Volumetric Combustion of Biomass in Boiler for CO and NOx Reduction

advertisement

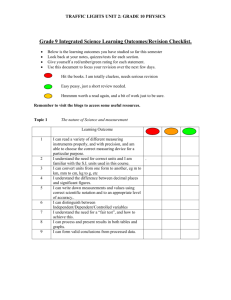

Volumetric Combustion of Biomass in Boiler for CO2 and NOx Reduction 1 Wlodzimierz Blasiak1 , Weihong Yang*1, Jun Li1, A. Ponzio2 Division of Energy and Furnace Technology, Royal Institute of Technology(KTH) Brinellvägen 23, 10044 Stockholm, Sweden Tele: +46 8 7908402 ; Email: weihong@kth.se 2 Jernkontoret, Box 1721, 111 87 Stockholm ABSTRACT: To achieve the urgent targets in environment, biomass substituting coal was considered as an effective and promising method during last decades. In this paper, the idea is further developed for a 100% pulverized biomass combustion in a boiler. A new concept of volumetric combustion technology was proposed, the properties of wood pellets combustion in high temperature oxidizer were investigated firstly. Then an Aspen model was used to describe and studied volumetric combustion system with three different kinds of fuel, and compared the CO2 and NOx emissions. At last, two application concepts of volumetric combustion were discussed. The results shows that wood pellets were ignited and combusted much faster than coal pellets, when the oxidizer was preheated to 1000°C, the ignition time to be almost independent of oxygen concentration; NOx emissions decreased with the recirculation ratio of flue gas increasing, and there is almost no NOx emission when recirculation ratio approaches to 10% in all fuel conditions; high percent of biomass combust in volumetric combustion system with high boiler efficiency, and high emissions reduction. So, it is an attractive and applicable technology in future. Key words: Volumetric combustion, Wood pellets, CO2, NOx -1 1. INTRODUCTION At year 2007 the EU adopted a far-reaching energy policy aimed at achieving a number of ambitious targets by the year 2020: to reduce greenhouse gases by 20 % compared to 1990, to raise the share of renew-able energy in the EU to 20 % and to improve energy efficiency by 20 %[1] . Biomass and coal co-combustion represents a near-term, low-risk, low-cost, sustainable, renewable energy option that promises reduction in effective CO2 emissions, reduction in SOx and often NOx emissions, and several societal benefits [2, 3]. For example, a 5% cofiring of biomass and coal in the globe power generation, we can get 40 GW, about 300 Mton CO2/year. Over the past 5-10 years there has been remarkably rapid progress over in the development of cofiring. Several plants have been retrofitted for demonstration purposes, while another number of new plants are already being designed for involving biomass coutilization with fossil fuels[3]. Approximate 40 pulverized coal fired power plants in the worldwide that cofiring biomass on a commercial basis, the average number is about 3% energy input. This leads to a 3.5 Mton of coal substituted, and make around 10 Mton of CO2 reduction[4]. Furthermore, The co-firing potential is huge, EU contributes about 50,000MWe and world contributes 160,000 MWe (50-160 nuclear power plants)[5]. Biomass is able to penetrate all energy sectarian markets, but economical constraints still limits its general deployment. Therefore, demanding a promote, efficient but sustainable biomass schemes. The economics of biomass cofiring are significantly impacted by the twin factors of deregulation and environmental requirement. Uncertainties in both arenas make investment in most, or all, biomass cofiring technologies difficult to justify. Consequently, biomass cofiring has become a tool for use in niche applications where relatively high coal costs and relatively abundant biomass converge. Such niches also require favorable regulatory treatment without the threat of New Source Review. Further on, new regulations force power sector to use biomass of agricultural origin, for examples, LCPD (Large Combustion Plant Directive), NECD (National Emission Ceilings Directive) and IPPCD (Integrated Pollution Prevention and Control Directive)[6]. Those regulations promot obviously large percentage (above 40 %) biomass co-firing will be used by power sector. -2 Combustion behaviors of biomass are different from coal’s. Biomass yields a much higher fraction of its mass through devolatilization than that does coal. Typically biomass of the size and under the heating rtes typical of pc-cofiring yields 90-95% of its dry, inorganic-free mass during devolatilization, compared with 55-60% for most coals. However, if biomass particles are too lager or dense, they may be not entrained into the flues gas, and enter the bottom ash stream with little or no conversion beyond drying if the biomass injection is not well organized. Additionally, the low biomass particles densities help biomass particles oxidizer at rates much higher than coal. Further on, if boilers do not mix flue gases effectively in furnace section, it will format striated flows, which is a common feature of biomass-coal combustion.Therefore, researching and development of an advanced combustion technology is a technical challenge for biomass, and / or larger percentage of cofiring with coal utilization with aims at a maximum efficiency and minimum emissions in larger scale electricity generation. The idea is to develop a combustion concept independently on available fuels including biomass. Concept of the Volumetric Combustion has been proposed by Prof. Blasiak[7]. Volumetric Combustion can be characterized as a very intensive mixing and internal recirculation inside of the combustion chamber. In this case, combustion occurs in a very larger volume with relatively uniform distribution of reacting species, temperature and heat fluxes. In this paper, the idea is further developed a new combustion concept for a 100% pulverized biomass combustion in a boiler---Volumetric Combustion. In order to control the combustion process of biomass in boiler, the properties of wood pellets combustion in high temperature oxidizer were investigated. Flame phenomenon, ignition time of wood pellets combustion were studied experimentally. Furthermore, the properties of volumetric combustion system were systematically studied by thermodynamic analysis method. Emissions reduction during volumetric combustion process was focused with three different kinds of fuel, namely, biomass only, co-combustion and coal only. At last, several possible technologies for volumetric combustion application were discussed. This work are not only to explain the probably for 100% biomass combustion boiler without reduction of efficiency, also to declare the emissions reduction properties with volumetric combustion technology. -3 2. Development Testing and Thermodynamic Analysis 2.1 Concept of volumetric combustion in a boiler Traditional air staging systems are not uncommon in utility and district heating boilers independent of firing configuration or combustion technology. Typical organization of staged combustion is shown in Figure 1. In order to prevent formation of nitrogen oxides from fuel-bound nitrogen, the primary combustion zone is operated under substoichiometric conditions with excess air number () less than one. To complete combustion a secondary air is introduced into the upper furnace by means of air supply system called Over-Fire Air (OFA). The secondary combustion zone is operated with excess air number () above one. Interaction between the two separated combustion zones is difficult to control in large scale combustion chambers particularly when boiler’s load and operational parameters change. Negative effects of such staged combustion are usually: too high content of carbon in fly ash (called Loss on Ignition, LOI) and carbon monoxide. Further on, NOx reduction for traditional systems is limited. Other known negative effects include a drop of steam temperature and water wall wastage. Reason of all negative effects is poor mixing inside combustion chamber. It results often in uncontrolled flow pattern typically characterized by so called “chimney” flow transporting part of gases and fuel particles through combustion chamber with too high velocity and thus too short residence time. Figure 1. Traditional staged combustion concept Flue gas recirculation is commonly used to design low-NOx combustion process [8, 9]. It is applied to design low-NOx burners and low-NOx combustion in large scale combustion chambers. In traditional approach external or internal flue gas recirculation is used. External recirculation has obvious drawbacks as for example drop of efficiency and high investment costs. Internal flue gas recirculation is usually very limited because the -4 traditional secondary air systems (OFA) are designed just to deliver the secondary air to complete combustion only. Usually just 10-15 % of air is supplied as a secondary air. In the developed Volumetric Combustion, a very intensive mixing and internal recirculation inside of the combustion chamber has been used as schematically shown in Figure 2, it is also commonly combined with air staging concept. Aim is to prevent formation of NOx originating mainly from fuel nitrogen. Figure 2. Volumetric Combustion Contrary to traditional OFA system, Volumetric Combustion allows to increase amount of secondary air up to about 30-40% without causing problems with combustion stability or incomplete combustion. The new concept promotes intensive internal recirculation of flue gases from the level of secondary air injection down to primary combustion zone. Combination of air staging and internal flue gas recirculation changes not only in-furnace flow but also affects the combustion. Due to intensive recirculation and good mixing between secondary air and flue gas the combustion volume is larger than with traditional staged combustion. Such combustion is termed “volumetric” combustion. The importance of extensive flue gas recirculation on combustion and formation of so called “flameless” combustion in industrial furnaces has been reported. Volumetric combustion of gas and oil has also been reported for conditions of High-temperature Air CombustionHiTAC[10], or flameless Oxidation[11]. It has been also used for oxygen enriched and oxyfuel combustion air [12]. 2.2 Experimental set-up and process Test facility is the batch type HiTAC/G facility at KTH, the introductions about this test facility and detailed test methods were reported by A. Ponzio[13]. Here, experiments with wood pellets were performed using 5g or 30 g of 8 mm wood pellets inserted in to a -5 small basket. A single wood pellet of 15mm diameter (4-5g) was attached to the certain piston with thermocouple wire, proximate and ultimate analysis of wood pellet is presented in Table 1. Experiments were carried out for three different oxygen concentrations in the oxidizer (5, 10 and 21 %) and three different temperatures of the oxidizer (600, 800 and 1000C). The total oxidizer flow was 10 Nm3/h in all 5g experiments and 4Nm3/h in both 30g and the single pellet experiments. The experimental cases are presented In Table 2. Table 1. Wood pellets properties Proximate analysis (av,%) Ultimate analysis(av,%) Moisture 7.7 C 51.0 Volatile 74.7 H 6.3 Fixed carbon 16.9 O 41.8 Ash 0.7 N 0.2 LHV (kJ/kg) 17270 S 0.01 Table 2. Experimental conditions in the experiment with wood pellets Oxidizer temperature 1000°C 800°C 600°C Oxygen concentration in oxidizer 21% 5g 15 s 30 s 45 s 1 min / 2 min / 3 min 5 min 5g 45 s 1 min 2 min 3 min 5 min 5g 1 min 2 min 3 min 5 min 10% Single pellet 15 s / / 1 min 1.5 min 2 min 2.5 min 3 min / 30 g / / / / 5 min / 30 g / / / / / / / / 5 min / / -6 5g 15 s 30 s 45 s 1 min / 2 min / 3 min 5 min 5g 45 s 1 min 2 min 3 min 5 min 5g 1 min 2 min 3 min 5 min 5% Single pellet / 30 s / 1 min 1.5 min 2 min / 3 min / 30 g / / / / 5 min / 5g 15 s 30 s 45 s 1 min / 2 min / 3 min 5 min 5g 45 s 1 min 2 min 3 min 5 min 5g 1 min 2 min 3 min 5 min 2.3 Model description The volumetric combustion system process was built using Aspen plus, including decomposition, volatile and chars combustion, and internal flue gas recirculation. Figure 10 shows Aspen Plus flowsheet of volumetric combustion. In this model, the CO2 and NOx emissions are focused when using three different kinds of fuel, namely, biomass only, cocombustion and coal only. Biomass decompostion Fuel Feed Primary Combustion Zone Air Supply Heat Exchanger Coal decompostion Secondary Combustion Zone High Temperature Flue Gas Recirculation Figure 3. Aspen plus flowsheet of volumetric combustion with biomass and (or) coal The main model assumptions as follows, 1) steady state flow; 2) potential and kinetic energies are negligible; 3) environment state at T=298K and P=1atm; 4) the gas obey the ideal gas relations. Firstly, biomass and coal were decomposited in two independent blocks, ‘BIOPYRO’ and ‘COALPYRO’ respectively. Specify the yield distribution according to the proximate and ultimate analysis of biomass and coal used in this study. The proximate and ultimate analysis of the used biomass and coal are given in Table 4 [14], which is different from the data in Table 1. The main reason is for comparing the results with reference data conveniently, and improving validation of this model. C, H, O and N are the weight -7 fractions of carbon, hydrogen, oxygen and nitrogen respectively in the used biomass and coal. Biomass and coal consists of mainly C, H, N, O, S, ash, and moisture. H, N, O, S and part of C constitute the gas phase, the fixed carbon and ash comprise of the solid phase after decomposition process. And then the stream was feed into the next block, ‘PC-ZONE’, in which fuel rich combustion happened with excess air ratio (λ) less than one, called this process as primary combustion in this study. After primary combustion, the stream was feed into the next block, ‘SC-ZONE’, in which oxygen rich combustion happened with excess air ratio (λ) above one, this process was called secondary combustion. After secondary combustion, some of flue gas was recycled back into the bottom of furnace for diluting oxygen concentration of combustion zone, and the others flowed into back-pass of boiler to exchange heat in economizer and air preheated. Table 4. Fuel analysis[14] Items Coal Biomass Moisture content (wt %) 9.20 8.80 Volatile matter 29.20 73.50 Fixed carbon 52.55 15.30 Ash 9.05 2.40 C 67.37 47.0 H 4.37 5.0 O 7.99 36.23 N 1.11 0.49 S 0.60 0.08 HHV (kJ/kg, ar) 27712 18969 Proximate analysis (wt%, ar) Ultimate analysis (wt% , ar) 3. RESULTS AND DISCUSSIONS -8 3.1 Flame phenomena of wood pellets combustion In Figure 4, typical flame appearances for three different oxygen concentrations oxidizers are showed, and all the oxidizers were preheated to 1000C. The photos are ordered from left to right by increasing oxygen concentration, 5%, 10% and 21%. When the oxygen concentration is 5%, 4s and 640ms after the experiments ignition stared smoothly, a long flame that wrapped the pellet developed and persisted to the end of the 3 minutes experiment; when the oxygen concentration is 10%, ignition started at 1s 760ms, the ignition started at the front of the pellet and a long flame appeared that wrapped the pellet. The flame extinguished at 2min and 11s; when air (21%) preheated to 1000°C was used to combust wood pellets, ignition occurred at 2s and 640ms after the start of the experiment, the flame was shorter than that of the diluted oxidizer cases, and the flame extinguished at 2 min 8s and 800ms. 5% 21% 10% Figure 4. Typical flame appearances in three different oxygen concentration oxidizers preheated to 1000°C From the flame phenomenon of Figure 4, it is clear that the lower oxygen concentration, the lager combustion volume, and the longer combustion time. It is very satisfied with the features of typical volumetric combustion, which is a large volume of process with relatively uniform distribution of reacting species, temperature and heat fluxes. 3.2 Ignition time of wood pellets In this work, there are two different approaches were used to determine ignition time: 1) by using a stop watch and the video-recording of the experiments and 2) by equalizing ignition time to the time of a temperature increase in the gases downstream from the sample. The latter method was used as a compliment of the stop-watch method due to the -9 difficulty to determine exactly when the flame appeared in the diluted cases because of its weak color. The results both of the two methods are showed in Figure 5. It can be noted that the two methods differ only significantly for 5% oxygen conditions in which the stopwatch method indicated longer ignition time, where presumably the flame was there for some time before it was actually visible. The properties of coal pellets combustion have been investigated by A. Ponzio (2008) [15]. In comparison to coal[15], wood ignited much faster than coal at low temperatures. However, the tendency of the ignition time to be almost independent of oxygen concentration at high temperatures (1000C) and highly dependent on oxygen concentration at low temperature (600C), which is same with coal[15]. For example, 5% oxygen concentration of oxidizer and 600C, the wood pellets did not ignite in five minutes. 300 300 5% O2 10% O2 21% O2 21% O2 (30 g) 10% O2 (30 g) 5% O2 (30 g) 200 150 100 200 150 100 50 50 0 500 5% O2 10% O2 21% O2 250 Ignition time, tV [s] Ignition time,tT [s] 250 600 700 800 900 1000 0 500 1100 600 700 800 900 1000 1100 Toxidizer [oC] Toxidizer [oC] (a) (b) (a: temperature increase record method;b: video record method) Figure 5. The effect of oxidizer temperature on ignition time of wood pellets 3.3 Mass loss properties of wood pellets The wood pellets combustion experiments were performed with a higher flow-rate of oxidizer and smaller samples both in weight and size, so a direct comparison should be avoided. However, one cannot but note the striking difference in reactivity between biomass and coal. In Figure 6, the wood showed a large difference between the mass loss rate in the “devolatilisation-zone” and the mass loss rate in the “char-zone”, and the mass loss rate in the “devolatilisation-zone” is much bigger than that in the “char-zone”. According to the coal pellets combustion results of A. Ponzio [15], there was little difference in mass loss rate between these two zones for coal pellets for 5-21% oxygen and almost no visible difference for 30-100% oxygen. This would suggest that the devolatilisation of wood is much faster than the devolatilisation of coal. -10 The explanations for this may be several. First and foremost, there were much higher oxygen to fuel ratio in the wood experiments due to higher flow-rate of the oxidizer and lower mass of the sample. However, when 30g wood samples were used, the five minutes conversions were between 84 and 89% for 800-1000°C and 5-21% oxygen concentration as showed in Table 3. The properties of lower density and higher porosity of wood than coal seem to be the second possible explanation for the quick mass loss rate. Moreover, the high volatile content of the biomass particle leaves a more accessible char that could be readily passed by reactants and products of all kinds. 1,0 Wood pellets 1000C 0,8 Moisture 1,0 Volatiles 0,8 Wood pellets 1000C Moisture 1 min Volatiles Mass [-] Mass [-] 3 min 0,6 21% O2 10% O2 5% O2 0,4 5 min 0,6 0,4 0,2 0,2 Char Char 0,0 0,0 0 1 2 3 4 5 6 7 8 9 0 5 Time [min] 10 15 20 25 30 Oxygen concentration [%] (a) Mass as function of time for different oxygen (b) Mass as function of oxygen concentration in concentrations in the oxidizer. the oxidizer for different duration of experiment. Figure 6. Influence of oxygen concentration on wood pellet combustion for Toxidizer=1000C Table 3. Five minutes conversion of wood pellets (8 mm, 30 g) samples. Cases 1000C 5% Conversion 0.86 800C 10% 21% 5% 10% 21% 0.84 0.86 0.84 0.89 0.87 In Figure 7, the mass-time curves for wood experiments performed with a single 15 mm pellet are shown. As can be seen, the mass loss rate was a slightly lower than in the cases for wood pellets presented above. Differences in the ratio between surface area and mass as well have been the explanation. However, with respect to coal[15], the results in Figure 7 confirm that wood pellets were combusted much faster than the coal pellets. The differences in density for the wood pellets and the coal pellets were significant. -11 Single wood pellet (15 mm), 1000C Moisture Volatiles Mass [-] 21% O2 10% O2 Char 0 0 1 2 3 4 5 6 7 8 9 Time [min] Figure 71. Influence of oxygen concentration on single 15 mm wood pellet combustion for Toxidizer=1000C The devolatilisation rate appeared to be independent of oxygen concentration when oxidizer was preheated to 1000C, while at 800C it seemed to be determined by it. In fact, the mass loss rate in the “devolatilisation zone” was significantly increased, mainly between 10 and 21%. This was also evidenced by an inclined 1 min curve in Figure 8b. A plausible interpretation is that at 800C, the heat of combustion is indeed an important promoting factor for the devolatilisation process. As was pointed out above, a similar, but less significant, tendency towards increased importance of oxygen concentration for low oxygen concentration and in the initial part of the experiment was seen in the coal case. The behavior of mass loss of wood was little dependent on temperature of the oxidizer, at least in the very initial part of the experiment. Wood pellets, 800C 1,0 0,8 Moisture 1,0 Volatiles 0,8 Wood pellets 800C Moisture 1 min Volatiles 0,6 Mass [-] Mass [-] 3 min 21% O2 10% O2 5% O2 0,4 5 min 0,6 0,4 0,2 0,2 Char Char 0,0 0,0 0 1 2 3 4 5 6 7 8 9 0 Time [min] 5 10 15 20 25 30 Oxygen concentration [%] (a) Mass as function of time for different oxygen (b) Mass as function of oxygen concentration in concentrations in the oxidizer. the oxidizer for different duration of experiment. Figure 8. Influence of oxygen concentration on wood pellet combustion for Toxidizer 800C There was very little dependence on the mass loss on oxygen concentration at 600C. This is in fact no surprise: a look at the ignition times reported above confirms that most -12 part of the experiment is merely devolatilisation (no significant combustion occurring). Flaming ignition occur only 1min30s to 2min30s into the process depending on the oxygen concentration, and if only 5% oxygen is used, there is no ignition at all. No or little combustion equals no or little heat release, thus no influence of the oxygen concentration on the mass lost, something confirmed by the almost flat curves in Figure 9b. 1,0 Wood pellets, 600C 0,8 Moisture 1,0 Volatiles 0,8 Wood pellets 600C Moisture 1 min Volatiles 0,6 Mass [-] Mass [-] 3 min 21% O2 10% O2 5% O2 0,4 0,2 5 min 0,6 0,4 0,2 Char Char 0,0 0,0 0 1 2 3 4 5 6 7 8 9 0 Time [min] 5 10 15 20 25 30 Oxygen concentration [%] (a) Mass as function of time for different oxygen (b) Mass as function of oxygen concentration in concentrations in the oxidizer. the oxidizer for different duration of experiment. Figure 9. Influence of oxygen concentration on wood pellet combustion for Toxidizer 600C 3.4 Model validation of volumetric combustion system The model was validated against the power plant boiler operating data B. Higgins et al. [14], which can reach 55MWe and provide 179MWt of heating output with maximum continuous output. The input data for both coal only and co-combustion was used in this paper [14], Table 5. The main input data in Aspen Plus Unit Coal only[14] Co-combustion[14] Biomass only Load MWt 179 179 179 Fuel Heat input 100% coal 55% coal +45%biomass 100% biomass Excess air % 20 20 20 Excess O2 % dry 3.6 3.6 3.6 Coal flow t/h 23 13 0 Biomass flow t/h 0 15 35 Total air flow t/h 254 245 234 -13 Results were found to be good agreement with the reported results. According to this model results, the NOx emission was 145mg/Nm3 in co-combustion condition; the NOx emission was 320mg/Nm3 in coal only without flue gas recirculation, which was an acceptable result with the operation result (300mg/Nm3). The under or over of operation result is a common problem for Aspen plus[16], because it is a steady state model of combustion process, and there are many influence factors affect the real operation result. Here, the main purpose is to obtain the CO2 and NOx emissions regular in different recirculation ratio conditions in thermodynamic method. 3.5 Emissions reduction of volumetric combustion Biomass as a renewable resource and the CO2 released during biomass combustion will be re-captured by the re-growth of the biomass through photosynthesis[17]. The neutrality of biomass CO2 has been recognized for many years by an abundance of studies and is universally accepted by agencies, institutions, regulations and legislation. CO2 emission from combustion of biomass fuel source is not assumed to increase net atmospheric CO2 levels[18]. Therefore, co-combustion is an effective pathway to reduce the emission of CO2, and the more percent of biomass replace coal (in heat), the less CO2 releases. In this work, three kinds of percents of biomass in total feed fuel were used in volumetric combustion, 0%, 45% and 100% as showed in Table 5. The properties of CO2 emission in three different kinds of fuel combustion process are compared, as showed in Table 6. Table 6. CO2 emission in three different kinds of fuel CO2 emission Coal only Co-combustion Biomass only (kg/h) 56815.4 32113.0 0 As mentioned before, internal flue gas recirculation in the volumetric combustion not only contributes to intense in-furnace flow, and beneficial to format lower oxygen concentration for reduction NOx. Therefore, the recirculation ratio R is an important factor in volumetric combustion. Here, R represents the fraction of recirculation part in total combustion productions. For example, R=0 means that there is no flue gas recirculation flue -14 gas back to furnace chamber, R=0.1 means that there are 10% flue gas back into primary combustion zone. Figure 10 shows the effect of recirculation ratio on NOx emission at different combustion conditions. One condition is un-staging combustion, in which the combustion air is feed in one position. Another is air staging combustion, in which the combustion air is divided into primary air and secondary air. Therefore, the combustion zone was divided into a primary zone run with a deficiency of air and a second burnout zone run with excess air. In this case, the solid fuel consists of 55% coal and 45% biomass; the combustion air temperature was kept in 493K both in un-staging combustion and air staging combustion conditions; the primary air ratio λ=0.7 in air staging combustion. Figure 10. Effects of recirculation ratio on NOx emission at different combustion conditions Obviously, the amount of NOx emission in un-staging combustion process linear decreased slightly with the R increasing. From Figure 10, the total amount of NOx decreased from 449mg/Nm3 to 350 mg/Nm3 with R range from 0 to 30%. The same decreased trend was obtained by Baltasar J. et al by experimental methods[9]. Compared to un-staging combustion, the amount of NOx emission reduced significantly in air staging combustion, the mechanistic pathways for formation and reduction of nitrogen oxides during air staging combustion were reported by Beer[19]. More interesting, the NOx emission firstly rapid increased then deceased sharply with the R increasing during air -15 staging combustion, the NOx almost approach 0mg/Nm3 when R=4%. The possible explaining for the NOx emission increasing firstly as follows, when the small part of high temperature flue gas recycled into boiler furnace, and it mainly contributed to furnace temperature but had less influence on formation enough low oxygen concentration zone. Thermal NOx formation is highly dependent on temperature, whereby higher temperature promotes NOx formation. Then with the recirculation ratio increased, more flue gas contributed to decrease oxygen concentration, and therefore the NOx emission is decreased. Fuel nitrogen is released from fuel as HCN and sometimes as NHi with i=1, 2, 3, these intermediate radicals subsequently react to form NOx in oxidizing environment and N2 in reducing environment[2]. Therefore, the higher flue gases recirculation ratio, the lower oxygen concentration in furnace, then was formatting a good reducing environment for reduction NOx. The result showed flue gas recirculation is a better method for reduction NOx. Especially, it plays an important role for reducing NOx emission during air staging combustion process, there is almost no NOx emission when recirculation ratio approached to 4%. Figure 11. The effect of recirculation ratio on NOx emission in different fuel conditions The effects of recirculation ratio on NOx emissions in three different kinds of fuel type, namely, biomass only, co-combustion and coal only are showed in Figure 11. From Figure 11, the same result was obtained, NOx emission increased firstly then decreased sharply, there is almost no NOx emission when recirculation ratio reaches to 10% in all three fuel -16 conditions, and the results further certificated the above explanation for the characteristic of NOx emission. More important things, the level of NOx emission during biomass combustion process is strikingly lower than that of coal combustion process, and the level of NOx emission in co-combustion is lower than coal combustion, but higher than biomass combustion. The first and obvious reason is the nitrogen component in biomass is lower than that of coal (Table 4). Munir (2010) analyzed the mechanism of the reduction NOx in biomass co-combustion[2]. According to Munir, there are two more possible explanations. Firstly, the volatile matter in biomass is higher than that in coal, and thus, the more percent of biomass replaced coal as fuel, the more volatile was released, the formation of NH3 and HCN increased with increasing fuel volatility, so the predominant combustion is gas-phase reactions. Secondly, as biomass contain less carbon and are highly oxygen compared coal (Table 4), the amount of stoichiometric air is less than coal combustion, it can cause locally stronger reducing environment with addition of biomass without changing the air supply conditions. When considering the flue gas recirculation in volumetric combustion system, the recirculation ratios corresponding to NOx emission reach to 0mg/Nm3 are different, 10%, 4% and less 3% in coal only combustion, co-combustion and biomass only, respectively. Obviously, the more percent of biomass in co-combustion, the less flue gas need to recycle for realizing zero NOx emission. In other words, in order to realize NOx zero emission in volumetric combustion, more drive power for recirculation is needed during coal combustion process, and less drive power for recirculation is needed during biomass combustion. There is no doubt that this is very interesting result, because volumetric combustion of biomass is possible for realizing zero NOx emission with lower investment cost and higher reliable. 4. APPLICATIONS OF VOLUMETRIC COMBUSTION 4.1 Application concepts Biomass co-combustion in volumetric combustion system is different from conventional co-combustion. In volumetric combustion, biomass combust blendly under a high temperature oxygen deficient atmosphere led by a strong internal flue gas recirculation. As analyzed before, volumetric combustion system has several benefits as bellow: A lower NOx emission (both Fuel-NOx and Thermal-NOx), -17- A lower particle matter (PM) emissions, A higher uniformity temperature profile, thus, a higher heat transfer, a higher exergy efficiency, A possibility for a bigger cofiring blends due to better combustion controlling, A lower corrosion possibility Keep the same steam parameters at the max. Based on those benefits, 100% biomass as fuel combust in power plant boiler is more realizable. Application concepts of volumetric combustion in a real boiler can be seen as Figure 13. One is used rotating secondary air supplied via high velocity air nozzles in upper furnace. Bigger momentum of high velocity air promotes intensive internal recirculation of flue gases from the secondary combustion zone down to primary combustion zone. In this way, cold secondary air swirl down along furnace wall, and hot flue gas from primary combustion zone swirl up inside furnace, as showed in Figure 13(a). Another application concept is located a wall tube inside furnace, the same with high velocity secondary air injection, bigger momentum of high velocity air promotes intensive internal recirculation as well. But, the differences from first concept are cold secondary air swirl down inside furnace, and hot flue gas swirl up along furnace wall, as showed in Figure 13(b). (a) (b) Figure 13. Two concepts of volumetric combustion in boiler -18 4.2 Application example A example of using volumetric combustion is the Rotating Opposed Fired Air (ROFA), a boosted over-fire air system that includes a patented rotation process[20], which is belong to the first application concept. For intensive recirculation and mixing in furnace, maybe there are several methods. On a typical ROFA System installation, 25-40% of the total combustion air is injected into the upper furnace through special asymmetricallyplaced air nozzles, which creates a sub-stoichiometric condition at the burner area, which significantly decreases NOx formations. Several different biomass fuels combustion with/without ROFA was operated and tested in real boiler, the alternative biomass fuels were straw pellets, willow pellets and wood pellets. Figure 14 shows that the results of biomass co-combustion test, with NOx emissions and LOI (Loss on Ignition) in the fly ash as a function of BSR (Burner Stoichiometric Ratio). In Figure 14, LNB-NOx means that coal combustion with LNB (lower NOx burner) condition; ROFA-NOx means coal combustion with ROFA condition; Biomass-NOx means 45% biomass and 55%coal co-combustion with ROFA condition. Both the two operation conditions are same with that showed in Table 5. The NOx emissions for the varying biomass fuels co-combustion shows significantly decreasing compared to coal-only combustion. Figure 14. NOx and LOI as a function of BCR for varying biomass fuel tests [14] -19 5. CONCLUSIONS A new concept of volumetric combustion was proposed in this paper, which intensive internal recirculation and good mixing between secondary air and flue gas, the combustion volume is larger than with traditional staged combustion. Several benefits showed in volumetric combustion system, those benefits contribute the possibility of realizing 100% biomass combustion in boiler. In this paper, the properties of wood pellets combustion in high temperature oxidizer were investigated firstly. Then an Aspen model was used to describe and studied volumetric combustion system with three different kind of fuel, namely, biomass only, co-combustion and coal only, and compared the CO2 and NOx emissions. At last, two application concepts of volumetric combustion were discussed, one application example of volumetric combustion shows striking emissions reduction. The main interesting conclusions are as follows: 1. Wood pellets were ignited and combusted much faster than coal pellets, when the oxidizer was preheated to 1000°C, the ignition time to be almost independent of oxygen concentration. However, the ignition time highly dependent on oxygen concentration at low temperature (600°C). 2. NOx emissions decreased with the recirculation ratio of flue gas increasing, and there is almost no NOx emission when recirculation ratio approaches to 10% in all fuel conditions, namely, coal only, co-combustion and biomass only. 3. Volumetric combustion is a suitable technology for combusting high percent of biomass with higher boiler efficiency, and higer reduction of CO2 and NOx emission. -20 6. REFERENCE [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] http://europa.eu/legislation_summaries/energy/european_energy_policy/l28012_en. htm." S. Munir, W. Nimmo, and B. M. Gibbs, "The effect of air staged, co-combustion of pulverised coal and biomass blends on NOx emissions and combustion efficiency," Fuel, vol. In Press, Corrected Proof, 2010. T. Nussbaumer, "Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction," Energy & Fuels, vol. 17, pp. 1510-1521, 2003. "EA Bioenergy Task 32, http://www.ieabcc.nl," 2005. "http://www.conference-biomass.com/index.htm." "http://ec.europa.eu/environment/air/pdf/final_report_05225.pdf." W. Blasiak, "Fuel Switch from fossil to 100% biomass Tangential fired PC boiler," in Proceedings of Power-GEN Europe Milan, Italy, 2008. H. K. Kim, Y. Kim, S. M. Lee, and K. Y. Ahn, "NO reduction in 0.03-0.2MW oxyfuel combustor using flue gas recirculation technology," Proceedings of the Combustion Institute, vol. 31, pp. 3377-3384, 2007. J. Baltasar, M. G. Carvalho, P. Coelho, and M. Costa, "Flue gas recirculation in a gas-fired laboratory furnace: Measurements and modelling," Fuel, vol. 76, pp. 919929, 1997. H. Tsuji , A.K. Gupta. T. Hasegawa , M. Katsuki , K. Kishimoto and M. Morita. High temperature air combustion : from energy conservation to pollution reduction: CRC Press 2002. J. A. Wuning and J. G. Wuning, "Flameless oxidation to reduce thermal noformation," Progress in Energy and Combustion Science, vol. 23, pp. 81-94, 1997. K. N. Wlodzimierz Blasiak, Weihong Yang, Joachim von Schéele, "Flameless oxyfuel combustion for fuel consumption and nitrogen oxides emissions reductions and productivity increase," Journal of the Energy Institute, vol. 80, pp. 3-11, 2007. A. Ponzio, S. Senthoorselvan, W. Yang, W. Blasiak, and O. Eriksson, "Ignition of single coal particles in high-temperature oxidizers with various oxygen concentrations," Fuel, vol. 87, pp. 974-987, 2008. L. Y. Brian Higgins, Hani Gadalla, John Meier, Tore Fareid, Guisu Liu, and A. R. Mirosław Milewicz, Michael Ryding, and Wlodzimierz Blasiak, "Biomass Co-firing retrofit with ROFA for NOx reduction at Edf-Wroclaw Kogeneracjia," 2009. A. Ponzio, "Thermally homogeneous gasification of biomass/coal/waste for medium or high calorific value syngas production," in Material Science and Engineering. vol. Doctoral thesis Stockholm: Royal Institute of Technology (KTH), 2008. W. Doherty, A. Reynolds, and D. Kennedy, "The effect of air preheating in a biomass CFB gasifier using ASPEN Plus simulation," Biomass and Bioenergy, vol. 33, pp. 1158-1167, 2009. -21 [17] [18] [19] [20] L. Zhang, C. Xu, and P. Champagne, "Overview of recent advances in thermochemical conversion of biomass," Energy Conversion and Management, vol. 51, pp. 969-982, 2010. "http://www.bipac.net/afpa/AFPACarbonNeutralityWhitePaper2_4_10.pdf." J. M. Beer, "Combustion technology developments in power generation in response to environmental challenges," Progress in Energy and Combustion Science, vol. 26, pp. 301-327, 2000. N. Mobotec, "http://www.nalcomobotec.com/technology/rofa-technology.html." 7. ACKONWLEDGEMENTS The authors would like to thank the IndComb AB Sweden and EIT/KIC Innoenergy for the financial support of this work. -22