Planning Relationships Planning Horizons Aggregate Planning

advertisement

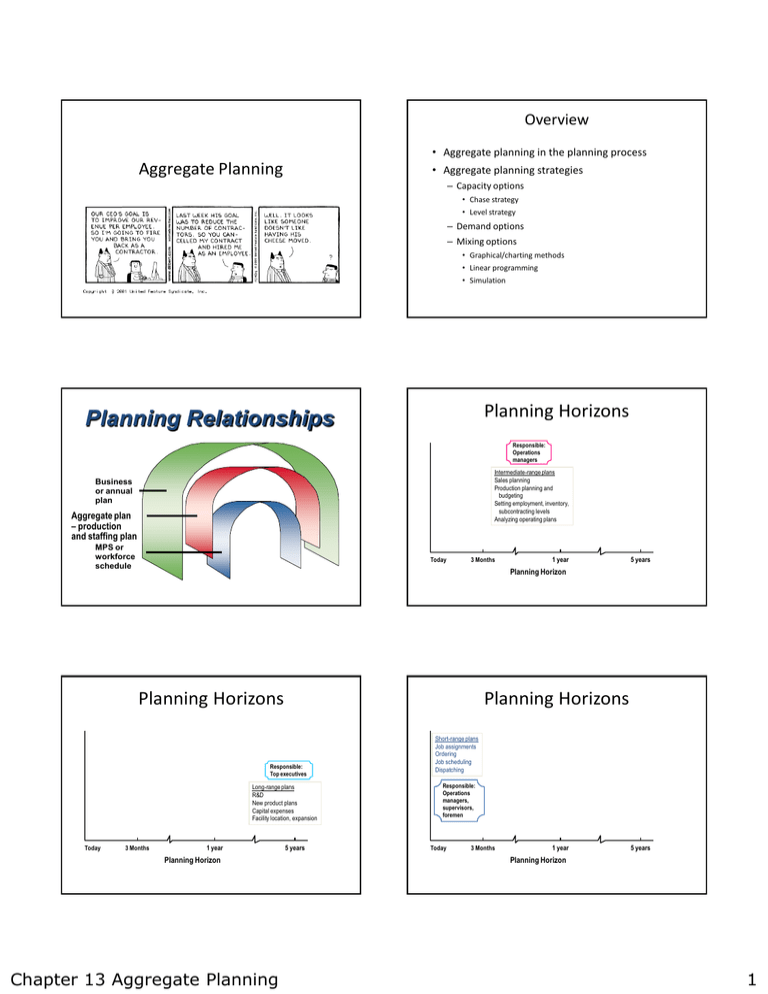

Overview • Aggregate planning in the planning process Aggregate Planning • Aggregate planning strategies – Capacity options • Chase strategy • Level strategy – Demand options – Mixing options • Graphical/charting methods • Linear programming • Simulation Planning Horizons Planning Relationships Responsible: Operations managers Intermediate-range plans Sales planning Production planning and budgeting Setting employment, inventory, subcontracting levels Analyzing operating plans Business or annual plan Aggregate plan – production and staffing plan MPS or workforce schedule Today 3 Months Planning Horizons 5 years Planning Horizons Responsible: Top executives Long-range plans R&D New product plans Capital expenses Facility location, expansion Today 1 year Planning Horizon 3 Months 1 year Planning Horizon Chapter 13 Aggregate Planning 5 years Short-range plans Job assignments Ordering Job scheduling Dispatching Responsible: Operations managers, supervisors, foremen Today 3 Months 1 year 5 years Planning Horizon 1 What is an aggregate plan? Planning hierarchy Long-range capacity planning Aggregate planning Aggregate Plan Master production schedule Production planning and control systems Pull systems (JIT) Push systems (MRP) Many other systems What is an aggregate plan? Amount to produce Demand forecast Amount to outsource Inventory Aggregate Plan Machine capacities and costs Labor capacities and costs Amount of labor and overtime required Projected Inventories Outsourcing capacities and costs Aggregate Planning Objectives Managerial Inputs Operations Current machine capacities Plans for future capacities Workforce capacities Current staffing level Materials Supplier capabilities Storage capacity Materials availability Distribution and marketing Customer needs Demand forecasts Competition behavior Aggregate plan Engineering New products Product design changes Machine standards Accounting and finance Cost data Financial condition of firm Human resources Labor-market conditions Training capacity Aggregate Planning Strategies Pure Strategies • Capacity Options — change capacity: Minimize Costs/Maximize Profits Maximize Customer Service Minimize Inventory Investment Minimize Changes in Production Rates Minimize Changes in Workforce Levels Maximize Utilization of Plant and Equipment Chapter 13 Aggregate Planning – changing inventory levels – varying work force size by hiring or layoffs – varying production capacity through overtime or idle time – subcontracting – using part-time workers 2 Aggregate Planning Strategies Pure Strategies Advantage/Disadvantages of Aggregate Planning Options • Demand Options — change demand: See Table 13.1 – influencing demand – backordering during high demand periods – counterseasonal product mixing Mixing the options: The Extremes Aggregate Planning Strategies • Level planning strategy Level Strategy Chase Strategy Production rate is constant Production equals demand – Produce same amount every month – Keep work force level constant • Find alternative work for employees when there is less demand – Vary non-work force capacity or demand options • Inventory levels allowed to fluctuate – Often results in lowest production costs – Toyota, Nissan employ this strategy Aggregate Planning Strategies • Chase planning strategy – Output rates match demand – Vary work force level • Hiring/laying off – Vary non-work force capacity or demand options • Overtime and outsource • Part time employees – Service industries often utilize this strategy • Hospitality, construction, education Chapter 13 Aggregate Planning 3