactured, –– AM system users require much more information available to be read into and out of an AM system in order to allow for better quality assurance and productivity optimisation, –– process data evaluation tools are needed in order to better understand process limits and allow for identification of process control limits, –– equipment of the same make and type must be able to produce material to identical quality levels, –– customers will need better transferability of process parameters and material 49 VGB PowerTech 12 l 2015 3D printing for gas turbine components of avoiding costly scrap and rejections. Traditional processes like casting and hotrolling are well-understood and process control limits are frequently used, in order to secure a flow of material with acceptable quality. In additive manufacturing, today no philosophy and, accordingly, no commercially available equipment exist, for on-line process monitoring control. This causes unnecessarily large efforts in terms of destructive testing and high cost added in production, causing AM to lose in terms of competitiveness. Currently, Siemens is looking for cooperation with AM OEMs to initiate development and implementation of process monitoring into AM equipment. Fig. 3. Customised EOS SLM machine for burner repairs. properties from one generation of SLM systems to the next, –– on-line monitoring systems must be developed and implemented in commercial products (F i g u r e 3). In order to address all these challenges in time and in proper order, cooperation between AM equipment suppliers and customers can be very beneficial for quick industrialisation of AM technology. As an example of such cooperation customisation of EOS equipment for Siemens’ needs can be mentioned. Based on Siemens’ request and specification, the company EOS individually adapted and modified one of its machines EOSINT M 280 for Siemens gas turbine burner repair. The scale of the machine’s interior was enlarged to accommodate the 800 millimeter burner. The manufacturer also amended further hardware components such as a camera system and an optical measuring system and made corresponding adjustments to the software. AM value chain VGB PowerTech - Autorenexemplar - © 2015 Powder materials Understanding powder composition and morphology are key factors to control when setting up and managing an AM process. Powder cleanliness, chemistry control and powder homogeneity are some of the parameters that must be well understood. Since powder manufacturing, especially for AM processes requires tight alloying element control and atomising equipment specialised to maximise yield and productivity for the very specific powder size ranges used, large efforts are put into setting up a process for additive manufacturing. A good example could be an AM plant where not only component but also powder manufacturing is established. Through this set up, it is possible to maximise the value added to any given component manufactured. Also the powder can be better utilised, since different AM processes will use different fractions of the atomised powder. Powder suitable for AM is typically sieved into fractions where the yield is gained 50 between 10 to 160 µm. When the powder is sieved to fit, for instance in SLM, a large portion of the powder has to be recycled with increased powder cost. If two complementary processes are utilising the same powder, the yield in atomising will dramatically increase. This would be the case comparing SLM and EBM manufacturing. Several suppliers can provide powders suitable for additive manufacturing. Gas atomised powder is required with sieving fractions in a relatively tight size range. Depending on equipment and setup (layer thickness), the sieved fractions will be in the range of 10 µm to 30 µm up to 10 µm 45 µm for thin layer thicknesses. Process parameters Equipment for AM processes is readily available. However, the knowledge regarding how to set up and maintain an AM process cannot easily be acquired. Knowledge on laser or electron beam performance, process parameter optimisation and process performance and stability it is hard to be gained from original equipment manufacturers (OEM). In many cases, the selection of available materials and corresponding process parameters does not match the needs from large companies. Especially advanced materials for aggressive environments and high temperatures are not readily available. This means that large efforts need to be put into the equipment process parameter development. In order to fully utilise the AM process, it is highly likely that several alternative process parameter packages could be available for one material. Depending on the component requirements, the process will need to be set up for best economy (speed), accuracy (tolerances and surfaces) or performance (strength). Post-treatment Materials manufactured with AM techniques are, in many cases, superior to traditionally manufactured components even without any post-processing. The materials created are very homogeneous without internal flaws and defects. However, there are a number of properties that might cause problems (surfaces, internal stresses, behaviour at extreme temperatures) that require improvements. Material response to external loading will also typically be anisotropic. These, and other factors, will put requirements on post-treatments to further optimise component performance. Depending on the type of post-processing, the cost associated with the treatment can be low (heat-treatment) or high (surface improvement). However, the cost associated with establishment of a cheap postprocessing operation might be substantial (e.g., as in development of heat treatments for optimal mechanical material properties for different applications). Material data and design criteria As previously mentioned, material data generation can be required for a number of variations of one given material. The cost associated with material data generation is very dependent on the application. Depending on the application, the cost associated with material data generation and implementation for one material into designer-friendly tools can range from modest numbers up to 1 to 1.5 m €. If generated, this type of data is today typically not readily available in open sources. At Siemens Power Generation, authors are keeping high focus on establishment of the process parameters for nickel based materials. It is very likely that the full understanding of AM materials can be gained only, if larger consortia are formed, where synergies will allow for good understanding of residual stresses, mechanical properties and physical properties coupled to process behaviour and part performance described as dimensional accuracy or bulk and surface quality. Process monitoring Design tools Process monitoring is, for all traditional manufacturing processes, a natural way Design criteria are not only material data and design data developed from material >>> VGB DIGITAL <<< VGB PowerTech 12 l 2015 1 Rapid prototyping Blade 1 Product: 3D printing for gas turbine components 2 Rapid repair Burner SGT Product: 3 Siemens is using AM (SLM) technology for three main applications (F i g u r e 4): –– rapid prototyping, –– rapid repair and –– rapid manufacturing. Rapid manufacturing Burner Product: SGT SGT Component: E.g. turbine blade 1 Component: Burner tip Component: Burner swirler Benefit: Significant reduction of time to market Benefit: Benefit: Status: Part ot standard process Status: 10 times faster, easy upgrades In commercial application Status: Swirler can only be made via SLM In commercial application Fig. 4. Three pillars of SLM application. performance. Design data also include design features and guidelines on how to and how not to design an element with additive manufacturing. This type of information can, to some extent, be found in open literature and can be used as an input. However, adoption to the local situation will always be required. Guidelines when to and when not to select an AM process also need to be available in order to minimise the needs for parallel development of a component adopted for different manufacturing processes. In order to fully utilise AM technologies, the mind-set of designers and engineers must be changed. Standards Today, standards for additive manufacturing in general and specifically for SLM are not readily available. The standards for SLM are limited to a handful documents within (sections here adopted as per ASTM grouping): VGB PowerTech - Autorenexemplar - © 2015 Design –– ISO/ASTM52915 – 13: Standard Specification for Additive Manufacturing File Format (AMF) Version 1.1 –– ISO/DIS 17296 – 4: Additive manufacturing – General principles – Part 4: Overview of data processing Materials and Processes –– ASTM F2924 – 12a: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion –– ASTM F3001 – 13: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion –– ISO/DIS 17296 – 2: Additive manufacturing – General principles – Part 2: Overview of process categories and feedstock Terminology –– ASTM F2792 – 12a: Standard Terminology for Additive Manufacturing Technologies –– ISO/CD 17296 – 1: Additive manufacturing – General principles – Part 1: Terminology Test Methods –– ISO/ASTM52921 – 13: Standard Terminology for Additive Manufacturing-coordinate Systems and Test Methodologies –– ISO/DIS 17296 – 3: Additive manufacturing – General principles – Part 3: Main characteristics and corresponding test methods It is obvious that the process is yet not fully standardised but also important to notice that the basic concepts are settling in the standards mentioned above. Applications As already mentioned, AM is a revolutionary technology enabling simultaneously enhancement of component performance and reduction of delivery time. SLM is a new dimension in integrated design and manufacturing, converting our dreams into reality, with practically no limitation and at extremely short delivery times. With this technology, complex multi-elements components could be produced as aone integral part with higher performance and, in majority of cases practically at the same cost (e.g. GT burners with lower emissions and higher lifetime, GT vanes with better cooling efficiency and longer life time). Rapid prototyping Integration of AM into the product development process enables significant speedup of design and validation of new components and system, as well as ensuring high reliability and performance of newly designed components prior to final engine testing and product release. In the past, due to long delivery time of new components manufactured by conventional methods (e.g. casting), component validation testing was done almost at the end of the development process, during the final engine test. This is why a conventional development procedure has some disadvantages and consequences: –– sequential development process, –– conservative development approach, –– moderate development targets/results, –– long development cycles. With new approach, when AM is an integral part of the development process (F i g u r e 5) and can be used for rapid components design and manufacturing, the following advantages can be realised: –– parallel and integrated development processes, –– radical development approaches, –– ambitious development targets/results, –– fast development cycles. Utilisation of AM technology for compressor turbine blade design enables the evaluation a few blade cooling concepts and their tests in a real engine environment in a few months instead of a few years. Rapid repair Repair of components has also been identified as an application with big potential. Damaged areas of material can be removed and new material built up. Just as for new manufacturing, the lead time reduction is expected to be significant, especially for complex compound structures or raw materials with long lead time from order to supply. Recently developed the repair procedures for SGT-700 & -800 burners tips using SLM Integrated development -> Iteration in a few months instead of years 3D-design SLM 3D-print Processing Instrument. Test 3D-integrated CAE/CAD/CAM Fig. 5. SLM as a part of product development process. >>> VGB DIGITAL <<< 51 VGB PowerTech 12 l 2015 3D printing for gas turbine components Metal powder Laser Platform Burner It starts on the computer - the gas turbine burner needs a new tip A layer of powder is applied A laser beam fuses the powder –– increased coating adhesion: micro-scale engineered surfaces, –– new powder alloys possible: improved lifetime of the components. Despite all these benefits and advantages, there are several aspects that make the AM process difficult to use today: –– the process is slow, development of equipment is needed, –– quality assurance measures need to be refined, –– design tools are not readily available, –– material data is not generated to the extent required by users, –– available materials do not match needs from industry. The research community and industry together need to resolve all these challenges to speed up industrialisation of AM to its full extent. References The platform lowers A new layer of metal by a few micrometers powder is applied The process is repeated, layer by layer This process gradually produces a new burner tip that is melted onto the rest on the component Fig. 6. SGT-800 & SGT-700 burner SLM repair procedure. technology is 10 times quicker than previously used “conventional” repair procedures, as it avoids quite a few manufacturing and inspection processes. Conventional repair procedure required prefabrication of a large portion of the burner tip. This prefabricated burner tip is used for replacement of the burner tip after the specified operation time (the old tip was cut off and the prefabricated one welded on). Conventional repair procedure was time-consuming, with a significant number of sub-processes and examinations. AM repair process of SGT-700 & SGT-800 burners is shown in F i g u r e 6. Replacement of conventional repair processes with SLM provided not only a significant reduction in repair time, but also an opportunity to modify repaired components to the latest burner design. VGB PowerTech - Autorenexemplar - © 2015 Rapid manufacturing AM technology industrialisation is also enabling new opportunities for spare part and supply chain enhancement: –– manufacturing of spare parts on demand, –– regionalisation of rapid repair and manufacturing of GT components, –– simplification of logistics and investment reduction on stocks. Currently, Siemens Power Generation is focusing on industrialisation of SLM for rapid repair and manufacturing of Siemens gas turbine components. Today, we already have burner swirls in commercial operation in one of our industrial gas turbines. We used AM technol52 ogy for this complex burner swirl, because AM was the only technology that can produce it. In the next few years we are planning to extend the scope of AM manufactured gas turbine components to burners, fuel strainers, heat shields and guide vanes. Conclusion Additive manufacturing enables a revolution in spare parts manufacturing and generates the following values and opportunities: Lead time reduction and life cycle improvement for complex parts: –– lead time reduction: faster technology validation and product development, shorter time to market, –– reduced number of process steps: simplified manufacturing and repair, faster manufacturing and repair, –– saving of material, –– reduced number of parts in a component: integrated functionality, –– eliminated tools: no time consuming casting process, –– on-demand, instant, de-centralized production (e.g. for service). Efficiency increase through practically unlimited options for internal and external cooling duct design: –– better heat transfer and lattice structures: thinner walls and larger surface areas, –– improved mixing of fuel and air: advanced nozzle designs, >>> VGB DIGITAL <<< [ 1] Navrotsky, V., Graichen A., and Brodin, H.: Industrialization of 3D printing for gas turbine components repair and manufacturing. VGB Conference “Gas Turbines and Operation of Gas Turbines 2015”, 06/07 May 2015, Lübeck/Germany. [ 2] Brodin, H, Navrotsky, V, Graichen A.: 3D printing at Siemens Power Generation Service. Total Conference, Paris, France, 1712-2015. [ 3] Navrotsky, V, Graichen A, and Brodin, H.: 3D printing at Siemens Power Generation Service. 3D printing technology, Las Vegas, USA, 18-02-2015. [ 4] Kumar, S.: Iron-based powders and SLS/ SLM for rapid tooling. PhD thesis, Katholieke Universitet Leuven, Leuven, Belgium, (2008). [ 5] Emmelmann, C., Petersen, M., and Goeke, A.: Laser freeform fabrication for aircraft applications, In: Proceedings of the fifth international WLT-conference on lasers in manufacturing, (2009), pp. 171-174. [ 6] Srivastava, D., Chang, I.T.H, and Loretto, M.H.: Intermetallics 9, (2001), pp. 10031013. [ 7] Santos, E.C., Shiomi, M., Osakada, K. and Laoui, T.: Int. J. Machine Tools Manuf., 46, (2006), pp. 1459-1468. [ 8] Costa, L., and Vilar, R.: Rapid Prototyping J.. 15, No. 4, (2009), pp. 264-279. [ 9] Kruth, J.P., Froyen, L., Van Vaerenbergh, J., Mercelis, P., Rombouts, M., and Lauwers, B.: J Mater. Process. Technol., 149, (2004), pp. 616-622, [10] Kruth, J.P., Levy, G., Klocke, F. and Childs, T.H.C.: Annals CIRP, 56, No. 2, (2007), pp. 730-759. [11] Ghany, K.A., and Moustafa, S.F.: Rapid Prototyping J. Vol. 12, No. 2, (2006), pp. 86-94. [12] Kruth, J.P., Wang, X., Laoui, T., and Froyen, L.: Assembly Automation, 23, No. 4, (2003), pp. 357-371, [13] Van Elsen, M., Al-Bender, F., and Kruth, J.P.: Rapid Prototyping J., 14, No. 1, (2008), pp. 15-22. [14] Mazumder, J., Choi, J., Nagarathnam, K., Koch, J., and Hetzner, D.: The direct metal deposition of H13 tool steel for 3D components. JOM, Vol. 49 No. 5, pp. 55-60, [15] Mumtaz, K.A., and Hopkinson, N.: J Mater. Processing Technol., 210, (2010), pp. 279l 287. International Journal for Electricity and Heat Generation 600 K 43 · ISSN Volume 90/2010 e Volum 009 89/2 K 43600 89/2009 · ISSN 14 35-3199 K 4360 199 0 35-3 N 14 · ISS Volume 1435-3199 Focus: Furnac es, Steam G and Stea enerators m Turb ines USC 70 0 Techno °C Power logy Focus: Pro Quality The Pro-quality Approach e nanc ainte ts s: M Focu wer Plan of Po of lants epts Conc Power P IGCC f o t n ssme r Asse rators fo lants Gene Power P Wind for Data nical Tech r Plants e s Pow ertie Prop 9 ation143O5-il3s19 Oxid Irb e N S in · S 5u of0T me Volu Quality in the Construction ts of New Power Plan of Quality Monitoring Steam Turbine Sets l Supply of Technica Documentations Volume 89/2009 · 20 85/ Ultra-lo w Combu NOx stion Replace Strategy ment Superh of a eater St age Volum Econom e 89/2 009 combu ic Post- · ISSN 1435-3199 stion C arbo Capture Process n K 43600 es 0 360 K4 Congress Issue ISSN 1435-3199 Interna tio for Elec nal Journal tricity and Heat Ge neration Publica onB tion of ti VG i PowerTec l Ed tiona h e.V. www.v na r gb.org Inte nal International Jour Heat Generation for Electricity and Publication of e.V. VGB PowerTech www.vgb.org tion l urna t Genera ea nal Jo natio ty and H ci Inter ectri for El of e.V. cation Publi werTech Po VGB gb.org .v www K 4360 0 tion International Edi Interna tional Ed ition Focus: in Com Power Plan ts petito n New P ower P P ro la n : je t cts of s ema Eskom Focus: VGB Congres ktth ergien n pun Qualit wer re E Power Plants 2009 y Assu Sch euerba fo s ra r y nce N n a ew Po Er thw vities wer P Report on the Acti n Pa lants roge rios Advan of VGB PowerTech Hyd Scena ta Flexib ges of and 2008/2009 le The – itions II rm G k r enera d al tion swe Con s Kop vailing n EDF Group Reduce t Pre Desig Marke its Carbon Footprin t Overv and fo ie r Impo ark ank rted C w w B ind P oal Optimising Wind Farm Arklohore W Maintenance Offs r e v te ti Wa Direc U E The mework Concept for Solar ts Internatio Fra n Hybrid Power Plan for nal Jo ditio Pu ur Electri city an nal d Heat Genera tion blicati VGB Po on of Qualifying ww rs werTech Power Plant Operatow.vgb.org e.V. on rati al ene ourn Heat G al J nal tion ity and International Jour rna Heat Generation Inte lectric for Electricity and E for of .V. he tion cation of lica erTec li Pub b u P e.V. Pow rg VGB PowerTech VGB .vgb.o w www.vgb.org ww al E tion rna Inte tion International Edi Interna tional Edition Please copy >>> fill in and return by mail or fax Yes, I would like order a subscription of VGB PowerTech. The current price is Euro 275.– plus postage and VAT. Unless terminated with a notice period of one month to the end of the year, this subscription will be extended for a further year in each case. Name, First Name Street Postal Code City Country Phone/Fax Return by fax to Date VGB PowerTech Service GmbH Fax No. +49 201 8128-302 Cancellation: This order may be cancelled within 14 days. A notice must be sent to to VGB PowerTech Service GmbH within this period. The deadline will be observed by due mailing. I agree to the terms with my 2nd signature. or access our on-line shop at www.vgb.org | MEDIA | SHOP. Date 1st Signature 2nd Signature VGB PowerTech DVD 1990 bis 2014: 25 Jahrgänge geballtes Wissen rund um die Strom- und Wärmeerzeugung Mehr als 25.000 Seiten Daten, Fakten und Kompetenz Fachzeitschrift: 1990 bis 2014 Bestellen Sie unter www.vgb.org > shop · 1990 bis 2014 · · 1990 bis 2014 · © Sergey Nivens - Fotolia Diese DVD und ihre Inhalte sind urheberrechtlich geschützt. © VGB PowerTech Service GmbH Essen | Deutschland | 2015 s uch al Jetzt a 4 D 201 C s e r en Jah usgab A n e l l ch mit a werTe € o P B der VG s: nur 98,– hre des Ja PowerTech-CD/DVD! Kontakt: Gregaro Scharpey Tel: +49 201 8128-200 mark@vgb.org | www.vgb.org Ausgabe 2014: Mehr als 1.100 Seiten Daten, Fakten und Kompetenz aus der internationalen Fachzeitschrift VGB PowerTech (einschließlich Recherchefunktion über alle Dokumente) Bruttopreis 98,- Euro incl. 19 % MWSt. + 5,90 Euro Versand (Deutschland) / 19,90 Euro (Europa)