Introduction to Compressible Flow ρ Compressible Flow

advertisement

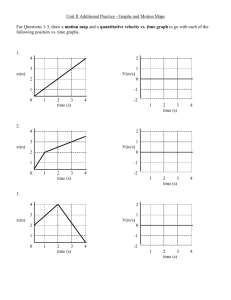

Introduction to Compressible Flow Dρ ≠0 Dt The density of a gas changes significantly along a streamline Compressible Flow Definition of Compressibility: the fractional change in volume of the fluid element per unit change in pressure p + dp p p p v p + dp v − dv p + dp p + dp p Compressible Flow 1. Mach Number: M = V local velocity = c speed of sound 2. Compressibility becomes important for High Speed Flows where M > 0.3 • M < 0.3 – Subsonic & incompressible • 0.3 <M < 0.8 – Subsonic & compressible • 0.8 <M < 1.2 – transonic flow – shock waves appear mixed subsonic and sonic flow regime • 1.2 <M < 3.0 - Supersonic – shock waves are present but NO subsonic flow • M > 3.0 – Hypersonic Flow, shock waves and other flow changes are very strong 1 Compressible Flow 3. Significant changes in velocity and pressure result in density variations throughout a flow field 4. Large Temperature variations result in density variations. As a result we now have two new variables we must solve for: T&ρ We need 2 new equations. We will solve: mass, linear momentum, energy and an equation of state. Important Effects of Compressibility on Flow 1. Choked Flow – a flow rate in a duct is limited by the sonic condition 2. Sound Wave/Pressure Waves – rise and fall of pressure during the passage of an acoustic/sound wave. The magnitude of the pressure change is very small. 3. Shock Waves – nearly discontinuous property changes in supersonic flow. (Explosions, high speed flight, gun firing, nuclear explosion) 4. A pressure ratio of 2:1 will cause sonic flow Applications 1. Nozzles and Diffusers and converging diverging nozzles 2. Turbines, fans & pumps 3. Throttles – flow regulators, an obstruction in a duct that controls pressure drop. 4. One Dimensional Isentropic Flow – compressible pipe flow. 2 Approach • Control volume approach • Steady, One-dimension, Uniform Flow • Additional Thermodynamics Concepts are needed • Restrict our analysis to ideal gases Thermodynamics • Equation of State – Ideal Gas Law p = ρ RT R= Universal Gas Constant 8314 J/(kmol ⋅ K) Ru = = = 287 J/(kg ⋅ K) Molecular mass of air 28 .97kg/kmol Mm Temperature is absolute and the specific volume is (volume per unit mass): 1 v= ρ Thermodynamics – Internal Energy & Enthalpy • Internal Energy – individual particle kinetic energy. Summation of molecular vibrational and rotational energy. u~ = u~ (v , T ) ∂ u~ ∂ u~ d u~ = dT + dv ∂T v ∂v T • For an ideal gas u~ = u~ (T ) d u~ = cv dT • Recall from our integral form of the Energy Equation for Enthalpy of an ideal gas: h = u~ + pv h = h (T ) dh = c p dT 3 Thermodynamics – Internal Energy & Enthalpy h = u~ + pv h = u~ + RT dh = d u~ + RdT p ρ = RT Substituting: dh = c p dT d u~ = c v dT dh = d u~ + RdT c p dT = c v dT + RdT c p = cv + R c p − c v = R = const Thermodynamics – Internal Energy & Enthalpy Define the ratio of specific heats: Then, k≡ cp cv = const kR k −1 R cv = k −1 cp = For Air: cp = 1004 J/kg-K k = 1.4 The 2nd Law of Thermodynamics & Isentropic Processes We define entropy by: δQ ds = T rev Combining the 1st and 2nd Laws gives us Gibb’s Equation Tds = dh − dp ρ Tds = c p dT − 2 2 ∫ ds = c ∫ p 1 1 dh = c p dT dp ρ 2 dT dp − R∫ T p 1 1 ρT = R p 4 The 2nd Law of Thermodynamics & Isentropic Processes s 2 − s1 = c p ln p T2 − R ln 2 p1 T1 For an Isentropic process: adiabatic and reversible We get the following power law relationship p 2 T2 = p1 T1 k k −1 ρ 2 = ρ1 k Control Volume Analysis of a Finite Strength Pressure Wave Moving Wave of Frontal Area A Stationary Wave Reference frame moving with wave c p p + ∆p ρ ρ + ∆ρ T V =0 T + ∆T 1 p 2 p + ∆p ρ ρ + ∆ρ T T + ∆T V = c − ∆V V =c ∆V Steady State Continuity Equation (Solve for the induced velocity ∆V): 0= ∫ ρ (V • nˆ )dA = − ∫ ρcdA + ∫ (ρ + ∆ρ )(c − ∆V )dA r CS 1 2 ρ cA = ( ρ + ∆ ρ )(c − ∆ V )A ρ c = c ( ρ + ∆ ρ ) − ∆ V (ρ + ∆ ρ ) ∆ρ ∆V = c (A) ρ + ∆ρ The Speed of sound (c) is the rate of propagation of a pressure wave of infinitesimal strength through a still fluid. Control Volume Analysis of a Finite Strength Pressure Wave p Steady State Momentum Equation: (Find ∆p and c) ∑F x = ∫ ρV (V • nˆ )dA = m& (V ρ r x 2 − V1 ) T V =c 1 2 p + ∆p ρ + ∆ρ T + ∆T V = c − ∆V CS pA − ( p + ∆ p ) A = ρ cA (c − ∆ V − c ) ∆ p = ρ c∆ V (B) Now combine A & B and solve for the speed of sound: c2 = ∆ p ρ + ∆ ρ ∆p = ρ ∆ρ ∆ρ c2 = ∂p ∂ρ ∆ρ 1 + ρ in the limit of ∆ ρ → 0 Small Amplitude moderate frequency waves are isentropic and p ρk = const 5 Control Volume Analysis of a Finite Strength Pressure Wave Calculating the Speed of Sound for an ideal gas: p ρk = const ∂p p =k ∂ρ ρ c= c= k p ρ = kRT Typical Speeds of Sound Fluid c (m/s) kRT Gases: For Air: k= H2 Air cp ≈ 1 .4 cv R = 287 J/(kg ⋅ K) 1,294 340 Liquids: Water Ethyl Alcohol 1,490 1,200 Data From White 2003 Example 1: Speed of sound calculation Determine the speed of sound in Argon (Ar) at 120 oC. MW = 40 kg/kmol: c= R= k= kRT Ru 8314 J/(kmol ⋅ K) = = 207 .9 J/(kg ⋅ K) Mm 4 0kg/kmol cp cv ≈ 1 .668 c = 1 .668 (207 .9 J/kgK )(393 K ) = 318 .8 ms -1 Movement of a sound source and wave propagation Source moves to the right at a speed V Zone of silence Mach cone α 3 c ∆t V>c V<c V=0 V ∆t V ∆t sin α = V ∆t V 1 = c M 6 Example 2: a needle nose projectile traveling at a speed of M=3 passes 200m above an observer. Find the projectiles velocity and determine how far beyond the observer the projectile will first be heard M =3 200 m α x Example 2: a needle nose projectile traveling at a speed of M=3 passes 200m above an observer. Find the projectiles velocity and determine how far beyond the observer the projectile will first be heard c = kRT = 1.4(287 )(300 ) = 347.2m/s V = Mc = 3(347.2 ) = 1041.6m/s 1 −1 1 o = sin = 19.5 M 3 200m tan α = x 200m x= = 565m tan 19.5 α = sin −1 Steady Isentropic Flow – Control Volume Analysis Applications where the assumptions of steady, uniform, isentropic flow are reasonable: 1. Exhaust gasses passing through the blades of a turbine. 2. Diffuser near the front of a jet engine 3. Nozzles on a rocket engine 4. A broken natural gas line 7 Steady Isentropic Flow 1 2 h + dh ρ + dρ T + dT p + dp h V ρ T p dx Steady State Continuity Equation: ( V + dV ) r 0 = ∫ ρ V • nˆ dA = − ρ1V1 A1 + ρ 2V 2 A2 CS ρ VA = ( ρ + d ρ )(V + dV )( A + dA ) ρ VA = ρ AV + ρ VdA + VAd ρ + Vd ρ dA + ρ AdV + ρ dAdV + Ad ρ dV + d ρ dAdV Steady Isentropic Flow 1 2 h + dh ρ + dρ T + dT p + dp h V ρ T p dx Steady State Continuity Equation: 0= ∫ ρ (V • nˆ )dA = − ρ V A r 1 1 1 V + dV + ρ 2V 2 A2 CS ρ VA = ( ρ + d ρ )(V + dV )( A + dA ) ~ 0 ~0 ~0 ~0 ρ VA = ρ AV + ρ VdA + VAd ρ + Vd ρ dA + ρ AdV + ρ dAdV + Ad ρ dV + d ρ dAdV 0= dA d ρ dV + + A ρ V Only retain 1st order differential terms & divide By ρVA Steady Isentropic Flow 1 2 h + dh ρ + dρ T + dT p + dp h V ρ T p V + dV dx Steady State Energy Equation with 1 inlet & 1 exit: Q& − W& s V 22 − V12 = + g ( z 2 − z1 ) + (u~ + pv )2 − (u~ + pv )1 m& 2 Neglecting potential energy and recalling: h = u~ + pv Q& − W& s V 22 − V12 = + h2 − h1 m& 2 Assuming and ideal gas: Q& − W& s V 22 − V12 = + c p (T2 − T1 ) m& 2 8 Steady Isentropic Flow 1 2 h + dh ρ + dρ T + dT p + dp h V ρ T p Steady State Energy Equation with 1 inlet & 1 exit, neglecting potential energy & assuming Isentropic duct flow: V + dV dx V22 V2 + h2 = 1 + h1 2 2 Assuming and ideal gas: V22 V2 + c p T2 = 1 + c p T1 2 2 V22 k V2 k RT1 + RT 2 = 1 + 2 k −1 2 k −1 Stagnation Conditions Insolated walls 2 1 Assume the area A2is so big V2 ~ 0, then h2 = V12 + h1 = ho 2 Stagnation enthalpy Similarly, as we adiabatically bring a fluid parcel to zero velocity there is a corresponding increase in temperature V22 V2 + c p T2 = 1 + c p T1 2 2 To = V2 +T 2c p Stagnation Temperature Stagnation Conditions – maximum velocity To = V2 +T 2c p (+) If the temperature, T is taken taken down to absolute zero, then (+) can be solved for the maximum velocity: V max = 2 c p To No higher velocity is possible unless energy is added to the flow through heat transfer or shaft work. 9 Stagnation Conditions – Mach number relations M = Recall, that the Mach number is defined as: To = V2 +T 2c p V c For Ideal gases: 1 kR c pT = T = kRT k −1 k −1 c2 cp k −1 2 To k − 1 V 2 M +1 = +1 = 2 T 2 c 2 2 To V = +1 T T 2c p To k − 1 2 = M +1 T 2 Stagnation Conditions – Isentropic pressure & density relationships To k − 1 2 = M +1 T 2 k k 1 1 p o To k −1 k − 1 2 k −1 = = M + 1 p T 2 ρ o To k −1 k − 1 2 k −1 = = M + 1 ρ T 2 Critical Values: conditions when M = 1 T* 2 = To k + 1 k p * 2 k −1 = po k + 1 1 ρ * 2 k −1 = ρo k +1 1 c* 2 2 = co k + 1 10 Critical Values: conditions when M = 1 For Air k = 1.4 T* 2 = = 0 .8333 To k + 1 k p * 2 k −1 = = 0 .5283 po k + 1 1 ρ * 2 k −1 = = 0 .9129 ρo k + 1 1 c* 2 2 = = 0 .9129 co k + 1 In all isentropic flow, all critical values are constant. Critical Values: conditions when M = 1 Critical Velocity: is the speed of sound c* 1 c* 2 2 = co k + 1 1 V * = c* = 1 2 2 2 kRT o 2 kRT * = c o = k +1 k +1 Example 3: Stagnation Conditions Air flows adiabatically through a duct. At point 1 the velocity is 240 m/s, with T1 = 320K and p1 = 170kPa. Compute (a) To (b) Po (c) ro (d) M (e) Vmax (f) V* 11 Steady Isentropic Duct Flow 1 V 2 h h + dh ρ T ρ + dρ T + dT p p + dp V + dV dx Recall, for Steady isentropic flow Continuity: (†) 0 = dA d ρ dV + + A ρ V dA d ρ dV =− − A ρ V For compressible, isentropic flow the momentum equation is: 2 (*) 0 = dp + dV = dp + VdV ρ 2 ρ Bernoulli’s Equation! neglecting gravity Substitute (†) into (*) dA dρ dp dp 1 dρ =− + = − ρ ρV 2 ρ V 2 dp A Steady Isentropic Duct Flow 1 V 2 h h + dh ρ T ρ + dρ T + dT p p + dp V + dV dA dp 1 dρ = − ρ V 2 dp A 2 Recall that the speed of sound is: c = ∂p ∂ρ dA dp 1 dp V 2 1 1 − 2 = − = A ρ V 2 c 2 ρ V 2 c Substituting the Mach number: dA dp = (1 − M 2 ) ρV 2 A M = V c Describes how the pressure behaves in nozzles and diffusers under various flow conditions Nozzle Flow Characteristics dA dp = (1 − M 2 ) ρV 2 A 1. 2. 3. 4. Subsonic Flow: M < 1 and dA < 0, then dP < 0: indicating a decrease in pressure in a converging channel. Supersonic Flow: M > 1 and dA < 0, then dP > 0: indicating an increase in pressure in a converging channel. Subsonic Flow: M < 1 and dA > 0, then dP > 0 : indicating an increase in pressure in a diverging channel. Supersonic Flow: M > 1 dA > 0, then dP < 0 : indicating a decrease in pressure in a diverging channel. P P P P P P P P 12 Steady Isentropic Duct Flow – Nozzles Diffusers and Converging Diverging Nozzles Describes how the pressure behaves in nozzles and diffusers under various flow conditions dA dp = (1 − M 2 ) ρV 2 A (††) Recall, the momentum equation here is: 0= dp ρ dp + VdV ρ = −VdV (**) Now substitute (**) into (††) : dA dV = (M 2 − 1) A V Or, ( dA A = M 2 −1 dV V ) Nozzle Flow Characteristics ( ) dA dV = M 2 −1 A V 1. 2. 3. 4. Subsonic Flow: M < 1 and dA < 0, then dV > 0: indicating an accelerating flow in a converging channel. Supersonic Flow: M > 1 and dA < 0, then dV < 0: indicating an decelerating flow in a converging channel. Subsonic Flow: M < 1 and dA > 0, then dV < 0 : indicating an decelerating flow in a diverging channel. Supersonic Flow: M > 1 dA > 0, then dV > 0 : indicating an accelerating flow in a diverging channel. Converging-Diverging Nozzles Amin Subsonic Supersonic M=1 Amax Subsonic Supersonic M<1 M>1 Subsonic Supersonic Flow can not be sonic 13 Choked Flow – The maximum possible mass flow through a duct occurs when it’s throat is at the sonic condition Consider a converging Nozzle: receiver po pr pe To Ve ρo plenum Mass Flow Rate (ideal gas): m& = ρ VA = m& = p M RT p VA RT M = kRT A = p V = c V kRT k MA RT k MA RT m& = p Choked Flow Mass Flow Rate (ideal gas): m& = p k MA RT Recall, the stagnation pressure and Temperature ratio and substitute: k po k − 1 2 k −1 = M + 1 p 2 m& = p o To k − 1 2 = M +1 T 2 k +1 k k − 1 2 2 (1− k ) MA 1 + M RT o 2 If the critical area (A*) is where M=1: k +1 m& = p o A * k k + 1 2 (1− k ) RT o 2 The critical area Ratio is: A 1 = A* M 2 + (k − 1)M 2 k +1 k +1 2 ( k −1 ) 14