Tendon

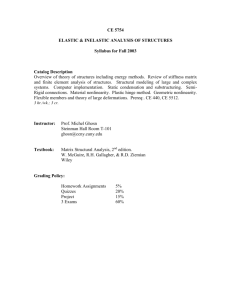

advertisement

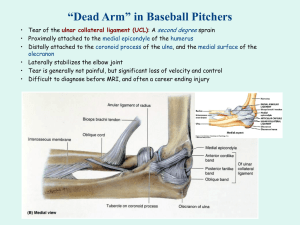

Tendon Tendon • Outline: – Function – Structure – Mechanical Properties – Significance to movement Function • • • • Connect muscle to bone, but are not rigid Are quite stretchy Passive but important Not just rigid, passive structural links b/n muscle and bone, but also affect movement through the overall function of the muscle-tendon-unit. • Function: – transmit muscle force and slide during movement – Store elastic energy Tendon properties affect force transmitted from muscle to bone Structure • Primarily collagen : a structural protein • Collagen fibril -> fascicle->tendon • Bad blood supply -> slow to heal • Parallel bundles of collagen fibers • Resist stretching along long axis of tendon • Sufficiently flexible Tendon • Outline: – Function – Structure – Mechanical Properties – Significance to movement Mechanical Properties • Many experiments on isolated tendons • Show same mechanical property across different tendons Tendon or ligament Force Linear region • “J-shaped” • Stiffness (k) = slope – units = N/m • Stiffness: force required to stretch tendon/ligament by a unit distance • Force per change in length • Hooke’s Law Toe region Displacement (Dx) – F=kx • F=elastic force • x=amount of stretch • k=stiffness Tendons/ligaments are viscoelastic • Purely elastic materials – force-displacement relationship does NOT depend on velocity of stretch or time held at a length or load • Viscoelastic materials – force-displacement relationship DOES depend on: • Velocity of stretching • Time held at a given length or load Think of other materials that are viscoelastic? Tendons are viscoelastic • • • • • Nonlinear response Hysteresis Velocity dependent loading Creep Load relaxation Viscoelasticity trait #1: Nonlinear Response Force Linear region • “J-shaped” • Stiffness (k) = slope – units = N/m • Stiffness: force required to stretch tendon/ligament by a unit distance • Force per change in length • Hooke’s Law Toe region Displacement (Dx) – F=kx • F=elastic force • x=amount of stretch • k=stiffness Viscoelasticity trait #2: Hysteresis (Stretch & recoil: ) Force Stretch Recoil • Hysteresis: Force vs. displacement different for stretch & recoil Displacement (x) Viscoelasticity trait #3: velocity dependent stiffness Fast stretch Force Slow stretch At faster stretching velocities: 1. More force needed to rupture tendon Displacement From Wainwright et al. (1976). “Mechanical design in organisms”. Viscoelasticity trait #4: Creep Displacement • Stretched with a constant force & displacement measured – Length increases with time Time Viscoelasticity trait #5: Load relaxation • Specimen held at a constant length & force measured Force 2-10 min Time ( N & F, Fig 3-10) Elastic energy • Stretch: mechanical work done on tendon/ligament equals elastic energy storage Force – Area under force - displacement curve Displacement Elastic energy stored during stretch Viscoelasticity trait #3: velocity dependent stiffness Fast stretch Force Slow stretch At faster stretching velocities: 1. More force needed to rupture tendon 2. More energy is stored Displacement From Wainwright et al. (1976). “Mechanical design in organisms”. Elastic energy • Stretch: mechanical work done on tendon/ligament equals elastic energy storage – Area under force - displacement curve • Recoil: material returns some (most) of energy stored elastically during stretch Mechanical energy stored & returned by tendon/ligament Force Force Displacement Elastic energy stored during stretch Displacement Elastic energy returned during recoil For normal stretches, 90-95% of the elastic energy stored in tendons & ligaments is returned Energy lost Force • Larger hysteresis loop greater energy loss • Hysteresis: indicates “viscoelasticity” Displacement Elastic energy • Stretch: mechanical work done on tendon/ligament equals elastic energy storage – Area under force - displacement curve (x,F) A) ½ Fx B) ½ kx C) ½ kx2 D) A & B E) A & C Force Area = Displacement Elastic energy stored during stretch Achilles elastic energy storage during stance phase of run Example of important equations: Uelastic = 0.5 k (DL)2 F = kDL FAchilles Known: kAchilles = 260 kN/m F = 4700 N Uelastic = ? Fg A)2.34 B)42120 C) 42 D)0.042 E) None of the above Strain • Can measure length change in terms of mm • But more useful as % of original length, so can compare tendons of different lengths • Strain (e) = L-Lo/Lo – L: current length – Lo:original length • ‘stretchiness’ Stress • Because tendons have different thickness, want to normalize force as well – Thicker tendons need more force and vice versa – So normalize by area – Stress (s)=Force/Area Stress/Strain (s/e) • By normalizing stress and strain, can now compare properties of materials of different sizes and shapes, regardless of absolute shape • Measure intrinsic tendon properties Stress/Strain Relation for Tendon/Ligament Plastic region Stress s (MN/m2) 100 syield Toe region Elastic region sfailure Failure (rupture) E s Injury e 8% Strain e Stress vs. Strain for tendon/ligament • Similar for all mammalian tendons & ligaments • Elastic modulus: slope • E=stress/strain, =s/e (MN/m2) 70 Stretch 35 – units of Pascals (N/m2), same as stress – kPa, Mpa, GPa Recoil 0 0 2.5 Strain (%) 5 Compare the stiffness of a rubber band and a block of soft wood A) rubber band is more stiff B) rubber band is less stiff C) stiffness is similar D) Not enough information Can compare different materials easily Tendon E = 1 GPa Soft wood (pine) E = 0.6 GPa Passive muscle E = 10kPa Rubber E = 20kPa Bone E= 20 GPa Walnut E= 15 Gpa Diamond E= 1000 Gpa Jello E = 1Pa Stress vs. strain: material not geometry Two important definitions: Stress = F / A F = force; A = cross-sect. area Units = N / m2 = Pa Strain (%) = (displacement / rest length) • 100 = (DL / L) • 100 Stiffness vs. Elastic Modulus • Elastic Modulus (a.k.a. “Young’s Modulus”) – Slope of stress-strain relationship – a material property • Stiffness – Slope of force-displacement relationship – depends on : • material (modulus) & geometry • Structural property Stress/Strain vs Force/Length • Material property vs. structural property • Stress/Strain ind of geometry • Force/Length (stiffness) depends on geometry. Geometry effects • Stress = Elastic modulus • Strain F / A = E • ∆L / L • Force = Stiffness • displacement F = k∆L • Combine (1) & (2) to find: k = EA/L – E: similar in all tendons/ligaments A or L causesk Extending the stress-strain relationship to injurious loads for tendon/ligament Stress (MN/m2) 100 Plastic region Elastic region Failure (rupture) Injury 8% Strain Stress/Strain vs Force/Length • Material property vs. structural property • Stress/Strain ind of geometry • Force/Length (stiffness) depends on geometry. Tendon strain • Achilles tendon during running: ~ 6% – close to strain where injury occurs (~ 8%) • Wrist extensor due to muscle force (P0): ~ 2% Tendon • Outline: – Function – Structure – Mechanical Properties – Significance to movement We need tendons with different stiffnesses for different functions. How is this accomplished? Possibilities: – different material properties – different geometry (architecture) High force vs. versus fine control • Muscles in arm/hand demand fine control – precision more important than energy Slinky vs. rope Ankle extensor tendon vs. wrist extensor tendon • Wrist extensor – k = 15 kN/m – F (muscle) = 60 N – DL = F / k = 0.004 m • Achilles tendon – k = 260 kN/m – F (muscle) = 4.7 kN – DL = F / k = 0.018 m Force Achilles Wrist ext. Displacement Basis for tendon stiffness variation? – different material properties? – different geometry (architecture)? Achilles tendon vs. wrist extensor tendon • Achilles tendon vs. wrist ext. tendon – k: 17 times greater • Geometric differences? – A: 30 times greater – L: 1.75 times longer k = EA/L E ~ 1.5 GN / m2 Useful tendon equations F = k DL Elastic Energy = 0.5 k (DL)2 Elastic Energy = 1/2 F DL k = A/L elastic modulus = stress/strain ~ 1.5 x 109 N/m2 for tendon stress = F/A strain = DL/L 10,000 cm2 = 1 m2 Human Tendons Compared E = 1.5 x 109 N/m2 for both tendons wrist Achilles L = 0.17 m L = 0.29m A = 1.67 x 10-6 m2 A = 0.00005 m2 k = EA/L = 15 kN/m k = EA/L = 260 kN/m elongation for 60N load? DL = F/k = 0.004m Strain? = DL/L = 0.004 / 0.17 = 2.4% elongation for 4,700N load? F/k = 0.018m = 0.018 / 0.29 = 6.2% Problem Solving Approach • • • • Write down what is given Write down what you need to find Write down the equations you will use Show work! – Step by step Practice Problem Design a wrist extensor tendon that when loaded with 60N of force will undergo the same %strain (6.2%) as the Achilles tendon. (Given L, determine A) L=0.17 m Practice Problem If the wrist extensor tendon in the example had a cross sectional area = to the Achilles tendon example, what would be the absolute length change with a load of 60 N? Given: Aachilles = 0.00005 m2; Lwrist = 0.17m