RHOPLEX™ AC-630

advertisement

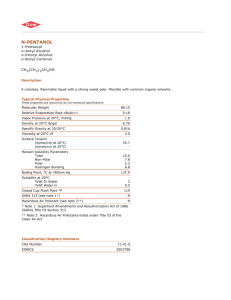

Technical Data Sheet RHOPLEX™ AC-630 100% Acrylic Polymer Emulsion Introduction RHOPLEX™ AC-630 emulsion is an all-acrylic polymer designed for tough, water-resistant sealers. These coatings are commonly factory-applied to retard efflorescence of cured cementitious products formed in plants under controlled conditions. Typical applications include roofing tiles and precast construction products. Advantages The advantages of using RHOPLEX™ AC-630 emulsion can be summarized as follows: Sealer Characteristics • Retards efflorescence • Water-resistant • Tough • Glossy • Clear and colorless Application Characteristics • Sprays readily at high solids • Good film formation • Low volatile organic content (VOC) Formulation Characteristics • Compounded easily • Requires low defoamer levels • Formulation stability Typical Physical Properties These properties are typical but should not be considered specifications. Appearance Milky white liquid Solids content, % by weight 50.0 pH 9-10 Viscosity, cPs 200-600 Density, lbs/gal 8.89 Dry bulking value 1.110 Minimum film formation temperature 17 (MFFT), °C Tukon hardness, KHN 2-3 Sealer Performance Sealer performance is sensitive to both formulation and application variables. Potential formulations should be evaluated thoroughly before being adopted on a commercial basis. Tests should include expected climatic conditions, exposure direction, substrate integrity and desired performance. Performance of waterborne systems is sensitive to environmental conditions at the time of application. For example, a combination of high humidity and low temperature detracts from the ability of aqueous coatings to form a film with maximum performance capability. Careful formulation is required to assure adequate film formation. Page 1 of 3 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ AC-630 / Dow Construction Chemicals July 2010 Mechanism of Film Formation When the wet coating has been applied to a substrate, the resin particles are separated from each other in the aqueous phase of the formulation. As the water evaporates, the particles are driven together until they touch. The formulation contains additives, often referred to as coalescents, which temporarily soften the latex particles during the drying process and then leave the film by evaporation. The capillary pressure created by the evaporating water deforms the “softened” particles so they coalesce into a tough and resistant continuous polymer film. The evaporation of water, and hence the process of film formation, can be affected significantly by several factors. Relative humidity, temperature and air flow all impact on evaporation rate. Relative Humidity Relative humidity is particularly important because it affects the evaporation of both coalescing solvents and water. During drying at low or moderate humidity, water leaves a coating more rapidly than typical coalescing solvents, leaving sufficient coalescent for film formation. Under conditions of low humidity, the coating film partially coalesces very quickly. The evaporation of coalescent slows as the film develops because the coalescent must diffuse (a slow process) through the partially formed film before it can volatilize into the atmosphere. The extended retention of coalescent slightly retards early development of hardness properties and lengthens tack-free time, but the quality of the final film is very good. The situation changes dramatically at high humidity. Water evaporates slowly at high relative humidity. Coalescent evaporation, on the other hand, continues at a relatively rapid rate because it does not have to diffuse through the partially formed film. Simple convection removes the solvent while the water remains behind. By the time the coating has dried enough for film formation to occur, enough coalescent may have left the coating for the polymer particles to return to their natural hard state. Without the coalescent to soften the particles, they may not deform sufficiently for adequate film formation. As a result, the coating may not demonstrate its full performance potential even though some properties such as gloss, hardness, and flexibility may be normal. Formulation Guidelines Page 2 of 3 Contact your local Dow representative for suggested starting point formulations and related information. ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ AC-630 / Dow Construction Chemicals July 2010 Product Stewardship Dow has a fundamental concern for all who make, distribute and use its products, and for the environment in which we live. This concern is the basis for our product stewardship philosophy by which we assess the safety, health and environmental information on our products and then take appropriate steps to protect employee and public health and our environment. The success of our product stewardship program rests with each and every individual involved with Dow products – from the initial concept and research to manufacture, use, sale, disposal and recycle of each product. Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and their applications of Dow products from the standpoint of human health and environmental quality to ensure that Dow products are not used in ways for which they are not intended or tested. Dow personnel are available to answer your questions and to provide reasonable technical support. Dow product literature, including safety data sheets, should be consulted prior to use of Dow products. Current safety data sheets are available from Dow. Disclaimer NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, the Customer is responsible for determining whether products and the information in this document are appropriate for the Customer’s use and for ensuring that the Customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. The Dow Chemical Company www.dowconstructionchemicals.com 215-592-3000 Page 3 of 3 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ AC-630 / Dow Construction Chemicals Form No. 832-00045-0710P&M July 2010