NAVAL POSTGRADUATE SCHOOL MBA PROFESSIONAL REPORT

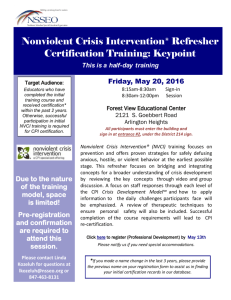

advertisement