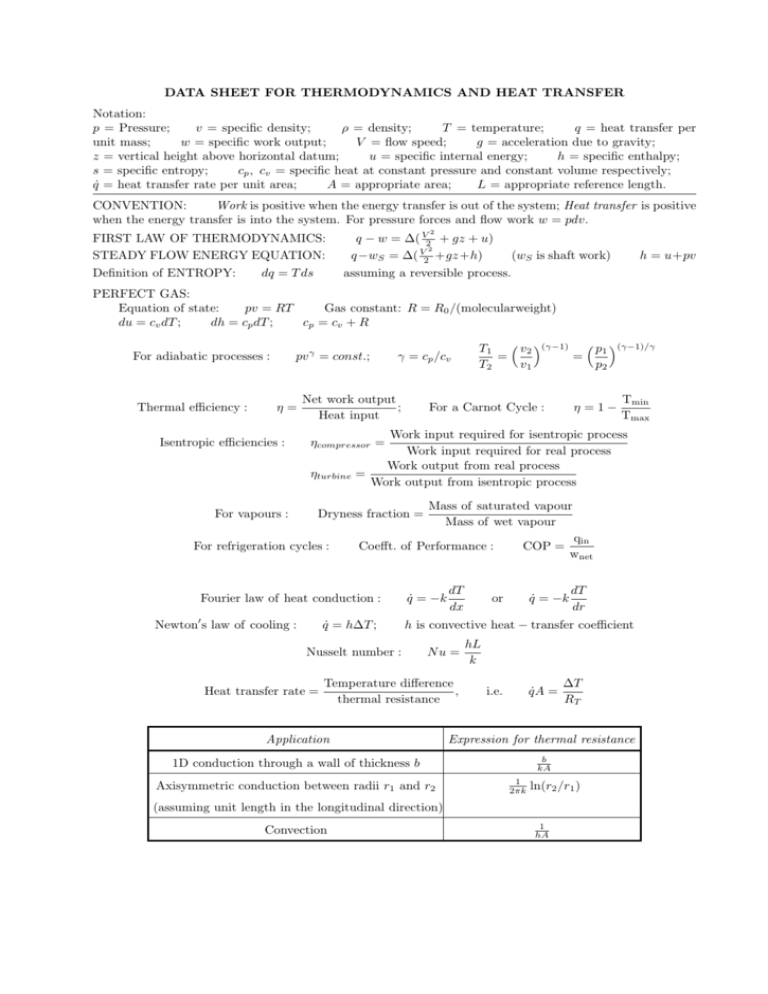

DATA SHEET FOR THERMODYNAMICS AND HEAT TRANSFER

advertisement

DATA SHEET FOR THERMODYNAMICS AND HEAT TRANSFER

Notation:

p = Pressure;

v = specific density;

ρ = density;

T = temperature;

q = heat transfer per

unit mass;

w = specific work output;

V = flow speed;

g = acceleration due to gravity;

z = vertical height above horizontal datum;

u = specific internal energy;

h = specific enthalpy;

s = specific entropy;

cp , cv = specific heat at constant pressure and constant volume respectively;

q̇ = heat transfer rate per unit area;

A = appropriate area;

L = appropriate reference length.

CONVENTION:

Work is positive when the energy transfer is out of the system; Heat transfer is positive

when the energy transfer is into the system. For pressure forces and flow work w = pdv.

FIRST LAW OF THERMODYNAMICS:

STEADY FLOW ENERGY EQUATION:

Definition of ENTROPY:

dq = T ds

2

q − w = ∆( V2 + gz + u)

2

q−wS = ∆( V2 +gz+h)

(wS is shaft work)

assuming a reversible process.

h = u+pv

PERFECT GAS:

Equation of state:

pv = RT

Gas constant: R = R0 /(molecularweight)

du = cv dT ;

dh = cp dT ;

cp = cv + R

pv γ = const.;

For adiabatic processes :

Thermal efficiency :

η=

Isentropic efficiencies :

Net work output

;

Heat input

v (γ−1) p (γ−1)/γ

T1

2

1

=

=

T2

v1

p2

η =1−

For a Carnot Cycle :

Tmin

Tmax

Work input required for isentropic process

Work input required for real process

Work output from real process

=

Work output from isentropic process

ηcompressor =

ηturbine

For vapours :

γ = cp /cv

Dryness fraction =

For refrigeration cycles :

Coefft. of Performance :

Fourier law of heat conduction :

Newton0 s law of cooling :

q̇ = h∆T ;

q̇ = −k

dT

dx

COP =

q̇ = −k

or

qin

wnet

dT

dr

h is convective heat − transfer coefficient

Nusselt number :

Heat transfer rate =

Mass of saturated vapour

Mass of wet vapour

Nu =

Temperature difference

,

thermal resistance

hL

k

i.e.

q̇A =

∆T

RT

Application

Expression for thermal resistance

1D conduction through a wall of thickness b

b

kA

Axisymmetric conduction between radii r1 and r2

1

2πk

ln(r2 /r1 )

(assuming unit length in the longitudinal direction)

Convection

1

hA

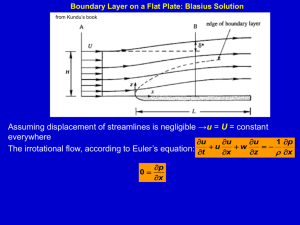

DATA SHEET FOR FLUID MECHANICS

Notation:

ρ = density

V = velocity (averaged over a cross-section)

p = pressure

A = cross-sectional area

d = diameter

u = local velocity in x-direction

V∞ = velocity in freestream flow (i.e undisturbed flow approaching body).

Conservation of mass (continuity equation) for steady flow through a control volume

Σ(ρV A)in = Σ(ρV A)out

Newton0 s Law of viscosity :

shear stress

τ =µ

du

dy

µ is (coefficient of) dynamic viscosity (the notation η is also used for dynamic viscosity) (units: N s/m2 );

ν = µ/ρ is the kinematic viscosity (units: m2 /s).

dp

= −ρg;

dy

Hydrostatic pressure with y upwards :

p = py=0 − ρgy

Bernoulli equation for steady, inviscid, incompressible flow;

1

p + ρV 2 + ρgz = constant along a streamline

2

It can also be written in terms of head (=p/ρg)

p

V2

+

+ z = total head (= const.)

ρg

2g

Definition of force coefficient (e.g. lift or drag coefficient)

CD or CL =

D or L

1

2

2 ρV∞ Area

Depending on the application (Length)2 (e.g. d2 ) is often used instead of area.

ρV∞ L

µ

V∞

Fr = √

gL

where L is a suitable choice of typical length. For some applications a different typical velocity from V∞ is

used.

For homogeneous incompressible flow CD = F n(Re) only.

For incompressible flows with free surfaces CD = F n(Re, F r) only.

For ships and other similar applications

Reynolds number :

Re =

CD =

CDF (Re)

| {z }

Froude number :

Skin−friction drag

Stokes drag formula for flow past a sphere at Re < 2

+ CDW (F r)

| {z }

Wave drag

D = 3πV∞ dµ.

Steady flow momentum equation as applied to a control volume:

Net force in x − direction

Rate of outflow

Rate of inflow

=

−

acting on control volume

of x − momentum

of x − momentum

similar equations can be written for the y and z-momentums.

Laminar-turbulent transition for the boundary layer on a flat plate occurs in the range

3 × 105 < Re < 3 × 106 and for pipe flow and other similar internal flows in the range 2000 < Re < 20000.

The sudden drop in drag for spheres and circular cylinders occurs at Re ' 3 × 105 .