Resume_KristenWoznick

advertisement

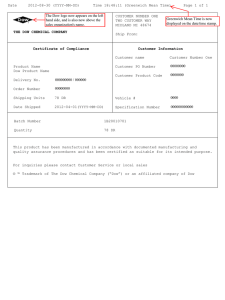

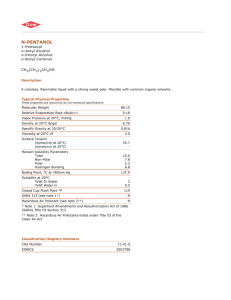

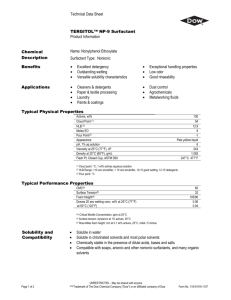

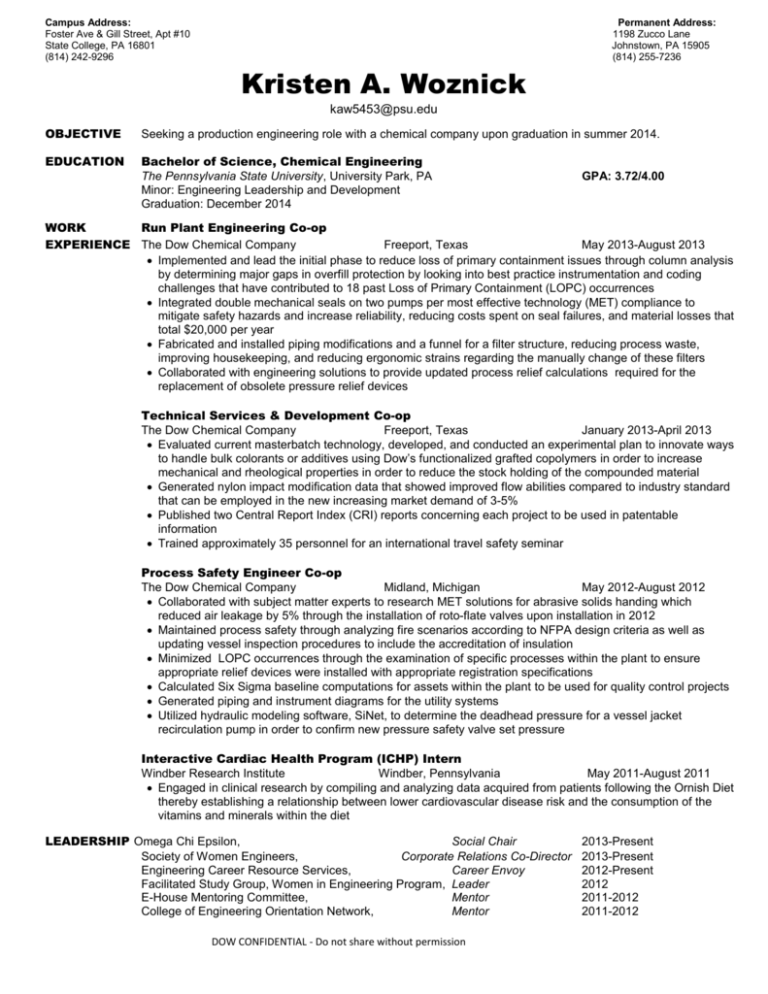

Campus Address: Foster Ave & Gill Street, Apt #10 State College, PA 16801 (814) 242-9296 Permanent Address: 1198 Zucco Lane Johnstown, PA 15905 (814) 255-7236 Kristen A. Woznick kaw5453@psu.edu OBJECTIVE Seeking a production engineering role with a chemical company upon graduation in summer 2014. EDUCATION Bachelor of Science, Chemical Engineering The Pennsylvania State University, University Park, PA Minor: Engineering Leadership and Development Graduation: December 2014 GPA: 3.72/4.00 WORK Run Plant Engineering Co-op EXPERIENCE The Dow Chemical Company Freeport, Texas May 2013-August 2013 Implemented and lead the initial phase to reduce loss of primary containment issues through column analysis by determining major gaps in overfill protection by looking into best practice instrumentation and coding challenges that have contributed to 18 past Loss of Primary Containment (LOPC) occurrences Integrated double mechanical seals on two pumps per most effective technology (MET) compliance to mitigate safety hazards and increase reliability, reducing costs spent on seal failures, and material losses that total $20,000 per year Fabricated and installed piping modifications and a funnel for a filter structure, reducing process waste, improving housekeeping, and reducing ergonomic strains regarding the manually change of these filters Collaborated with engineering solutions to provide updated process relief calculations required for the replacement of obsolete pressure relief devices Technical Services & Development Co-op The Dow Chemical Company Freeport, Texas January 2013-April 2013 Evaluated current masterbatch technology, developed, and conducted an experimental plan to innovate ways to handle bulk colorants or additives using Dow’s functionalized grafted copolymers in order to increase mechanical and rheological properties in order to reduce the stock holding of the compounded material Generated nylon impact modification data that showed improved flow abilities compared to industry standard that can be employed in the new increasing market demand of 3-5% Published two Central Report Index (CRI) reports concerning each project to be used in patentable information Trained approximately 35 personnel for an international travel safety seminar Process Safety Engineer Co-op The Dow Chemical Company Midland, Michigan May 2012-August 2012 Collaborated with subject matter experts to research MET solutions for abrasive solids handing which reduced air leakage by 5% through the installation of roto-flate valves upon installation in 2012 Maintained process safety through analyzing fire scenarios according to NFPA design criteria as well as updating vessel inspection procedures to include the accreditation of insulation Minimized LOPC occurrences through the examination of specific processes within the plant to ensure appropriate relief devices were installed with appropriate registration specifications Calculated Six Sigma baseline computations for assets within the plant to be used for quality control projects Generated piping and instrument diagrams for the utility systems Utilized hydraulic modeling software, SiNet, to determine the deadhead pressure for a vessel jacket recirculation pump in order to confirm new pressure safety valve set pressure Interactive Cardiac Health Program (ICHP) Intern Windber Research Institute Windber, Pennsylvania May 2011-August 2011 Engaged in clinical research by compiling and analyzing data acquired from patients following the Ornish Diet thereby establishing a relationship between lower cardiovascular disease risk and the consumption of the vitamins and minerals within the diet LEADERSHIP Omega Chi Epsilon, Social Chair Society of Women Engineers, Corporate Relations Co-Director Engineering Career Resource Services, Career Envoy Facilitated Study Group, Women in Engineering Program, Leader E-House Mentoring Committee, Mentor College of Engineering Orientation Network, Mentor DOW CONFIDENTIAL - Do not share without permission 2013-Present 2013-Present 2012-Present 2012 2011-2012 2011-2012