– Tulevaisuuden ReFuel dieselpalamistekniikat synteettisille ja uusiutuville polttoaineille

advertisement

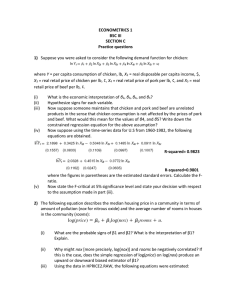

ReFuel – Tulevaisuuden dieselpalamistekniikat synteettisille ja uusiutuville polttoaineille Kalle Lehto, Aalto-yliopisto 26.1.2012 VI Liekkipäivä, Lappeenranta Aalto University, School of Engineering, Deparment of Energy Technology • Internal Combustion Engine Research Group • Located in Otaniemi, Espoo • Staff of about 25 • Research Focus – experimental research • alternative fuels • extreme values • fuel sprays – computational research • spray simulation • process simulation VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel • a three year research project (2009-2011) • goal – utilize the potential of the renewable high cetane number parafinic fuels and their oxygenate blends develop optimum combustion technologies for them • tools – - literature study simulations (CFD) emission mapping calculations spray measurements engine tests with medium- and high-speed engines VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel • a three year research project (2009-2011) • goal – utilize the potential of the renewable high cetane number parafinic fuels and their oxygenate blends develop optimum combustion technologies for them • tools – - literature study simulations (CFD) emission mapping calculations spray measurements engine tests with medium- and high-speed engines VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel • research partners – – – – • industry partners – – – – Aalto VTT ÅA TUT Neste Oil Agco Sisu Power Wärtsilä Aker Arctic • financing – Tekes – Industry – Universities and VTT VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – High-speed engine tests, LEO VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto EN590 vs. Hydrogenated Vegetable Oil (HVO) • commercial EN590 summer grade diesel as a reference fuel • 100 % HVO as a test fuel Quantity Unit Cetane number (IQT) EN590 HVO 56 88,2 Density kg/m3 837,3 779,9 Total aromatics wt-% 18,7 0,3 6,4 5,6 3,587 2,985 C/H ratio Viscosity (at 40 °C) mm2/s VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – High-speed engine tests, LEO • goal – a 70 % reduction in emissions (NOx, PM) by using Hydrotreaded Vegetable Oil (HVO) together with Exhaust Gas Recirculation (EGR) and Miller timing • test run campaigns – – – – reference tests with both EN590 and HVO separate miller- and EGR-test runs combined miller and EGR with injection parameter optimization test runs with HVO + oxygenate blend VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel - LEO • LEO is a single-cylinder high-speed diesel research engine • perfectly suited for this sort of test runs – Electro Hydraulic Valve Actuators enable easy miller cycle operation – easily controllable simulated EGR rate with neat nitrogen – fully adjustable fuel injection parameters (SOI, Inj.p, Inj.dur., pilot- and post injections...) LEO electro hydraulic valve actuators (EHVA) VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto LEO – Miller timing with an Electro Hydraulic Valve Actuator system (EHVA) Miller Timing Valve Lift Curves Exhaust Intake ref Miller 30 Miller 50 Valve Lift Miller 70 90 180 270 360 450 540 630 Crank Angle [deg] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – LEO, Results from the separate EGR- and miller test runs VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel LEO – Reducing NOx and FSN emission by using HVO, EGR + Miller • EN590 reference NOx - FSN LEO - 50 % Load 1,4 1,2 Smoke [FSN] 1 0,8 0,6 0,4 0,2 0 0 50 100 150 200 250 300 350 NOx [ppm] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel LEO – Reducing NOx and FSN emission by using HVO, EGR + Miller • EN590 reference • HVO (NExBTL) Reference NOx - FSN LEO - 50 % Load 1,4 1,2 Smoke [FSN] 1 0,8 0,6 0,4 0,2 0 0 50 100 150 200 250 300 350 NOx [ppm] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel LEO – Reducing NOx and FSN emission by using HVO, EGR + Miller • EN590 reference • HVO (NExBTL) Reference • HVO + 2,5 % EGR NOx - FSN LEO - 50 % Load 1,4 1,2 Smoke [FSN] 1 0,8 0,6 0,4 0,2 0 0 50 100 150 200 250 300 350 NOx [ppm] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel LEO – Reducing NOx and FSN emission by using HVO, EGR + Miller • EN590 reference • HVO (NExBTL) Reference • HVO + 2,5 % EGR • HVO + 2,5 % EGR, Miller 70 NOx - FSN LEO - 50 % Load 1,4 1,2 Smoke [FSN] 1 0,8 0,6 0,4 0,2 0 0 50 100 150 200 250 300 350 NOx [ppm] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel LEO – Reducing NOx and FSN emission by using HVO, EGR + Miller NOx - FSN LEO - 50 % Load 1,4 1,2 1 Smoke [FSN] • EN590 reference • HVO (NExBTL) Reference • HVO + 2,5 % EGR • HVO + 2,5 % EGR, Miller 70 • HVO + 10 % EGR, Miller 70, Inj.p +100 bar 0,8 0,6 0,4 0,2 0 0 50 100 150 200 250 300 350 NOx [ppm] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – LEO Optimized process (combined EGR + Miller) • Three engine loads (50, 75, and 100 %) • for each load a ”Low NOx”, ”Low Smoke” and an ”Opt” setup was created by varying EGR, miller, and fuel injection • The target was a 70 % reduction in one emission component without the other being higher than in the reference run with EN590 • The charge air mass flow was kept constant by adjusting the charge air pressure and the load was kept constant by adjusting injection duration VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – High-speed engine tests, LEO – 50 % Load Emission EGR Miller Inj. p var. SOI var. NOx FSN Opt. 5% 70 +100 bar 0 -31 % -54 % Low NOx 10 % 70 +100 bar 0 -60 % +2 % Low Smoke 2,5 % 70 +100 bar -3 -1% -73 % EN590 reference NOx - Smoke 50 % Load HVO refefence HVO Optimized 1,4 1,2 1,0 Smoke [FSN] 50 % Load Point 0,8 0,6 0,4 0,2 0,0 0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 NOx [g/kWh] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – High-speed engine tests, LEO – 75 % Load Emission EGR Miller Inj. p var. SOI var. NOx FSN Opt 10 % 70 +400 bar 0 -52 % -53 % Low NOx 10 % 70 +400 bar +2 -64 % -19 % Low Smoke 2,5 % 70 +200 bar 0 -12 % -75 % EN590 reference NOx - Smoke 75 % Load HVOreference HVO Optimized 1,4 1,2 1,0 Smoke [FSN] 75 % Load Point 0,8 0,6 0,4 0,2 0,0 0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 NOx [g/kWh] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto ReFuel – High-speed engine tests, LEO – 100 % Load Emission EGR Miller Inj. p var. SOI var. NOx FSN OK 10 % 70 +600 bar 0 -54 % -58 % Low NOx 12 % 70 + 600 bar +1 -66 % -13 % Low Smoke 2,5 % 70 + 400 bar 0 -10 % -85 % EN590 reference NOx - Smoke 100 % Load HVO reference HVO Optimized 0,8 0,7 0,6 Smoke [FSN] 100 % Load Point 0,5 0,4 0,3 0,2 0,1 0,0 0 1 2 3 4 5 6 NOx [g/kWh] VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto Specific Fuel Consumption - 100 % Load Specific Fuel Consumption [g/kWh] 250 Low Smoke Low NOx 50 OK 100 HVO ref 150 EN590 ref SFC [g/kWh] 200 0 200 0 Low NOx 50 OK 100 HVO ref 150 EN590 ref Low NOx 50 OK 100 HVO ref 150 SFC [g/kWh] 200 Low Smoke 250 EN590 ref SFC [g/kWh] 250 Low Smoke Specific Fuel Consumption - 75 % Load Specific Fuel Consumption - 50 % Load 0 VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto Summary • at least 70 % reduction in smoke emissions was achieved at each load point without NOx penalty • at least 60 % reduction in NOx emissions was achieved at each load point without smoke penalty • with 75 % and 100 % loads over 50 % reduction in smoke and NOx emissions was achieved at the same time • improved SFC in all load points VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto Publications • • • • • • Kaario et al. ”Analyzing local combustion environment with a flamelet model and detailed chemistry ” Kaario et al. ”Studying Local Conditions in a Heavy-Duty Diesel Engine by Creating Phi-T Maps” Gong et al. ” A computational investigation of hydrotreated vegetable oil sprays using RANS and a modified version of the RNG kepsilon model in OpenFOAM” Imperato et al. ”Large-Bore CompressionIgnition Engines: High NOx Reduction Achieved at Low Load with Hydro-Treated Vegetable Oil” Imperato et al. ”Hydrotreated Vegetable Oil and Miller Timing in a Medium-Speed CI Engine” Hulkkonen et al. ”Experimental Study of Spray Characteristics between Hydrotreated Vegetable Oil (HVO) and Crude Oil Based EN 590 Diesel Fuel” • • • • • • • VI Liekkipäivä, Lappeenranta Lehto et al. ”Emission Reduction Using Hydrotreated Vegetable Oil (HVO) With Miller Timing and EGR in Diesel Combustion” Erkkilä et al. ”Emission performance of paraffinic HVO diesel fuel ” Tilli et al. ”High Cetane Number Paraffinic Diesel Fuels and Emission Reduction in Engine Combustion” Kaario et al. ”Studying Equivalence ratio – Temperature Maps in a Heavy-Duty Diesel Engine” Gong et al. ”Large eddy simulations of hydrotreated vegetable oil sprays using OpenFOAM” Imperato et al. “High NOx Reduction Achieved at Low Load Using Very Advanced Valve Timing with Hydro-Treated Vegetable Oil” Hulkkonen et al. ” Spray Studies and Diesel Fuel Comparison” 26.1.2012 Kalle Lehto Thank you for your time! Any questions? Contact kalle.lehto@aalto.fi VI Liekkipäivä, Lappeenranta 26.1.2012 Kalle Lehto