Topic 6: Case Studies

advertisement

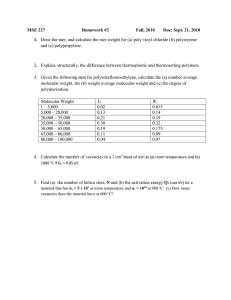

Topic 8: Case study: polyethylene & high impact polystyrene Overview of polymers • Carbon and hydrogen atoms are basic building blocks (in hydrocarbons); other elements include chlorine, fluorine, nitrogen, oxygen, etc. • Backbone of hydrocarbons are C-C covalent bonds: CH4, C2H6, C2H4, C2H2 Name Boiling points Methane -161 C Ethane -89 C Propane -42 C Stronger van der Waals bonds Poly-”mer” Ethane vs. Ethylene vs. Acetylene Ethane Ethylene Acetylene • Each carbon has four bonds with neighboring atoms • Single, double & triple bonds • Although polyethylene has single bonds, and looks like a long version of ethane, its starting material is ethylene Polyethylene • Most common polymer found in milk containers, trash cans, dish pans, pipes, grocery bags, etc. • The development of polyethylene is an interesting story: serendipity. – In the 1930’s scientists were curious about the effects of really high pressures on organic gases. Among the gases investigated was ethylene. – Ethylene was placed in a very strong, rigid container and squeezed with 1000 atm pressure. – When the container was opened a “white waxy solid” was found to have formed. – This rather crude experiment led to the investigation of how the polymerization process could be controlled to make a useful product Synthesis of polyethylene • The formation of polyethylene from ethylene occurs by a process called addition polymerization and involves the use of high pressures, high temperatures and catalysts • Catalytic reaction: Synthesis of polyethylene (contd.) • There are also other possibilities: termination of polymerization • Chain branching: hydrogen is replaced by an ethylene mer; chain branching can be controlled by temperature, pressure and catalysts • Short-chain branching produces: – – – lower density material because of inefficient packing of chains low crystalline content as crystallinity requires long, straight and parallel chains weaker materials less bonding between chains in shorter chains Low density polyethylene (LDPE) High density polyethylene (HDPE) • Produced under high pressure (~ 20,000 psi), moderate temperature ( ~ 200 C), oxygen containing catalysts • Under such conditions considerable short-chain branching are produced • Density = 0.92 gm/cc • Tensile strength = 3,000 psi • Young’s modulus = 40,000 psi • Translucent (grocery bags) • Low degree of crystallinity; hence less scattering of light • Produced under low pressure (~ 200 psi), low temperature ( ~ 100-170 C), titanium and aluminum chloride catalysts • Under such conditions very little shortchain branching are produced • Density = 0.96 gm/cc • Tensile strength = 5,500 psi • Young’s modulus = 180,000 psi • Opaque (garbage cans) • High degree of crystallinity; scattering at interfaces between crystalline and amorphous regions Both types are thermoplastic softens when heated and hardened when cooled, reversibly recycleable In conclusion, materials properties are controlled by processing that in turn controls microstructure even though electronic and atomic structures are the same! Rubber & High Impact Polystyrene (HIPS) • Natural rubber mer: • Natural rubber molecules are not cross-linked but are considerably entangled. Thus, chains can slowly move over each other, leading to substantial stretching if it is deformed slowly. But, it becomes much stronger and brittle if it is deformed very fast. Under this condition, the chains do not have time to disentangle and the material becomes stronger. • “Silly putty” behaves similarly! Time and temperature are important factors. (Balloons behave similarly too!) • Cross-linked rubber (vulcanization using sulfur) does not flow easily, but still can stretch a lot. Vulcanization should be just enough to stop the chains from flowing past each other, but not too much so that they are locked up and cannot straighten and entangle again (coiled again) Variants of natural rubber Butadiene mer (synthetic) Very ductile Natural rubber mer Soft & ductile Styrene mer (synthetic) Brittle • Can we take advantage of these 2 synthetic materials to make a material that is strong, hard and ductile? The answer to this is HIPS • How can we make high impact polystyrene? Blends Polystyrene-polybutadiene blends • Mix polystyrene and rubber physically … Polystyrene (PS) crack Polybutadiene (PB) • … but this produces very little improvement. Cracks propagate in only polystyrene region in such a blend Copolymers • A copolymer is a combination of 2 or more different monomers (or mers) in one chain • Each circle represents a monomer • In this example, we have 2 different types of mers in one chain • (a) Random copolymer • (b) Alternating copolymer • (c) Block copolymer • (d) Graft copolymer Polystyrene-polybutadiene copolymer blends - HIPS • In HIPS, we still have polybutadiene rubber regions in a polystyrene matrix, but now we have styrene-butadiene graft copolymer added to the mix. The graft copolymer acts to join the two components in a much stronger manner because the grafted rubber chain prefers to be in the rubber region while the polystyrene chain wants to be in the polystyrene matrix polystyrene polybutadiene • Now, any crack that tries to pass around polybutadiene particles has to interact with the network of rubbery branches connecting the PS matrix to the PB particles. The result is the trapping of the crack round the PB particle and the crack spreads in all directions producing crazing of the PS in this area • HIPS becomes very strong, rigid and tough and is used in the dashboard of your car, in the lining of your refrigerator, in computer and telephone housing, etc. Summary • Chain polymerization of polyethylene • High impact polystyrene – polystyrenepolybutadiene copolymer blends • Reading assignment: Ch. 16-17